酿酒葡萄曲轴式振动脱粒收获装置研制

2020-06-20袁盼盼朱兴亮韩长杰张学军

袁盼盼,朱兴亮,尤 佳,韩长杰,张学军,郭 辉

酿酒葡萄曲轴式振动脱粒收获装置研制

袁盼盼,朱兴亮,尤 佳,韩长杰,张学军※,郭 辉

(新疆农业大学机电工程学院,乌鲁木齐 830052)

针对酿酒葡萄机械化采收时对植株损伤大、果粒破损率高、脱粒效率低等问题,该文设计了一种曲轴式振动脱粒收获装置,该装置主要由曲轴、弹性夹持振动机构、传动系统、机架等组成。对曲柄摇杆机构的运动和弹性振动杆变形进行了分析,获取了影响作业效果的主要因素。根据Box-Benhnken 中心组合设计方法,以夹持间距、转速和偏心距为影响因子,酿酒葡萄脱粒率和破损率为响应函数进行三因素三水平二次回归正交试验设计,建立了响应面数学模型,并进行了参数优化和验证。结果表明,酿酒葡萄脱粒率影响因素的显著性顺序为转速、偏心距和夹持间距,破损率的影响显著性顺序为转速、夹持间距和偏心距;最优参数组合为夹持间距193 mm、曲轴转速720 r/min、曲轴偏心距38.8 mm,在此参数下测得的酿酒葡萄脱粒率为93.06%,破损率为4.57%,与模型优化理论值相比脱粒率降低了1.09个百分比,破损率增加了1.45个百分点。该研究可为酿酒葡萄的机械化收获及其他林果的振动采收装置设计提供参考。

农业机械;收获;振动;酿酒葡萄;曲轴

0 引 言

葡萄是世界四大水果之一[1],中国酿酒葡萄种植面积已超越法国,成为世界第二大酿酒葡萄种植区[2]。新疆是优质葡萄主产区[3],目前,酿酒葡萄收获作业还停留在传统人工采摘。酿酒葡萄枝条无序生长,人工采收困难,且效率低。国外酿酒葡萄主要产区如意大利、美国、法国等均已基本实现机械化采收[4-5],但由于气候和自然条件上的差异,国内外酿酒葡萄在树形、空间形态、果实集中度等方面差异巨大,亟需开发适用于中国酿酒葡萄种植和管理模式特点的采收机构。

振动采收是目前浆果采收的主要手段之一[6-11],国内外蓝莓、黑加仑、葡萄等浆果,主要利用激励源振动果树,迫使果穗或果粒与相连的枝条或果梗产生相对运动(拉、弯、扭),使连接处变形直至断裂,实现果实采收,酿酒葡萄主要采收果粒[12-16],使葡萄粒从果梗上分离脱落。Caprara利用偏心摇杆机构驱动2排挠性肋条旋转击打葡萄藤实现果实采收[17],Roger 等利用曲柄摇杆机构以及伺服液压交替振动机构产生旋转运动驱动2排交错肋条对葡萄进行振动采收[18],Baisan利用偏心圆盘摇杆机构驱动尼龙弹性杆振摇葡萄藤实现酿酒葡萄采收[19],国内外在葡萄树形、果实分布方面差异较大,振动能量传递效率不同,国外葡萄收获机在中国作业时易造成葡萄植株、葡萄粒损伤大。李成松等基于RSSR空间四杆机构和平面双摇杆机构设计了双支撑酿酒葡萄果实振动分离装置,作业可靠性及稳定性有待改进优化[20-21]。王业成利用可调偏心连杆式振动机构进行试验,分析了振动频率、振幅和激振位置对黑加仑采收率的影响[22],史亮等利用双偏心块旋转产生的反向力偶驱动拨杆圆盘实现蓝莓的采收[23],王海滨等利用采摘滚筒旋转带动蓝莓树振动进行采收[24-25]。目前国内酿酒葡萄收获装备并不成熟,作业时对植株损伤大、脱粒效率低、果粒破损率高、可靠性及稳定性低等问题。

基于上述问题,本文提出了一种曲轴式振动脱粒收获装置,弹性振动杆夹持葡萄植株进行振动脱粒收获,振动脱粒部分主要结构和工作参数均可调,分析了影响葡萄脱粒率和破损率的主要因素,将获得的最优参数应用于酿酒葡萄收获机中,以期为酿酒葡萄及其他浆果和林果的振动采收装备参数设计提供参考。

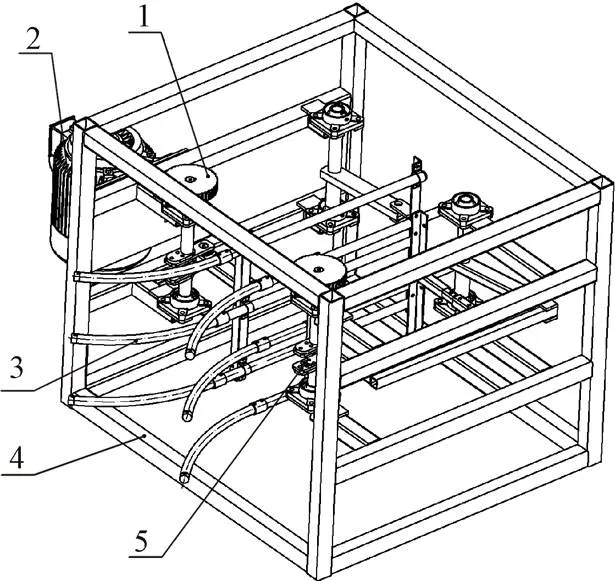

1 装置结构与工作原理

酿酒葡萄振动脱粒收获装置主要由曲轴、弹性夹持振动机构、传动系统、机架等组成,如图1所示。其中,弹性夹持振动机构由左、右弹性夹持单体构成,结合新疆酿酒葡萄为篱架种植,叶幕形宽度为0.8 m左右,在葡萄行的两侧利用弹性夹持振动机构左、右单体间的配合夹持酿酒葡萄植株,根据叶幕形实际宽度通过夹持间距调节杆进行调整,主要参数如表1所示。

1.同步带传动系统 2.电机 3.弹性夹持振动机构 4.机架 5.曲轴

表1 酿酒葡萄振动脱粒装置主要参数

作业时,弹性夹持振动机构左单体的曲轴在电机驱动下转动,将电机输出的旋转运动转换为弹性振动杆的非圆周变向运动;通过同步带传动系统,弹性夹持振动机构右单体与左单体保持同相位、同方向和同步运动;弹性夹持振动机构夹持酿酒葡萄植株做有规律的变速变向运动,使酿酒葡萄粒从葡萄梗上脱落,实现脱粒。

2 关键部件设计

2.1 弹性夹持振动机构

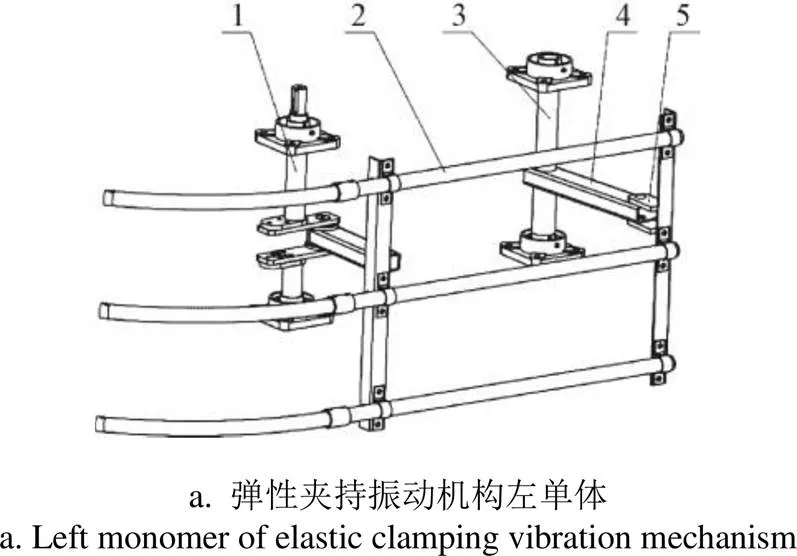

弹性夹持振动机构由曲轴、夹持杆组、转动轴、转动连杆和夹持间距调节杆等组成,图2a和2b分别为弹性夹持振动机构的左单体和右单体,连杆与夹持杆组间固接,转动连杆与夹持杆组间采用销轴连接。夹持杆组上分布3组弹性杆,间距为300 mm,每组弹性杆通过骑马卡固定在竖直的连接杆上,骑马卡的直径、孔距等与弹性杆的尺寸相配合。

曲轴、夹持杆组、转动轴和机架构成了曲柄摇杆机构。为实现左右并联、对称的夹持杆组上下错位布置的2组曲柄摇杆机构同相位、同向和同步运动,右侧夹持杆组不能直接安装在曲柄摇杆机构的连杆上,需在曲柄摇杆机构的连杆上设置一组连接杆将夹持杆组与左侧夹持杆组反向且平行安装。在弹性夹持振动机构右单体曲柄摇杆机构的连杆上安装2个平行的夹持间距调节杆用于连接夹持杆组,使其与左单体同向运动。

1.曲轴 2.夹持杆组 3.转动轴 4.转动连杆 5.连接板 6.夹持间距调节杆

1.Crankshaft 2.Clamping rod group 3.Axis of rotation 4.Rotating connecting rod 5.Connecting plate 6.Clamping spacing adjusting rod

图2 弹性夹持振动机构

Fig.2 Elastic clamping vibration mechanism

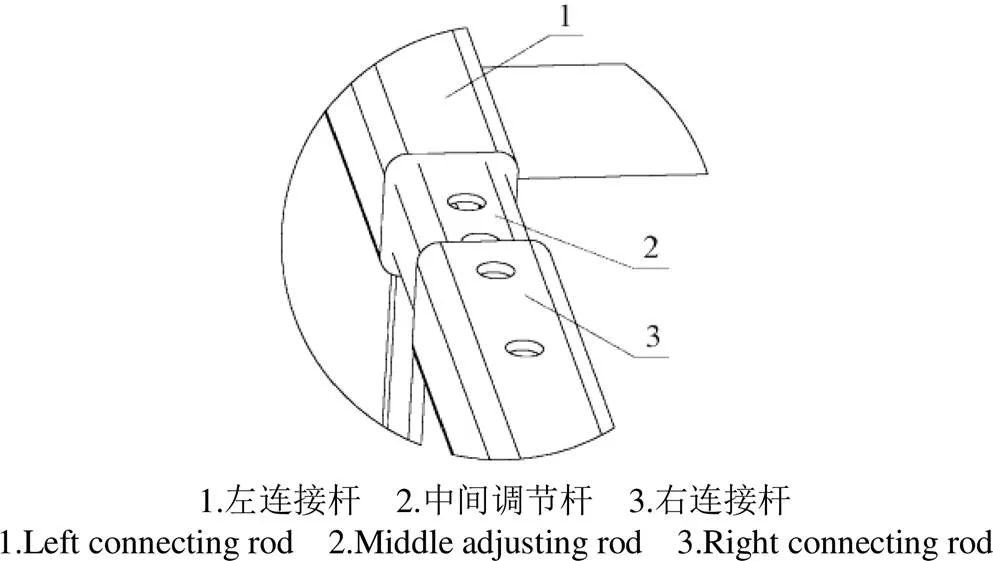

夹持间距调节杆通过调节安装孔的位置调整左右2组夹持振动杆组的间距,具体结构如图3所示。左连接杆和中间调节杆焊合固接,中间调节杆和右连接杆上按一定间距对应分布孔,中间调节杆(尺寸为25×25,mm)在右连接杆(尺寸为30×30,mm)中通过伸缩调整间距。

图3 夹持间距调节杆

2.2 夹持振动机构运动分析

夹持振动机构利用偏心曲轴的旋转运动带动夹持振动杆做非圆周运动,为曲柄摇杆机构,如图 4所示。

该机构的封闭矢量方程以复数形式表示为[26]

按欧拉公式展开得

实部和虚部分别相等,即

注:AB为曲柄;CD为弹性振动杆;BCD为连杆;DE为摇杆;AE为机架;AB1C1D1E为曲柄摇杆机构的极限位置;、、和分别为曲柄、连杆、摇杆及机架的长度,mm;为曲柄转动的角速度,rad·s-1;为曲柄的转角,rad;为连杆的方位角,rad;为摇杆摆角,rad。

由此求得摇杆摆角为

同理可求得

将公式(1)对时间求导数,按欧拉公式展开,求得连杆的角速度为

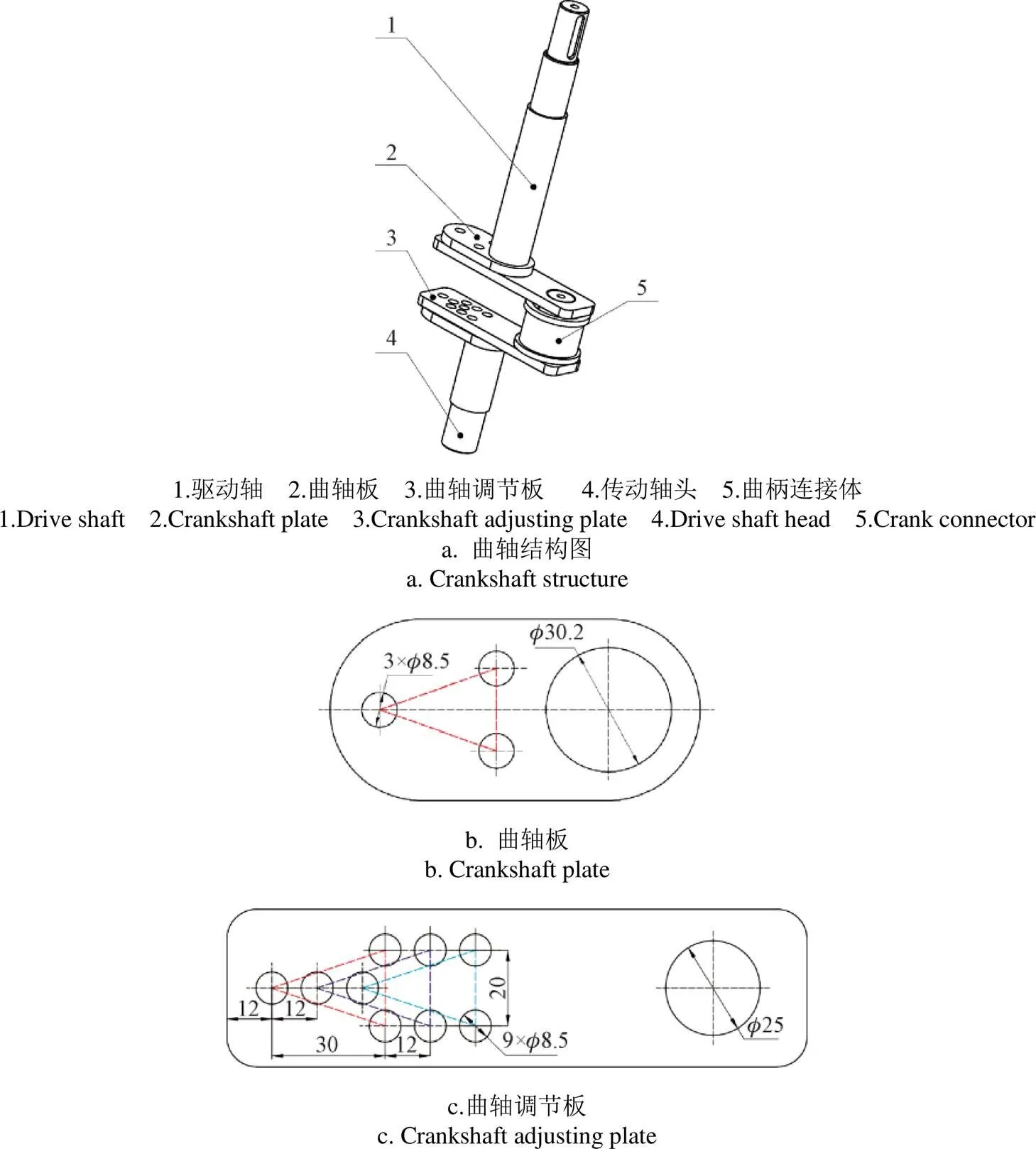

2.3 曲轴

曲轴主要由驱动轴、曲轴板、曲轴调节板、传动轴头和曲柄连接体组成,如图5a所示,驱动轴、传动轴和曲轴板均采用焊合固接,曲轴板和调节板的厚度均为8 mm,二者采用3组螺栓进行连接,螺栓安装间距分别为30和20 mm,曲柄连接体将上下曲轴调节板连接。曲轴板和调节板配合如图5b和5c所示,通过调整曲轴板和曲轴调节板上孔的对应安装位置,曲柄长度可调,曲柄长度调整间距为12 mm。

图5 曲轴及其调整板

曲柄连接体是将曲轴的曲柄和连杆进行连接,主要是由心轴、轴承座、圆锥滚子轴承、卡簧和套筒组成,心轴的上下端与曲柄调节板通过螺纹连接。

2.4 弹性振动杆

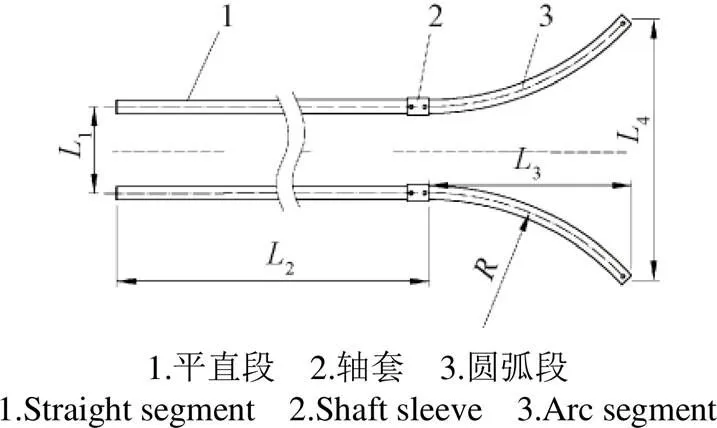

弹性振动杆分为平直段和圆弧段,2段间用轴套连接,如图6所示。平直段采用PA6材质尼龙棒,具有韧性好、耐磨力强和弯曲强度高等特点,根据前期研究[9],确定振动杆的直径为25 mm,平直段长度为900 mm。圆弧段将分散及外伸的葡萄藤蔓和枝条进行收拢聚集进入平直段工作区,在收拢聚集时,为避免工作部件对葡萄串及植株造成损伤,要求圆弧段材质具有较好的柔性,因此,圆弧段采用PU聚氨酯棒,具有较高的机械强度、柔性和回弹性,能够满足工作要求。

注:为夹持间距,mm;为弹性振动杆平直段长度,mm;为圆弧段有效长度,mm;为收拢区入口最大宽度,mm;R为圆弧段半径,mm。

在进行非圆周变向振动过程中,弹性振动杆存在一定程度的弯曲变形,最大变形量由公式(8)计算[28]。

由此可得弹性振动杆的振动变形量为

3 收获性能试验

3.1 试验材料与设备

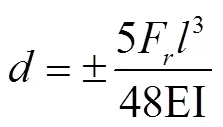

为验证理论分析的正确性,获取最优结构和工作参数,2019年8月29日,在新疆农业大学农业工程装备创新设计实验室进行试验,采样地点为新疆兵团十二师三坪农场三坪二连,北纬43°57′ 6″ ,东经87°19′ 35″ ,品种为“赤霞珠”,树龄6 a,在采样时,选取不同位置枝蔓、不同直径的挂果枝条进行剪枝,采样枝条直径为6~16 mm,枝条挂果串数1~4串,枝条长度约1 m左右。试验如图7所示。

1.弹性夹持振动机构 2.酿酒葡萄枝条 3.曲轴 4.电机 5.夹持间距调节杆 6.变频器

试验设备有:i-SPEEDFS高速摄像机(包含摄像机主机、触发开关,控制显示器等,2 000 帧/s时的分辨率为1 280×1 024(像素),配套图像分析软件i-SPEED Suite,日本Olympus公司);Altivar38HD12N4变频器(功率3 kW,施耐德公司);TCS电子台秤(精度20 g,量程1~100 kg,上海地久商贸有限公司);计算机。

3.2 试验指标与方法

根据《GB/T 25393—2010 葡萄栽培和葡萄酒酿制设备葡萄收获机试验方法》和《GB/T5667—2008 农业机械生产试验方法》规定的试验方法[30-31],考察所设计的曲轴式振动脱粒收获装置的作业性能,选取脱粒率和破损率为试验指标。

3.3 试验方案

根据对曲轴振动机构的运动学及振动弹性杆的分析,确定影响酿酒葡萄脱粒效果的主要因素为曲柄转速、曲轴偏心距(曲柄长度)和夹持间距,因此,选取曲柄转速、偏心距和夹持间距为试验因素。根据前期参与的研究[9],整机田间试验获得的较优作业速度为2 km/h,以模拟2 km/h进行脱粒试验,换算为0.56 m/s,夹持振动杆平直段长度为900 mm,收拢区有效长度为400 mm,因此,有效夹持振动部分对葡萄植株的振动时间约2 s,电机启动加速度过大,会造成瞬间载荷增大,影响试验效果,设定振动时间为9 s,其中电机转速由0加速至试验转速时长为7 s[32],稳定试验转速2 s。采用Box-Benhnken中心组合设计方法[33-34],以三因素和三水平二次回归正交为试验方案,每组试验进行3次,取3次测试结果的均值作为该组的试验结果,对指标的因素进行显著性分析,获取机构各参数最优组合。根据预试验结果设置试验因素水平,如表2所示。

表2 试验因素水平

4 结果与分析

4.1 振动脱粒试验结果分析

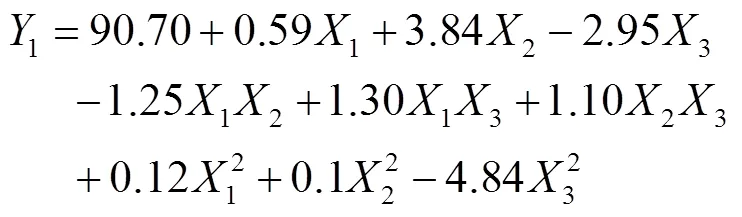

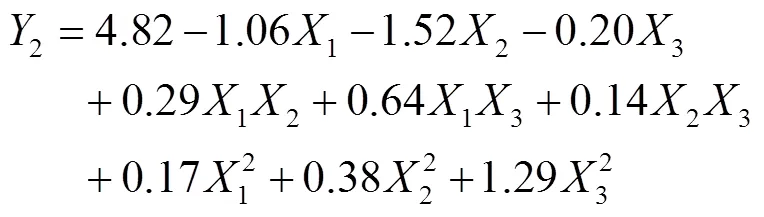

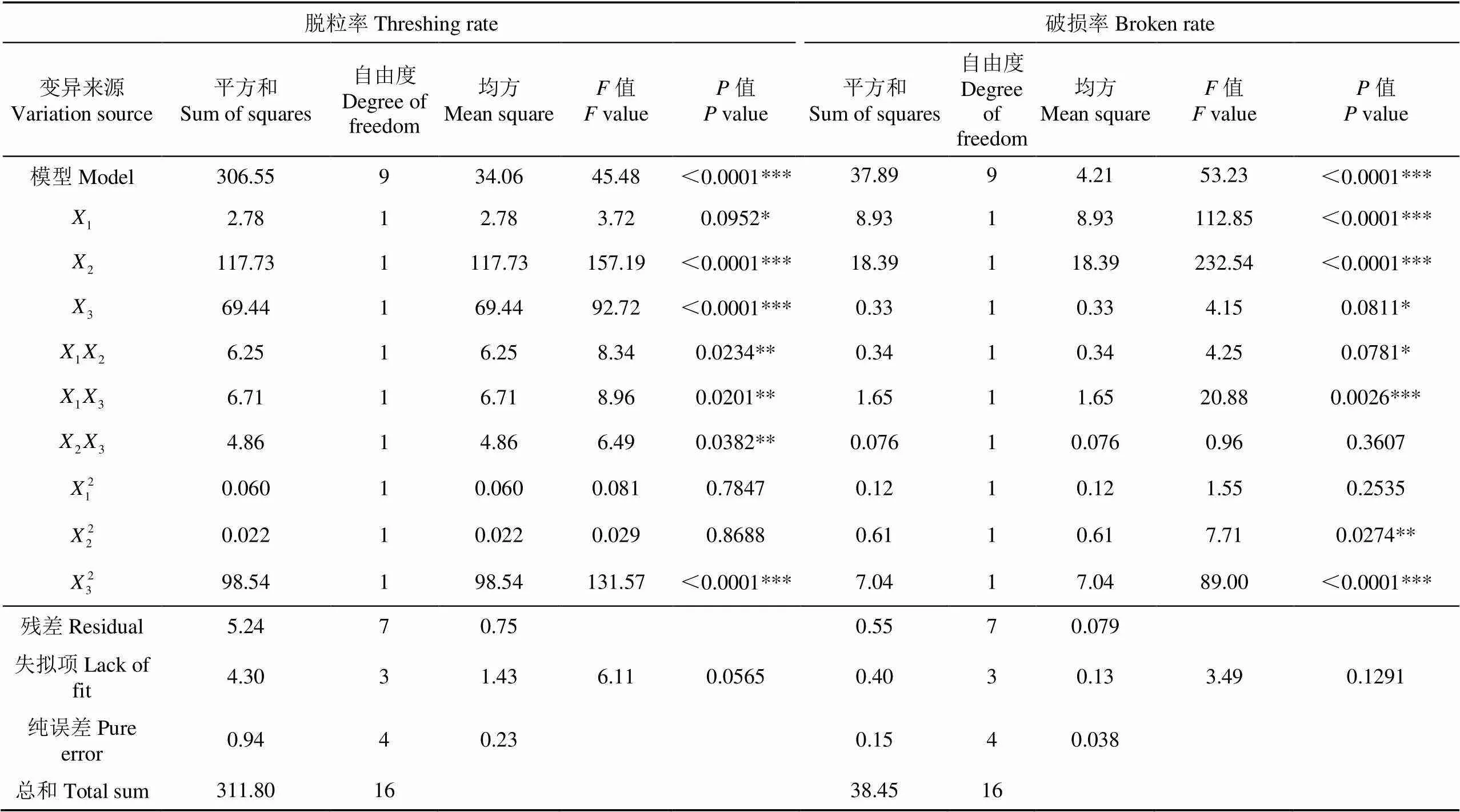

根据表3中的试验数据,利用Design Expert 8.0.6软件对试验结果进行二次回归分析[35],建立葡萄脱粒率和破损率对夹持间距、转速和偏心距的二次响应面回归模型,并对其进行方差分析,结果如(12)~(13)和表4所示。

表3 试验结果

表4 脱粒率与破损率方差分析

注:“***”表示极显著(≤0.01);“**”表示显著(0.01<≤0.05);“*”表示较显著(0.05<≤0.1)。下同。

Note: “***” means highly significant (≤0.01), “**” means very significant(0.01<≤0.05), “*” means significant (0.05<≤0.1). The same below.

图8a为脱粒率对转速和偏心距的响应曲面图,可看出当曲轴的偏心距固定时,脱粒率随着转速的增加而增大,当曲轴转速固定时,脱粒率随着偏心距的增大先增大后减小。图8b为破损率对偏心距和夹持间距的响应曲面图,可看出当曲轴的偏心距固定时,破损率随着夹持间距的增大而增大;当夹持间距固定时,破损率随着偏心距的增大先减小后增大。

图8 各因素对酿酒葡萄脱粒率和破损率的交互作用

4.2 参数优化与试验验证

利用Design-Expert软件中的Optimization(最优化)模块,对脱粒率和破损率回归模型进行优化求解,以脱粒率最大和破损率最小为优化目标,约束函数如式(14)。

求得的优化组合为:夹持间距192.93 mm、曲轴转速720 r/min、曲轴偏心距38.79 mm,此时脱粒率与破损率的预测值分别为94.15%和3.12%。

为验证优化结果的准确性,将装置优化参数组合的夹持间距圆整为193 mm,曲轴转速为720 r/min,曲轴偏心距圆整为38.8 mm,进行3次重复验证试验,试验材料和方法与上述相同,取3次试验的结果均值为验证值。试验结果表明,圆整优化参数下作业的葡萄脱粒率为93.06%,破损率为4.57%,与模型预测结果基本一致。

5 结 论

1)设计了一种曲轴式振动脱粒收获装置,主要由曲轴、弹性夹持振动机构、同步带传动系统、机架等组成,利用并联的弹性夹持振动机构左、右单体实现同相位、同向和同步运动。

2)对酿酒葡萄脱粒率显著性影响顺序依次为曲轴转速、曲轴偏心距离和夹持间距;各因素对破损率影响显著顺序依次为曲轴转速、夹持间距和曲轴偏心距离。

3)通过优化分析与试验验证,最佳参数组合为:夹持间距为193 mm、曲轴转速为720 r/min、曲轴偏心距为38.8 mm,试验结果为酿酒葡萄脱粒率为93.06%,破损率为4.57%,与模型优化预测结果基本一致,结构设计合理。

[1] 刘崇怀. 中国葡萄属(L. )植物分类与地理分布研究[D]. 郑州:河南农业大学,2012. Liu Chonghuai. Studies on Taxonomy and Geographical Distribution of Chinese Wild Grape Species[D]. Zhengzhou: Henan Agricultural University, 2012. (in Chinese with English abstract)

[2] 李超. 基于柔性梳脱的酿酒葡萄脱粒机理与装置的研究[D]. 北京:中国农业大学,2017. Li Chao. Study of Wine Grape Threshing Mechanism and Device by Flexible Combing Triping Mechanism[D]. Beijing: China Agricultural University, 2017. (in Chinese with English abstract)

[3] 王丽红,袁盼盼,李成松,等. 酿酒葡萄振动脱落机构运动分析及研究平台设计[J]. 农机化研究,2015,37(8):53-56. Wang Lihong, Yuan Panpan, Li Chengsong, et al. Analysis of vibratory mechanism movement for wine grape and design of virtual prototype research platform[J]. Journal of Agricultural Mechanization Research, 2015, 37(8): 53-56. (in Chinese with English abstract)

[4] 胡志超,王海鸥,胡良龙,等. 美国葡萄生产机械化[J]. 中国农机化,2005(6):107-109. Hu Zhichao, Wang Haiou, Hu Lianglong, et al. Mechanization of grape production in America[J]. Chinese Agricultural Mechanization, 2005(6): 107-109. (in Chinese with English abstract)

[5] 吴清分. 纽荷兰公司VMLPLUS系列新型葡萄收获机[J]. 当代农机,2017(2):60-61.

[6] 杜小强,倪柯楠,潘珂,等. 可调振幅单向拽振式林果采收机构参数优化[J]. 农业工程学报,2014,30(16):25-32. Du Xiaoqiang, Ni Ke’nan, Pan Ke, et al. Parameter optimization of stroke-adjustable and monodirectional pulling fruit harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(16): 25-32. (in Chinese with English abstract)

[7] 蔡菲,王春耀,王学农,等. 基于高速摄像技术的振动落果惯性力研究[J]. 西北农林科技大学学报:自然科学版,2013,41(4):208-212. Cai Fei, Wang Chunyao, Wang Xuenong, et al. Inertia force of fruits abscised by vibration based on high-speed video camera technology[J]. Journal of Northwest A & F University: Natural Science Edition, 2013, 41(4): 208-212. (in Chinese with English abstract)

[8] Yuan Panpan, Zhu Xingliang, Wang Lihong, et al. Design and test of separation harvesting device for wine grape[J], International Agricultural Engineering Journal, 2018, 27(3): 116-122.

[9] 杨兰涛,王丽红,坎杂,等. 4PZ-1型自走式酿酒葡萄收获机的研制与试验[J]. 农业工程学报,2017,33(1):38-44. Yang Lantao, Wang Lihong, Kan Za, et al. Development and test of 4PZ-1 self-propelled wine grape harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 38-44. (in Chinese with English abstract)

[10] 散鋆龙,杨会民,王学农,等. 振动方式和频率对杏树振动采收响应的影响[J]. 农业工程学报,2018,34(8):10-17. San Yunlong, Yang Huimin, Wang Xuenong, et al. Effects of vibration mode and frequency on vibration harvesting of apricot trees[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(8): 10-17. (in Chinese with English abstract)

[11] 杜小强,李松涛,贺磊盈,等. 三维激振果品采收机构优化设计与试验[J]. 农业工程学报,2017,33(16):48-55. Du Xiaoqiang, Li Songtao, He Leiying, et al. Optimal design and experiment on vibratory fruit harvesting mechanism with three-dimensional excitation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 48-55. (in Chinese with English abstract)

[12] Du Xiaoqiang, Chen Du, Zhang Qin, et al. Dynamic responses of sweet cherry trees under vibratory excitations[J]. Biosystems Engineering, 2012, 111(3): 305-314.

[13] Roger P, Gialis J M. Shakers with adjustable stiffness for harvesting machines and harvesting machines using such shakers: United States Patent, 7841160B2[P].2009-07-27.

[14] 杜小强,倪柯楠,武传宇. 基于外旋轮线轨迹的果品振动采收机构研究[J]. 农业机械学报,2016,47(3):59-66. Du Xiaoqiang, Ni Ke’nan, Wu Chuanyu. Vibratory harvesting mechanism for tree fruit based on epitrochoid[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(3): 59-66. (in Chinese with English abstract)

[15] 袁盼盼,张学军,坎杂,等. 末端驱动式酿酒葡萄分离机构的设计及分析[J]. 农机化研究,2016,38(9):104-107. Yuan Panpan, Zhang Xuejun, Kan Za, et al. Design and analysis of end driven separation mechanism for wine grape[J]. Journal of Agricultural Mechanization Research, 2016, 38(9): 104-107. (in Chinese with English abstract)

[16] 鲍玉冬,杨闯,赵彦玲,等. 基于碰撞变形能的机械采收蓝莓果实碰撞损伤评估[J]. 农业工程学报,2017,33(16):283-292. Bao Yudong, Yang Chuang, Zhao Yanling, et al. Collision injury assessment of mechanical harvesting blueberry fruit based on collision deformation energy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 283-292. (in Chinese with English abstract)

[17] Caprara C, Pezzi F. Measuring the stresses transmitted during mechanical grape harvesting[J]. Biosystems Engineering, 2011, 110(2): 97-105.

[18] Roger Pellenc, Jean-Marc Gialis. Berry harvesting machine, especially grape harvesting machine, equipped with a shaking system and mechatronic shaking control for this system: United States Patent: 2010/0024373 A1[P]. 2010-02-04.

[19] Baisan Ioan. Theoretical studies concerning elastic bars deformation from grapes harvesting machine[J]. Journal of Engineering Studies and Research, 2012, 18(2): 18-24

[20] 李成松,高振江,坎杂,等. 双支撑酿酒葡萄果实振动分离装置作业机理[J]. 农业工程学报,2015,31(4):26-32. Li Chengsong, Gao Zhenjiang, Kan Za, et al. Operation mechanism of double support vibration separation device for wine grape berry[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(4): 26-32. (in Chinese with English abstract)

[21] 李成松. 酿酒葡萄振动分离机理及装置的研究[D]. 北京:中国农业大学,2015. Li Chengsong. Study on Vibration Separation Mechanism and Equipment of Wine Grape[D]. Beijing: China Agricultural University, 2015. (in Chinese with English abstract)

[22] 王业成,陈海涛,林青. 黑加仑采收装置参数的优化[J]. 农业工程学报,2009,25(3):79-83. Wang Yecheng, Chen Haitao, Lin Qing. Optimization of parameters of blackcurrant harvesting mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(3): 79-83. (in Chinese with English abstract)

[23] 史亮,范久臣,乔晗. 基于ADAMS 的蓝莓采摘机构设计与仿真[J]. 机械研究与应用,2015,28(4):158-160. Shi Liang, Fan Jiuchen, Qiao Han. Design and simulation of blueberry picking mechanism based on the ADAMS[J]. Mechanical Research & Application, 2015, 28(4): 158-160. (in Chinese with English abstract)

[24] 王海滨,郭艳玲,鲍玉冬,等. 振动式蓝莓采摘的机理分析与仿真[J]. 农业工程学报,2013,29(12):40-46. Wang Haibin, Guo Yanling, Bao Yudong, et al. Mechanism analysis and simulation of blueberry harvest by vibration mode[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(12): 40-46. (in Chinese with English abstract)

[25] 郭艳玲,鲍玉冬,何培庄,等. 手推式矮丛蓝莓采摘机设计与试验[J]. 农业工程学报,2012,28(7):40-45. Guo Yanling, Bao Yudong, He Peizhuang, et al. Design and experiment analysis of hand-push lowbush blueberry picking machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(7): 40-45. (in Chinese with English abstract)

[26] 孙恒. 机械原理[M]. 北京:高等教育出版社,2005.

[27] 李成松,高振江,坎杂,等. 酿酒葡萄果-蒂振动分离试验[J]. 农业工程学报,2015,31(9):39-44. Li Chengsong, Gao Zhenjiang, Kan Za, et al. Experiment of fruit-pedicle vibration separation of wine grape[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(9): 39-44. (in Chinese with English abstract)

[28] 蒲应俊. 面向柑橘机械化收获的树冠振动系统设计与性能试验[D]. 杨凌:西北农林科技大学,2018. Pu Yingjun. Design and Performance Experiments of a Canopy Shaking System for Mechanical Harvesting Citrus[D]. Yangling: Northwest A & F university, 2018. (in Chinese with English abstract)

[29] 李建波. PA6/TPU/MMT复合材料叶片挤出机制备及其结构性能研究[D].华南理工大学,2014. Li Jianbo. Study on Structure and Performance of PA6/TPU/MMT Composites Processed by Vane Extruder[D]. Guangzhou: South China University of Technology, 2014. (in Chinese with English abstract)

[30] 葡萄栽培和葡萄酒酿制设备葡萄收获机试验方法:GBT25393-2010[S]. 北京:中国标准出版社,2011.

[31] 农业机械试验条件测定方法的一般规定:GB/T5262-2008[S]. 北京:中国标准出版社,2009.

[32] 骆春晓. 蔬菜钵苗取苗机构的优化设计及试验研究[D]. 杭州:浙江理工大学,2013. Luo Chunxiao. The Optimization Design and Test Study of Pick-up Mechanism for Vegetable Potted Seeding[D]. Hangzhou: Zhejiang Sci-Tech university, 2013. (in Chinese with English abstract)

[33] 邱轶兵. 试验设计与数据处理[M]. 北京:中国科学技术大学出版社,2008.

[34] 葛宜元. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨:哈尔滨工业大学出版社,2014.

[35] 张学军,白圣贺,靳伟,等. 气力式矮密栽培红枣捡拾机研制[J]. 农业工程学报,2019,35(12):1-9. Zhang Xuejun, Bai Shenghe, Jin Wei, et al. Development of pneumatic collecting machine of red jujube in dwarfing and closer cultivation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(12): 1-9. (in Chinese with English abstract)

Development of crankshaft vibration threshing and harvesting equipment for wine grape

Yuan Panpan, Zhu Xingliang, You Jia, Han Changjie, Zhang Xuejun※, Guo Hui

(,,830052,)

At present, the wine grape harvesting method is still the traditional manual picking with scissor, because the grape fruit is randomly distributed among the branches, the manual harvesting is difficult and the operation efficiency is low. Therefore, mechanized harvesting of wine grape has become an urgent need. Vibration harvesting is one of the main methods of fruit harvesting at home and abroad. The mechanical harvesting of blueberries, blackcurrant, grape and other berries mainly vibrates the fruit tree by means of incentive source, so that the fruit and the connected branches produced a relative movement, the joints produced deformation and fracture, and the fruits falling. However, the domestic wine grape harvesting machines are immature, which has great damage to plant, low threshing efficiency, high fruit broken rate, low reliability and so on. In order to meet the requirements of wine grape mechanization harvest, a crankshaft vibration threshing device was put forward, the device was mainly composed of crankshaft, clamping vibration mechanism, elastic vibration rod, synchronous belt driving system, frame and so on, the driving crankshaft and the driving crankshaft were connected by a synchronous belt, and the elastic vibration monomers composed of parallel crank and rocker mechanism on both sides were in the same phase and moved synchronously in the same direction. The wine grape plant was held by the clamping vibration mechanism on both sides, and was driven to perform a regular variable motion, so that the wine grape grains fall off the grape stem. The angular displacement and angular velocity of the working parts were obtained based on the kinematics analysis of the crank and rocker mechanism. The main factors affecting the vibration operation effect were the length and angular velocity of the crank. The elastic vibrating rod were divided into straight segment and arc segment. The material of PA6 nylon and PU polyurethane with high mechanical strength, flexibility and resilience were selected as the material of vibrating rods. Based on the elastic deformation theory of the elastic vibrating rod, the maximum deformation of the elastic vibration rod was calculated, the influence of the elastic deformation of the elastic vibration rod on the amplitude was analyzed, and the amplitude of the elastic vibration rod in the vibration state was obtained. Furthermore, the clamping spacing, rotating speed and eccentricity were selected as the influencing factors, and wine grape threshing rate and broken rate were selected as the response value for three factors and three levels two Sub-regression orthogonal test design, and the regression equations to describe the relationships between the factors and assessment indexes were established by using the regression analysis and response surface analysis with the software Design-Expert 8.0.6. The optimum combination of the selected parameters was obtained and verified, and the experimental verification of the mathematical model was also conducted. The test results showed that the factors had great effects on the performance of wine grape vibration threshing device. The significant effects of rotating speed, eccentricity and clamping spacing on threshing rate were in a decreasing order. The significant effects of rotating speed, clamping spacing and eccentricity on broken rate were in a decreasing order. Verification test results indicated thtat when the clamping spacing was 193 mm, the rotating speed was 720 r/min and the eccentricity was 38.8 mm, wine grape threshing rate of the device was 93.06% and broken rate was 1.54%, which was basically consistent with the prediction results of model optimization, and the structural design was reasonable. This study provides a reference for the mechanization harvesting of wine grape and vibration harvesting of other fruits.

agricultural machinery; harvesting; vibration; wine grape; crankshaft

袁盼盼,朱兴亮,尤佳,等.酿酒葡萄曲轴式振动脱粒收获装置研制[J]. 农业工程学报,2020,36(9):67-74.doi:10.11975/j.issn.1002-6819.2020.09.008 http://www.tcsae.org

Yuan Panpan, Zhu Xingliang, You Jia, et al. Development of crankshaft vibration threshing and harvesting equipment for wine grape[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 67-74. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.09.008 http://www.tcsae.org

2019-12-05

2020-03-23

国家自然科学基金(51605411);国家自然科学基金(51805461);新疆高校科研计划项目(XJEDU2017S018)

袁盼盼,讲师,主要从事农业机械设计与智能农业装备的研究。Email:ypp_xnd@163.com

张学军,博士,教授,博士生导师,主要从事农业机械设计与智能农业装备的研究。Email:tuec@163.com

10.11975/j.issn.1002-6819.2020.09.008

S225.99

A

1002-6819(2020)-09-0067-08