Water Bath Extraction Optimization of Polyphenols from Qing Brick Tea and Raw Material Selection for Tea Polyphenol Extraction

2020-09-28XuejieWUGuangpingDINGJiandongLAI

Xuejie WU, Guangping DING, Jiandong LAI

Hubei University of Science and Technology, Xianning 437000, China

Abstract In this paper, single-factor experiments and orthogonal experiment were conducted to optimize the water bath extraction of polyphenols from Qing Brick Tea, and the optimal extraction conditions obtained were as follows: solvent of 50% ethanol, solid/liquid ratio of 1∶30, temperature of 80 ℃, and time of 6 min. Under the optimal water bath extraction conditions, polyphenols in fresh tea leaves, fresh tea petioles, fresh tea blades, finished brick tea, finished tea petioles, finished tea blades, tea dregs after brewing and tea dregs after boiling were extracted, respectively. It was found that the quality fraction of polyphenols extracted from fresh tea leaves was the highest, with the best extraction effect. The extraction effect of leaf blades was better than that of leaf petioles, and the extraction effect of tea dregs after brewing was better than that of tea dregs after boiling.

Key words Qing Brick Tea, Tea polyphenol, Extraction process, Extraction material

1 Introduction

The border-selling tea of Hubei originated in the Song Dynasty. According to theWanquanCountyAnnals, during the Jingde period of Song Dynasty, the government used the tea from the two lakes to trade with border areas and Mongolia, which was the embryonic form of miles of tea road. To facilitate storage and transportation, during the Yongle period of Ming Dynasty, the traditional method of using rice milk to make cake tea was replaced by steam heating and stepping on to make cylindrical "hat box tea", forming the predecessor of Qing Brick Tea. During the Qianlong period of the Qing Dynasty, the processing technology further developed, cake tea was transformed into brick tea, the capital of Shanxi merchants flowed in, and a large number of tea houses with brand of "川" (chuan, a Chinese character) were opened, and the Qing Brick Tea of "川" (chuan, a Chinese character) brand had become the main trade commodity in the thousands of miles of tea road between China and Russia. At present, promoted by the "One Belt, One Road" Initiative and the Yangtze River Economic Belt, the tea ceremony will be revived, which is an important measure of local response to the great national policy[1]. Hubei Qing Brick Tea is an important chess piece in thousands of miles of tea road between China and Russia. The brick tea of "川" (chuan, a Chinese character) brand has a long history and a strong brand, and it will definitely play a pivotal role. However, the comprehensive economic value of Qing Brick Tea is not high, and there is still a blank in the research on its deep processing and functional ingredients, and therefore, there is huge potential to be tapped. It is still relatively rare to find out about the extraction of functional ingredients and the efficacy of Qing Brick Tea, but there have been some studies on other dark teas. Taking Anhua Fu brick tea as the research object, He Guowenetal.[2]conducted research on the extraction and anti-oxidation of the brown pigments in Fu brick tea. It is found that the extraction effect is good and the tea has a good anti-oxidant application prospect.

Xia Lietal.[3]extracted flavonoids from Fu brick tea and optimized the extraction process. Song Shasha[4]extracted and studied polyphenols in Fu brick tea. In this paper, the Qing Brick Tea of Laoliao brand produced by Zhaoliqiao Tea Factory Co., Ltd. in Chibi, Xianning was used as the raw material, and the extraction process of tea polyphenols and the selection of the most suitable raw materials for polyphenol extraction were explored, in order to find out the best extraction technology and the most suitable extraction materials for Qing Brick Tea polyphenols and lay a foundation for the development of deep-processing products, reuse of tea dregs, extension of the tea industry chain, and increase of added value of Qing Brick Tea.

2 Experimental design, materials and methods

2.1 Experimental design and methods

2.1.1Experimental design. Single-factor experiments and orthogonal experiment were conducted to explore the optimal solid/liquid ratio, extraction temperature and extraction time, with five replicates for each treatment. Under the optimal extraction conditions concluded, the polyphenols in fresh tea leaves, fresh tea petioles, fresh tea blades, finished brick tea, finished tea petioles, finished tea blades, tea dregs after brewing and tea dregs after boiling were extracted, respectively. Five replicates were arranged for each treatment.

2.1.2Determination method of tea polyphenol content. The Qing Brick Tea was chopped, dried in an oven at 70 ℃ to constant weight, crushed, sieved (80-mesh), and packaged into a sealed brown bottle for later use. The leaching rate of tea polyphenols was determined with the national standard method of ferrous tartrate spectrophotometry[5].

2.2 Experimental materialsThe Qing Brick Tea of Laoliao brand produced by Zhaoliqiao Tea Factory Co., Ltd. was used as the experimental material for optimizing extraction conditions in water bath. For screening of most suitable extraction material, 8 different materials including fresh tea leaves, fresh tea petioles, fresh tea blades, finished brick tea, finished tea petioles, finished tea blades, tea dregs after brewing and tea dregs after boiling were used (Fig.1) (in order to ensure the regular state of tea dregs as much as possible, the brewing was conducted with popular conventional boiling water until it is tasteless, and the boiling was performed using a boiling teapot commonly used by the general public until it is tasteless).

Note: a, fresh tea leaves; b, fresh tea petioles; c, fresh tea blades; d, finished brick tea; e, finished tea petioles; f, finished tea blades; g, tea dregs after brewing; h, tea dregs after boiling.

2.3 Apparatus and drugs

2.3.1Experimental apparatus. Constant-temperature water bath; high-precision electronic balance; oven; ultraviolet spectrophotometer; high-speed universal crusher; circulating water vacuum pump; pipettes (200 μL, 1 000 μL and 5 mL); conical flasks of various specifications, measuring cylinders, volumetric flasks, beakers,etc.

2.3.2Experimental drugs. Ferrous sulfate (FeSO4·7H2O) AR, absolute ethanol AR, potassium sodium tartrate (C4H4O6KNa·4H2O) AR, disodium hydrogen phosphate (Na2HPO4·12H2O) AR, potassium dihydrogen phosphate (KH2PO4) AR, distilled water.

3 Extraction process of tea polyphenols from Qing Brick Tea

3.1 Water bath extraction

3.1.1Single-factor experiments. The main influencing factors in the extraction of tea polyphenols by water bath are extraction solution, extraction time, extraction temperature and solid/liquid ratio. The study results of Yang Lili[6]show that the optimal extraction solution is 50% ethanol, and in this paper, 50% ethanol was used as the extraction solution.

(i) Extraction time. A certain amount (1 g) of the processed tea sample was placed in an conical flask, added with 15 mL of 50% ethanol, sealed with a breathable sterile membrane filter, bathed in water (60 ℃) for 20, 30, 40, 50, 60, 70, 80, 90 and 120 min, respectively, and filtered while hot. The contents of tea polyphenols was determined. The results are shown in Fig.2. The results show that 60 min is the optimal extraction time. Taking Qing Brick Tea as experimental material, Huang Mingjunetal.[12]investigated the effect of extraction time on extraction rate of tea polyphenols by response surface methodology, and it was found that extraction time had little effect on the extraction rate of tea polyphenols, which is similar to the result of this study.

Fig.2 Effect of extraction time on mass fraction of tea polyphenols extracted

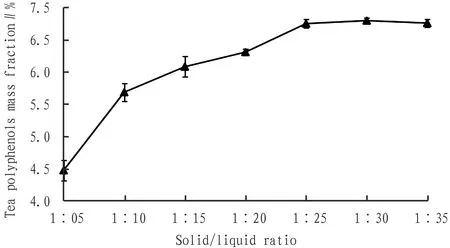

(ii) Solid/liquid ratio. The extraction time was fixed at 60 min, and the solid/liquid ratio was set as 1∶5, 1∶10, 1∶15, 1∶20, 1∶25, 1∶ 30 and 1∶35, respectively. The tea polyphenol contents determined are shown in Fig.3. It could be observed that under the solid/liquid ratio of 1∶30, the mass fraction of tea polyphenols was the highest, so it was the optimal solid/liquid ratio.

Fig.3 Effect of solid/liquid ratio on mass fraction of tea polyphenols extracted

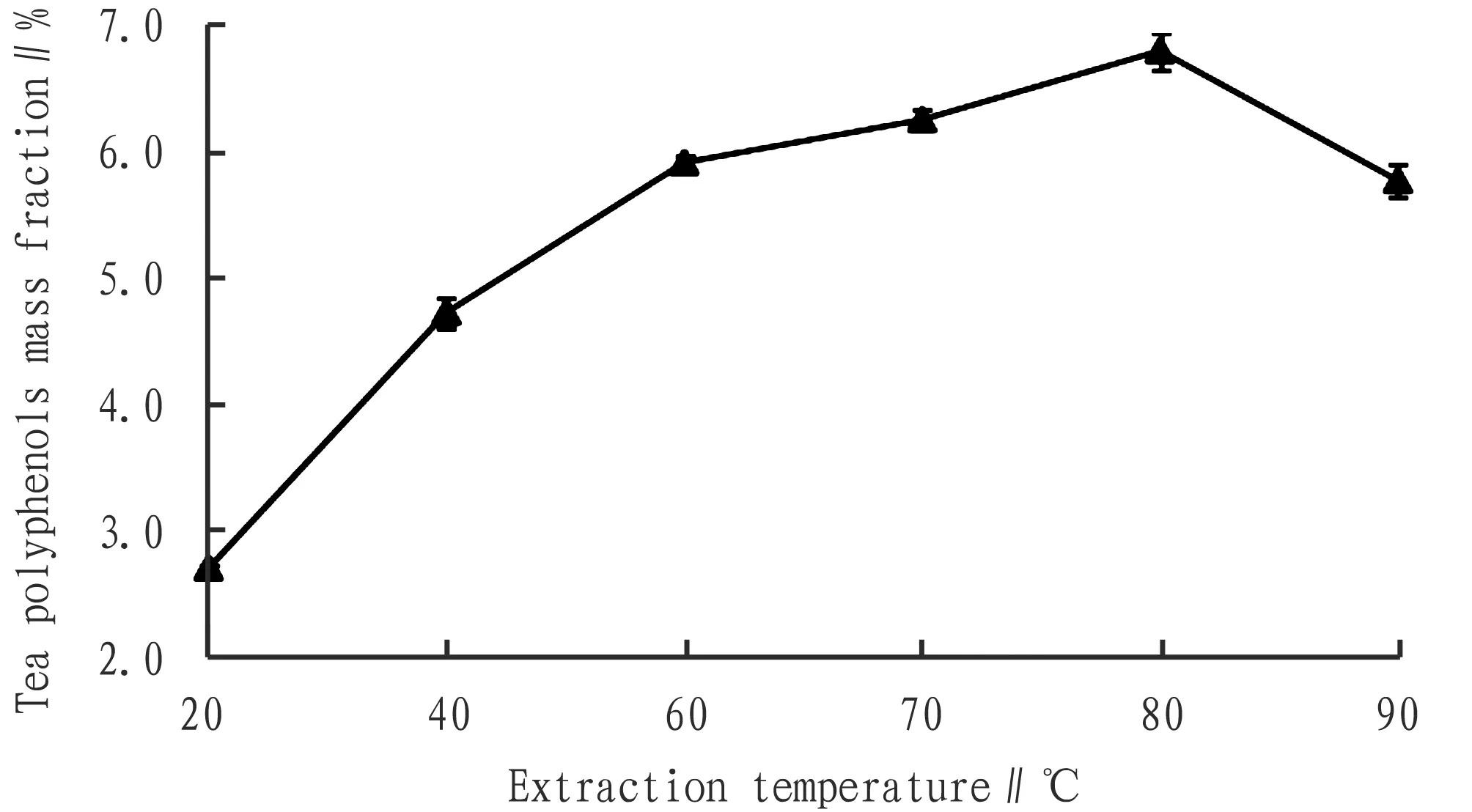

(iii) Extraction temperature. The extraction time and solid/liquid ratio were fixed at 60 min and 1∶30, and the extraction temperature was set as 20, 40, 60, 70, 80 and 90 ℃, respectively. The contents of tea polyphenols were determined (Fig.4). The higher the temperature, the better the leaching of tea polyphenols. When the temperature was 80℃, the content of tea polyphenols was the highest, and then as the temperature increased, the content of tea polyphenols dropped sharply. Therefore, it was concluded that 80 ℃ was the best extraction temperature, and further increasing the temperature might cause a large amount of tea polyphenols to decompose, reducing the content of tea polyphenols.

Fig.4 Effect of extraction temperature on mass fraction of tea polyphenols extracted

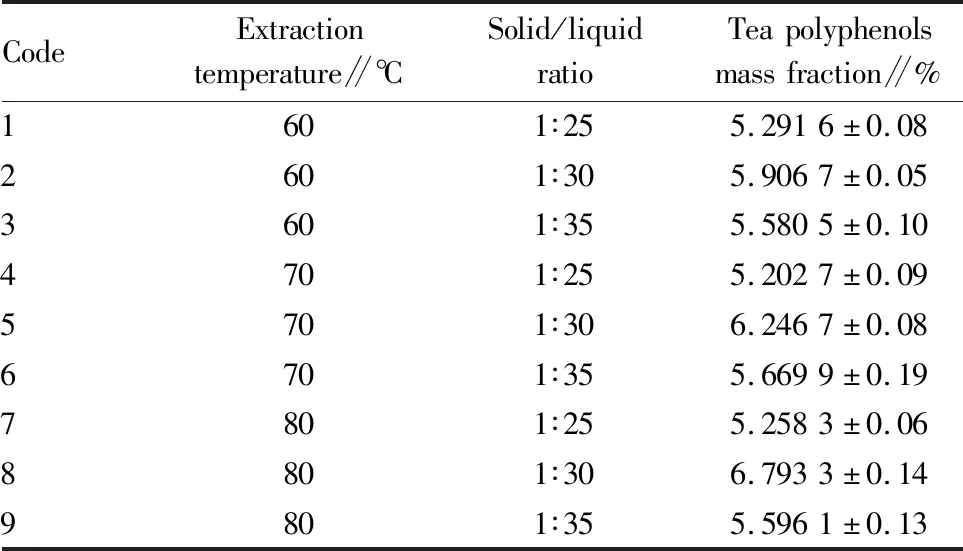

3.1.2Orthogonal experiment of water bath extraction of tea polyphenols. In order to avoid inaccuracy of single-factor experiments and interference among influencing factors, an orthogonal experiment was conducted on extraction temperature and solid/liquid ratio. Since the extraction time had a little influence on the experimental results, it was not taken into account. A certain amount (1 g) of the processed tea sample was placed in a conical flask and submitted to experiment under the above conditions. The extraction time was 60 min, and five replicates were arranged for each treatment. The contents of tea polyphenols determined are shown in Table 1. The mass fraction of tea polyphenols was the highest in group 8 (extraction temperature of 80 ℃ and solid/liquid ratio of 1∶30). The analysis results of variance (Table 2) show that the extraction temperature (60-80 ℃) had no significant influence on the yield of tea polyphenols (P=0.833>0.05), which is different from the single-factor experiment result. This may be because that when the extraction temperature reached 60-80℃, the yield of tea polyphenols differed insignificantly, and also, it was caused by experimental errors. Differently, solid/liquid ratio showed a significant influence on the yield of tea polyphenols (P=0.007<0.05), consistent with the result of single-factor experiment. According to the size of F value, it can be seen that the solid/liquid ratio had a far greater influence on the yield of tea polyphenols than the extraction temperature. Combining the results of single-factor experiments, the optimal extraction conditions for water bath extraction of polyphenols from Qing Brick Tea were determined as follows: extraction solution of 50% ethanol, extraction temperature of 80 ℃, extraction time of 60min and solid/liquid ratio of 1∶30.

Table 1 Results of orthogonal experiment

Table 2 Analysis results of variance

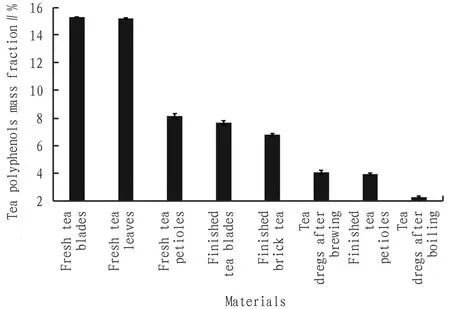

3.2 Selection of extraction materialsUnder the optimal water bath extraction conditions (extraction solution of 50% ethanol, extraction temperature of 80 ℃ and solid/liquid ratio of 1∶30) concluded above, polyphenols in fresh tea leaves, fresh tea petioles, fresh tea blades, finished brick tea, finished tea petioles, finished tea blades, tea dregs after brewing and tea dregs after boiling were extracted, respectively, five replicates for each treatment. The contents of tea polyphenols determined are shown in Fig.5. Among the 8 kinds of raw materials, fresh tea blades are the best material for extracting tea polyphenols, and the mass fraction of extracted tea polyphenols was 15.30%. Whether it was raw material or finished product of Qing Brick Tea, tea blades contained more tea polyphenols than tea petioles. The mass fraction of polyphenols extracted from tea dregs after brewing was higher than that extracted from tea dregs after boiling. The content of polyphenols in tea dregs after brewing was still 4.07%. If the polyphenols, polysaccharides, caffeine and other ingredients in tea dregs are extracted and developed into deep-processed products, and the dry matter such as fiber is pressed into practical products such as tea cups and ornaments, the value of the Qing Brick Tea industry will be enhanced greatly.

Fig.5 Yield of tea polyphenols in 8 kinds of materials

4 Conclusions

The optimization of tea polyphenol extraction process from Qing Brick Tea and the selection of the best extraction material were explored in this study. The following results are obtained. (i) Optimization of the extraction process of polyphenols from Qing Brick Tea. Through single-factor experiments, the effect of different temperatures, different solid/liquid ratios and different extraction times on the extraction of polyphenols in Qing Brick Tea was investigated. Orthogonal experiment was designed. The optimal extraction conditions are preliminarily obtained: extraction solution of 50% ethanol, extraction temperature of 80 ℃, extraction time of 60 min, and solid/liquid ratio of 1∶30. (ii) Selection of extraction materials for tea polyphenols. Under the optimal extraction conditions, the contents of polyphenols in eight different materials were determined to screen out the most suitable material for extracting tea polyphenols in Qing Brick Tea. The results show that fresh tea blades are the best material for extracting tea polyphenols, and the mass fraction of extracted tea polyphenols was 15.30%. In both raw materials and finished products, tea blades contain more polyphenols than tea petioles. The tea dregs after brewing had a higher content of tea polyphenols than the tea dregs after boiling, and the content of polyphenols in the tea dregs after brewing was still up to 4.07%, suggesting that tea dregs also have a certain use value and development prospect.

杂志排行

Asian Agricultural Research的其它文章

- Impact of COVID-19 Epidemic on the International Food Supply Chain and Countermeasures of Shandong Province

- Study of Factors Influencing China-ASEAN Agricultural Product Trade Development in the Context of "the Belt and Road"

- Comprehensive Evaluation on the Level of Agricultural Economic Development in Hubei Province Based on Principal Component Analysis

- Effect of Foliar Application of Selenium Fertilizer on Yield, Selenium Content and Heavy Metal Contents of Waxy Maize

- Effects of Applying Trace Clements on Yield and Quality of Flue-cured Tobacco Cuibi-1

- Analysis of the Correlation between Middle-season Rice Yield and Meteorological Factors in Jingdong County from 2009 to 2016