Optimization of Acetic Acid Fermentation Process of Apple Cider Vinegar

2020-04-10*

*

1. Jinan Fruit Research Institute of All China Federation of Supply, Jinan 250014, China; 2. Lvjie Co., Ltd., Longkou 265718, China

Abstract This paper studied the fermentation rules of apple cider vinegar from fruit juice, to provide a theoretical guidance for the production of apple cider vinegar. Using Fuji apples as raw materials, the process parameters (fermentation temperature, fermentation time, stirring speed, and inoculation amount) of apple cider vinegar fermentation were optimized through single-factor experiments and response surface analysis. The results indicated that the fermentation temperature had no significant effect on the total acid content of apple cider vinegar fermentation, the fermentation time had an extremely significant effect on the total acid content of apple cider vinegar fermentation, and the stirring speed and inoculation amount had a significant effect on the total acid content of apple cider vinegar fermentation. Through process optimization, the optimal process parameters for apple cider vinegar fermentation are fermentation temperature of 33 ℃, fermentation time of 39 h, stirring speed of 1 500 r/min, and acetic acid bacteria inoculation amount of 7%. Under such conditions, the total acid content of fermented apple cider vinegar is 62.22 g/L, very close to the predicted value of the model, indicating that the process parameters of acetic acid fermentation obtained by response surface methodology (RSM) optimization are reliable and can be used for actual production prediction.

Key words Apple cider vinegar, Fermentation, Process, Response surface methodology (RSM)

1 Introduction

China’s apple planting area and yield rank first in the world, but the total amount of processed apples is less than 20% of the apple yield, and the processing form is mainly concentrated apple juice[1]. Apple cider vinegar is a healthy drink made from apple juice as a raw material and fermented by microorganisms. It contains a variety of nutritional and functional ingredients that are beneficial to the human body and it has the dual health effects of fruits and vinegar[2-4]. In addition, apple cider vinegar can also be used as a condiment. At present, most apple cider vinegar products in Chinese domestic market are made from concentrated apple juice, and they are even prepared with vinegar, vinegar essence, sweeteners, and food flavorings. With the people’s awareness of the health effects of apple cider vinegar products, apple cider vinegar brewed with apple juice as a raw material will have a huge market[5-6]. The study of apple cider vinegar fermentation technology has become a research direction of the apple deep processing. In recent years, there have been extensive studies about the processing technology and process of apple cider vinegar fermentation, but most of them focus on strain selection, laboratory shaker process optimization and analysis[7-12]. There are only a few research reports on fruit vinegar, and no research has been conducted to optimize the fermentation process of apple cider vinegar. In this paper, using the response surface methodology (RSM), we analyzed the optimal process parameters of fermentation temperature, fermentation time, stirring speed and inoculation amount of apple cider vinegar in total acid fermentation process.

2 Materials and methods

2.1 Experimental materials

2.1.1Bacterial strain.Saccharomycescerevisiae(CTCF0001) andAcetobacteraceti(CTCF0001) were provided by the Fermentation Technology Research Laboratory of Jinan Fruit Research Institute of All China Federation of Supply.

2.1.2Raw materials. Fuji apples were provided by Lvjie Co., Ltd. and pectinase was provided by NOVOZYMES.

2.1.3Test reagents. Analytical reagents including potassium dihydrogen phosphate, magnesium sulfate, hydrochloric acid, sodium hydroxide, potassium sodium tartrate, copper sulfate pentahydrate, calcium carbonate, and glucose; yeast extract, agar powder, and edible alcohol.

2.2 Test equipmentHH-4 digital electroheating thermostatic water bath (Jintan Ronghua Instrument Manufacturing Co., Ltd.); YXQ-LS-100A full automatic vertical pressure steam sterilizer (Shanghai Boxun Industry & Commerce Co., Ltd.); SW-CJ-2FD vertical flow clean bench (Suzhou Antai AirTech Co., Ltd.); ZWYR-2112B whole temperature shaker cabinet (Shanghai Zhicheng Analytical Instrument Manufacturing Co., Ltd.); BA310 C digital biological microscope (Motic China Group Co., Ltd.).

2.3 Determination methods of physical and chemical indicatorsDetermination of total acid: acid-base titration method (GB/T12456-2008).

2.4 Experimental method

2.4.1Apple cider vinegar fermentation process. Apple → Crushing → Juice → Primary sterilization → Inoculation with yeast (simultaneous addition of enzyme preparation) → Alcoholic fermentation → Secondary sterilization → Inoculation with acetic acid bacteria → Acetic acid fermentation → Deslagging → Brewing → Filtration → Tertiary sterilization → Finished product.

2.4.2Key points of operation. Alcohol fermentation: proper amount of yeast was added into the fermentation liquid under the sterile condition, and proper amount of air can be passed during the initial fermentation to facilitate the rapid reproduction of the yeast and the alcohol fermentation. In this process, it is necessary to control the appropriate fermentation temperature. When the alcohol in the fermentation broth is above 6.5% (V/V) and the content of residual reducing sugar is about 0.5% to 0.6%, it can be considered that the alcohol fermentation is finished, and then measure and make a record of the alcohol content of the fermentation broth.

Enlarged culture of acetic acid bacteria: (i) primary seed culture: take a ring of activated acetic acid bacteria and inoculate them into a test tube containing 10 mL of liquid seed culture medium, and culture on a rotary constant temperature shaker at 33 ℃ and 200 min for 24 h. (ii) Secondary seed culture: 1% (V/V) inoculation volume is used to transfer the primary seeds after 24 h of cultivation to two 1 000-mL shake flasks containing 300 mL secondary seed culture solution, then culture on a constant temperature shaker at 33 ℃ and 200 min for 33 h.

Acetic acid fermentation stage: the secondary seed liquid of acetic acid bacteria is inoculated to the alcohol fermentation mash, and control the appropriate temperature, speed, fermentation time and other process parameters; at the same time, measure the total acid in the fermentation liquid at regular intervals. When the total acid in the fermented mash no longer increases, the acetic acid fermentation is finished.

But, sitting lonely, time soon began to hang heavy on her hands. One day she said to the old woman: It is dull for me, grandmother, to sit idly hour by hour. My hands want work to do. Go, therefore, and buy me some flax, the best and finest to be found anywhere, and at least I can spin.

2.5 Design of acetic acid fermentation optimization experiment

2.5.1Single factor experiment. We selected fermentation temperature of 33 ℃, fermentation time of 36 h, inoculation amount of acetic acid bacteria of 8%, stirring speed of 1 400 r/min as experimental factors, and take the conversion rate of alcohol in the fermentation mash (total acid content in the fermentation mash) as the indicators, change one factor level each time to carry out four single-factor experiments with different fermentation temperature, fermentation time, acetic acid bacteria inoculation amount and stirring speed.

2.5.2Response surface optimization experiment. Based on a single factor, we took the total acid content in the mash as the indicator, and the four factors, namely, fermentation temperature, fermentation time, inoculation amount of acetic acid bacteria, and stirring speed, as independent variables, carried out the response surface optimization with the aid of Design Expert 8.0 software, to analyze optimal conditions for apple cider vinegar fermentation.

2.6 Statistical analysisWith the aid of Microsoft Excel 2010 and Design Expert 8.0 software, we analyzed the experimental data, and analyzed the significance of the the response surface model obtained from the experimental data.

3 Results and analysis

3.1 Single factor experiment

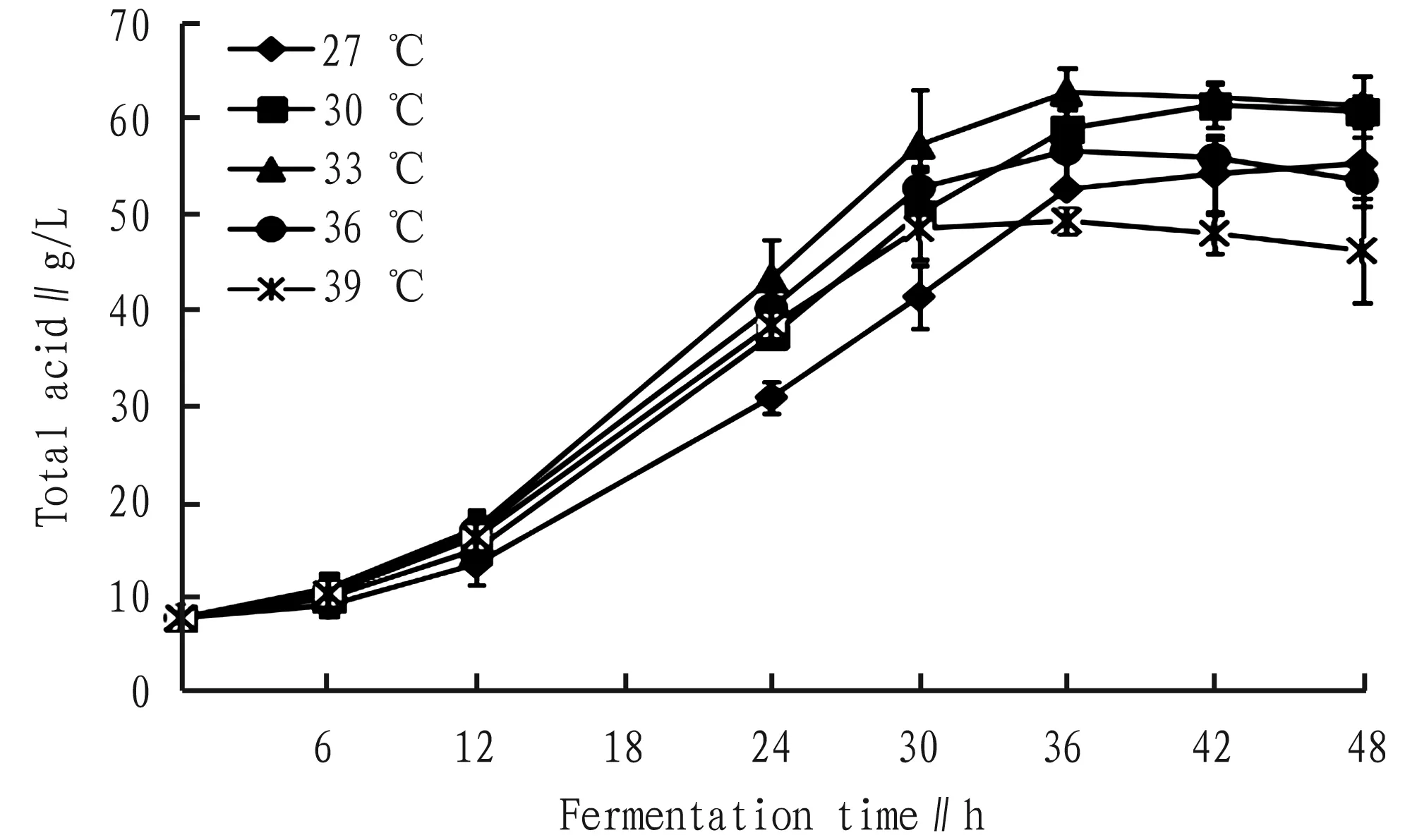

3.1.1Effects of fermentation temperature on the total acid content of apple cider vinegar. Under the conditions of apple cider vinegar fermentation time of 36 h, acetic acid bacteria inoculation amount of 8%, and stirring speed of 1 400 r/min, the fermentation temperature of acetic acid bacteria at 27, 30, 33, 36, and 39 ℃, we investigated the effects of apple cider vinegar fermentation temperature on total acid production. According to the experiment, the fermentation temperature affected the growth and reproduction rate and acid production rate of acetic acid bacteria. If the fermentation temperature is too low, the fermentation will be slow and the acid production rate will be low; if the fermentation temperature is too high, the volatilization of alcohol and acetic acid bacteria will be accelerated, acetic acid will be oxidized to carbon dioxide and water, and the acetic acid bacteria will be aged in advance, making the acetic acid fermentation efficiency become low. From Fig.1, it can be seen when the fermentation temperature was 27 ℃ and 30 ℃, the acetic acid bacteria produced acid slowly and it took a long time, and the total acid content in the final fermentation mash was low. When the fermentation temperature was 33 ℃ and 36 ℃, it produced high acid, and the total acid content of the final fermentation mash was the highest at 33 ℃, and the fermentation took only 33 h. When the fermentation temperature is 39 ℃, an excessively high fermentation temperature led to an early aging of the bacteria. Even if there was a short fermentation time, the acid production was low. According to the experimental results, it was found that the optimal temperature for acetic acid fermentation was 33 ℃ (Fig.1).

Fig.1 Effects of fermentation temperature on the total acid content of apple cider vinegar

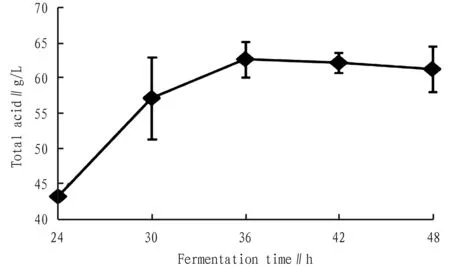

3.1.2Effects of fermentation time on the total acid content of apple cider vinegar. Under the conditions of apple cider vinegar fermentation temperature of 33 ℃, acetic acid bacteria inoculation amount of 8%, and stirring speed of 1 400 r/min, the fermentation time of acetic acid bacteria at 24, 30, 36, 36, 42, and 48 h, we investigated the effects of apple cider vinegar fermentation time on total acid production. The fermentation of acetic acid bacteria can be divided into 3 stages. The early stage of fermentation was the adaptation period of acetic acid bacteria. At this stage, the bacteria grew slowly, produced less acid, and the acidity of the fermentation mash was low. The middle stage was the logarithmic growth phase of acetic acid bacteria, and at this stage, the acid production rate increased rapidly. At the later stage, a large amount of acetic acid bacteria oxidase was secreted, which catalyzed the combination of ethanol and oxygen in the air to form acetic acid, but the oxidation reaction gradually slowed down, the acidity tended to a stable value, and the fermentation time continued to extend and the acetic acid content in mash slowly decreased. From Fig.2, it can be seen that the fermentation time between 24 and 30 h was a period of rapid increase of total acid in apple cider vinegar. When the fermentation time was between 30 and 36 h, the total acid in the fermentation broth continued to increase, but the rate of increase of total acid started to slow down; when the fermentation was 36 h, the total acid in apple cider vinegar reached the maximum value; in the later fermentation period, the activity of acetic acid bacteria weakened and the acidity tended to a stable value. If the fermentation time was extended, the acetic acid content would drop (Fig.2). This may be because the amount of acetic acid produced by the aerobic fermentation is less than the amount of small amounts of residual alcohol converted into acetic acid and the acetic acid is converted into carbon dioxide and water. According to the experimental results, the optimal fermentation time for acetic acid was set at 36 h.

Fig.2 Effects of fermentation time on the total acid content of apple cider vinegar

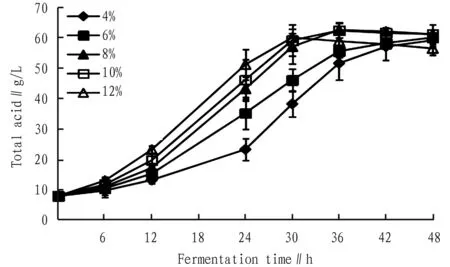

3.1.3Effects of inoculation amount of acetic acid bacteria on the total acid content of apple cider vinegar. Under the conditions of acid apple cider vinegar fermentation temperature of 33 ℃, acetic bacteria inoculation amount of 8%, and stirring speed of 1 400 r/min, the inoculation amount of acetic acid bacteria at 4%, 6%, 8%, 10%, and 12%, we investigated the effects of acetic bacteria inoculation amount on apple cider vinegar total acid production. Under other conditions unchanged, when the inoculation amount of acetic acid bacteria was 4% and 6%, the fermentation rate was slow and the acid production was relatively low; when the inoculation amount of acetic acid bacteria was 8% and 10%, the change trend of total acid was basically the same, the acid production rate was faster from 12 to 30 h. At 36 h of fermentation time, the total acid concentration in the fermentation mash with 8% inoculation amount was the highest. When the inoculation amount was 12%, the acid production rate was fastest in a short time, but the total acid content in the final fermentation mash was lower than the total acid content of 8% and 10% inoculation amount (Fig.3). This may be because when the inoculation amount was too large, the nutrients in the fermentation broth did not increase correspondingly, but the acetic acid bacteria need to consume more nutrients during growth and reproduction, leading to the decline in the amount of acetic acid produced and a large inoculation amount would adversely affect the flavor of fermented products[13]. Combined with the experimental data analysis, the optimal inoculation amount was set at 8%.

Fig.3 Effects of inoculation amount of acetic acid bacteria on the total acid content of apple cider vinegar

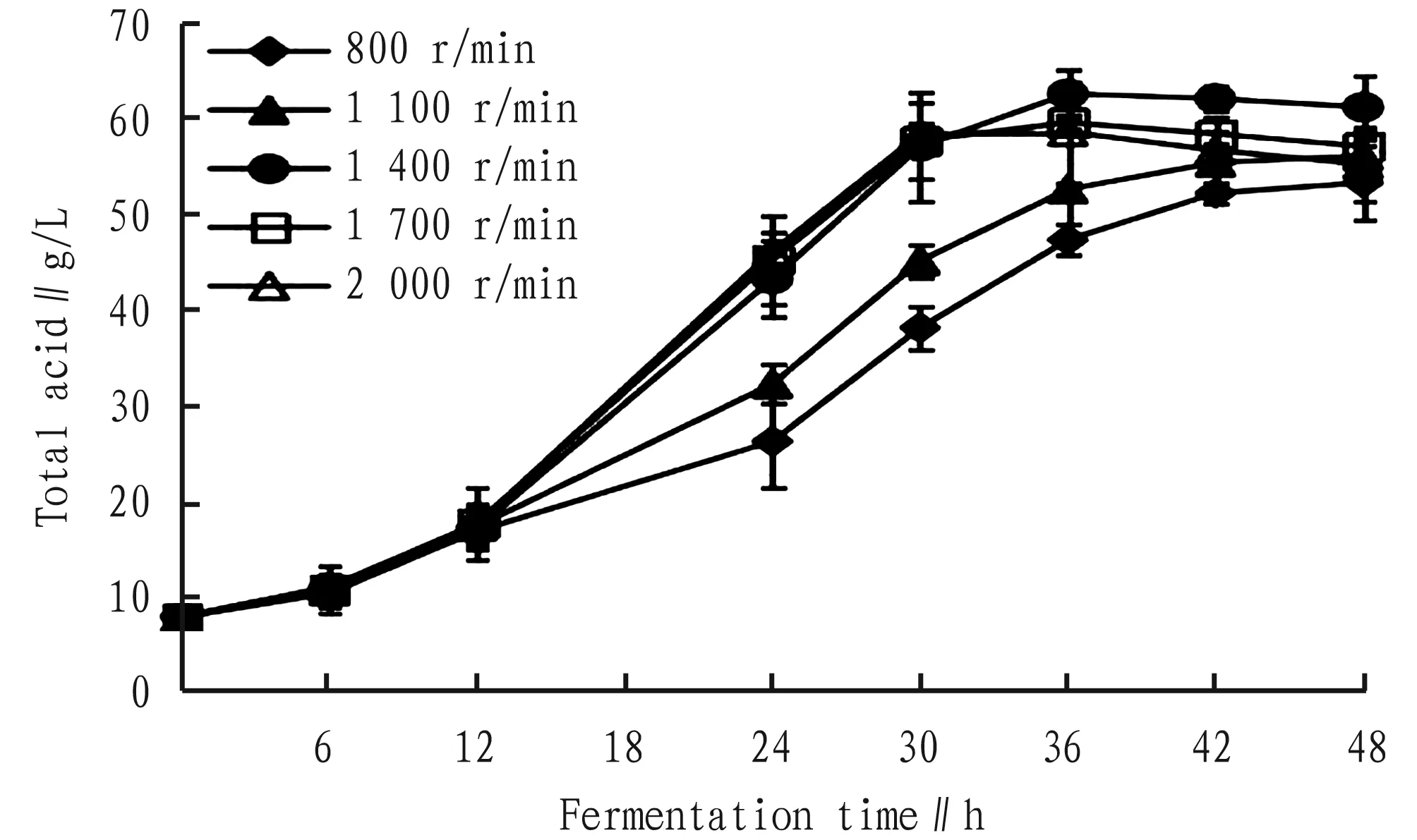

3.1.4Effects of and stirring speed on the fermentation total acid content of apple cider vinegar. Under the conditions of apple cider vinegar fermentation temperature of 33 ℃, fermentation time of 144 h, and inoculation amount of acetic acid bacteria of 8%, the stirring speed was set at 800, 1 100, 1 400, 1 700 and 2 000 r/min, we investigate the effects of the stirring speed on the total acid production. The stirring speed exerted a great effect on the fermentation of apple cider vinegar. There was a large correlation between the stirring speed and the dissolved oxygen in the fermentation broth. In the first 12 h of fermentation, because the acetic acid bacteria needed less oxygen, the stirring speed exerted little effect on the production of acetic acid; after 12 h of fermentation, when the stirring speed was 800 and 1 100 r/min, the production of acetic acid was slow due to the lack of dissolved oxygen in the fermentation broth, but the acetic acid production rate at the stirring speed of 1 100 r/min was significantly faster than that at the stirring speed of 800 r/min; when the fermentation rate was higher than 1 400 r/min, the total acid growth curve of fermentation time from 0 to 36 h was basically the same, but after 30 h, the total acid content in the mash at the stirring speed of 1 400 r/min was the highest (Fig.4). This may be because (i) too much dissolved oxygen makes the acetic acid bacteria grow vigorously and consumes a large amount of nutrients in the fermentation broth, and (ii) the high rotation speed causes the alcohol and acetic acid in the fermentation broth to volatilize, and the conversion rate in the later stage of fermentation continuously decreases. Thus, we determined the optimal stirring speed at 1 400 r/ min.

Fig.4 Effects of and stirring speed on the total acid content of apple cider vinegar

3.2 Response surface experiment

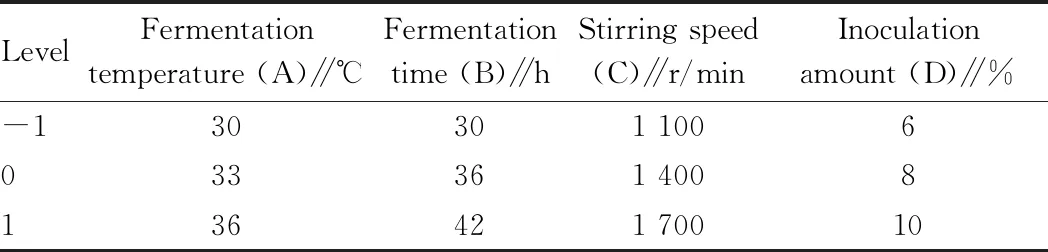

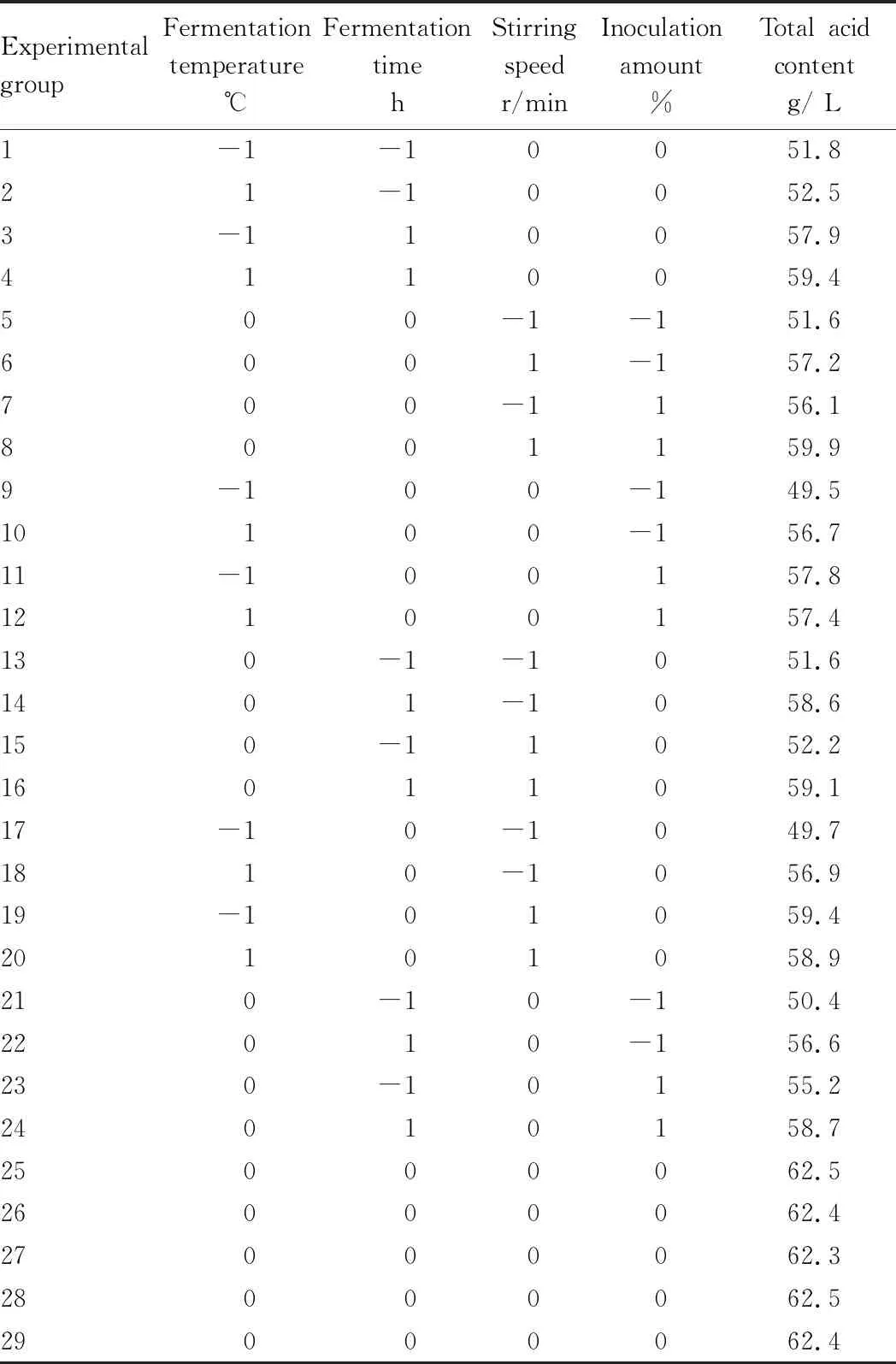

3.2.1Response surface analysis scheme, experimental results and variance analysis. On the basis of single-factor experiments, in order to study the effects of different factors on the production of total acid (acetic acid), we determined the optimal process parameters of apple cider vinegar fermentation, and selected fermentation temperature, fermentation time, stirring speed, and inoculation amount as the response surface optimization factors. According to the Box-Behnken design principle in the Design Expert 8.0 software, we designed a four-factor three-level response surface optimization analysis experiment, taking the total acid production in the fermentation broth as the response value (Y) expressed by -1, 0, and 1 to represent low, medium and high level factors. The experimental design and results are shown in Table 1 and Table 2.

Table 1 Factors and levels of response surface experiment

The results in Table 2 include 24 three-dimensional vertices consisting of values A, B, C, and D, and repeated test points with zero points in 5 areas. Based on regression analysis of the experimental results in Table 2, we obtained the quaternary quadratic regression equation of the total acid content in fermentation process of apple cider vinegar against fermentation temperature, fermentation time, stirring speed, and inoculation amount:

Y=60.42+1.31A+3.05B+1.84C+1.92D+0.20AB-1.92AC-1.90AD-0.025BC-0.68BD-0.48CD-2.35A2-2.83B2-1.95C2-2.46D2.

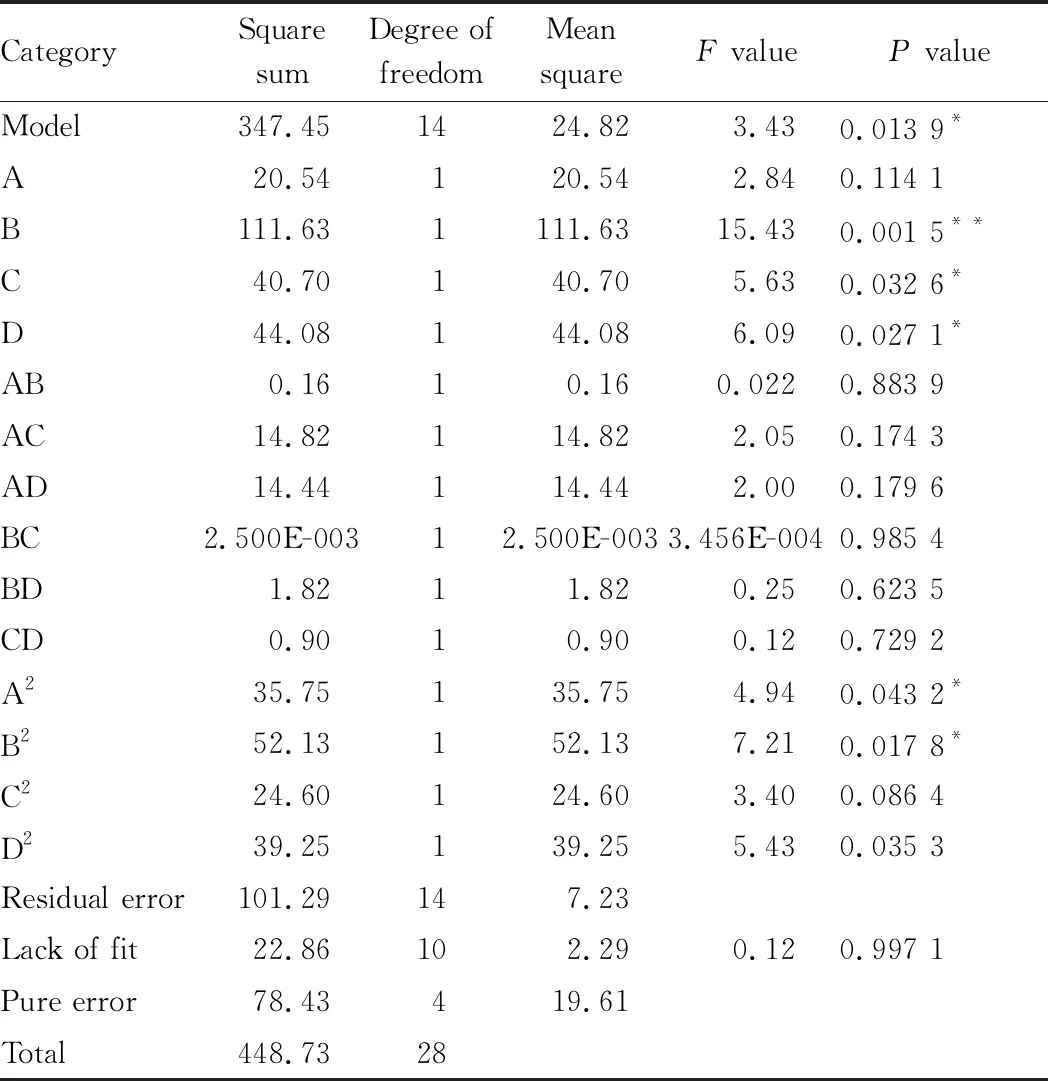

The results of mutation analysis and significance test on the obtained regression equation are shown in Table 3. From Table 3, it can be seen that the regression term of the model isP<0.013 9, indicating that the selected response surface regression model is significant. The lack of fitP=0.997 1>0.05, that is, the difference of the lack of fit is not significant, indicating that the quadratic regression model can significantly fit the effect of fermentation temperature, fermentation time, stirring speed, and inoculation amount on the total acid production in apple cider vinegar. Thus, this model can take the place of the real point of the experiment to analyze the experimental data. From Table 3, we can obtain the significance of the quaternary quadratic regression equation coefficient. The stirring speed (C), the inoculation amount (D), the quadratic term of the fermentation temperature (A2), and the quadratic term of the fermentation time (B2) had a significant effect on the total acid production in apple cider vinegar; the fermentation time (B) exerted an extremely significant effect on the total acid content of apple cider vinegar fermentation; the interactive term of fermentation temperature (A), fermentation temperature (A) and fermentation time (B), interactive term of fermentation temperature (A) and stirring speed (C), interactive term of fermentation temperature (A) and inoculation amount (D) , interactive term of fermentation time (B) and stirring speed (C), interactive term of fermentation time (B) and inoculation amount (D), and interactive term of stirring speed (C) and inoculation amount (D) had no significant effect on the total acid production in apple cider vinegar.

Table 2 Design and response values of RSM experiment

Table 3 Regression model variance analysis

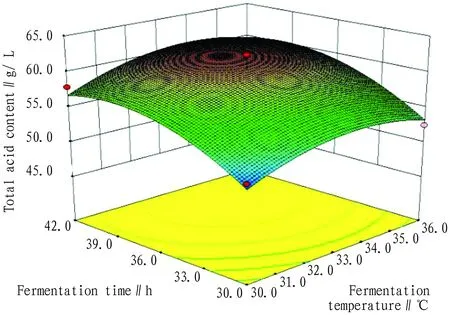

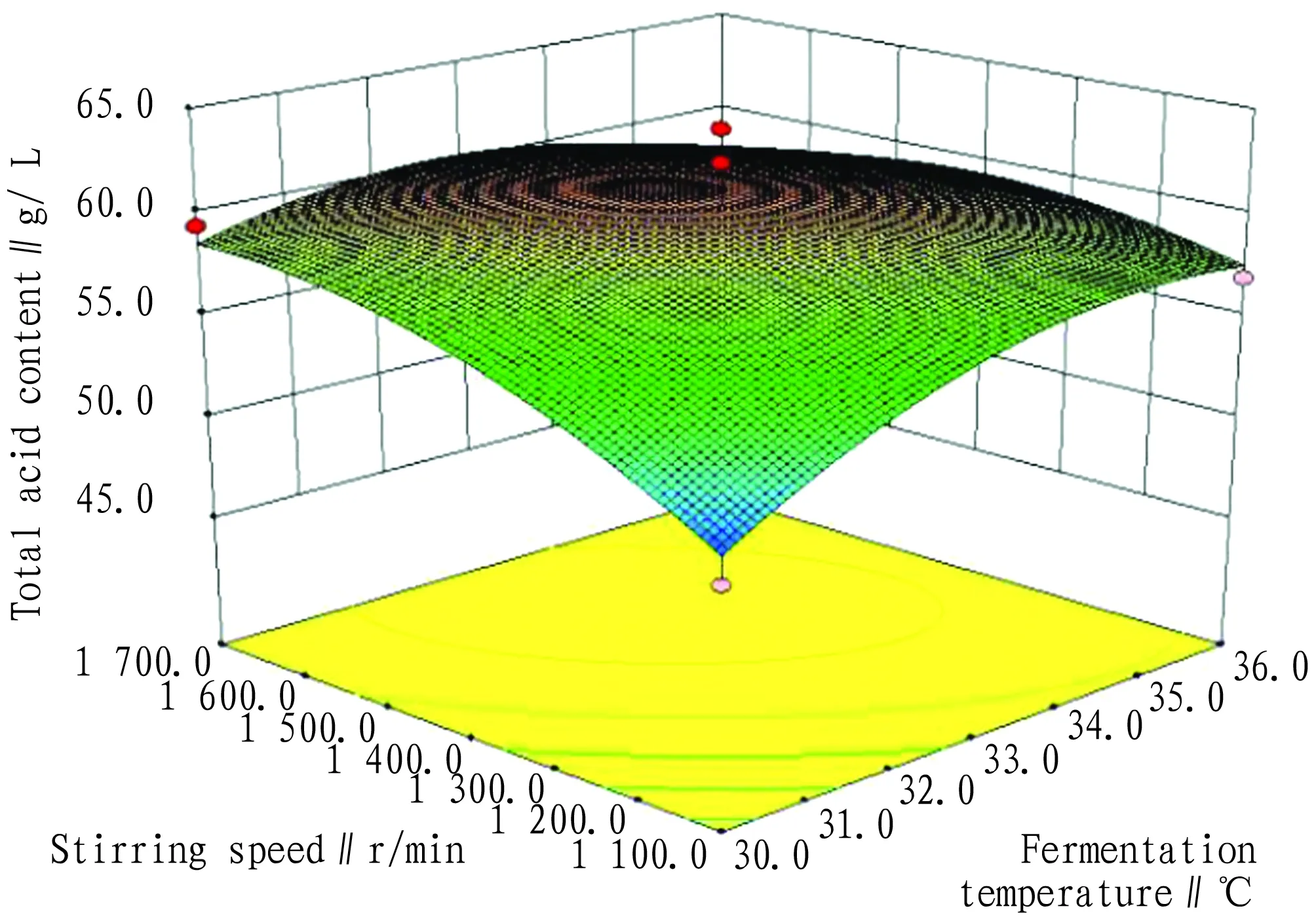

3.2.2Analysis of response surface model. With the aid of Design Expert 8.0.5b software, we performed quaternary quadratic regression fitting analysis on the experimental data in Table 2, and obtained the response surface plots (see Fig.5 to Fig.10). The effect of various factors and their interactions on the total acid production of apple cider vinegar can be intuitively reflected by the response surface plots. The contour lines at the bottom of the response surface plots can reflect the strength of the interaction between the two factors: an ellipse indicates a stronger interaction between the two factors, and a circle indicates a weaker interaction[14-15]. Fig.5 shows the effect of fermentation temperature and fermentation time on the total acetic acid content produced. From Fig.5, it can be seen that the interaction between fermentation temperature and fermentation time on the amount of acetic acid is strong, manifested relatively steep and dense contour lines. Fig.6 illustrates the effect of fermentation temperature and stirring speed on the amount of acetic acid produced. From Fig.6, it can be seen that fermentation temperature and stirring speed have a strong interactive effect on the amount of acetic acid produced.

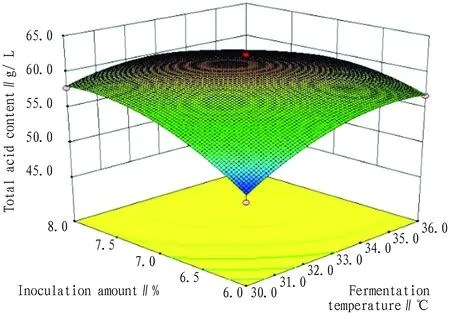

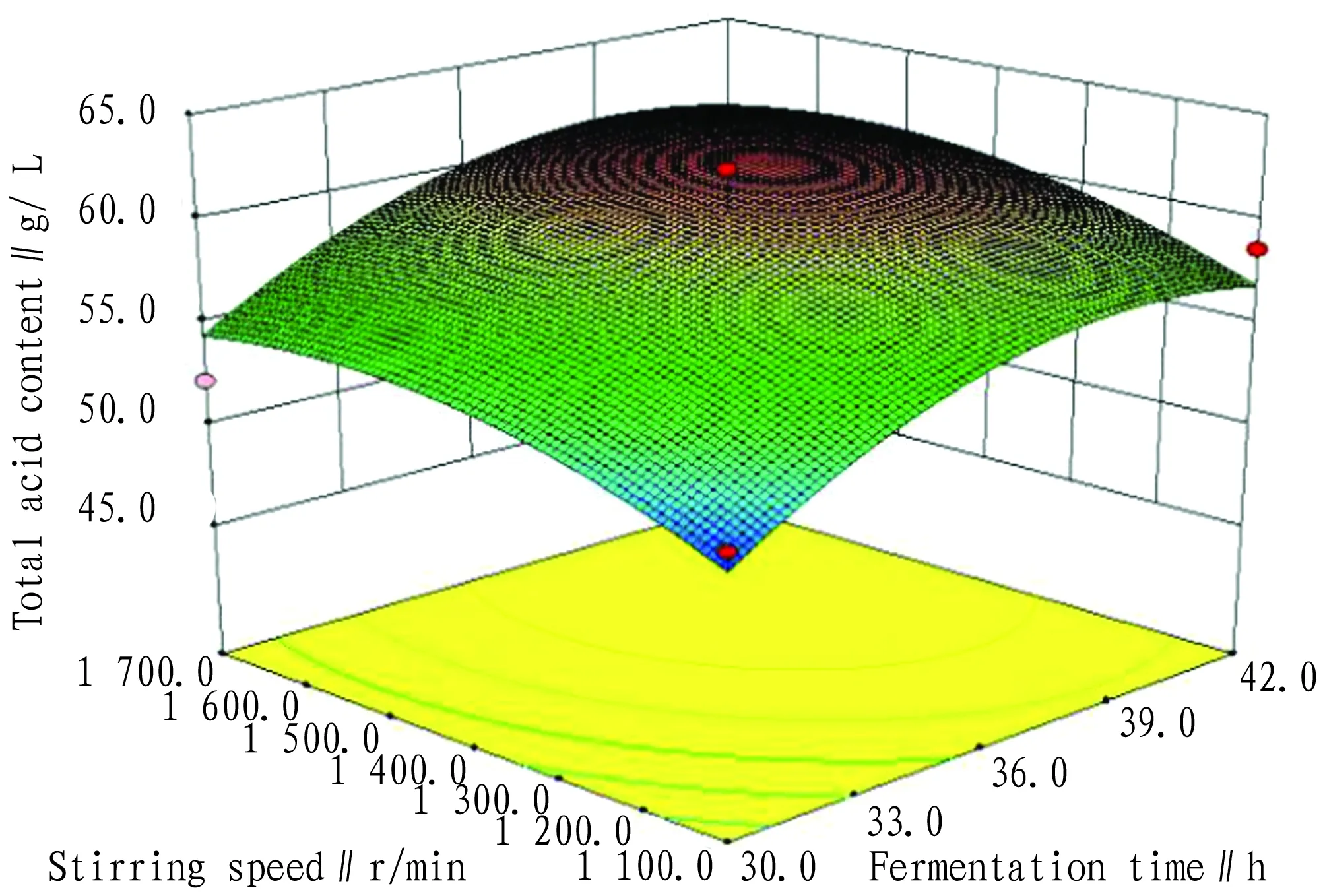

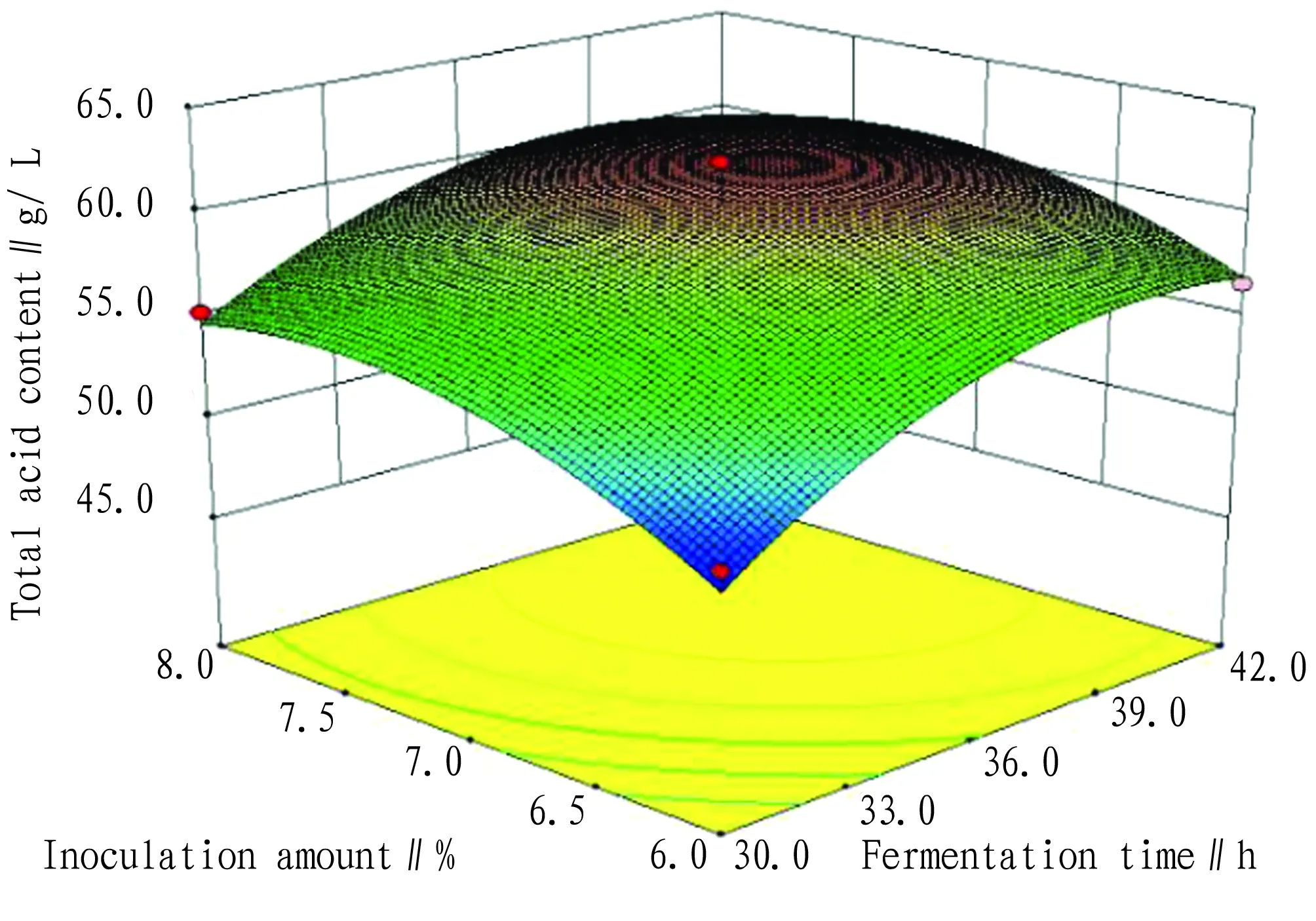

From Fig.7, it can be seen that the interaction between fermentation temperature and inoculation amount on the total acid production is strong, and the amount of apple cider vinegar fermentation inoculation is greater than the effect of fermentation temperature on the total acid production. Fig.8 illustrates the effect of fermentation time and stirring speed on the total acid production. From Fig.8, it can be seen that fermentation time and stirring speed have a strong interactive effect on the total acid production, and fermentation time and stirring speed have a high effect on the total acid production of apple cider vinegar. Fig.9 shows the effect of fermentation time and inoculation amount on total acid production. From Fig.9, it can be seen that the interaction between fermentation time and inoculation amount on total acid production is stronger, and the fermentation time has a slightly stronger effect than the inoculation amount on total acid of apple cider vinegar. Fig.10 illustrates the effect of stirring speed and inoculation amount on the total acid production. From Fig.10, it can be seen that stirring speed and inoculation amount have a strong interaction, and the inoculation amount has a higher effect than the stirring speed on the total acid production.

3.2.3Prediction and verification of optimal process parameters. With the aid of the response surface software, we optimized and predicted the experimental data, the optimal process parameters to obtain the total acid production of apple cider vinegar fermentation: fermentation temperature of 33 ℃, fermentation time of 39 h, stirring speed of 1 529.1 r/min, and inoculation amount of 7.3%, under such process parameters, the acetic acid production in the fermented mash was predicted to be 61.9 g/L. Combined with the actual test and the operability of production, we modified the technological parameters of acetic acid fermentation to: fermentation temperature of 33 ℃, fermentation time of 39 h, stirring speed of 1 500 r/ min, and acetic acid bacteria inoculation amount of 7%. Under such process parameter, we verified the prediction parameters of the model, and obtained that the total acid content of fermented apple cider vinegar was 62.22 g/L, which was very close to the predicted value of the model, indicating that the process parameters of the acetic acid fermentation obtained by response surface method optimization are reliable.

4 Conclusions

Taking Fuji apples as raw materials, through single-factor experiments and response surface analysis, we studied the effects of fermentation temperature, fermentation time, stirring speed, and inoculation amount on the total acid production of apple cider vinegar. Using response surface analysis method, we established the response surface model for the effects of fermentation temperature, fermentation time, stirring speed, and inoculation amount on the total acid content of apple cider vinegar fermentation. This model can be used for prediction. Within the optimization interval of the parameters of fermentation temperature, fermentation time, stirring speed, and inoculation amount taken in response surface experiments, the fermentation temperature had no significant effect on the total acid content of apple cider vinegar fermentation, the fermentation time had an extremely significant effect on the total acid content of apple cider vinegar fermentation, and the stirring speed and inoculation amount had a significant effect on the total acid content of apple cider vinegar fermentation, and the interaction of four factors (fermentation temperature, fermentation time, stirring speed and inoculation amount) had no significant effect on the total acid content. In conclusion, the optimal parameters for apple cider vinegar fermentation are fermentation temperature of 33 ℃, fermentation time of 39 h, stirring speed of 1 500 r/min, and acetic acid bacteria inoculation amount of 7%.

Fig.5 Effects of interaction between fermentation temperature and fermentation time on the total acid production of apple cider vinegar

Fig.6 Effects of interaction between fermentation temperature and stirring speed on the total acid production of apple cider vinegar

Fig.7 Effects of interaction between fermentation temperature and inoculation amount on the total acid production of apple cider vinegar

Fig.8 Effects of interaction between fermentation time and stirring speed on the total acid production of apple cider vinegar

Fig.9 Effects of interaction between fermentation time and inoculation amount on the total acid production of apple cider vinegar

杂志排行

Asian Agricultural Research的其它文章

- Empirical Research on E-commerce to Increase the Scale of Agricultural Products Trade: Taking Guangxi Hezhou Zhengfeng Modern Agriculture Co., Ltd. as an Example

- Current Status and Development Countermeasures of Forest Land Resources in Southern Cixi City

- Organic Carbon: A New Concept for Development of Modern Fertilizers and Plant Nutrition Theory

- An Empirical Analysis on the Impact of Rural Financial Development on the Income Gap between Urban and Rural Residents in Heilongjiang Province

- Research on the Problem Investigation and Standardized Improvement Paths of Farmers’ Cooperatives

- A Preliminary Study on the Rational Utilization of Land Resources in the Poverty-Stricken Mountainous Areas in the Upper Reaches of the Yangtze River: A Case Study of Xueshan Township