Industry survey:Progress on resuming production

2020-04-20

knitting machinery

While strengthening the prevention and control of the COVID-19 epidemic, enterprises in the knitting machinery industry have resumed production in accordance with local prevention and control policies and their own conditions. On February 12th, the China Textile Machinery Association conducted a follow-up survey of more than 110 flat knitting machines, circular weft knitting machines, warp knitting machines, hosiery machines and their supporting enterprises. The general situation is as follows:

Some enterprises have achieved limited resumption of administration, sales and service (online and telephone);

The enterprises that have resumed production mainly focus on overseas orders and orders before the Spring Festival;

On the one hand, the start-up of the entire industry is limited by the review by local governments, the shortage of protective materials, the isolation of migrant workers, and the insufficient resumption of supporting enterprises;

Although the logistics from overseas countries such as Germany to China is relatively normal, the speed of domestic shipment and distribution is still greatly affected.

Specific to the main fields of flat knitting machines, circular weft knitting machines, warp knitting machines, hosiery machines and knitting machines supporting equipment:

Flat knitting machine field: A few main engine enterprises resumed production on February 10th, and some enterprises started after February 17th. Nearly 40% of the main engine enterprises are still in pending. Among supporting enterprises, electronically controlled production enterprises have begun to resume production on the 10th and 11th; major yarn feeder and antenna station production enterprises are expected to resume production on the 18th; some needle bed production enterprises are expected to resume production after the 21st; mountain boards, storage feeder production enterprises are still applying to the local government for start-up.

Circular weft knitting machine field: Nearly 40% of the main engine enterprises resumed production mainly from February 10th to 12th, nearly 20% of the enterprises are still in the process of applying to the local government, the start time of some enterprises was postponed to the 24th. Among the supporting enterprises, some manufacturers of yarn feeders, yarn guide wheels, knitting cam, and frequency converters have resumed production on February 10th; some needle cylinder and fabric winding machine manufacturers have resumed production on February 13th; the resumption time of major yarn feeder manufacturers and electronically controlled production enterprises is yet to be reviewed by the government.

Warp knitting machine field: A few main engine enterprises have resumed production on February 10th and 11th. Some enterprises are applying to the government to start production, and some plan to resume pro- duction around February 25th. More than 40% of main engine production enterprises have not yet been identified the start date. Among the supporting enterprises, section beam manufacturing enterprises in Zhejiang are scheduled to start production around February 20th; Jacquard warp knitting machine supporting production enterprises are expected to resume production to wait until February 17th.

Hosiery machine field: Some enterprises have decided to resume production on February 18th, and the specific resumption time of most enterprises after February 18th needs to be examined and approved by the government.

Knitting needle manufacturing enterprises: More than half of the enterprises have resumed production from February 10th to 13th. A few enterprises plan to resume production after February 17th, and some enterprises are applying for government approval.

wool textile industry

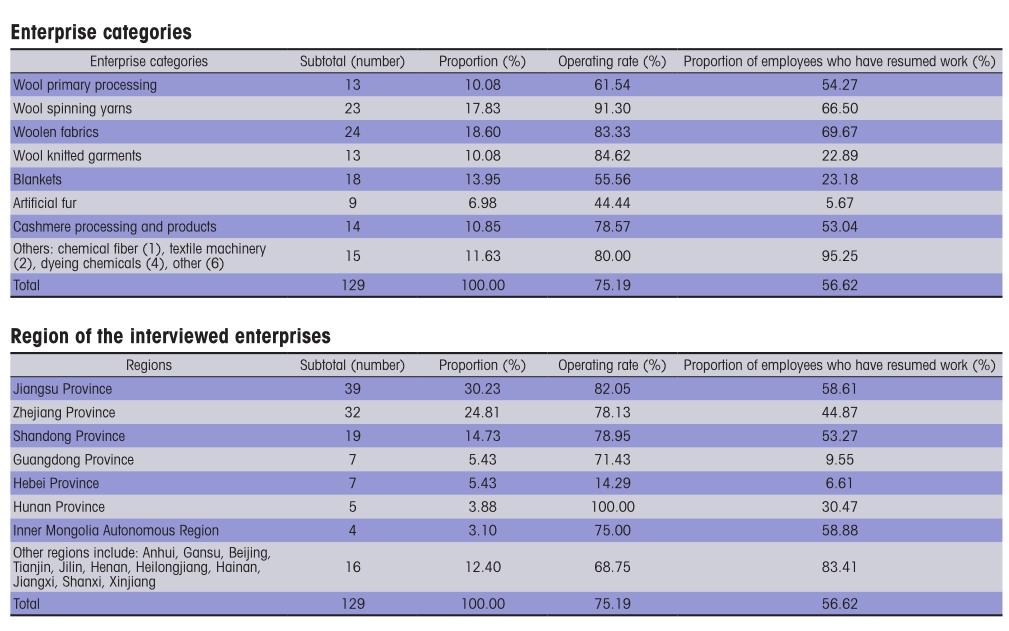

According to statistics, from 14:30 on February 13th to 13:30 on February 23rd, a total of 129 member enterprises participated in the survey and reported 407 times. The enterprises involved in 20 provinces, regions and municipalities across the country, covering woolen raw materials, wool primary processing, wool spinning yarns, woolen fabrics, wool knitted garments, cashmere product processing, blankets, artificial fur and other related industries, as well as related fields such as dyestuffs, textile machinery. The basic situation is as follows:

Resumption of production

At 13:30 on February 22nd to 13:30 on February 23rd, 30 enterprises were reported and 25 enterprises resumed production, with a resumption rate of 83.3%. As of 13:30 on February 23rd, 129 woolen textile enterprises participating in the survey have resumed production, with a resumption rate of 75.2%, and two new resumed enterprises; the total number of workers in the normal production of 129 enterprises totaled 71,492, and the number of workers who had got back to work was 40,477, and the proportion of those who had resumed work was about 56.6%, and the proportion of those who had resumed production increased slightly. The progress of resuming production varies from place to place, and it is related to the speed of the local governments review and approval of the resumption of enterprises. For example, enterprises in Xinjiang and Hebei have not yet started. (The statistics are for reference only.)

The main problems facing enterprises to resume production

The survey results of 30 enterprises reported from 13:30 on February 22nd to 13:30 on February 23rd showed that the proportion of problems in poor logistics and difficult procurement of protective supplies were 56.7% and 60%. For enterprises reporting yesterday, such difficulties were alleviated. 76.7% of the reported enterprises continued to say that the shortage of workers is an important factor affecting the resumption of production.

Resumption of industrial clusters

There are many small and micro enterprises in the wool textile industry cluster, and the situation of resuming production is complicated, and the work is relatively more difficult. For the past week, local industry authorities have conducted strict site inspections to ensure safe, and orderly resumption of production. Zhejiang Puyuan sweater market launched the “online market opening” on the 15th, ushering in a “wave of online orders.” On the 21st, Tongxiang Puyuan sweater market was fully resumed, and offline trading was resumed in 20 market trading areas. From the opening of online and offline markets to the 22nd, Puyuans online and offline revenue has exceeded 200 million yuan. Relevant persons in charge of Guangdong Dalang recently went through the inspections of enterprises and communities. On the premise of ensuring safety, they will fully resume production. China Dalang Wool Textile Trade Center will resume trading on March 1st. (Data source: China Wool Textile Association)

chemical fiber industry

According to the survey results, as of 13:30 on February 24th, the chemical fiber industry has received a total of 38 enterprises who have completed valid questionnaires. 36 enterprises have already resumed production, and the operating rate is 94.7%. The number of workers for normal production of the above enterprises is 82,323, and the number of workers who have resumed work is 62,822, accounting for 76.3%. (The statistics are for reference only.)

According to the survey results, enterprises report that the procurement of protective supplies, shortage of workers, and poor transportation and logistics are the main difficulties currently facing the industry. Among them, about 76.9% of the survey enterprises report that the logistics factors such as the cross provincial and cross regional logistics barriers, the high freight and other logistics factors affect the purchase of raw materials and auxiliary products and the sales of products, which is still the biggest difficulty faced by the industry; about 64.1% of the surveyed enterprises reported that the difficulty in purchasing epidemic prevention supplies resulted in the delay of start; about 48.7% of surveyed enterprises report that labor shortages are prominent; and 25.6% of surveyed enterprises had other problems, such as high inventory, shortage of funds and insufficient supply of some raw and auxiliary materials.

industrial textile industry

As of February 19th, a total of 106 industrial textile enterprises have submitted questionnaires. Of the 106 enterprises, 67 have resumed work, with a resumption rate of 63.2% and a resumption rate of workers is 56.5%.

Among the enterprises that have resumed production, raw and auxiliary materials enterprises, product enterprises, and equipment enterprises in the mask, medical protective clothing, and disinfection wipes industry chain have basically resumed production, and orders are sufficient, while the startup situation of enterprises in other fields is not good; the resumption rate of enterprise workers, mainly local employees, is over 80%, while the work resumption rate of enterprise workers with a high proportion of non-local employees is relatively low. The resumption of production of large enterprises is significantly better than that of SMEs. The 15 key enterprises tracked continuously by the China Nonwovens & Industrial Textiles Association have all resumed work, and the resumption rate of workers is 61%.

The difficulties encountered by enterprises in the resumption of production are mainly: the poor flow of materials and personnel caused by traffic control and the increase in transportation costs; the difficulty of getting back to work for migrant employees; the difficulty in purchasing anti-epidemic materials; the lack of demand and the decline in orders.

dyeing and printing enterprises

At present, the COVID-19 epidemic continues, while upstream and downstream enterprises in the textile industry chain are doing their best to ensure the supply of anti-epidemic materials, they are gradually resuming production in an orderly manner.

In order to understand the progress of the production resumption of dyeing and printing enterprises in the epidemic situation and the problems encountered, the China Dyeing and Printing Association has carried out followup surveys on industrial enterprises and clusters through various ways since February 13, 2020. During the survey from February 13 to 29, the resumption of production in the dyeing and printing enterprises steadily progressed. The number of resumption enterprises increased. However, the production resumption of enterprises still faced some practical problems.

Enterprises resume production

Online survey

According to the deployment and requirements of the Ministry of Industry and Information Technology, since February 13, China National Textile and Apparel Council has established the “Daily reporting system for resumption of production of enterprises”. As of 12:00 on February 29, the China Dyeing and Printing Association had received a total of 127 valid questionnaires. The survey information is summarized as follows:

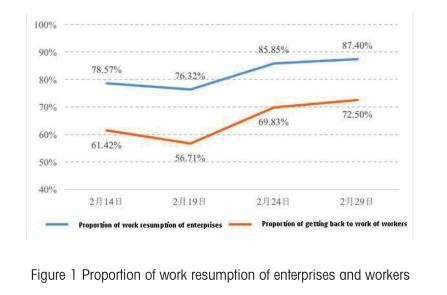

According to the statistics of the China Dyeing and Printing Association, 87.40% of the 127 dyeing and printing and related enterprises participating in the online survey have gradually resumed work; of these, 111 enterprises have 110,877 employees, accounting for 72.50% of the total number of employees under normal circum- stances.

The Dyeing and Printing Association extracted the daily summary information of the resumption of production at four different points in time, which were February 14, 19, 24, and 29 respectively. The proportion of 42, 76, 106 and 127 enterprises that have resumed production and the proportion of returned workers are shown in Figure 1.

The results of the data show that with the increase in the number of participating enterprises, the proportion of enterprises that have resumed production and the number of workers who have resumed work is generally on the rise, indicating that the production resumption of enterprises is steadily advancing.

From the perspective of enterprise distribution area

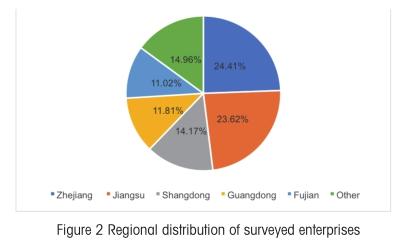

Of the 127 enterprises participating in the survey, over 80% were located in the eastern coastal areas of Shandong, Zhejiang, Jiangsu, Fujian, and Guangdong. Only 14.96% of the enterprises were located in the central and western regions. The specific distribution is shown in Figure 2.

The statistical results show that among the enterprises participating in the survey, the resumption of dyeing and printing enterprises in Shandong Province is relatively good, with the enterprise resumption rate and staff arrival rate over 85%. The analysis is due to the fact that most enterprises in Shandong Province are mainly local employees. Although the enterprise resumption rate in Zhejiang Province and Fujian Province is high, the enterprise staff arrival rate is relatively low, which is one of the main reasons that affect the recovery progress of enterprises.

From the perspective of enterprise scale

The 127 enterprises participating in the survey are mainly small and medium-sized enterprises, accounting for 72.23%, and micro-enterprises are less, accounting for less than 3%.

The statistical results show that the proportion of large and mediumsized enterprises getting back to work is significantly higher than that of small and micro enterprises, and the rates of getting back to work for large and medium-sized enterprises are more than 90%, which are 16.47 and 20.70 percentage points higher than those of small enterprises.

Survey of key enterprises

As of February 29, the China Dyeing and Printing Association received a total of 180 key member enterpriseseffective feedback on the current situation of resumption of production. Among them, 168 have been resumed, and the rate of resumption is 93.33%; 148 enterprises out of 180 enterprises reported the current employees getting back to work, and the total number of employees in the 148 enterprises under normal production was about 164,470, and the number of employees is about 93,651 now. The rate of employees getting back to work was 56.94%. Judging from the operating rate data reported by enterprises, the operating rate of most enterprises is around 70%, the operating rate of some key enterprises has reached 80% to 90%, which indicates that the operation situation of most of resumption enterprises is obviously better than that in the first ten days of February.

Resumption of main industrial clusters

As of February 25, 108 dyeing and printing enterprises in Keqiao District of Shaoxing City have resumed production, with the resumption rate of 75%. With the introduction of incentive measures to support the resumption of production, it is expected that by the end of February, dyeing and printing enterprises in Keqiao District will basically achieve full resumption of production, and the overall production capacity will restore to more than 80%.

As of the end of February, the dyeing and printing enterprises in the three industrial clusters in Shishi City have basically resumed work, with 70% to 80% of employees getting back to work and 40% to 50% of the companys production capacity.

There are 46 dyeing and printing enterprises in the Yancheng Textile Dyeing and Finishing Industrial Park, including 25 enterprises above the designated size. As of February 18, all enterprises in the park have resumed work. The total number of employees getting back to work has reached 6,000, of which 5,000 are enterprises above designated size, accounting for 83.33%.

The main problems faced by enterprises in resumption of work

The investigation of various channels shows that enterprises are faced with a series of difficult problems when they resume work. The problems reflected by enterprises are mainly labor shortage, poor logistics, and difficulties in purchasing epidemic prevention supplies.

The survey results show that 63.78% of the surveyed enterprises report that poor transportation and logistics are the top issue for their overall resumption of work and production; 61.42% of the surveyed enterprises report that the shortage of workers limits the enterprises capacity utilization; 47.24% of the surveyed enterprises reported that the difficulty in purchasing protective equipment resulted in the inability to fully resume work.

杂志排行

China Textile的其它文章

- China’s cotton exports in December 2019 increased by 5.28% year-on-year

- Impact of the COVID-19 epidemic on economic development of textile and garment industry cluster

- INDO INTERTEX 2020 will be postponed to July 14 to 17

- Over 90% of central enterprises resume work and production

- Jingwei Textile Machinery’s first N95 mask machine passed the identification

- All parties are speeding up to resume production.Why are masks still in short supply?