Characteristics of fast-growing wood impregnated with nanoparticles

2020-05-22IstieRahayuWayanDarmawanLukmanulHakimZainiEstiPrihatini

Istie Rahayu · Wayan Darmawan · Lukmanul Hakim Zaini · Esti Prihatini

Abstract Falcataria moluccana or sengon is one of the fast-growing wood species widely grown in Indonesia.However, its wood is low quality with low density, and poor strength, durability, and dimensional stability. This study determined the effects of impregnation with monoethylene glycol (MEG) and nano-SiO2 on the characteristics of sengon wood, including its dimensional stability and density. Impregnation with MEG and nano-SiO2 had a significant effects on dimensional stability in terms of the weight percent gain, anti-swelling efficiency, water uptake,bulking effect, and density. The impregnated wood was examined by scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy and X-ray diffraction. The results show that MEG and nano-SiO2 were distributed homogeneously into cell walls of wood treated with 0.5% MEGSiO2.

Keywords Falcataria moluccana · Fast-growing species ·Impregnation: monoethylene glycol · Nanoparticles ·Dimensional stability

Introduction

The amount of wood material used in the Indonesian forest product industry in 2013 has reached over 64 million m3.However, in the same year, logs harvested from natural forests were less than 24 million m3(Ministry of Environment and Forestry 2014). Therefore, there is a gap between supply and demand; this forces wood industries to find other sources of raw materials to meet the growing demand. One source is community forests owned and managed by the communities themselves (Darusman and Hardjanto 2006). Community forests are predominantly planted with fast-growing species that usually have short cutting cycles (less than 10 years). Sengon (Falcataria moluccana (Miq.) Barneby and J.W. Grimes) is a fastgrowing species, widely planted in Indonesia (Krisnawati et al. 2011), but also in Brunei, Cambodia, Cameroon, Fiji,French Polynesia, Japan, Laos, Malaysia, Myanmar, The Philippines, Thailand, the United States of America, and Vietnam (Orwa et al. 2009). The species originated from Indonesia, Papua New Guinea, the Solomon Islands and Australia (Soerianegara and Lemmens 1993). In 2015, the production of sengon logs in Indonesia reached 2.6 million m3(6% of the total national log production of 43.9 million m3) (BPS 2016). However, the rapid growth of sengon results in a low density, poor strength material, and possibly a significant proportion of juvenile wood with numerous knots, which has inferior physical and mechanical properties compared to mature wood (Zhang et al.2004). According to Rahayu et al. (2014), five-year-old sengon is 100% juvenile wood, with a specific gravity between 0.24 and 0.49, with an average of 0.33, and wood density between 0.3 and 0.5 g cm-3(Martawijaya et al.2005). Sengon wood in Indonesia is generally used for packaging.

Wood modification is a promising approach for enhancing the properties of fast-growing species. One technique is impregnation to alter the properties of the wood by intervening at the cell wall level (Hill 2011).Several researchers have studied the impregnation of fastgrowing wood species with various chemicals, including styrene (Darma et al. 2002; Jasni et al. 2004) and methyl methacrylate (MMA) (Wardani et al. 2012; Hadi et al.2013, 2015). In this research, monoethylene glycol (MEG)was used for impregnation because it is water soluble,colorless, and odorless; it has low viscosity, a high boiling point, and molecular weight of 62.07 g mol-1liquid(Eisenreich et al. 1981; ATSDR 1997). However, since it is water soluble, it is also easily washed out from impregnated wood in contact with water. Further, glycol attracts moisture (Rowell and Writer 1987), resulting in a MEGtreated surface becoming moist when touched, and certain metals in contact becoming corroded. However, nanoparticles have yet to be incorporated into these impregnation suspensions, and impregnation using MEG is not widely utilized. There have been studies of wood impregnation using polyethylene glycol (PEG). Meints et al. (2018)found reduced swelling in oak wood after being impregnated with PEG. Tangential and radial shrinkage was reduced in Tasmanian oak (Eucalyptus spp.) after PEG treatment (Ralph 2006). Wood soaked in PEG for several days to several months is widely used, depending on the wood dimensions (Stamm 1959; Merz and Cooper 1968).According to Mitchell (1972), PEG- treated wood tends to have moist surfaces so only particular finishing material should be covered with PEG-treated wood.

Nanoparticle-based treatments can enhance the performance of wood products more than conventional wood treatments owing to natural penetration and distribution,good dispersion stability, and low viscosity of nanoparticles (Fufa and Hovde 2010). SiO2(silicon dioxide) has been used for wood modification, either in its pure form or in combination with various additives. Shi et al. (2007)demonstrated that urea formaldehyde resin, along with nano-SiO2, can improve the properties of poplar wood such as reducing water absorption, enhancing flame resistance,and increasing hardness. Dong et al. (2014) showed that the properties of poplar wood were improved by impregnation with furfuryl alcohol (FA) and nano-SiO2. The wood had improved mechanical properties (hardness, compression modulus, modulus of elasticity, water uptake), anti-swelling efficiency, hydrophobicity, and dimensional stability(Dong et al. 2015). In this study, we used MEG and nano-SiO2to improve characteristics of sengon wood (fast growing species). Nano-SiO2was added to MEG to improve monoethylene glycol leachability and MEG-treated surface quality, especially for finishing. Hopefully treated sengon wood may become an alternative raw material source for interior purposes such as housing and furniture. The aim of this study is to determine the effects of impregnation with MEG and nano-SiO2on the characteristics of sengon wood, including its dimensional stability and density.

Materials and methods

Sample collection and preparation

Three five-year-old sengon trees from a community forest in Bogor, West Java, Indonesia were harvested. Average breast height diameters were 29 cm. Average height of the branch-free stem was 8 m. Logs were cut into 100-cm lengths from the bottom of the stem to produce 20 mm × 20 mm × 20 mm samples (BS 373:1957).Weight percent gain (WPG), anti-swelling efficiency(ASE), water uptake (WU), bulking effect (BE), and densities were measured before and after treatment in five replicates.

Preparation of impregnation solutions

MEG and nano-SiO2(diameter 15 ± 5 nm; Anhui Elite Industrial Co, Ltd, China) were used to make the following impregnation solutions: distilled water (for water-treated samples), 50% MEG; 0.5% nano-SiO2particles in 50%MEG (referred to as 0.5% MEGSiO2); and 1.0% nano-SiO2particles in 50% MEG (referred to as 1% MEGSiO2).Distilled water (for water-treated samples) was used as a control. The compositions of these solutions are shown in Table 1. A sonicator (Cole Palmer) was used to mix MEG and nano-SiO2at 40% amplitude for 60 min.

Table 1 Compositions of MEG and nano-SiO2 solutions used for impregnation

Impregnation method

The impregnation method is illustrated in Supplementary Material Fig. S1 and was adopted from that used by Dong et al. (2014) to impregnate poplar wood with a mixture of furfuryl alcohol FA and nano-SiO2particles.

Measurements of weight percent gain and dimensional stability

After impregnation, the WPG, BE, WU (Hill 2006), ASE(Rowell and Ellis 1978), and density (Bowyer et al. 2007)were measured as noted below.

The WPG (weight percent gain) was calculated as:

where W0and W1are the weights (g) of the oven-dried samples before and after treatment, respectively.

The dimensional stability of the treated wood was measured in terms of the ASE using the repeated watersoaking method (Rowell and Ellis 1978). This water-saturation oven drying was repeated four times.

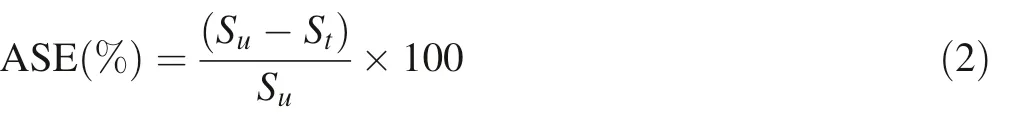

The ASE (anti-swelling efficiency) was measured as follows:

where Suand Stare the volumetric swelling measurements of the water-treated and treated samples, respectively.

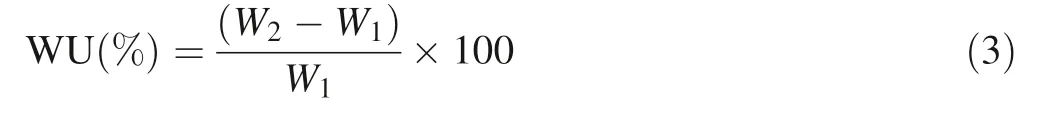

The WU (water uptake) was calculated as:

where W2is the weight of the sample after immersion in deionized water for 24 h.

The BE (bulking effect) was calculated as follows:

where V0and V1are the dried sample volumes before and after treatment, respectively.

The density, ρ, was evaluated after treatment by considering WPG and BE values, and water-treated density as a base line.

Characterization of impregnated sengon wood

Impregnated sengon wood was examined by scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) and X-ray diffraction(XRD).

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX)

The penetration and distribution of MEG and nano-SiO2particles into the cell walls were analyzed using SEM(Zeiss Evo 50 Type, Germany). Tangential and radial sections of both treated and water-treated samples(0.5 cm × 0.5 cm × 0.5 cm) were mounted on conductive adhesives, sputter-coated with gold, and observed by SEM at an accelerating voltage of 15 kV, a chamber pressure between 10 and 400 Pa, under a low vacuum mode, and a working distance of 8 mm. The impregnated samples were also analyzed by SEM coupled with EDX (Zeiss Evo 50 Type, Germany) using a spectra mode to analyze their chemical compositions. In addition, pit diameters were measured by analyzing images with ImageJ software.

X-ray diffraction analysis

Impregnated samples were milled with a Willey mill into a 40-60 mesh powder, and the crystallinity of each sample was evaluated by XRD with an XRD-7000 diffractometer(Shimadzu Co., Ltd., Japan). The measurements were conducted with Cu Kα radiation with a graphite monochromator at a constant voltage of 40 kV and an electric current of 30 mA over a 2θ scanning range of 5°-40° at a scanning speed of 2° min-1.

Data analysis

WPG, ASE, WU, BE, and density data were collected and an analysis of variance (ANOVA) used to characterize the effects of the impregnation treatments (water-treated,MEG, 0.5% MEGSiO2, 1% MEGSiO2). The mean differences between the treatments were determined using Duncan’s multiple range test.

Results and discussion

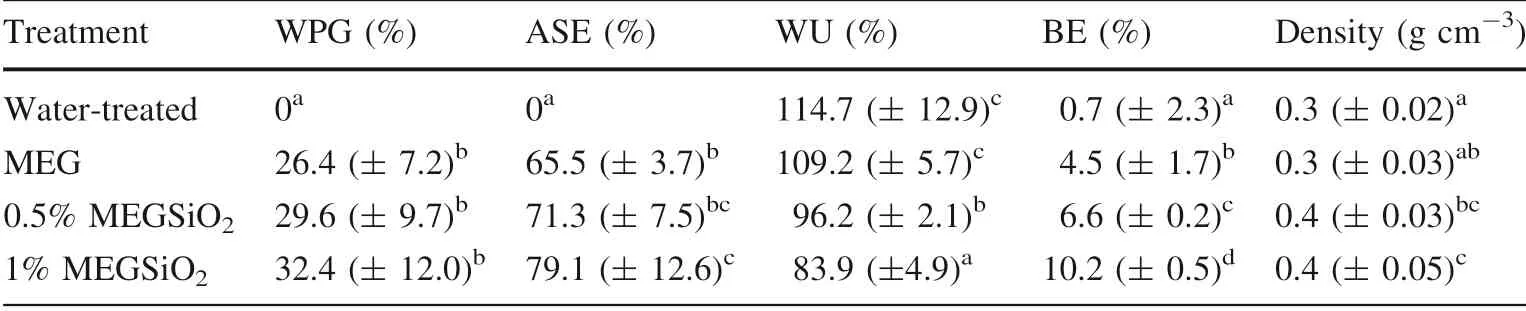

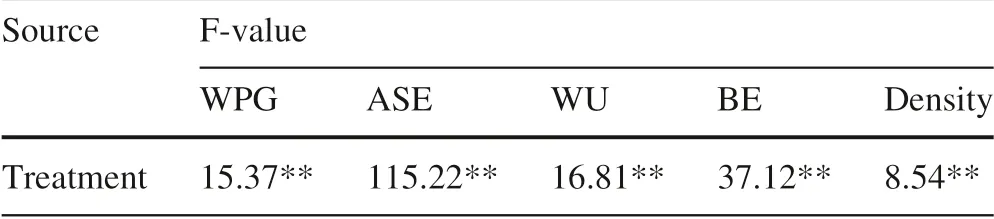

Weight percent gain (WPG)

The ratio between the weight gain of the sample and the weight before the treatment is expressed as the WPG(Table 2). The WPG values of the treated samples were greater than those of the water-treated samples, and increased with an increase in the nano-SiO2concentration in the impregnation solution. The ANOVA results indicate that impregnation had a statistically significant effect on the WPG (p <0.01) (Table 3). The results of Duncan’s multiple comparison test (Table 2) confirm that the WPG values of the treated samples were significantly different from those of the water-treated sample. However, theseresults also indicate that the WPG values of the MEG,0.5% MEGSiO2, and 1% MEGSiO2samples were not significantly different. The sample impregnated with 1%MEGSiO2had the highest WPG (32.4%) because the addition of nano-SiO2enhanced the polymerization of MEG and nano-SiO2into the cell walls. MEG and MEGSiO2also bonded with the cell walls and filled the cell lumens.

Table 2 WPG and dimensional stability measurements

Table 3 F-values of variance analysis

This observation is consistent with the findings reported by Guigo et al. (2009) who showed that the addition of nano-SiO2led to an increase in WPG due to the interpenetrating networks formed between furfuryl alcohol and SiO2in FA/SiO2hybrid materials. This may have affected the polymerization of FA within the wood. Further, Hill(2006) showed that the presence of a non-leachable material in the cell walls would cause the walls to swell as the polymer penetrated into and filled the microvoids of the wall, enhancing the dimensional stability of the wood.

Anti-swelling efficiency (ASE)

The dimensional stability was characterized in terms of the resistance to dimensional changes under variations in environment moisture. The WU, ASE and BE were used as parameters of dimensional stability. The ASE values(Table 2) increased from water-treated to treated samples,0 (water-treated), 65.5% (MEG), 71.3% (0.5% MEGSiO2),and 79.1% (1% MEGSiO2). The ANOVA results (Table 3)indicate that the nano-SiO2concentration in the impregnation solution had a significant effect on the ASE(p <0.01). The results of Duncan’s multiple comparison test (Table 2) also confirm that the ASE of water-treated samples is statistically different from that of treated samples; however, the difference between the ASE values of MEG and 0.5% MEGSiO2, and between the ASE values of 0.5% and 1% MEGSiO2are not statistically significant.The enhancement of the anti-swelling efficiency with greater nano-SiO2concentrations was caused by the increasing contact of MEG along with nano-SiO2to the cell walls.

Previous studies have demonstrated improvements in dimensional stability and reductions in hygroscopicity due to an increase in penetration and effective area, and to nano-ZnO distribution uniformity (Freeman and McIntyre 2008; Clausen et al. 2009, 2010). When the cell walls are filled with a polymer, the polymer bonds with cellulose to reduce the diffusion of water. This leads to reduced wood hygroscopicity and increased ASE, which corresponds to a reduced ability to absorb water from the environment(Rowell 1980; Hill et al. 2010).

Water uptake (WU)

The WU is the ratio as a percentage of the sample weight after immersion in water for 24 h and the original weight of the sample. The WU represents the ability of the wood to absorb water; high WU values indicate a strong capacity to absorb water. The WU values in Table 2 decrease from water-treated to treated samples, namely, 114.7% (watertreated), 109.2% (MEG), 96.2% (0.5% MEGSiO2), and 83.9% (1% MEGSiO2). The ANOVA results indicate that the nano-SiO2concentrations in the impregnation solutions had a significant effect on WU (p <0.01) (Table 3). The results of Duncan’s multiple comparison test indicate that WU values of the water-treated samples are significantly different from those of the 0.5% and 1% MEGSiO2treated samples, but not significantly different between the MEG samples (Table 2). However, WU values of samples treated with 0.5% and 1% MEGSiO2are statistically different, and increasing concentrations of nano-SiO2resulted in low WU values. Furthermore, there was a negative correlation between the WPG and WU values; an increase in WPG was accompanied by a decrease in WU. This is because high amounts of MEG and MEGSiO2occupying the spaces within the cell walls reduced the availability of space for water molecules to occupy.

Bulking effect (BE)

The bulking effect is the effect of the bulking agent on the dimensional stability of wood. The BE values increased from water-treated to treated samples (Table 2). These values were 0.7% (water-treated), 4.5% (MEG), 6.6%(0.5% MEGSiO2), and 10.2% (1% MEGSiO2). The ANOVA results shown in Table 3 indicate that the concentration of nano-SiO2in the impregnation solution had a significant effect on BE (p >0.01). The results of Duncan’s multiple comparison test indicate that the BE values of the water-treated samples, and the MEG, 0.5% and 1%MEGSiO2samples are significantly different (Table 2).

The increasing BE values, particularly after 0.5% and 1% MEGSiO2impregnation, reveal that MEG and nano-SiO2behaved as bulking agents. This is consistent with the results reported by Hill (2006) that physical properties are improved by the bonding of the impregnation materials with the cell walls via diffusion reactions, leading to low hygroscopicity in the treated samples. Silicon-based aqueous wood modification agents are capable of entering cell walls and achieve a certain bulking effect (Pries et al.2013).

Increasing ASE values were followed by increasing BE values (Table 2). There was a positive linear correlation between ASE and BE (R2= 0.98) which coincides with Mai et al. (2007) who discovered the same correlation with Pinus sylvestris L. impregnated with amino-silicone emulsion. The increasing concentrations of nano-SiO2produced the highest ASE and BE values due to MEG and nano-SiO2filling microvoids in cell walls to reduce the availability of space for water molecules to bond with cell wall components.

Density

Density the ratio between weight and volume (Tsoumis 1991), was measured. The ANOVA results indicate that impregnation had a significant effect on density (p <0.05)(Table 3). The results of Duncan’s multiple comparison test show that the density of the water-treated samples is statistically different from that of the 0.5% and 1%MEGSiO2samples, and that the density of the 1%MEGSiO2sample significantly differs from that of the 0.5% MEGSiO2sample (Table 2). These results confirm that the MEG and nano-SiO2solutions fill the micropores,resulting in cell wall swelling. This observation is consistent with the results reported by Bowyer et al. (2007) that cell wall thickness has a positive correlation with wood density.

Characterization of impregnated sengon wood morphology of water-treated and treated samples by SEM

Figure 1a shows empty cell walls and pits in the watertreated sample. These spaces were occupied by MEG(Fig. 1b) or MEGSiO2(Fig. 1c, d) in the treated samples.MEG agglomerated and covered the pits in the treated samples (Fig. 1b). Notably, the vessel walls were rough and the pits filled with the polymer as indicated by the wavy structure of the walls (Fig. 1c, d). Thus, the treated wood samples were filled with resin or nano-SiO2and became hydrophobic, as they could no longer adsorb water,and led to improved dimensional stability in the treated wood.

The morphological differences between water-treated and treated samples are distinct. The average diameter of the empty pits in the water-treated sample is 373.37 μm.After being treated with MEG, the average diameter was 309.80 μm and became smaller due to MEG agglomerated(diameter size of MEG agglomeration is 2276.9 μm), and covered the vessel walls once the pits underneath were filled with the polymer (Fig. 1b). With the 0.5% MEGSiO2samples, the pits were completely filled with polymer(Fig. 1c). Figure 1c, d show that the treatments with 0.5%and 1% MEGSiO2caused the polymer to have intimate contact with the pits and cover the vessel walls.

The SEM images in Fig. 1c, d demonstrate vessel wall covered as a result of treatments with 0.5% and 1%MEGSiO2. The morphology of 0.5% MEGSiO2- and 1.0%MEGSiO2-treated samples show checks on the wall surfaces (Fig. 1c, d) due to the brittle characteristics of nano-SiO2(Koksal et al. 2008). There were numerous checks in 0.5% MEGSiO2samples but did not separate so that the vessel walls could still be covered by polymer. The checks of the 1.0% MEGSiO2samples were fewer but separated,and polymer did not cover the vessel walls completely.This is similar to the results of Hadiyawarman et al. (2008)who found that nano-SiO2in certain amounts could improve cristalinity but large quantities could lead to material brittleness.

This observation explains why the WPG, ASE, BE, and density values were higher and the WU values lower in the treated samples than those in the water-treated samples.MEG not only filled the vessels but also the pits in the vessel walls because the nanoscale particles could easily penetrate into the pits (Xue and Zhao 2008).

Fig. 1 Scanning electron micrographs of sengon wood samples at 250× magnification:a water-treated, b MEG treated,c 0.5% MEGSiO2 treated, and d 1% MEGSiO2 treated

From the above results, 0.5% MEGSiO2was considered optimal for the impregnation of sengon wood.

Chemical composition of treated wood by SEM coupled with energy-dispersive X-ray spectroscopy(EDX)

The chemical composition of the samples treated with MEG and MEGSiO2were analyzed by SEM-EDX(Table 4; Fig. 2). No SiO2was detected in the watertreated and MEG samples (point 1; Fig. 1b), but the silicon contents in the 0.5% and 1% MEGSiO2samples were 1.6%(point 2; Fig. 1b) and 6.1% (point 3; Fig. 1b), respectively.Therefore, it was concluded that nano-SiO2could readily fill microvoids or fractures in the cell walls and lumens of the wood in the presence of MEG, which acted as a medium to facilitate nano-SiO2penetration.

Table 4 Chemical composition of water-treated and impregnated wood samples (XRD results)

X-Ray diffraction (XRD) analysis

XRD analysis is widely used to characterize the crystal structure and quality of a material by comparing the measured spectrum with baseline data that comprises 60,000 crystal diffraction spectra (Leng 2002). In general,crystallinity is an important characteristic of polymers and indicates the presence of even bonding between molecules in a chain. In this case, the high degree of crystallinity indicates a strong and rigid bonding between MEGSiO2polymers. Figure 3 shows the XRD spectra of water-treated, MEG, 0.5% MEGSiO2, and 1% MEGSiO2samples;the XRD peaks corresponding to the cellulose crystal planes, I0022θ = 22.6°, occurred at diffraction angles of 22.28° (water-treated), 22.41° (MEG), 22.65° (0.5%MEGSiO2), and 22.23° (1% MEGSiO2) (Cave 1997).Moreover, according to Cave (1997), the occurrence of a peak at a diffraction angle of 18.2° proves the presence of an amorphous wood region. In addition, the XRD peaks at diffraction angles of 20.71° and 20.65° in the 0.5% and 1%MEGSiO2samples, respectively, are attributed to the cellulose crystal planes I100.

The results indicate an increase in the degree of crystallinity from MEG (27.8%) to 0.5% MEGSiO2(28.2%)and to 1% MEGSiO2(29.1%) samples owing to the presence of nano-SiO2(Table 5). These results are consistent with those of Dong et al. (2014) who found that the degree of crystallinity in poplar wood increased after treatment with 42.29% FA and 43.83% FASiO2. However, a slight decrease in the degree of crystallinity between watertreated (30.98%) to MEG-treated (27.75%) samples was due to the amorphous characteristics of MEG (Trung et al.2003). This observation is consistent with Dong et al.(2014) who showed that the degree of crystallinity decreased from water-treated to FA-treated poplar samples,as the FA monomer entered and was polymerized in situ in the amorphous cellulose region which may lead to augmentation of this region.

Fig. 2 EDX spectra of a watertreated, b MEG treated, c 0.5%MEGSiO2 treated, and d 1%MEGSiO2 treated sengon wood

Fig. 3 XRD spectra of water-treated and treated sengon wood

Table 5 Degrees of crystallinity in water-treated and treated samples

Based on the XRD results, the effects of nano-SiO2on the WPG, ASE, WU, BE and density of sengon wood were demonstrated. Silicon peaks were detected on the diffraction planes (in line with ICDC database), which explains the increasing degree of crystallinity as a result of the impregnation with 0.5% and 1% MEGSiO2.

Conclusion

Based on these findings, the impregnation of sengon wood with MEG and nano-SiO2have significant effects on dimensional stability and density. The improvements in the weight percent gain, anti-swelling efficiency, bulking effect, water uptake, and density show that MEGSiO2filled the microvoids in the cell walls of the wood samples. The morphological differences between water-treated and treated samples observed by scanning electron microscopy indicated that MEGSiO2covered the pits in the cell walls.Furthermore, the EDX results confirm that silicon was present in the MEGSiO2-treated samples. In addition, the XRD diffraction patterns show that treatment with MEGSiO2caused an increase in the degree of crystallinity.Together, these results indicate that impregnation with 0.5% MEGSiO2was optimal to improve the dimensional stability of sengon wood.

AcknowledgementsThe authors would like to thank the Directorate of Research and Innovations of Bogor Agricultural University.

杂志排行

Journal of Forestry Research的其它文章

- Past, present and future of industrial plantation forestry and implication on future timber harvesting technology

- Effects of climate changes on distribution of Eremanthus erythropappus and E. incanus (Asteraceae) in Brazil

- Effects of climate and forest age on the ecosystem carbon exchange of afforestation

- Effect of gap size and forest type on mineral nitrogen forms under different soil properties

- Effect of forest thinning on hydrologic nitrate exports from a Nsaturated plantation

- Floristic analysis and dominance pattern of sal (Shorea robusta)forests in Ranchi, Jharkhand, eastern India