Sustainability Evaluation of Sheep and Goat Rearing in Southern Italy. A Life Cycle Cost/Benefit Assessment

2020-06-22NausicaaPollaroRemoSantagataSergioUlgiati

Nausicaa Pollaro,Remo Santagata†,Sergio Ulgiati,2

1 Department of Science and Technology,Parthenope University of Napoli,Napoli,Italy

2 School of Environment,Beijing Normal University,Beijing,China

Keywords Sheep and goat rearing Goatcheese production Life cycle assessment Circular economy

Abstract Sheep and goat farming represent a non-negligible share of the worldwide livestock productions. Ovine rearing, although knowing time periods of growth and descents,is today gaining more interest especially with regards of milk and dairy products.This is due to the rediscovery of the economic,social and environmental potential of this type of farming and its products.This work aims to analyze goat farming and its productions using the life cycle assessment (LCA) method. LCA makes it possible to evaluate and understand the environmental impacts of livestock farming and dairy processing throughout all the phases of their production. The purpose is to highlight and localize the opportunities for reducing the environmental impacts;compare similar products to each other;evaluate and compare the effects related to different environmental and resource management policies.Two zootechnical companies, located in the province of Salerno (Italy),are investigated. The production process analyzed is precisely that of goat cheese, specifically the “Cacioricotta Cilentana”, a very well-known kind of Italian cheese. The characteristics of goat breeding and the production of Cacioricotta Cilentana are examined in this study. The similarities and differences between the two companies have been highlighted,linked to the breeding, cheese making and sale phases of the finished product. Applying the LCA approach, the environmental impacts of the production process were analyzed and quantified,according to the ReCiPe Midpoint(H)method to derive impact indicators relating to the most significant impact categories(including climate change,human toxicity,acidification,depletion of fossil resources,depletion of water resources).The evaluation highlights the critical points of the process so as to be able to suggest improvement options.

1 Introduction

The ruminant sector is globally represented for about the 56% by small ruminants, namely sheeps and goats,with a population of about 1178 million of sheeps and 1000 of goats, numbers expected to increase 60% by 2050. Sheeps and goats farming contribution to global meat and milk production increased of 1.7%and 1.3%respectively in the 1993-2013 time frame(Marino et al.,2016). As for the general livestock sector, meat is the main product of sheep and goat rearing process,with a coproduction of skin,wool and dairy products,the latter of greater importance than meat consumption in some countries(Zygoyiannis,2006).

Fig.1 World sheep and goat milk production trends from 1960 to 2016(solid line)and forecast to 2030 by using time-series model(dashed line)(Pulina et al.,2018).

FAO/OECD (2015) recognized the sheep sector as the most dynamic trend with an expected production increase of 23% during the period 2014–2024. Dairy ovines represent the 21% of the global sheep and goats population, contributing to the annual global dairy production for respectively 1.3%and 1.9%. Sheep and goat milk production doubled in the past 50 years,and it is expected to increase even more in the near future(+26%and+53%more respectively by 2030,Figure 1)(Pulina et al.,2018).

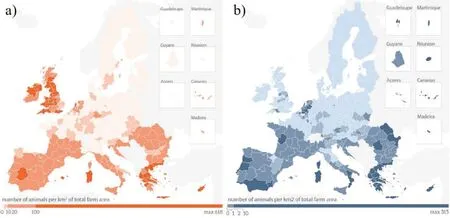

Sheep and goat population in Europe reached a count of almost 100 million heads in 2017,with sheep population(Figure 2a)mainly based in UK(28%)and Spain(19%),while 31%of EU’s goat population(Figure 2b)is based in Greece and 25%in Spain(Rossi,2018). Nowadays,EU ovine population shows constant numbers,after a declining time-frame (2000-2016) primarily due to the outbreak of diseases and to policy changes in public funding(Rossi,2018).

Sheep and goat rearing occupy large areas, mostly in the countryside, contributing for almost the 4% to European meat production, a number that is expected to lower in the near future. On the other hand, the consumption of dairy products is becoming more popular, with rising trends in the supply of dairy products and in kid meat exports to third countries. Sheep and goats grazing on country grasslands are part of the landscape and cultural heritage of many European countries. The sector provides employment in disadvantaged agricultural areas and the high-quality traditional products they yield are broadly recognized as the result of a sustainable and multifunctional form of agriculture that contributes to preserving the environment and social cohesion in rural areas(Rossi,2017).

Fig.2 a)Sheep flock and b)goat herd density in the EU(Rossi,2017).

Italy is the third country in EU-28 for sheep population, with more than 7 million sheep heads in about 68 thousand farms(Vagnoni et al.,2017). The ovine sector in Italy is characterized mostly by semi-extensive farms,with seasonal grazing. Dairy sheeps are mainly located in central Italy and in the islands(almost 22%). For the wide part (71%), milk is processed by the dairy industry, while the remaining 29 percent is processed on the farm. In the present days, sheep milk has risen in great consideration in many countries, including the United States. Sheep dairy products have benefit of a great market presence thanks to product’s quality, high yield,and nutritional value, the latter due to the higher concentrations of proteins, fats, vitamins, and minerals when compared to the milks from other domesticated mammals(Balthazar et al.,2017). Most of the milk is processed into dairy products like cheese,with 30%of milk used for the production of Pecorino Romano cheese(Pulina et al.,2018). Sheep are of great importance as a major source of livelihood of the small farmers and the landless in rural communities. In rural and extensive farming systems,the strong interaction of sheep with the environment makes the environmental quality of soils,air,and sediments related to water supply,a key factor to guarantee a safe and secure alimentary intake of sheep derived foods.

In this work,Cacioricotta Cilentana goat cheese production from two different companies in Southern Italy is assessed, in order to explore the differences between a semi-intensive and an intensive livestock and dairy products production and to identify the main burdens and flaws,with the aim to address the demands of an ever increasing food consumption and the needs for the least possible impacts and pollution.

2 Materials and methods

This work uses the LCA framework to analyse the investigated case study,as defined by ISO standards and ILCD Handbook guidelines (ISO 14040, 2006; ISO 14044, 2006; JRC,2010). Life Cycle Assessment is a methodological framework to assess the potential environmental impacts and resources used throughout a product’s life cycle, from raw material acquisition, via production and use phases, to waste management. The resulting environmental impacts are caused by consumption of resources, emissions of substances into the natural environment,and other environmental exchanges. LCA provides indicators related to many different environmental impact categories, such as climate change, stratospheric ozone depletion, depletion of resources, toxicological effects, among others (Pennington et al., 2004). LCA is a relatively recent method that has rapidly grown to become a standard tool to investigate the environmental performance of a wide range of human-dominated processes. LCA methodology is standardized as a four stages tool(definition of goal and scope,inventory analysis, impact assessment and interpretation) for environmental management at global level (ISO 14040, 2006;ISO 14044, 2006; JRC, 2010). The study has been performed utilizing the openLCA software version 1.7.3(https://openlca.org), the Ecoinvent database version 3.1(Wernet et al., 2016), and the ReCiPe method (Goedkoop et al., 2009) for impacts assessment. ReCiPe Midpoint (H) v.1.11 method has been chosen. It allowed the exploration of a large number of impact categories of interest in agriculture/livestock systems (i.e. climate change potential, eutrophication). The ReCiPe method provides characterization factors to quantify the contribution of processes to each impact category and normalization factors to allow a comparison across categories(Europe ReCiPe Midpoint (H), 2000, revised 2010). Characterized results cannot be compared, due to their different physical units, therefore a normalization procedure is applied. Normalization is a life cycle impact assessment tool used to express characterized impact indicators in a way that they can be compared, with reference to average impact values calculated for a given area in a given year. Normalization is carried out by dividing characterized values by a selected reference value for each category. There are numerous methods for selecting a reference value, including, for example, the total emissions or resource use in a given area, global,regional or local(Santagata et al.,2017). The impact categories explored in this study are listed in Table 1.

Table 1 Impact Categories considered within the ReCiPe Midpoint(H)v.1.11 impact method.

2.1 Case study description

Two sheep and goat farming systems have been taken into account in this study. The two farms (labelled as Company A and Company B),are both located in the province of Salerno in Campania region(southern Italy),counting respectively 57 and 95 animals:

• Company A is a family-run farming business,operating in sheep and goat semi-wild rearing and fruit trees cultivation. It covers an extension of 37 ha, organic certified since 2001 from ICEA (Ethical and environmental certification organization), a non-profit consortium involving bodies, associations, businesses,and organizations of the civil society. The company area,within the Cilento and Vallo di Diano National Park, is developed from 800 to 150 meters above sea level. 10 ha are destined to trees cultivation, 15 ha are for bushy and wooded pastures and 12 ha are wooded areas with essences typical of the Mediter-ranean scrub. Animals often graze aromatic essences, whose aromas are perceived in aged cheeses. The cacioricotta goat cheese is obtained from goat rearing. Company A annual production is about 2400 cacioricottas, each weighing about 600 g,for a total production of about 1440 kg of cheese. Goats are fed with commercial feeds,bales of alfalfa and oats(purchased from the market)and through grazing,the latter representing 10%of the total food requirements. Lambs are fed with breast milk,avoiding the artificial milk and lowering the potential rearing yield. Thus,Company A should be considered as a semi-intensive rearing company. The production of Company A consists of i)cacioricotta cheese,sold to the market;ii)manure and whey leaving the system either as by-products or sold to the market;iii)meat,to be butchered and sold to the market.

I looked up, surprised. She seemed so calm and gentle. Seemingly11 out of the blue, someone had found me and offered help. I wiped the tears from my cheek.

Table 2 Production data about related to Company A and Company B.

• Company B, as Company A, is a family-run business for the production of vegetables and cereals, that has seen the introduction of goat rearing and cheese production in recent years. Company B, located in Capaccio Paestum, Salerno province, is characterized by an intensive breeding and loose housing of animals. Lambs are fed with milk replacers,and the milk from goats is only intended for the production of cheese. Adult animals are fed according to their life stage needs,with feed from market and self-produced bales of alfalfa and hay. The production of Company B consists of i) cacioricotta and ricotta cheese;ii) manure used as fertilizer for own fodder production; iii) whey fed back to the animals; iv) meat for butcheries;v)fodder for animal feeding(about 26 t/year).

Data about Company A and Company B are shown in Table 2.

2.2 Goal and scope definition

The main purpose of this work is to evaluate the impacts and to quantify energy and material consumption related to goat cheese production. The most crucial phases of the process are identified and analyzed in order to propose suitable potential improvements. The two companies are taken into account and confronted,comparing rearing and transformation methods.

The Functional Unit (FU) chosen, to which all data is proportioned, is 1 kg of Cacioricotta goat cheese produced. The physical boundaries of the processes are identified as system boundaries,thus adopting a“gate to gate”approach,focusing on the steps conducted within the two companies. Both processes can be divided in different steps,each with its own input and output flows,identified as:1)Sheep and goat rearing;ii)Cheesemaking;iii)Aging;iv)Sale(Figure 3).

2.3 Life cycle inventory

All quantitative data has been provided by the investigated companies. Secondary data has been retrieved from scientific and technic literature, and from the Ecoinvent database, used to build the inventories. All data used for the construction of the Life cycle inventory (LCI) has been properly scaled to the chosen FU of 1 kg of Cacioricotta goat cheese produced, and it is referred to the year 2018, for both Company A (Table 3) and Company B(Table 4).

The allocation of the resulting impacts between the different co-products of both companies has been performed based on the exergy content of cheese,manure and whey(Table 5,exergy values from Szargut(1989)andBsch et al. (2012)). Exergy content refers to the different output flows of a system or a process. A low exergy content would generally indicate the by-product to be close to the equilibrium with the surrounding environment and therefore no longer considerable as a product at the scale of the investigated system(Santagata et al.,2019).

Table 3 Life cycle inventory related to Company A(annual data).

Table 4 Life cycle inventory related to Company B(annual data).

Table 5 Exergy based allocation of goat cheese,manure and whey in Company A and Company B.

Fig.3 Flow chart highlighting the main phases of goat cheese production.

3 Results

LCA characterized impacts for the production of 1kg of goat cheese within Company A and Company B are shown in Table 6. Numbers are very diverse, confirming the wide difference between the semi-intensive conducted Company A and the intensive rearing of Company B.Company A shows larger impacts in most impact categories of Table 1,while Company B has the larger burdens in a few remaining ones(ALOP,NLTP,TETP).The Table also shows the adimensional normalized impacts of the two farms. In particular,it can be noted that,in the case of Company A,the 6 categories GWP,FETP,FEP,METP,MEP and NLTP account for about 84%of total normalized impacts, while for Company B about 81.4% of total impacts affect the 6 categories FETP,FEP,METP,MEP,NLTP and TAP.Figure 4 graphically compares the normalized impacts of both systems. The ReCiPe Midpoint Normalization factors do not include the Water Depletion Factor, likely due to the difficult accounting of different water uses (power plants, domestic, household, etc). Other studies (EC-JRC, 2011,Benini et al., 2014), suggest tentative values, not included in this work. The chart confirms that the difference between a semi-intensive and an intensive sheep and goat dairy process does not reside in the overall burdens per se,when calculated per unit of product,but is also affected by the total yield per year(intensity of production).

Table 6 ReCiPe Midpoint(H)characterized and normalized impacts for the production of 1 kg of Cacioricotta goat cheese.

Fig.4 ReCiPe Midpoint(H)normalized impacts related to Company A and Company B.

4 Discussion

This research has investigated a still poorly studied sector, the sheep and goat rearing activity and the related goat dairy processing sector,contributing to filling a gap within the food production scientific literature. In fact,other livestock sectors have been more extensively studied, providing performance indicators and frameworks(Ghisellini et al.,2014),while the ovine sector has always received much less attention,in spite of its importance in small scale rural economies.

Regarding Company A,the larger impacts are related to the toxicity of water(FETP and METP),the natural land use change (NLTP)and the global warming (GWP).FETP is largely caused by the use of electric energy from the Italian electricity mix(83%)and from the supply network of water(12%),while only 1%is due to the agricultural fodder production. A very similar situation is observed within METP,with a contribution of 83%from electricity, 15%from water supply network and 1%from fodder production. Once again, electric energy is the major responsible within NLTP (74%), followed by oil extraction and refinement processes (11%), and the actual rearing phase (10%). GWP almost exclusively depends on the cheesemaking phase (88%), due to the combustion of LPG,with other relevant contributions from the use of electric energy (7%)and the rearing phase (4%). Company B presents a similar situation, with FETP and METP as categories with the highest impacts,followed by NLTP and MEP.As in Company A,FETP and METP are caused mainly by the electricity used (respectively 87% and 96%) and the rearing process (respectively 11% and 2%). Electricity is the main contributor also to NLTP (56%), together with the rearing phase (39%) and the oil extraction and refinement process. The contribution from the rearing phase depends on the production of the animal feed used. MEP is mainly due to the electricity production(63%)and the rearing phase(37%).

The difference between Company A and Company B are related on how they perform their businesses. The exploration of the presented results makes it possible to:

i)understand which environmental compartments are the more impacted;

ii)formulate adequate improving scenarios.

The different impacts emerging when comparing the two companies,reflect the difference between the two investigated systems: Company A is a semi-intensive farm,importing fodder from the market,coupled to animal grazing, while Company B is an intensive farming system, importing a large amount of feed from the market but also self-producing some fodder thanks to manure-based fertilization(no grazing). These differences reflect on the obtained results, with companies showing impacts in different categories. Company A shows some advantages of non-intensive productions (i.e. less dependence from the market, less impacts from industrial animal feeding),while Company B shows the benefits of intensive productions(i.e. larger yield of products). If the totals of normalized values are calculated,Company A shows to be globally slightly more impacting(Total:2.53E-11) than Company B (Total: 1.99E-11). The difference is not very large, 21% less impact in favor of Company B,but it is indicative of how different production models may translate into comparable impacts. It should be noted that this difference is related to 1 kg of goat cheese produced,but Company A(semi-intensive),has a production of 1440 kg per year, while Company B (intensive) will produce 3500 kg of cheese per year,thus explaining the smaller unit impact.

4.1 Implementing circular economy patterns in cheesemaking production

Circular Economy (CE) (Ellen MacArthur Foundation, 2012) is gaining more and more momentum in recent years,due to the general deterioration of environmental system,the pressing waste and pollution problems and the more and more raising awareness of people recognizing the importance of personal and institutional actions to tackle environmental issues. The recent European Commission Circular Economy Package defines CE as a framework with the aim to maintain products value and material as long as possible through their recovery,generating further value, to reduce waste and resource use (European Commission, 2015a, 2015b). The final goal is to overcome the linear paradigm“take-make-dispose”towards a more efficient use of available resources,thus bringing an increased wellbeing through minimum environmental costs.

The bio-based sector is a major producer and consumer of natural resources in Europe, is recognized as a focal point in the context of circular economy implementation, in particular in Northern and Western Europe(Leipold and Petit-Boix,2018). Different example of processes and systems oriented to closing the loop through feedback frameworks can be found in literature, with a particular attention to agri-food waste and by-products,at laboratory or industrial scale, which may be applied to the presented systems in order to develop circularity patterns.

Santagata et al. (2019,2017)showed how animal by-products not destined to human consumption could be recovered and processed in order to generate power,purified fat and animal meal to be exported to market for the production of different kind of commodities. Manure,in addition to its recovery and reuse as organic fertilizer spread on crops, can be converted through anaerobic digestion in biogas, a valuable form of renewable energy to be reused within the agricultural processes (Andr´e et al., 2018; Angelonidi and Smith, 2015; Browne and Murphy,2013;Burg et al.,2018;Buˇsi´c et al.,2018;Cestonaro et al.,2015;Hamelin et al.,2014;Holm-Nielsen et al., 2009; Scarlat et al., 2018; Siddique and Wahid, 2018). Florio et al. (2019) illustrated that the use of upgraded bioCH4 in substitution to natural gas generates lower environmental burdens compared to different fossil fuels. Goat manure may be treated through pyrolysis to generate bio-oil,representing the starting material for the generation of various chemicals or bio-fuels(Erdogdu et al.,2019).

Whey is commonly wasted,recovered to be used as organic fertilizer or fed back for animal feeding. Proteins from whey could be extracted in different ways (magnetic, hydrophobic resin, membrane, precipitation, etc.)for biotechnological applications (Nicol´as et al., 2019). Biosynthesis of whey after hydrolysis can generate biopolyesters (Koller et al.,2017). Single cell oils,lipids used as substituent of natural oil and fats for chemical production,are generated by microbial fermentation of whey(Uc¸kun Kiran et al.,2015). Whey can also be biodigested for the production of biogas or to boost poultry manure anaerobic digestion(Gelegenis et al.,2007).

4.2 Exergy allocation to co-products

As previously noted,Table 5 highlights the exergy allocation percentages assigned to the output flows of rearing and cheesemaking processes in both Company A and B.The largest fraction of exergy,a thermodynamic measure of work potential,is assigned, within the rearing process,to the flow of manure,while the main product of the sub-process, milk,is assigned a 11%fraction in Company A and 20%in Company B.In the cheesemaking sub-process,cheese is assigned 16%of exergy in Company A and 11%in Company B,so once again the largest fraction is assigned to the by-product,whey. It is commonly accepted within LCA method that the main product,in a multi-product system, is to be assigned the largest fractions of the impacts generated, in a way acknowledging that it is the main reason why the process or the system is conducted. In the systems investigated in this work, the main commercial product is in a considerably smaller quantity when compared to the production of whey in cheese manufacturing and manure in livestock. In order to assign the largest fraction of impacts to the cheese and milk output flows,the only way would be to perform an allocation based on the economic value of the outputs, considering the high market value of the cheese and milk and the almost equal to zero economic value of manure and whey. However, this perspective is rooted in the human point of view of recognizing the financial worth as the main, most relevant characteristics. Instead, manure plays a significant role both within this study and in the general economy,as it is used as organic fertilizer in crops. In the presented work,manure,with an average N content of about 2%(Moral et al.,2005),is used for growing the fodder to be used as livestock feed,avoiding the use of about 1500kg in the case of Company A and about 2700kg in the case of Company B of a common 46% N industrial fertilizer, in a way allowing the production of the main product: cheese. This way, manure usage acquires a value that stands beyond its economic worth, embedding part of the emissions from the livestock supply chain and avoiding emissions from industrial fertilizers(Leip et al.,2019). Moreover,manure can be processed and converted to a wide range of energy and materials,further confirming its value. A similar interpretation could be applied to whey,in this work fed back to the processes and used as fertilizer or animal feeding. This confirms the added value of materials until now considered as by-products, or waste,that instead keep a significant worth when managed properly,in a circular economy perspective.

5 Conclusions

The present study aimed to perform a comprehensive assessment of goat cheesemaking production through a life cycle perspective,exploring constraints and potentialities of the investigated systems.

In this work, two different companies from Southern Italy, delivering a similar product through businesses run in different ways. The study confirmed the different impacts related to semi-intensive and intensive agri-food processes, generated by different resources use from the market and different approaches in livestock farming.The agri-food framework is once again identified as one of the most inclined frameworks for developing circular patterns. The cheesemaking phase is the most impacting one, as the industrial transformation process of an agricultural product, but the entire supply chain shows a great potential in burden lowering and circularity implementation. Impacts reduction could be achieved by introducing renewable, or less impacting, energy sources, and by shifting from an intensive rearing to a more extensive one, by implementing free grazing of animals and self-production of feed and bedding,and other techniques like fertirrigation,that have been proved to contribute in lowering environmental burdens(Buonocore et al.,2018). Further,the by-products generated in agro-food systems show an excellent potential of recovery and reuse in order to establish feedbacks and develop circularity strategies to help in abandon the too old,too impacting,linear framework.

Acknowledgement

The Authors gratefully acknowledge the support from the Italian Ministry of Foreign Affairs and International Cooperation (MAECI - No. PGR00767) within the framework of the High Relevance Sino-Italian bilateral project“Analysis of the metabolic process of urban agglomeration and the cooperative strategy of circular economy”.

杂志排行

Journal of Environmental Accounting and Management的其它文章

- An Integrated Pollution Prevention Ecosystem for Small-Scale Production of Raw Coco-nut Jelly in Craft Villages

——A Case Study from Mekong Delta,Vietnam - Green Economy as a Paradigm of Sustainable Development of the Republic of Kazakhstan

- Biochar as Improver of Methane Production in Anaerobic Digestion of Food Waste

- Can Increase in the Share of Renewable Energy in Economic Growth Shift Turning Point of EKC?Evidence from Time-series Analysis in India

- The Prevalence of Students and Teachers’Ideas about Global Warming and the Use of Renewable Energy Technology

- Do the Improved Water Sources for 203 Countries Converge over Time?