基于热力学机理与数据挖掘的磨煤机预警系统

2020-05-21朱朋成钱虹江诚

朱朋成 钱虹 江诚

摘 要:为实现磨煤机状态预警,提高磨煤机运行的稳定性。以热力学为基础,对Hp934型中速磨煤机内部煤质量、水分质量、能量平衡进行分析,确定了表征磨煤机运行状态的特征参数。用相关性分析、正态分布和置信度算法等方法对大量实际生产数据进行挖掘整理,确定了各工况下磨煤机稳定运行的各特征参数边界,制定了预警规则,建立了磨煤机的预警模型。测试结果表明,该模型能判断磨煤机运行的早期异常,证明了该预警模型的有效性和可行性,能为实现磨煤机的运维提供参考。

关键词:热力学机理;数据挖掘;正态分布;特征参数;状态预警

DOI:10.15938/j.jhust.2020.01.007

中图分类号: TM621

文献标志码: A

文章编号: 1007-2683(2020)01-0043-08

Abstract:In order to realize the early warning of the coal mill and to improve the stability of the coal mill -On the basis of thermodynamics, the internal coal quality, moisture quality, and energy balance of the Hp934 medium-speed coal mill were analyzed, and the characteristic parameters that characterize the operation of the coal mill were determinedUsing correlation analysis, normal distribution and confidence algorithm to excavate a large number of actual production data, determine the boundaries of various characteristic parameters of stable operation of the coal mill under various operating conditions, formulate the early warning rules, and establish the early warning model of coal mill-The test results show that the model can accurately determine the early operation anomalies of the coal mill earlier, prove the effectiveness and feasibility of the early warning model, and provide reference for the operation and maintenance of the coal mill-

Keywords:thermodynamic mechanism, data mining, normal distribution, characteristic parameter,early state warning

0 引 言

目前,在火力發电厂中,磨煤机是锅炉燃烧制粉系统的核心设备。磨煤机出现故障,将会直接影响锅炉机组的稳定和经济运行,并导致机组出力异常[1]。传统的单参数越限报警,其可靠性低,往往不能在故障发生前发生警报,这种形式的报警很难对机组设备的运行起到保护作用。而基于多参数的设备故障预警可以在故障初期判断出设备的异常状态,发出相应的预警信息,为运行维护人员争取更多的故障处理时间。随着大数据技术的高速发展,各行各业都在对海量的数据进行挖掘分析,从而获取新的知识。发电企业也积累了大量设备日常运行的数据,但这些数据没有得到有效的利用,将数据挖掘技术引入到电站设备的预警功能中,对提高设备运行稳定性、降低生产成本、提高生产效率十分必要。

针对传统报警方法的缺点,可以建立多参数的自适应阈值预警模型。目前,多参数的选取方法主要有机器学习和机理模型[19,23]。文[2]利用逻辑回归的方法选取车辆的特征,实现了对车辆的检验;文[3,4]提出了基于支持向量机(SVM)的特征选择算法,优化了特征选择方法的分类性能,选择较少的特征,提高了分类精度;文[5]通过SVM-RFE算法计算不同特征的权重,得到特征重要性排序,从而选择最佳特征子集。文[6]使用随机森林和决策树来选择特征和支持决策。文[7]使用决策树进行特征选择,减轻了数据集中的冗余。基于机理模型的特征选择方法首先对设备的运行特性进行分析,然后利用物理规律描述设备参数之间的联系,最终确定能够表征设备运行状态的特征参数[8]。很多研究是利用专家经验或设备厂家参数去设定模型的阈值、限值,这样实施起来方便、高效。然而,这些设定值过于主观,也不能随着运行情况和环境的变化做出调整。文[9]使用数据挖掘技术从大型系统参数集中提取继电器设置信息。对这些结果的挖掘确定了继电器阈值设置的边界,确保其可以检测孤岛操作。基于数据挖掘的自适应阈值的方法[10],可以分析特征参数的相关性与分布规律,从而确定设备异常的边界。

针对磨煤机运行环境复杂和工况多变的情况,本文提出一种以磨煤机运行机理和大数据分析相结合的预警方法。对磨煤机内部质量、能量平衡进行分析,结合故障的特征征兆确定预警的特征参数。在此基础上采用相关性分析和正态分布等方法对包含特征参数在内的大量实际生产数据进行挖掘,得出了不同工况下预警的各特征参数自适应边界,建立了磨煤机状态预警的数学模型,并采用概率密度与置信规则[11-12]相结合实现对磨煤机的预警。

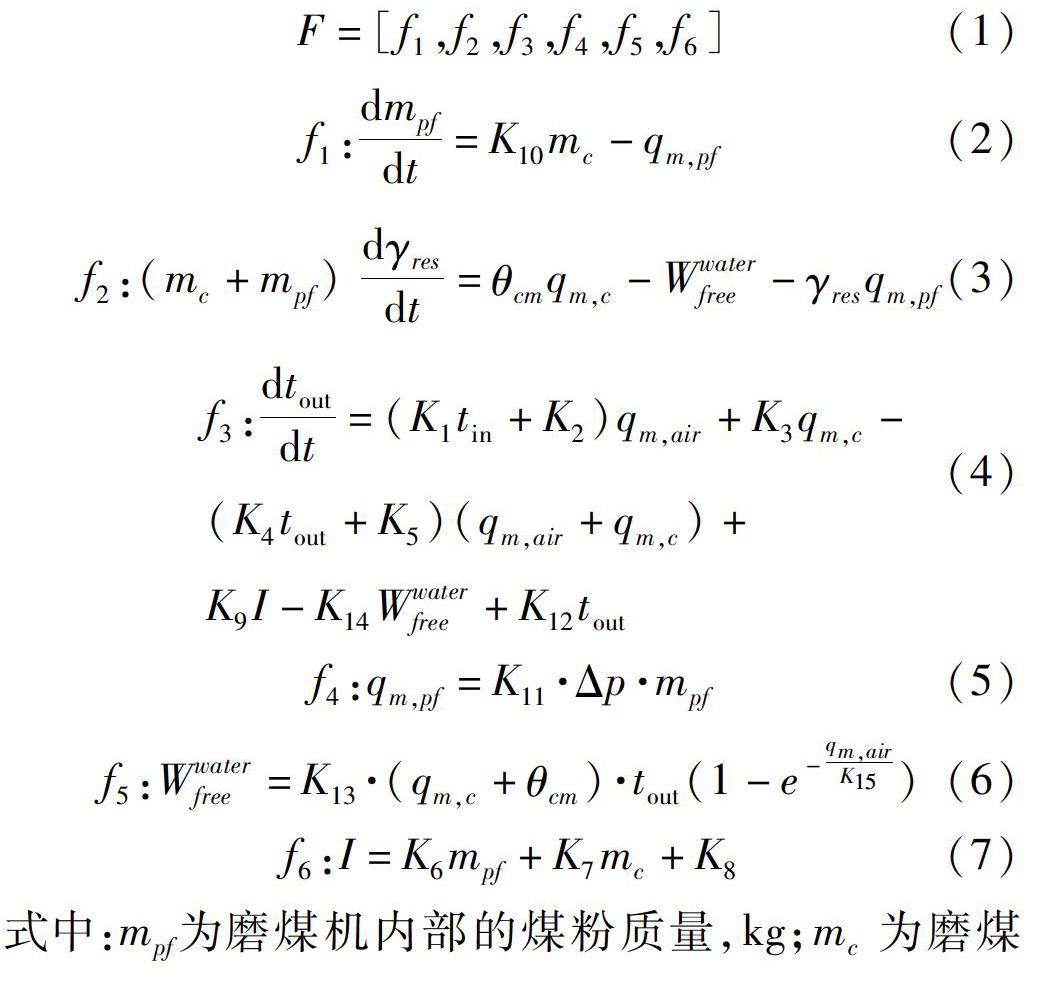

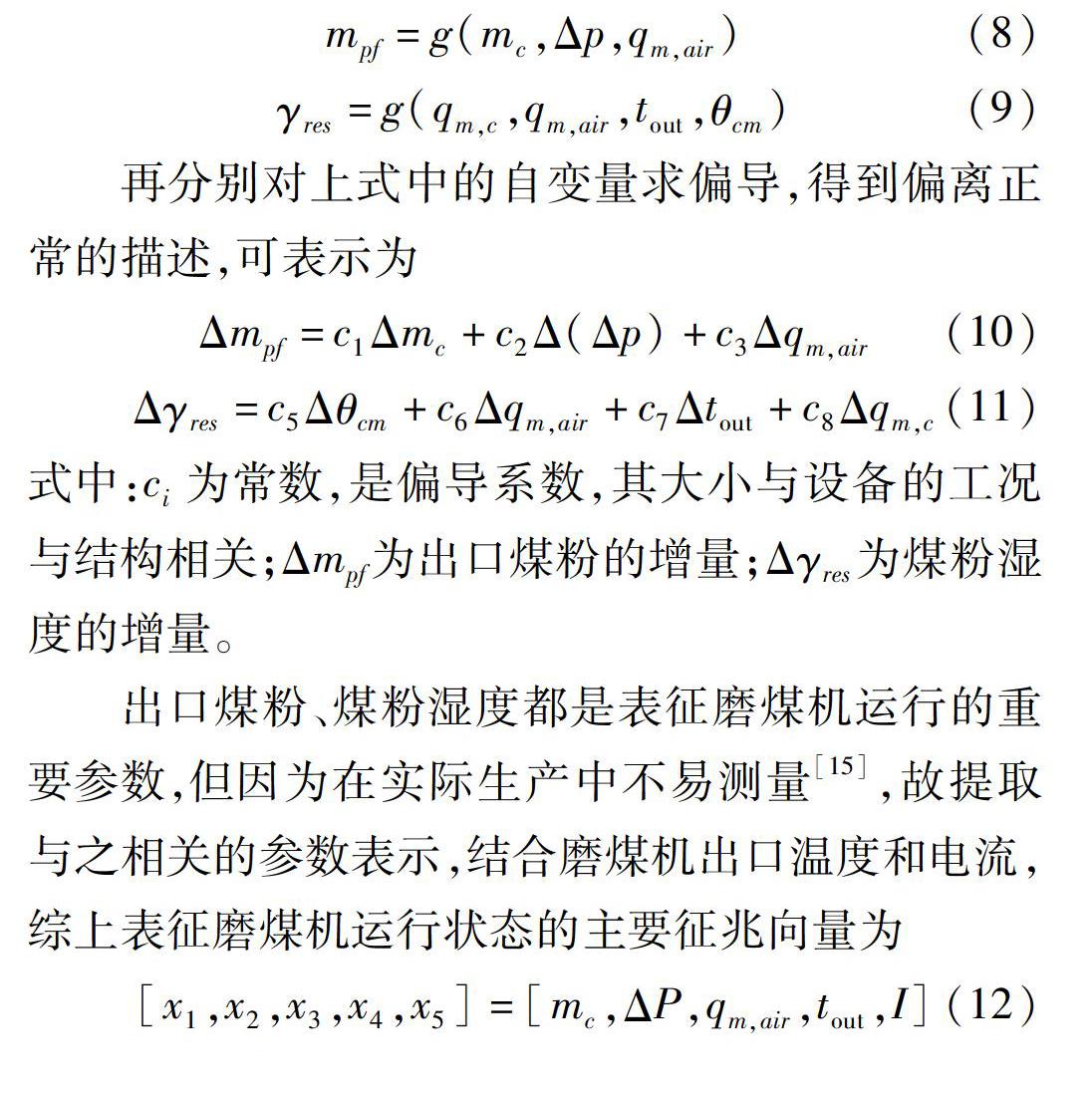

1 基于热力学的磨煤机预警特征参数的确定

中速磨直吹式制粉系统中的主要设备有给煤机、磨煤机、煤粉分离器及燃烧器等[20-21]。原煤从给煤机进入落煤管,再进入碾磨区,通过碾磨部件之间的相互挤压变为煤粉。一次风进入磨煤机,干燥煤粉的同时也将其吹入粗粉分离器,在分离器中细的煤粉被送到锅炉中燃烧,较粗的煤粉落到落煤管中继续碾磨[13]。

4 结 语

本文以磨煤机运行热力学机理为指导,确定表征磨煤机稳定运行的特征参数,以给煤量作为磨煤机运行工况,并结合大量磨煤机生产大数据,确定了各工况下磨煤机稳定运行的特征参数边界,同时使用数据挖掘的方法,制定了磨煤机预警的判断规则。初步结果表明,磨煤机预警的判断规则能为机组运

行人员提供可信度更高磨煤机运行异常提示,有助于实现磨煤机故障的早期预警。

但稳定工况下,机组参数本身有一定的波动性,可考虑用数据滤波处理方法做进一步处理;随样本数量不断积累,特征参数的上、下边界也可不断优化;但目前的预警,还没有能实现磨煤机运行异常的原因分析和故障定位,这还有待于进一步深入探讨。

参 考 文 献:

[1] AGRAWAL V, PANIGRAHI B K, SUBBARAO P M V. Intelligent Decision Support System for Detection and Root Cause Analysis of Faults in Coal Mills[J]. IEEE Transactions on Fuzzy Systems, 2017, 25(4):934.

[2] LEE C, KIM J, PARK E, et al. Multi-feature Vehicle Detection Using Feature Selection[C]. Manchester: IEEE, 2013:234.

[3] DAI K, YU H Y, LI Q. A Semisupervised Feature Selection with Support Vector Machine[J]. Journal of Applied Mathematics, 2013(1):1.

[4] TAN J, ZHANG Z, ZHEN L, et al. Adaptive Feature Selection Via a New Version of Support Vector Machine[J]. Neural Computing & Applications, 2013, 23(3-4):937.

[5] CHEN G S, ZHENG Q Z. Online Chatter Detection of the End Milling Based on Wavelet Packet Transform and Support Vector Machine Recursive Feature Elimination[J]. International Journal of Advanced Manufacturing Technology, 2017, 95(5):1.

[6] Al-MAATHIDI M M, LI F F. Audio Content Feature Selection and Classification a Random Forests and Decision Tree Approach[C]. Nanjing: IEEE, 2015:108.

[7] FERREIRA B, SILVA R G, PEREIRA V. Feature Selection Using Non-binary Decision Trees Applied to Condition Monitoring[C]. Limassol: IEEE, 2017:1.

[8] 钱虹, 宋亮, 陈琪琪,等. 基于生产数据挖掘的吹灰需求度置信规则库研究[J]. 热力发电, 2017, 46(6):113.

QIAN H, SONG L, CHEN QQ, et al. Research on Confidence Rule Base of Soot-blown Demand Based on Production Data Mining[J]. Thermal Power Generation, 2017, 46(6): 113.

[9] El-ARROUDI K, JOOS G. Data Mining Approach to Threshold Settings of Islanding Relays in Distributed Generation[J]. IEEE Transactions on Power Systems, 2007, 22(3):1112.

[10]朱曉东,袁坤杰,王艳玲.基于隐马尔科夫模型的石油钻井事故预警方法[J].郑州大学学报(工学版), 2018, 39(4):51.

ZHU XD, YUAN KJ, WANG YL. Early Warning Method of Oil Drilling Accidents Based on Hidden Markov Model[J]. Journal of Zhengzhou University(Engineering Science Edition), 2018, 39(4): 51.

[11]CHANG L, ZHOU Z J, YOU Y, et al. Belief Rule Based Expert System for Classification Problems with New Rule Activation and Weight Calculation Procedures[J]. Information Sciences, 2016, 336(C):75.

[12]LI Bin, WANG Hongwei, YANG Jianbo, et al. A Belief-rule-based Inference Method for Aggregate Production Planning Under Uncertainty[J]. International Journal of Production Research, 2013, 51(1):83.

[13]魏乐, 苑召雄, 闫媛媛,等. 基于系统动力学的MPS中速磨煤机建模与仿真[J]. 热力发电, 2016, 45(8):26.

WEI L, YUAN ZX, YAN YY, et al. Modeling and Simulation of MPS Medium-speed Coal Mill Based on System Dynamics[J]. Thermal Power Generation, 2016, 45(8): 26.

[14]NIEMCZYK P, BENDTSEN J D, RAVN A P, et al. Derivation and Validation of a Coal Mill Model for Control[J]. Ifac Proceedings Volumes, 2012, 20(5):519.

[15]孟令虎, 刘鑫屏. 双进双出钢球磨煤机制粉系统煤粉流量软测量[J]. 热力发电, 2018,47(2):97.

MENG LH, LIU XP. Soft Measurement of Pulverized Coal Flow in a Double-inlet and Double-outlet Ball Mill Coal Pulverizing System[J]. Thermal Power Generation, 2018,47(2): 97.

[16]TENG W, CHENG L P, ZHAO K J. Application of Kernel Principal Component and Pearson Correlation Coefficient in Prediction of Mine Pressure Failure[C]// IEEE Chinese Autonation Congress, Jinan, China, 2017:5704.

[17]AGTERBERG F. Pareto-Lognormal Modeling of Known and Unknown Metal Resources[J].Natural Resources Research, 2017, 26(3):265.

[18]钱虹, 马萃萃. 基于事件触发机制的核电站智能诊断专家系统置信规则库的研究[J]. 原子能科学技术, 2017, 51(3):485.

QIAN H, MA CC. Research on Confidence Rule Base of Intelligent Diagnosis Expert System for Nuclear Power Plant Based on Event Triggering Mechanism[J]. Atomic Energy Science and Technology, 2017, 51(3): 485.

[19]宋智超, 康健. 特征选择方法中三种度量的比较研究[J]. 哈尔滨理工大学学报, 2018(1):111.

SONG ZC, KANG J. A Comparative Study of Three Metrics in Feature Selection Methods[J]. Journal of Harbin University of Science and Technology, 2018(1): 111.

[20]荣盘祥, 张亮, 孙国兵,等. 磨煤机组合方式优选在锅炉系统中的应用[J]. 电机与控制学报, 2017,21(12):100.

RONG PX, ZHANG L, SUN GB, et al. Application of Coal Mill Combination Method Optimization in Boiler System[J]. Journal of Electrical Engineering and Control, 2017,21(12): 100.

[21]温玄, 王培东, 张海英. 中储式球磨机制粉系统控制器设计[J]. 哈尔滨理工大学学报, 2010, 15(2):47.

WEN X, WANG PD, ZHANG HY. Design of the Controller for the Powder System of the Ball Mill Mechanism in the Middle Storage[J]. Journal of Harbin University of Science and Technology, 2010, 15(2): 47.

[22]李輝, 李洋, 杨东,等. 基于EMD相关去噪的风电机组振动噪声抑制及特征频率提取[J]. 电机与控制学报, 2016, 20(1):73.

LI H, LI Y, YANG D, et al. Vibration Noise Suppression and Characteristic Frequency Extraction of Wind Turbine Based on EMD Correlation Denoising[J]. Journal of Electrical Engineering and Control, 2016, 20(1): 73.

[23]荣盘祥, 曾凡永, 黄金杰. 数据挖掘中特征选择算法研究[J]. 哈尔滨理工大学学报, 2016, 21(1):106.

RONG PX, ZENG FY, JIN JJ. Research on Feature Selection Algorithm in Data Mining[J]. Journal of Harbin University of Science and Technology, 2016, 21(1): 106.

(编辑:温泽宇)