转轮下环间隙对混流式水轮机内部流动特性的影响

2020-11-30吴子娟梁武科高晨辉陈帝伊

吴子娟,梁武科,董 玮,高晨辉,陈帝伊

转轮下环间隙对混流式水轮机内部流动特性的影响

吴子娟1,梁武科1※,董 玮2,高晨辉1,陈帝伊2

(1. 西安理工大学水利水电学院,西安 710048;2. 西北农林科技大学水利与建筑工程学院,杨凌 712100)

水轮机转轮间隙内的泄漏涡、泄漏流等复杂的湍流易影响水轮机的性能与稳定性。为了分析下环间隙对混流式水轮机能量特性和内部流态的影响,该文基于N-S方程和SST湍流模型,考虑了0.6d(d为设计流量工况)、0.8d、d、1.2d共4种流量工况,对5种下环间隙下的混流式水轮机模型机进行三维全流道数值计算。通过对比不同下环间隙方案对混流式水轮机效率与容积损失的影响,结合不同水轮机内部流场特征,分析下环间隙与水轮机性能的关系。计算结果表明:下环间隙由0.4 mm增大到1.3 mm,机组泄漏量增大,水轮机效率整体呈下降趋势。其中,当机组在小流量0.6d工况运行时,间隙对水轮机能量特性影响最为明显,效率下降了4.1个百分点。当机组在小流量0.6d与0.8d工况运行时,下环间隙增大,间隙内部流场与尾水管内部流场呈现小幅度恶化;当机组在大流量1.2d工况运行时,下环间隙增大,转轮叶片吸力面压力分布以及尾水管内部流场均得到改善。该研究可为混流式水轮机结构设计提供有效参考。

混流式水轮机;模型;下环间隙;性能;容积损失

0 引 言

混流式水轮机转轮间隙的大小决定了机组的容积损失,这种泄漏直接影响着水轮机的效率及出力[1-2]。间隙结构的变化会引起间隙内部水流流场的变化[3-5],间隙出流对水轮机转轮与尾水管内部流态具有明显的干扰作用[6]。

近年来,针对水力机械内部间隙流动,国内外学者做了大量研究[7-9]。水泵间隙流的研究主要集中在叶顶间隙与密封间隙。高杰等[10-11]通过分析混流泵内部主流的压力脉动与涡流特性,发现叶顶间隙越大,泄漏量越大,泵的扬程和效率均降低。Kim等[12]用CFD方法对直型和阶梯型2种密封结构下的泄漏量进行了预测分析,发现随着间隙的增大,阶梯式密封相对于直型密封更具优势。Kim等[13]通过对4种尺寸叶顶间隙下的涡轮泵进行试验研究,证实非空化条件下,叶顶间隙越大,泵扬程越低。混流式水轮机转轮域的间隙主要包括上冠间隙与下环间隙。目前,对混流式水轮机间隙流的研究主要集中在上冠间隙对机组性能的影响。冯建军等[14-16]通过对转轮圆盘效率损失的定量计算发现,考虑了转轮圆盘损失后,在最优单位转速附近,CFD计算得到的水轮机效率和模型试验结果吻合良好。王文全等[17]为了研究水轮机间隙流道内涡结构特征,通过分步投影法求解N-S方程,在不同雷诺数下阐述了上冠间隙内压力场、速度场以及涡量的分布规律。间隙的结构直接影响机组泄漏量的大小,周大庆等[18-19]通过分析混流式水轮机主流道内速度和压力分布以及空腔、泄水孔和上冠间隙内的流动特征,揭示了泄漏量随上冠间隙增大而增大的规律。关于混流式水轮机下环间隙对机组性能影响的研究尚未开展,因此,分析下环间隙流对转轮进出口流态的影响,进而总结下环间隙结构与机组性能之间的关系十分必要。

本文以混流式水轮机为研究对象,提出5种下环间隙方案,得到该水轮机的能量特性及内部流场。通过分析设计流量d,小流量0.6d、0.8d,大流量1.2d共4个工况下,5种下环间隙对水轮机效率、容积损失以及内部流态的变化规律,来探究下环间隙对混流式水轮机能量特性与内部流动特性的影响,为混流式水轮机下环间隙的设计提供重要的参考依据。

1 模型参数与数值仿真

1.1 几何模型及计算工况

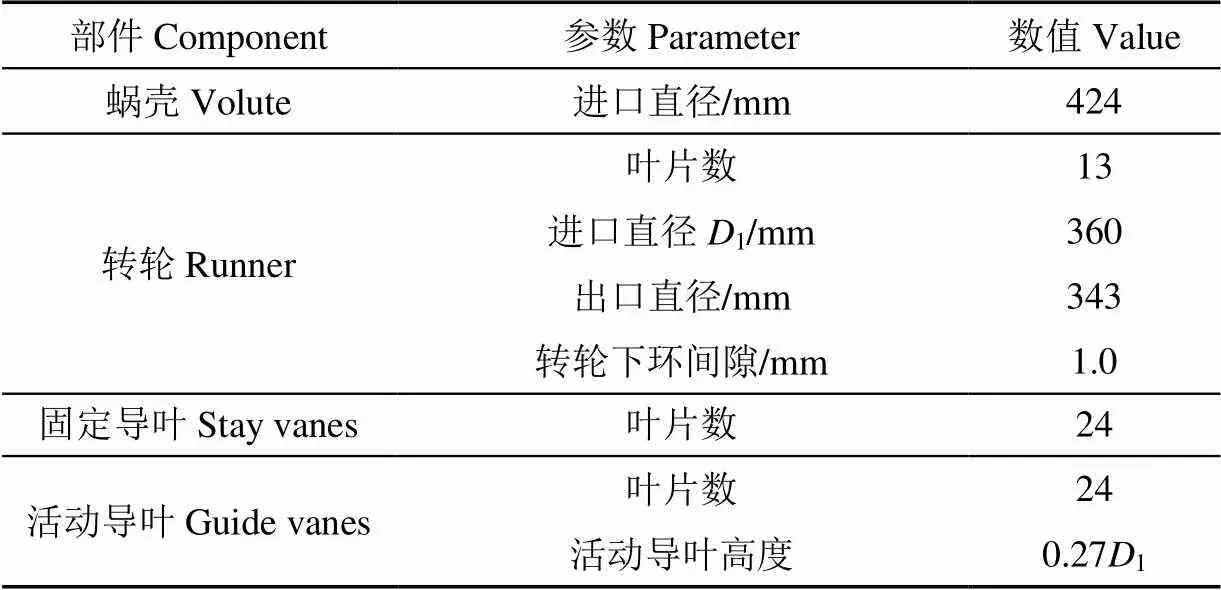

本文研究对象为国内某电站混流式水轮机模型,该电站原型水轮机真机运行水头范围为91~112 m,额定水头为96 m。模型水轮机的几何参数见表1。图1为该模型机全流道三维模型计算域。图2是下环间隙的剖面示意图,水轮机下环间隙记为。为了探究下环间隙对水轮机性能的影响,在该水轮机模型机原始下环间隙1 mm的基础上,增大下环间隙取得1.3 mm的下环间隙方案,减小下环间隙取得0.4、0.6、0.8 mm的下环间隙方案,其中0.4 mm为该模型机可达到的最小下环间隙。

表1 主要部件几何参数

图1 水轮机全流道三维模型

1.转轮叶片 2.活动导叶 3.底环 4.基础环 5.下固定密封环 6.尾水管

1.Runner blade 2.Guide vane 3.Bottom ring 4.Foundation ring 5.Lower stationary sealing ring 6.Draft tube

注:为转轮的下环间隙。

Note:is the seal clearance of runner, mm.

图2 下环间隙轴向剖面图

Fig.2 Axial profile of seal clearance

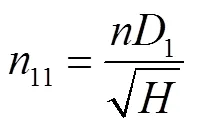

水轮机原型机与模型机具有相似性,水轮机单位转速11与单位流量11的定义为[20]:

式中为水轮机转速,r/min;为通过水轮机的流量,m3/s;1为转轮直径,m;为水轮机工作水头,m。

该模型机设计工况单位转速11=69 r/min,单位流量11=0.765 m³/s,该单位流量记为d。考虑到本文研究的水轮机在设计工况运行的时段通常只占总运行时间的30%左右,为综合分析水轮机在不同工况下运行的性能,本文计算工况为设计单位转速下,单位流量包括小流量0.6d、0.8d工况,设计流量d工况和大流量1.2d工况,工作水头=30 m。

1.2 控制方程与湍流模型

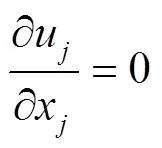

水轮机的三维瞬态不可压缩控制方程可由如下方程来描述[21-23]:

式中为流体密度,kg/m3;u和u为速度在直角坐标系中的分量,m/s;为时间,s;x与x为空间坐标分量,m;为压强,Pa;为流体的动力黏性系数,Pa∙s;F为坐标系中的单位质量力,N/kg。

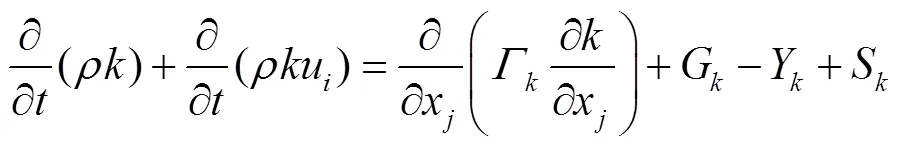

本文采用剪切应力输运(shear stress transport,SST)模型对方程进行封闭[24-26],其控制方程为:

式中Г和Г为和的有效扩散系数;G为湍动能的生成项;G为耗散率的生成项;Y和Y为湍流引起的湍动能与耗散率的耗散项;D为交叉扩散项;S和S为用户定义的源项。

式(6)中正交扩散项D的表达式为:

蜗壳进口采用质量流量,进口水流方向处垂直于进口断面;尾水管出口设置为压力为0的平均静压;在临近壁面采用的是标准的壁面函数,壁面采用无滑移边界;固定部件和转动部件交界面采用冻结转子来进行数据传递;计算收敛精度为最大残差小于10-4。

1.3 网格划分与网格无关性验证

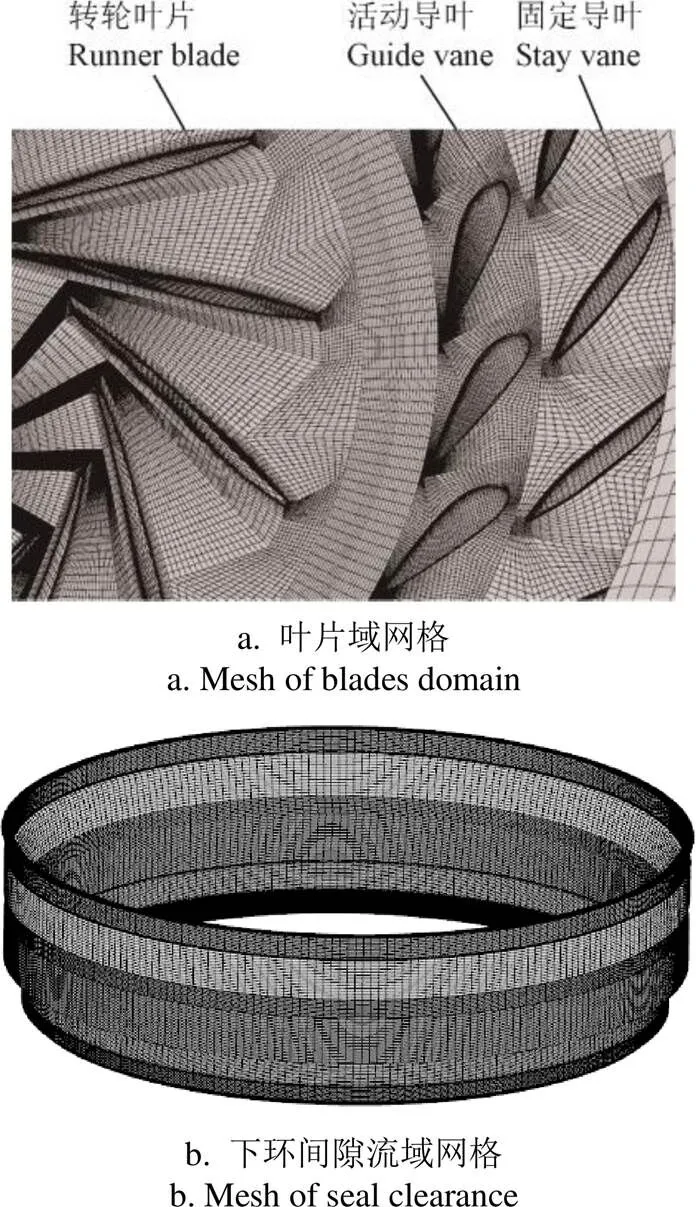

本文采用分块网格技术,使用网格生成软件ICEM-CFD对各个计算域进行网格划分,计算域网格均采用六面体结构化网格,并对固定导叶、活动导叶叶片表面、转轮叶片表面,下环间隙壁面等重要的流场壁面处进行网格加密,以便于捕捉更加精细的流场信息,如图3所示。

为了验证网格数的合理性,保证计算精度,本文选取水轮机效率随网格数变化的曲线作为无关性验证的判断依据。网格无关性验证[27]选择在d流量工况,下环间隙为1 mm的原始间隙下进行,通过对比不同网格数下的水轮机效率变化情况,d流量工况下的水轮机效率随网格数变化曲线如图4所示。由图4可见,当网格数由653万增加到740万,效率增量为0.009%,得到网格无关解,最终确定全流道数值计算的网格总数为653万。

图3 部分流体域网格

图4 网格无关性验证

1.4 数值计算结果的试验验证

对本文所研究的水电站水轮机进行真机效率试验,试验工况选取设计工况单位转速11=69 r/min,单位流量取0.512 m³/s至0.915 m³/s共8个工况。数值计算取下环间隙为1 mm的方案。效率试验结果与数值计算结果的对比如图5所示。从图中可看出,数值计算结果与试验结果相接近,由于真机水流中存在泥沙等固体颗粒,造成机组能量转换的损失,数值计算中未考虑泥沙含量这一因素,计算结果整体略高于试验值。单位流量为0.795 m³/s的工况出现最大误差,为2.06%,在可接受范围内。

图5 效率试验与数值计算结果对比

2 计算结果与分析

2.1 下环间隙对水轮机能量特性的影响

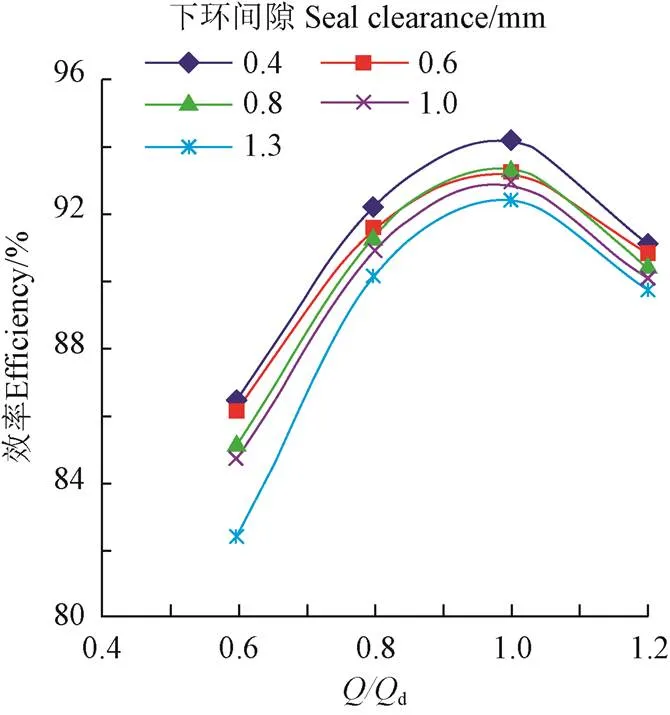

如图6所示,通过分析不同下环间隙对混流式水轮机效率的影响可以发现:当机组在非设计工况运行时,当间隙在0.4~1.3 mm范围内,下环间隙增大,水轮机效率呈下降趋势。下环间隙从0.4增大到1.3 mm,0.6d流量工况下的水轮机效率下降了4.08个百分点,下降幅度最大;0.8d与1.2d流量工况下,效率分别下降了2.15与1.38个百分点。

注:Q为通过水轮机的流量,Qd为该水轮机的设计流量。

设计工况下,当下环间隙从0.4增大到1.3 mm,水轮机效率呈先下降,再上升,后下降的变化趋势。其中,间隙由0.4增大到0.6 mm时,效率下降了0.97个百分点;间隙由0.6增大到0.8 mm时,效率上升了0.15个百分点;间隙由0.8增大到1.3 mm时,效率下降了0.97个百分点。

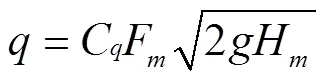

水轮机转轮下环间隙的泄漏量可以根据公式(8)计算得出[28]

式中C为流量系数;F为密封环间隙的过流断面面积,m2;H为间隙进出口的水头损失,m;D为密封环内径,m;为重力加速度,m/s2。

将间隙泄漏量与总流量的比值,即泄漏比作为无量纲容积损失进行分析,图7为机组在0.6d、0.8d、d、1.2d4种工况运行时,水轮机下环间隙容积损失随下环间隙变化的规律。从图中可以看出,下环间隙增大,4种流量工况下的机组容积损失均呈上升趋势。随着活动导叶开度的增大,当下环间隙增大,下环间隙泄漏量增大的幅度逐渐减小。机组在小流量0.6d工况运行时,下环间隙的变化对下环间隙泄漏量影响最为明显,当间隙值由0.4增大到1.3 mm,泄漏比由0.18 %增大至0.54 %。

2.2 下环间隙对水轮机内部流态的影响

2.2.1 下环间隙内部流态分析

4种流量工况下,下环间隙变化,间隙内部流场呈相同的变化趋势。图8为设计工况下不同间隙的内部流场。随着下环间隙的增大,间隙内平均流速逐渐增大,受下环转动壁面的影响,间隙出口水流具有与转轮旋转方向相同的速度环量。由下环间隙子午面的流线分布可知,随着间隙增大,下环间隙进、出口压力腔中的涡流强度逐渐增大。间隙内部的湍流漩涡可以将水流部分能量以热能的形式耗散不使其恢复为压能,过于强大的漩涡可以引起机组自激振动,导致机组运行不稳定。

图7 不同下环间隙下的容积损失

2.2.2 下环间隙对转轮内部流态的影响

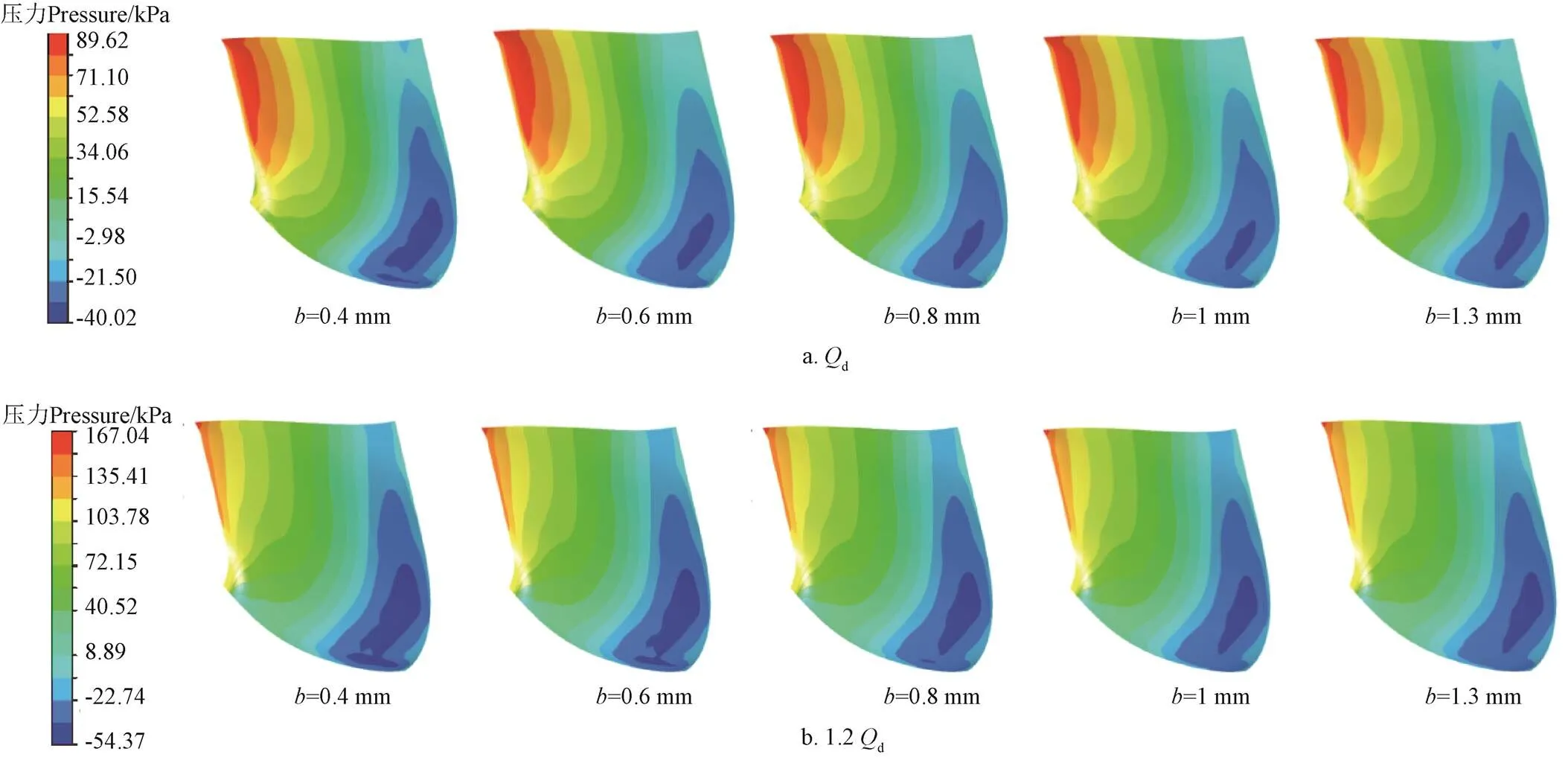

通过数值计算发现,下环间隙的变化对转轮叶片压力面的影响不明显,因此,本文仅对转轮叶片吸力面的流场进行分析。0.6d、0.8d流量工况下,随着下环间隙的增大,转轮叶片吸力面压力分布并未出现明显改变。这是由于小流量工况下,间隙进口尺寸的改变对水流的阻尼作用较小,导致泄漏量对转轮的扰动作用并不明显。图9为设计工况与大流量工况下转轮叶片吸力面压力分布。从图中可以看出:d、1.2d流量工况下,随着下环间隙增大,转轮叶片吸力面靠近下环出水边负压区面积在逐渐减小。产生这种现象的原因是:下环间隙的增大引起机组泄漏量增加,导致流经转轮内水流流量减少,水流流速随之减小,转轮区域的压力逐渐上升,其中压力上升较为明显的区域主要在叶片吸力面靠近下环出水边附近。

图8 设计工况下的下环间隙子午面速度场与流线形态

图9 转轮叶片吸力面压力分布

2.2.3 下环间隙对尾水管内部流态的影响

下环间隙出流具有一定的正向速度环量,不同间隙方案下流经间隙的水流流量不同,间隙出流对尾水管主流干扰的程度不同。图10为尾水管直锥段与弯肘段中心剖面压力云图与流线形态。从图中可以看出,不同间隙方案下,尾水管直锥段与弯肘段流场差异较为明显。0.8d流量工况下,随着下环间隙的增大,尾水管进口中心处的负压区范围逐渐扩大,水流流态呈小幅度恶化的趋势。小流量工况下,由于尾水管进口的水流周向湍流强度较强,表现为明显的旋转湍流形式,尾水管近壁区域具有较强的湍流特性[29-30],且尾水管直锥段中心轴处存在不稳定空腔涡带。此时具有正向环量的间隙出流与尾水管主流汇合时加剧了水流的流动分离,增加了尾水管主流的不稳定性,间隙增大,间隙出流对尾水管主流的干扰作用更强。大流量1.2d工况下,随着下环间隙的增大,尾水管直锥段与弯肘段的回流减少,流线更为顺畅,尾水管中心区域的空腔涡带强度减弱。这是由于大流量工况下,转轮出口水流具有与转轮旋转方向相反的分量,具有正向环量的间隙出流与具有反向圆周速度的尾水管主流汇合后,减弱了尾水管内水流的旋转湍流强度,减少流动分离损失,从而改善了尾水管的压力恢复,涡带强度降低。d流量工况下,下环间隙为0.6 mm时,尾水管直锥段与弯肘段处存在明显回流,其他4组间隙方案下,尾水管内部水流基本顺畅,处于理想状态。

图10 尾水管压力场及流线形态

3 结 论

本文以混流式水轮机为研究对象,探究了机组在0.6d、0.8d、d、1.2d共4种流量工况运行时,下环间隙在0.4~1.3 mm范围内,下环间隙对混流式水轮机能量特性与内部流态的影响,具体结论如下:

1)当机组在非设计流量工况运行时,下环间隙由0.4增大到1.3 mm,水轮机效率呈现逐渐下降的趋势。设计流量工况下,下环间隙增大,水轮机效率呈先下降,后上升,再下降的趋势。

2)当下环间隙在0.4~1.3 mm范围内,4种流量工况下的间隙泄漏量随下环间隙增大而增大,间隙内水流平均流速、漩涡强度均随着下环间隙的增大而增大,间隙内水流流态变差。

3)0.6d与0.8d流量工况下,间隙对转轮叶片吸力面流场影响较小;设计工况与1.2d流量工况下,下环间隙增大,转轮叶片吸力面靠近下环出口处的负压区会减小,转轮域流场有所改善。

4)0.8d流量工况下,下环间隙增大,尾水管进口中心处空腔涡带体积增大,内部水流流态呈恶化趋势。设计流量工况下,下环间隙对尾水管内流场影响不明显。1.2d流量工况下,随着下环间隙的增大,尾水管直锥段与弯肘段的流场有明显改善,尾水管进口中心的空腔涡带强度减弱。

在混流式水轮机优化设计中,下环间隙的设计应当结合水轮机实际运行工况。对于偏工况主要集中在小流量工况运行的机组,在保证制造与安装工艺满足要求,且转轮与固定部分不会发生撞击的条件下,下环间隙可取最小值。

[1]Nishimura H, Sugiyama K, Tsujimoto Y, et al. Theoretical estimates of rotordynamic fluid forces on a front shroud of Francis turbine caused by leakage flow[J] International Journal of Fluid Machinery and Systems, 2018, 11(3): 344-356.

[2]Liu Yabin, Tan Lei, Wang Binbin. A review of tip clearance in propeller pump and turbine[J/OL]. Energies, 2018, 11(9):2202.

[3]马薇,梁武科,赵道利,等. 混流式水轮机转轮密封间隙值对机组稳定性的影响[J]. 水力发电学报,2010,29(4):219-223. Ma Wei, Liang Wuke, Zhao Daoli, et al. The influence of sealing clearance value of Francis runner on the unit stability[J]. Journal of Hydroelectric Engineering, 2010, 29(4): 219-223. (in Chinese with English abstract)

[4]戴勇峰,王海,张克危,等. 混流可逆式转轮密封装置的泄漏量及其对机组运行的影响[J]. 水力发电学报,2005,24(2):103-107. Dai Yongfeng, Wang Hai, Zhang Kewei, et al. Analysis of the leakage rate francis of the francis pump-turbine runner's sealing device and its effect on operation of the set[J]. Journal of Hydroelectric Engineering, 2005, 24(2): 103-107. (in Chinese with English abstract)

[5]李进博. 含下环密封间隙的混流式水轮机稳定性研究[D]. 西安:西安理工大学,2009. Li Jinbo, Stability Research of Francis Turbine with Sealing Clearance of the Ring[D]. Xi'an: Xi'an University of Technology, 2009. (in Chinese with English abstract)

[6]Celic D, Ondracka H. The influence of disc friction losses and labyrinth losses on efficiency of high head Francis turbine[C]// Journal of Physics Conference Series, Trondheim, Norway, 2014.

[7]Koirala Ravi, Zhu Baoshan, Neopane Hari Prasad. Effect of guide vane clearance gap on Francis turbine performance[J/OL]. Energies, 2016, 9(4):275.

[8]董云山,杨爱玲,陈二云,等. 口环间隙泄漏射流对离心通风机流场品质的影响[J]. 动力工程学报,2016,36(4): 286-263. Dong Yunshan, Yang Ailing, Chen Eryun, et al. Influence of clearance leakage jet flow in wear-rings on flow characteristics of a centrifugal fan[J]. Journal of Chinese Society of Power Engineering, 2016. 36(4): 286-263.

[9]韩伟,陈雨,刘宜,等. 水轮机活动导叶端面间隙磨蚀形态演变预测[J]. 农业工程学报,2018,34(4):100-107. Han Wei, Chen Yu, Liu Yi, et al. Prediction of erosional shape evolution in end-surface clearance of turbine guide vane[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 100-107. (in Chinese with English abstract)

[10]高杰,郑群,刘云宁,等. 涡轮叶片叶顶间隙变化减敏研究[J].航空动力学报,2015, 30(11): 2638-2646. Gao Jie, Zheng Qun, Liu Yunning. et al. Investigations on desensitization of blade tip clearance variation in turbine blades[J]. Journal of Aerospace Power, 2015, 30(11): 2638-2646.

[11]Liu Yabin, Tan Lei. Tip clearance on pressure fluctuation intensity and vortex characteristic of a mixed flow pump as turbine at pump mode[J]. Renewable Energy, 2018, 129: 606-615.

[12]Kim T S, Cha K S. Comparative analysis of the influence of labyrinth seal configuration on leakage behavior[J]. Journal of Mechanical Science and Technology, 2009, 23(10): 2830-2838.

[13]Kim C, Kim S, Choi C H, et al. Effects of inducer tip clearance on the performance and flow characteristics of a pump in a turbopump[J]. Journal of Power and Energy, 2017: 398-414.

[14]冯建军,罗兴锜,吴广宽,等. 间隙流动对混流式水轮机效率预测的影响[J]. 农业工程学报,2015,31(5):53-58. Feng Jianjun, Luo Xingqi, Wu Guangkuan, et al. Influence of clearance flow on efficiency prediction of Francis turbines[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(5): 53-58. (in Chinese with English abstract)

[15]Feng Jianjun, Luo Xingqi, Zhu Guojun, et al Investigation on disk friction loss and leakage effect on performance in a Francis model turbine[J]. Advances in Mechanical Engineering, 2017, 9(8): 526-528

[16]Zhou Daqing, Chen Huixiang, Zhang Jie, et al. Numerical study on flow characteristics in a Francis turbine during load rejection[J/OL] Energies, 2019, 12(4): 716.

[17]王文全,尹锐,闫妍. 不同雷诺数下混流式水轮机密封间隙通道内流动特征分析[J]. 排灌机械工程学报,2014,32(7):611-616. Wang Wenquan, Yin Rui, Yan Yan. Analysis of flow in side chamber and path of comb-labyrinth seal in Francis turbine at different Reynolds numbers[J]. Journal of Drainage and Irrigation Machinery Engineering (JDIME), 2014, 32(7): 611-616. (in Chinese with English abstract)

[18]周大庆,陈洋. 含泄水孔混流式水轮机间隙流动数值模拟[J]. 农业机械学报,2015,46(4):53-58. Zhou Daqing, Chen Yang. Numerical simulation of clearance flow in Francis turbine with weep holes[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(4): 53-58. (in Chinese with English abstract)

[19]李琪飞,张毅鹏,敏政,等. 混流式水泵水轮机密封间隙流动分析[J]. 兰州理工大学学报,2016,42(1):57-61. Li Qifei, Zhang Yipeng, Min Zheng, et al. Analysis of sealing clearance flow of mixed-flow pump-turbine[J]. Journal of Lanzhou University of Technology, 2016, 42(1): 57-61. (in Chinese with English abstract)

[20]刘大恺. 水轮机(第三版)[M]. 北京:中国水利水电出版社,2008.

[21]Kang Can, Mao Ning, Zhang Wenbin, et al. The influence of blade configuration on cavitation performance of a condensate pump[J]. Annals of Nuclear Energy, 2017, 110: 789-797.

[22]陶文铨. 数值传热学(第二版)[M]. 西安:西安交通大学出版社,2001.

[23]Marsh P, Ranmuthugala D, Penesis I, et al. The influence of turbulence model and two and three-dimensional domain selection on the simulated performance characteristics of vertical axis tidal turbines[J]. Renewable Energy, 2017, 105: 106-116.

[24]Campobasso M S, Yan M, Bonfiglioli A, et al. Low-speed preconditioning for strongly coupled integration of Reynolds- averaged Navier–Stokes equations and two-equation turbulence models[J]. Aerospace Science and Technology, 2018, 77(6): 286-298.

[25]Silva P A S F, De Oliveira T F, Brasil A C P, et al. Numerical study of wake characteristics in a horizontal-axis hydrokinetic turbine[J]. Anais da Academia Brasileira de Ciencias, 2016, 88(4): 2441-2456.

[26]Chitrakar S, Dahlhaug O G, Neopane H P. Numerical investigation of the effect of leakage flow through erosion-induced clearance gaps of guide vanes on the performance of Francis turbines[J], Engineering Applications of Computational Fluid Mechanics, 2018, 12(1): 662-678

[27]张金凤,黄茜,袁寿其,等. 基于PIV的低比转速离心泵网格无关性[J]. 排灌机械工程学报,2016,34(7):567-572,583. Zhang Jinfeng, Huang Xi, Yuan Shouqi, et al. Grid-independence in low specific speed centrifugal pump based on PIV[J]. Journal of Drainage and Irrigation Machinery Engineering, 2016, 34(7): 567-572, 583. (in Chinese with English abstract)

[28]敏政,梁昌平,董志强,等. 混流式水泵水轮机泄漏量的计算及分析[J]. 排灌机械工程学报,2014,32(8):41-46. Min Zheng, Liang Changping, Dong Zhiqiang, et al. Calculation and analysis of leakage of Francis pump-turbine[J]. Journal of Drainage and Irrigation Machinery Engineering, 2014, 32(8): 41-46. (in Chinese with English abstract)

[29]郭涛,张立翔. 混流式水轮机尾水管近壁湍流特性和流场结构研究[J]. 农业机械学报,2014,45(9):117-123 Guo Tao, Zhang Lixiang. Numerical study of swirling flow fields in Francis turbin eunder small opening condition[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(9): 117-123. (in Chinese with English abstract)

[30]钟林涛,赖喜德,廖功磊,等. 混流式水轮机出口旋流与尾水管涡带关系分析涛[J]. 水力发电学报,2018,37(9):42-48. Zhong Lintao, Lai Xide, Liao Gonglei, et al. Analysis on the relationship between swirling flow at outlet of a Francis turbine runner and vortex rope inside draft tube[J]. Journal of Hydroelectric Engineering, 2018, 37(9): 42-48. (in Chinese with English abstract)

Influence of seal clearance of runner on internal fluid field in Francis turbine

Wu Zijuan1, Liang Wuke1※, Dong Wei2, Gao Chenhui1, Chen Diyi2

(1.-,,710048,; 2.,,712100,)

The performance and stability of turbine are easily affected by the complex turbulence such as clearance vortex and leakage flow. For the purpose of analyzing the influence of seal clearance on the energy features and interior flow characteristics of Francis turbine, with referencing N-S equation and SST turbulence model, the three-dimensional steady flow in the full flow passage of the Francis turbine model under five schemes of clearance were calculated. Four flow rates were chosen as: 0.6d, 0.8d,dand 1.2d. Five schemes of clearance size were selected of 0.4, 0.6, 0.8, 1.0 and 1.3 mm. By comparing the effects of different clearance schemes on the efficiency and volume loss of Francis turbine, the relationship between clearance and turbine performance was analyzed based on the characteristics of internal fluid field, and the calculation results showed that by increasing the size of clearance, the turbine efficiency could be reduced, and the leakage of the turbine indicated an upward trend. When the turbine operated at a small flow rate of 0.6d, the clearance appeared the most obvious influence on the energy features of the turbine. With the increase of clearance, the leakage ratio increased from 0.18% to 0.54%, and the efficiency decreased by 4.1 percentage points. At the flow rate of 1.2d, the clearance presented the least influence on the energy features of the turbine. The leakage ratio increased from 0.07% to 0.27%, and the efficiency decreased by 1.38 percentage points when the clearance was increased. If the turbine was operated at small flow rates of 0.6dand 0.8d, the clearance increased, and the internal fluid fields inside both the clearance and the draft tube deteriorated slightly. The average velocity in the clearance increased gradually, and the eddy current intensity in the inlet and outlet pressure chambers of the clearance increased little by little, the volume of vortex rope in the center of draft tube inlet was increased simultaneously. If the unit was operated at a large flow rate of 1.2d, with the clearance increased from 0.4 mm to 1.3 mm, the characteristics of fluid field inside clearance and the pressure distribution on the suction surface of the runner blades, also the fluid field inside the draft tube were all improved. The area of negative pressure zone on suction surface of runner blades decreased, and the volume of the cavity vortex rope at the inlet center of the draft tube decreased, the streamline inside the draft tube also tended to be smooth. This study could provide an effective reference for the design of seal clearance of Francis turbine.

Francis turbine; models; seal clearance; performance; volume loss

吴子娟,梁武科,董 玮,高晨辉,陈帝伊. 转轮下环间隙对混流式水轮机内部流动特性的影响[J]. 农业工程学报,2020,36(2):23-29. doi:10.11975/j.issn.1002-6819.2020.02.004 http://www.tcsae.org

Wu Zijuan, Liang Wuke, Dong Wei, Gao Chenhui, Chen Diyi. Influence of seal clearance of runner on internal fluid field in Francis turbine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(2): 23-29. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.02.004 http://www.tcsae.org

2019-08-16

2019-12-30

国家优秀青年科学基金项目(51622906);陕西省水利科技项目(2019slkj-10);中央高校基本科研业务费专项资金资助(Z1090219041)

吴子娟,博士生,主要从事水力机械内部流场分析与优化设计研究。Email:wuzijuan.xa@qq.com

梁武科,博士,教授,主要从事水轮机设计、运行、改造及故障诊断研究。Email:liangwuke@vip.163.com

10.11975/j.issn.1002-6819.2020.02.004

TK733+.1

A

1002-6819(2020)-02-0023-07