Trap distribution of polymeric materials and its effect on surface flashover in vacuum

2020-05-06ChengyanREN任成燕ChuanshengZHANG张传升DuoHU胡多ChengZHANG章程FeiKONG孔飞TaoSHAO邵涛andPingYAN严萍

Chengyan REN (任成燕),Chuansheng ZHANG (张传升),Duo HU (胡多),Cheng ZHANG (章程),Fei KONG (孔飞),Tao SHAO (邵涛) and Ping YAN (严萍)

1 Key Laboratory of Power Electronics and Electric Drive,Institute of Electrical Engineering,Chinese Academy of Sciences,Beijing 100190,People’s Republic of China

2 University of Chinese Academy of Sciences,Beijing 100049,People’s Republic of China

3 Northeast Electric Power Design Institute of China Power Engineering Consulting Group Corporation,Changchun 130021,People’s Republic of China

Abstract

Keywords: surface flashover,trap distribution,vacuum,trap level,polymer

1.Introduction

Vacuum flashover is a type of discharge phenomenon that occurs on the surface of vacuum and dielectric.It severely limits the service life and operational reliability of power equipment.Through the secondary electron emission avalanche (SEEA) model,we know that surface trapping can participate in the development of SEEA and significantly affect the surface flashover characteristics of insulating materials in vacuum[1–5].In the theory of electron triggered polarization relaxation (ETPR),trapped charge is also the main cause for vacuum surface flashover [6,7].In recent years,researchers have paid more attention to the surface trap and generally believe that the trap parameters of insulating materials are a key influencing factor of vacuum flashover.

Figure 1.Schematic diagram of vacuum experimental platform.

Li et al reported that deep trap helps to increase the vacuum flashover voltage by suppressing the carrier migration[8,9]and Zhang et al held the same view[10].Shao et al reported that the treatment of polymethyl methacrylate(PMMA) by Ar/CF4atmospheric pressure plasma jet increases the trap level and trapped charge of the material,and then increases the vacuum flashover voltage by 30% [11].However,Du et al found that the introduction of shallow traps on the surface of the sample by fluorination makes the charge dissipate more easily,reduces the electric field distortion caused by surface charge,and suppresses the accumulation of surface discharge and thus increases the flashover voltage[12,13]; Sun et al reported the selection of insulating materials with less surface charge accumulation to improve their vacuum insulation strength [14].He et al indicated that charge injection and migration along the insulation surface can be controlled by trap levels,shallow traps are beneficial for charge transport,and deep traps can suppress charge injection from the electrodes under DC voltage [15].They also put forward that the insulating materials with deep traps could be used to restrain the electron migration in a temperature gradient environment[16].Zhang et al studied the effect mechanism of fluorination on the vacuum flashover voltage,pointing out the increase of flashover voltage mainly depends on the decrease of secondary electron yield(SEY)and SEY is influenced by surface roughness and trap characteristics[17,18].Shao et al reported that the introduction of shallow traps increases the surface charge dissipation of Al2O3-filled epoxy resins [19,20].

In general,although in relevant studies in recent years appropriate deep or shallow traps have been suggested to improve the flashover voltage or to change the charge distribution,there is still no convincing explanation for the influence mechanism of trap on vacuum surface flashover.Researchers mainly emphasize the role of charge capture and carrier migration suppression for deep trap in discharge evolution.As to shallow trap,fast dissipation of surface charge and change of electric field distortion are mainly mentioned.Though an increase of the trap level helps to capture more charge carriers,it also increases the accumulation of surface charge.It has double effects for trap on the flashover characteristics.Meanwhile the type and location of surface charges accumulated on the insulation surface have an important effect on surface discharge development in vacuum.Therefore,further experimental verification is necessary.In addition,the influence mechanism of trap distribution on vacuum flashover needs to be studied in depth.

In consideration of the possible effect of different materials and power supplies,three types of polymeric materials were studied by three types of power supplies in this paper.The trap parameters of the samples were tested and calculated,and the flashover experiment was developed under different forms of applied voltages.Then the influence of trap parameters on vacuum flashover was analyzed based on the dynamics process of charge trapping and de-trapping.Meanwhile,the influence of the charging condition of the dielectric surface on flashover under DC and pulsed voltages was also analyzed.Finally,the influence mode of the trap parameters on vacuum flashover was discussed combining with the full-exposure image of flashover by camera and surface potential measurement.

2.Experimental setup and measurement

2.1.Experimental setup

Figure 1 is a schematic diagram of the vacuum experimental platform and measurement system.The vacuum flashover experimental platform used in this paper consists of a vacuum chamber,finger-type electrodes,and high voltage power supplies.The electrodes are made of oxygen-free highconductivity copper and the curvature radius of the electrode tip is 12 mm.The electrodes are polished to attain a mirror finish before the experiment.The high voltage power system used includes a DC power supply (0–40 kV),a microsecond pulsed power supply with output pulse rise time of 500 ns,and a full width at half maximum (FWHM) of 8 μs,and a Marx generator with output pulse rise time of 120 ns and FWHM of 300 ns.The electrical signal measurement part is composed of a voltage probe (Tektronix P6015,1000:1) and an oscilloscope(Tektronix DPO2024,200 MHz,1 GS s-1).A digital camera (Canon EOS 700D) is used to capture the time-integrated photos of the flashover process.In the vacuum flashover experiment,the degree of the vacuum is about (4–6) × 10-4Pa.

Figure 2.Surface trap parameters of polymer samples.

The insulating samples used include polytetrafluoroethylene (PTFE),PMMA,and polyamide (PA6) with a size of 2 × 50 × 50 mm3.The surface roughness Raof PTFE,PMMA,and PA6 is 0.51,0.01,and 0.02 μm,respectively,measured by a surface roughometer (TR210).They were firstly cleaned in absolute ethyl alcohol and deionized water for 5 min,respectively,and then baked at 70°C for 5 h before the vacuum flashover experiment.Meanwhile the front ends of the two finger-type electrodes were polished and cleaned before the experiment.The electric field strength of the dielectric surface is different under different voltage forms.In order to obtain the surface withstand voltage characteristics of PTFE,PMMA,and PA6 in vacuum,the flashover experiments were carried out in microsecond pulse,nanosecond pulse,and DC voltage based on the three types of power supplies mentioned above.In the microsecond pulsed experiment,the distance between the electrodes is fixed at 1.2 mm and it is 4 mm in DC experiment,and the electrode distance is 2,4,6,8,and 10 mm,respectively,during the nanosecond pulsed experiment.

2.2.Measurement of surface trap parameters

The charge accumulation and dissipation behaviors of insulating materials can be usually reflected by surface potential measurement.Furthermore,the trap parameters can be calculated based on the surface potential and these parameters have an important effect on the charge behavior.Considering that the isothermal surface potential decay(ISPD)reflects the trap parameters in the surface layer of the insulating material about 2 μm [21],it has the advantages that the material surface to be tested does not need to be vapor-deposited,and it is a type of non-contact measurement.So the ISPD method is widely used to characterize the surface trap parameters of insulating samples [22].

Figure 3.Flashover voltages excited by microsecond pulse and DC.

The surface potential decay was measured and recorded by a self-constructed test system after negative corona charging [23].In our experiment,the insulating sample was firstly charged with a DC voltage of -3.5 kV for 1 min,and then it was quickly moved to the Kelvin electrostatic probe (Trek-6000B) for a surface potential test.The whole measurement process is maintained at a temperature of(25 ± 2) °C and a relative humidity of 37% ± 5%.According to the isothermal current decay theory proposed by Simmons [22],the surface trap density and trap energy level of samples can be calculated as follows:

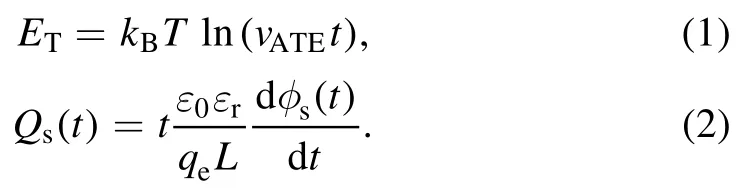

In equation (1),ETis the trap energy level,kBis the Boltzmann’s constant,Tis the sample temperature,vATEis the escape frequency of trapped charge(4.17 × 1013s-1),andtis the time of potential decay.In equation (2),ε0is the vacuum dielectric constant,εris the relative dielectric constant,φs(t)is the time-dependent surface potential of the materials,andLis the thickness of the samples.

3.Results and discussion

3.1.Trap parameter distribution and vacuum flashover voltage

Figure 2 shows the results of the measurement of the surface trap parameters of PTFE,PMMA,and PA6 in whichETis the energy level of traps andQsis the trapped charge density.It can be seen that both PTFE and PMMA have two trap peaks and their trap levels are obviously deeper than those of PA6.The trap level of PTFE,corresponding to the highest peak at whichQsis largest,is slightly larger than that of PMMA,while that of PA6 is significantly shallower and is about 0.92 eV.For PTFE,the shallow trap level is about 1.01 eV and the deep trap level is about 1.07 eV.The trap levels of PMMA are respectively 1.05 and 1.1 eV.The electron trap density of PA6 is the maximum,then PMMA,and that of PTFE is the minimum.

Figure 4.Flashover voltage with different gap distances excited by a nanosecond pulse.

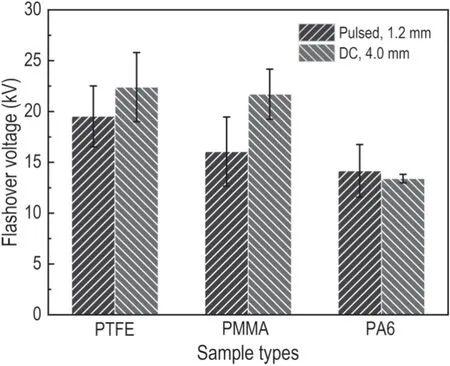

The experimental results of microsecond pulse flashover and DC flashover are shown in figure 3.It can be seen that the surface flashover voltage of PTFE is the highest among the three materials,then PMMA,and that of PA6 is the lowest in vacuum.The experimental results are similar in DC voltage.Combined with figure 2,we can see that there is a positive correlation between the vacuum flashover voltage of the insulating material and its trap level,especially in DC voltage.The DC withstand voltages of PTFE and PMMA are approximate and much higher than that of PA6.However,the microsecond pulsed withstand voltage of PMMA is lower than that of PTFE,which is close to that of PA6.

The experimental results of nanosecond pulse flashover are shown in figure 4.It can be seen that the surface withstand voltages of PTFE are always higher than those of PMMA and PA6 in different discharge spaces,and the voltages of PMMA and PA6 are relatively close,and sometimes the flashover voltage of PA6 is higher than that of PMMA.Combining the experiment results in figures 2–4,we can see that the PTFE sample always has the highest vacuum flashover voltage in different voltage forms.This is related to the deeper trap level of PTFE.In addition,its smaller dielectric constant and lower SEY [23] are beneficial to reduce the field distortion at the cathode triple junction(CTJ)and electron multiplication,and then to improve the flashover voltage.

As we know,the intrinsic characteristics and surface parameters of polymer all have an effect on vacuum flashover voltage,such as the dielectric constant,resistivity,SEY,and surface roughness.The dielectric constant of insulating samples directly affects the electric field distortion rate at the CTJ,and the larger dielectric constant is,the higher the field distortion rate is.The dielectric constant is about 2.1,3.3,and 5 for PTFE,PMMA,and PA6,respectively.The electron multiplication process on the insulation surface mainly depends on SEY,and the larger SEY is,the faster the electron multiplication is.For polymer,SEY reaches the maximum when the incident electron energy is about 300 eV.The SEY of PTFE is the smallest among the three materials,and those of PMMA and PA6 are similar.

Surface roughness has effect on surface charge accumulation and SEY,so it is also related to vacuum flashover voltage.The surface roughness of PTFE is larger than those of PMMA and PA6,which are similar to each other.It is generally considered that large surface roughness,larger than 1–2 μm,could reduce surface charge accumulation and SEY[24,25],and then improve the flashover voltage.But a small change of surface roughness,lower than 1 μm,has an ambiguous effect on the trap distribution due to different surface processing [17,24].In our previous work,the effect of surface roughness on trap distribution was studied for three materials[24],and in this paper the result shows that different surface roughnesses of the three materials has little effect on the analysis of the trap and surface flashover.As to surface resistivity,it is respectively 1.2 × 1017Ω,2.3 × 1016Ω,and 3.8 × 1013Ω for PTFE,PMMA,and PA6,which will affect the dissipation of surface charges along with the trap parameter.Besides,PTFE is a typical non-polar polymer with low surface energy and surface tension,so it has excellent chemical durability and in-adhesion.PMMA and PA6 are polar dielectrics with larger surface energy and stronger hygroscopicity,which is disadvantageous to enhance the withstand voltage [23].

The DC flashover voltage of PMMA is close to that of PTFE,but its dielectric constant and SEY are higher than those of PTFE.So the flashover characteristic in DC voltage mainly depends on the trap parameter and surface resistivity of the insulation samples.On the other hand,the pulse flashover voltage of PMMA is close to that of PA6 though the surface trap level of PMMA is much deeper than that of PA6.Meanwhile,the dielectric constant of PMMA is smaller than that of PA6 and their SEYs are similar.So we could deduce that trap has little effect on the pulse flashover voltage of the polymer samples and the trap parameters may react on the withstand voltage after some voltage action time.

3.2.Analysis of the charge trapping and de-trapping dynamics process

The preceding results indicate that the trap parameters have different effects on vacuum flashover under different types of applied voltages.In order to further analyze the role of trap parameters in the vacuum flashover process,it is necessary to combine the kinetic equations of charge trapping and detrapping to estimate the possible effects of trap parameters on flashover.The possible forms of the trap distribution for polymer materials are single discrete,multiple discrete,exponential,and Gaussian distribution energy levels.The trap density distribution affects the effective carrier mobility,while the carrier mobility affects the probability of charge trapping.According to the results of previous experiments,the probability of charge trapping is in the range of 10-3–10-1s-1[4,22].

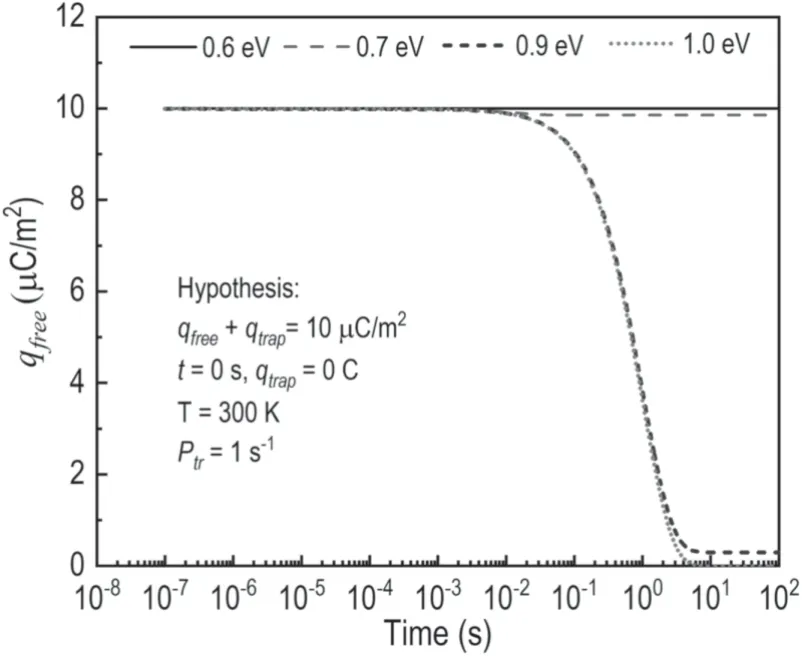

A single discrete energy level refers to an energy level in which all traps in the dielectric have the same level of values,and two discrete energy levels refer to all traps in the dielectric distributing at two different energy levels,which are one type of multiple discrete energy levels.The kinetic equation does not change with the change of trap distribution forms.The first-order dynamic equation[26]can describe the change in the amount of charge during the trapping and de-trapping process.The calculation results are shown in figures 5 and 6.

Figure 5.The change in the amount of free charge with time at a single discrete level.

The variation of the amount of free charge with time is shown in figure 5 at a single discrete level.The trap level is chosen to be 0.6–1.0 eV.From the figure,we can see that few free charges are captured when the trap level is shallow(0.6 eV,0.7 eV),while the deep trap (0.9 eV,1.0 eV) could capture almost all free charges.In addition,the effective time of shallow trap capture is on the scale of 10-5s,but the trapped charge is few.Although deep traps can capture more charges,the capture time is distributed in the range of 10-1to 1 s.

With regard to the vacuum surface flashover under microsecond and nanosecond pulses,the discharge time is generally on the scale of 10-8–10-7s[27,28].Therefore,the effective mode of trap on flashover is not to reduce the quantity of charged particles during the electron multiplication process,and there might be other influential ways.

The variation of trapped charge with time is shown in figure 6 at two discrete energy levels.In figure 6(a),the trap with an energy level of 0.9 eV captures nearly 100% of the free charges,while the trapped charges with a 0.7 eV trap level increase firstly and then decrease,and the reduced charges are captured again by the deep trap.After a few seconds,the trapping and de-trapping process of the charges reaches a steady state.In figure 6(b),the trap levels are 0.4 eV and 0.6 eV,respectively.The time to reach a steady state is 10-4–10-3s,which is shorter than that shown in figure 6(a).In addition,the total amount of trapped charges does not exceed 1% of the initial free charges,and there is no such situation that the captured charges escape from the shallow trap and then are trapped by deep trap,as shown in the figure 6(a).The effect of traps on charge carriers at two discrete energy levels is generally similar to that at a single energy level.

3.3.Discharge channel of vacuum flashover

Figure 6.The variation of trapped charge with time at two discrete energy levels.

The discharge images in vacuum surface flashover can help to discriminate the effect of the electric field component on the development of flashover[29,30]and to obtain the flashover development speed [31],etc.Therefore,we obtained the discharge channel images by means of the time integral photos of the whole flashover process to further analyze the role of traps on vacuum flashover.Figure 7 shows the typical fullexposure flashover discharge channels of the PMMA samples in DC and pulsed voltages.Although the full exposure will record all partial discharge and discharge channel evolution in each time period,the impact mode and mechanism of the trap on the flashover development could be still analyzed.

Our previous research results indicate that a slight luminescence appears before the flashover moment caused by the pre-discharge on the surface of insulating samples [27].Meanwhile,the insulation samples have been partially decomposed even in the process of pre-discharge stage,which is proved by results of the photomultiplier tube and light emission spectrum.So the luminescence mainly comes from the collision between electrons and gas molecules and the ionization process.The gases include desorption gases from the insulation and electrode surface,and some decomposition gases from the sample surface caused by applied voltage and electron collision.Thus the image of the discharge could reflect the electron trace to a certain extent.For the pulseexcited flashover,it contains the electrons that are‘up thrown’near the cathode,the electrons that flow into the anode,and the filament-like discharge path between two electrodes.Through multiple discharge photographs,it is often found that the electrons near the CTJ are up thrown as shown in figures 7(a) and (c).

Figure 7.Image of discharge channel of flashover in vacuum with full-process exposure.

Figure 8.Surface potential distribution under DC and pulsed voltage.

A possible cause of the filamentary discharge path is that near the CTJ,the up thrown electrons and accumulated negative charges act together to affect the electric field above the sample surface.As a result,the normal electric field intensity component is weakened,and the horizontal electric field component dominates in this region.So some electrons are accelerated almost parallel to the sample surface,the kinetic energy increases,and then some electrons strike the sample surface,causing electron multiplication.At last,the electrons arrive at the anode,and the flashover occurs.In addition,the electric field gradient in pulsed voltage is much higher than that in DC voltage.Thereby the filamentary discharge path is easy to be find in pulsed voltage.

For the flashover of DC excitation,it can be seen from the luminous image of the discharge channel in figure 7 that the electrons deviate from the sample surface in the middle part of two electrodes.There is no obvious ‘up throwing’phenomenon near the CTJ,while it occurs in the middle region of the sample surface from figure 7(d).That is,as the spatial position gradually approaches,the electrons that are up thrown and the electrons that are introduced into the anode constitute a discharge channel.Different from the spatial shape of the 10 mm discharge channel,when a flashover occurs at 4 mm spacing,a certain number of electrons appear to be up thrown near the cathode,as shown in figure 7(b).The up throwing phenomenon of electron is related to the charged state of the sample surface.

The surface potential distribution of PMMA was measured under different applied voltages to further verify the relationship between trap and flashover (shown in figure 8).The potential near the CTJ is positive and high(about 2.5 kV)after the DC voltage (-5 kV) is applied for 1 min,and the potential in other regions between the electrodes is negative.So the luminescent intensity is high and the discharge evolves close to the insulation surface near the CTJ under DC voltage.However,the discharge channel deviates from the sample surface due to the negative potential in the middle of samples.Under pulsed voltage(about 40 kV)the potential between the electrodes is mostly negative after flashover,so the electrons near the CTJ are repelled and the discharge image has an up throwing phenomenon near the CTJ.The measurement results of surface potential further explain the discharge images in figure 7 and also prove that traps affect the discharge process by changing the surface potential distribution of insulation materials.The negative charges mainly accumulate near the CTJ and the sample surface between two electrodes after pulsed flashover,so the electron up throwing phenomenon is prominent in pulsed voltage.However,the positive charges accumulate near the CTJ under DC voltage,and some negative charges locate in the middle region between the two electrodes,which results in different electron motion trajectory and discharge images.

It is worth mentioning that in our study the SEEA model is still dominant in the discharge development,and we are mainly concerned about how the traps affect the SEEA in this paper.Since the time for trap capture is longer than the flashover formation time,the trap distribution plays a lesser role in the electron avalanche of single discharge,especially in pulsed voltage.The traps affect the surface charged state of the insulating samples [32],change the electric field distribution,and then change the trajectory of the electron motion,which ultimately affects the vacuum flashover voltage.Furthermore,the capture effect of the traps maintains the electric field established by the surface charge,so the trap parameters could affect the subsequent withstand voltage in repetitional discharges.That is to say,there is a certain accumulation effect for the trap capture.We also studied the change of flashover voltage and trap parameter after sample conditioning by repeated flashovers in a previous work [23].The results showed that the surface withstand voltage of three types of materials increases with the discharge times,which keeps rising even after 4000 flashovers for PMMA under microsecond pulsed voltage.This is mainly related to the conditioning effect of previous discharges,including the surface morphology and trap change.The trap level is deeper and the trap charge density is higher after thousands of discharges,which is beneficial to improve the flashover voltage by changing the charged state of the sample surface.This also verifies the effect of trap on the surface withstand voltage in multiple discharges.

4.Conclusions

The relationship between the surface trap and vacuum flashover voltage was analyzed in this paper.There is a positive correlation between the withstand voltage and the deep trap of polymeric materials.The trap parameter has more explicit effect on the DC flashover voltage compared with the pulsed one.The first-order dynamic equations of charge trapping and de-trapping are applied to the analysis of single and two discrete energy levels.The calculation results show that the time required for free charge to be converted into trapped charge is longer than the discharge development time.It is not a major factor for trap to affect the flashover by trap capture to reduce the secondary electron quantity participating in the discharge development process.

The trapping action of the deep trap can change the electric field distribution of the dielectric surface and allow the electric field established by the surface charge to be maintained for a long time.This electric field will further affect the electron motion trajectory.The negative charges near the CTJ make some electrons deviate from the sample surface and also reduce the field distortion at the CTJ,which then reduce the number of electrons participating in the electron multiplication.So it is beneficial to improve the surface withstand voltage in vacuum.However,the positive charges near the CTJ have the opposite effect.The accumulation state of surface charge is different under different voltage types,so it has different effects on the flashover characteristics.The effect of traps on the vacuum flashover via the change of electric field and electron trajectory is also verified by the discharge channel images and surface potential measurement.

Acknowledgments

This work is supported by National Natural Science Foundation of China (Nos.51977202,U1830135,51807189) and the Scientific Instrument Developing Project of the Chinese Academy of Sciences (No.YJKYYQ20170004).

猜你喜欢

杂志排行

Plasma Science and Technology的其它文章

- Study on influencing factors of ion current density measurement in corona discharge of HVDC transmission lines

- Improvement of the electrical resistivity of epoxy resin at elevated temperature by adding a positive temperature coefficient BaTiO3-based compound

- Controlling fine particles in flue gas from lead-zinc smelting by plasma technology

- Kinetic simulation of an electronegative plasma with a cut-off distribution and modified Bohm criterion

- Suppression of a spontaneous dust density wave by modulation of ion streaming

- An investigation of the L-shell x-ray conversion efficiency for laser-irradiated tin foils