Effects of Straw Utilization Methods on Dry Matter Production and Yield of Japonica Rice in Northern China

2020-03-18

Liaoning Tieling Academy of Agricultural Sciences, Tieling 112616, China

Abstract To study the effects of straw utilization methods on dry matter production and yield of japonica rice in northern China, taking the super japonica rice Shennong 265 as the test material, using the planting method of seedling transplanting, setting four treatments, namely, the conventional production, directly returning straws to field (6 t/ha), returning straws to field at low amount of biochar (2 t/ha) and returning straws to field at high amount of biochar (40 t/ha), this paper analyzed the changes in production and yield of super japonica rice Shennong 265. According to the experimental results, compared with the conventional production, after the straws were directly returned to the field, the dry matter accumulation of japonica rice was insufficient, and the leaf output rate and contribution rate were significantly reduced by 41.19% and 34.69%, respectively; the number of filled grains per panicle, 1 000-grain weight, and panicles per plant showed negative effect, leading to a decline in the yield; under the condition of returning straws to field at high amount of biochar, the dry matter accumulation showed a decline trend, both the leaf and stem sheath significantly reduced by 21.41% and 17.43%, and the number of filled grains per panicle also declined; under the condition of returning straws to field at low amount of biochar, the dry matter accumulation increased, and the leaf contribution rate increased by 11.68%, the number of filled grains per panicle, 1 000-grain weight, and panicles per plant showed positive effect, showing the potential of yield increase. In conclusion, returning suitable straw biochar to field (2 t/ha) is favorable for promoting the japonica rice production in northern China.

Key words Straw, Biochar, Japonica rice, Dry matter production

1 Introduction

For a long time, a large amount of straw resources have not been fully and properly utilized, they are just burned or discarded, which not only causes great waste of biomass resources, but also aggravates the greenhouse effect and environmental pollution. Therefore, it is an important work to explore the efficient utilization of straws, it concerns the resources, environment and sustainable development of agriculture. The direct return of straw to the field can increase the fertility and rice yield[1]. However, due to cold water irrigation and cold climatic factors, the cold paddy fields in northern China have lower soil temperature, there is a problem that straws are difficult to be decomposed after returning directly to the field, accordingly leading to floating rice seedlings[2]. With the progress in the straw thermal cracking carbonization technology and the development of industrial model, an in-depth study and proper utilization of straw biochar returning to the field technology will have great significance for the high yield, high efficiency and sustainable development of japonica rice in northern China.

Direct return of straws to field can improve soil structure and physical and chemical properties, increase nutrient recycling efficiency, optimize farmland ecological environment, and avoid resource waste and environmental pollution[3]. However, if the amount of straw is improper or the pressing quality is not good, direct return of straws to field may produce negative effects such as allelopathy, nitrogen competition, and insects and diseases, as well as runt seedlings, leading to yield decline[4-5]. Carbonized straw in field can rapidly increase the soil stability carbon storage, improve nutrient utilization, increase the photosynthetic efficiency of rice leaves, and increase the dry matter accumulation of aboveground rice and yield of rice[2, 6-7], but the yield increase effect of the biochar is connected with many factors such as the application rate, soil type and environmental conditions, so the uncertainty is high[8].

At present, the research on straw returning to field and carbonization is mainly concentrated in warm and humid tropical or subtropical regions. There are few studies on paddy fields in the northern cold regions. The northeastern China is the main producing area of high quality japonica rice, and takes up a large agricultural proportion and many straw resources. The research on the impact of biochar on the dry matter production of japonica rice in this region is of great value for improving and deepening the understanding of the agronomic effect of biochar.

In this experiment, we selected the representative super japonica rice Shennong 265 as the test material, using the planting method of seedling transplanting, we studied the effects of straw utilization methods on the dry matter production and yield of japonica rice at different growth stages, to provide a theoretical reference for the application of straw biochar in the production of northern japonica rice.

2 Materials and methods

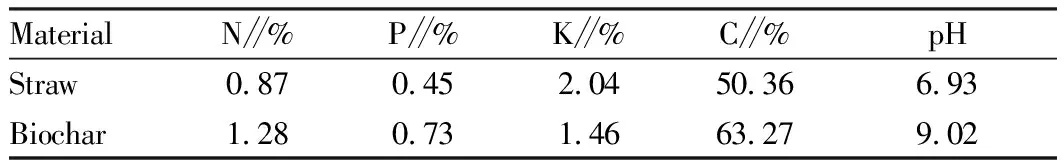

2.1 Experimental materialsWe took super japonica rice Shennong 265 as the test variety, which had 15 main stem leaves and had the characteristics of compact plant, strong tillering ability, and erect panicle type. The test straws were pulverized into 0.5-1.0 cm small sections. The biochar was produced by the Liaoning Biochar Engineering Technology Research Center under the condition of 400-500 ℃ pyrolysis and anoxic conditions, and about 1/3 of the straws became 1.5-2.0 mm biochar. The main physical and chemical properties of straw and biochar are listed in Table 1.

Table 1 Main physical and chemical properties of straw biochar

MaterialN∥%P∥%K∥%C∥%pHStraw0.870.452.0450.366.93Biochar1.280.731.4663.279.02

2.2 Experiment designThe experiment was performed in the rice experimental field of Tieling Academy of Agricultural Sciences. The soil nutrient indicators at 0-20 cm soil layer were as follows: 1.06 g/kg of total nitrogen, 0.85 g/kg of total phosphorus, 17.24 g/kg of total potassium, 93.64 mg/kg of available nitrogen, 38.28 mg/kg of available phosphorus, and 75.06 mg/kg of available potassium, 10.73 g/kg of organic carbon, and pH 6.36. Four treatments were set. (i) Conventional production (control): conventional fertilization (456.5 kg/ha of 46% urea, 875 kg/ha of 12% calcium phosphate and 202 kg/ha of 52% potassium sulfate), denoted as CK; (ii) Direct return of straws to field: on the basis of CK, applied 6 t/ha of straws, denoted as S; (iii) Returning straws to field at low amount of biochar: on the basis of CK, applied 2 t/ha of biochar (calculated as per straws converted to 30% biochar), denoted as C1; (iv) returning straws to field at high amount of biochar: on the basis of CK, applied 40 t/ha of biochar, denoted as C2.

The experiment was carried out in 2013 and 2014. Using the planting method of seedling transplanting, the rice was sown on April 18, 2013, transplanted on May 28, harvested on October 8, 2013, and another time the rice was sown on April 14, 2014, transplanted on May 27, and harvested on October 9, 2014. The specification of seedling transplantation was 30 cm×13.3 cm, and 3 seedlings per hole, randomized block design, each treatment was repeated 3 times, 12 blocks in total, and the block area was 21 m2. Each block was arranged separately with ridge, provided with water supply and drainage channels for separate irrigation and drainage. Nitrogen fertilizer was applied at the ratio of 5∶3∶2 (base fertilizer: tillering fertilizer: panicle fertilizer). Straws and biochar were 100% applied before rice transplanting, evenly sprinkled to the soil surface, then rotary tillering for uniform mixing, superphosphate was 100% applied as base fertilizer, potassium sulfate was used as base fertilizer and panicle fertilizer for separate application of 50%. Other cultivation management measures were consistent with the conventional rice field production procedures.

2.3 Measurement items and methods

2.3.1Dry matter accumulation. At the tillering stage, jointing stage, heading stage, grain filling stage, and maturing stage, 5 holes of representative plants were selected from each block. Leaves, stem sheaths, and panicles were separated, dried (in blast drying oven, fried at 105 ℃ for 30 min, and dried at 80 ℃), and dry weight was weighed.

2.3.2Yield and components of yield. In each block, selected 6 m2to harvest, dried and converted to standard moisture content, then calculated the yield; investigated 10 holes of plants in each block to measure the panicles per plant, took the average panicles of each hole as the standard, and selected 4 holes with representative plant height and panicle type in each block, determined the traits such as total number of grains per panicle, seed setting rate, and 1 000-grain weight.

2.3.3Calculation methods for related parameters. Output rate (%)=[Dry weight of leaf (stem sheath at heading stage)-Dry weight of leaf (stem sheath at maturing stage)]/Dry weight of leaf (stem sheath at heading stage)×100; Contribution rate (%)=Dry weight of leaf (stem sheath at heading stage)-Dry weight of leaf (stem sheath at maturing stage)]/(Dry weight of panicle at maturing stage-Dry weight of panicle at heading stage)×100.

2.4 Data statistics and analysisIn this experiment, all data were processed with the aid of Microsoft Excel 2010. Besides, one-way ANOVA was performed for the test data of different treatments with the aid of DPS 7.05 software. TheLSDmultiple comparison was carried out to judge the difference between the treatments (P<0.05). All the measurement results were expressed as mean±standard deviation.

3 Results and analysis

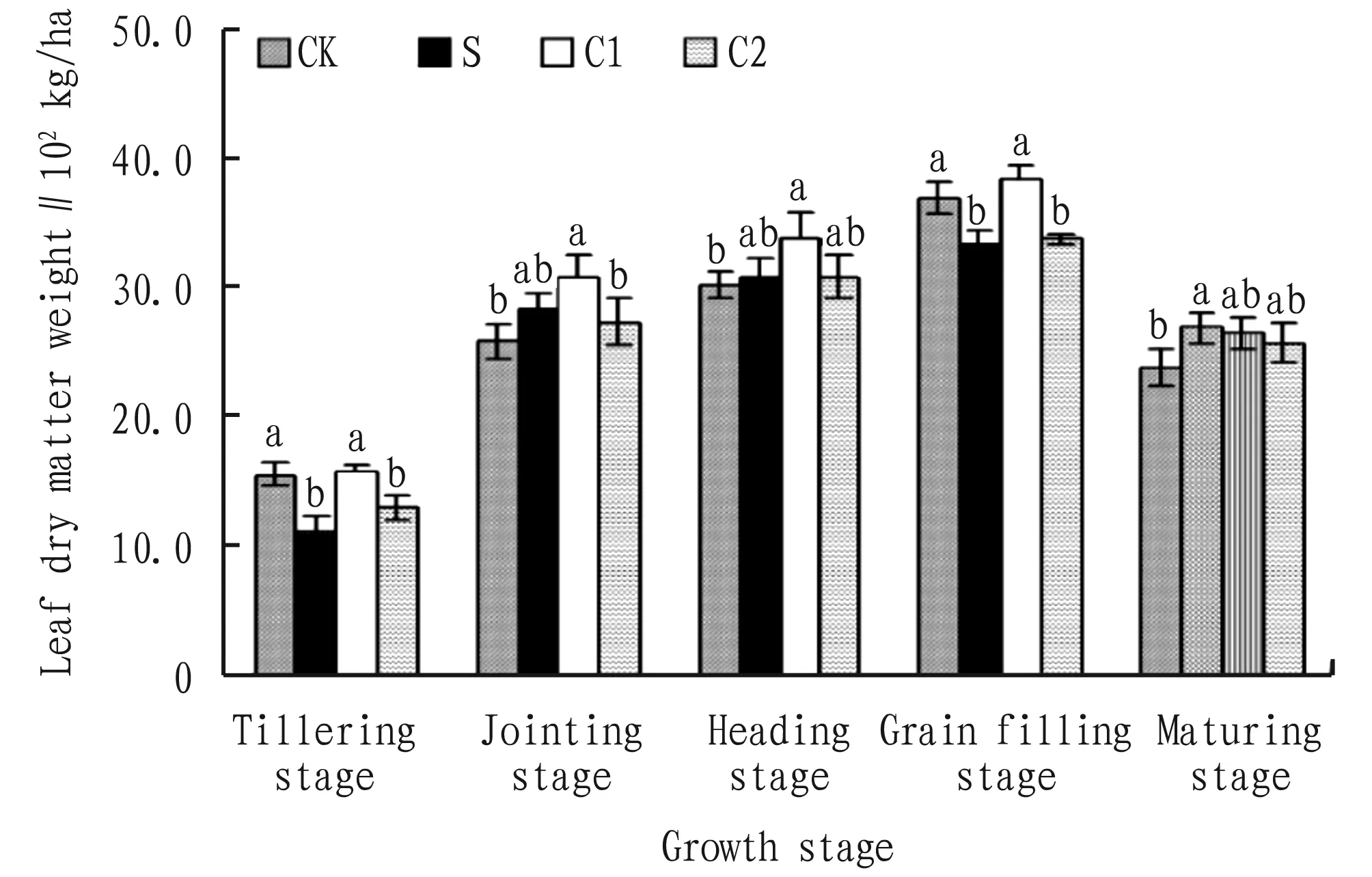

3.1 Dry matter accumulation of leavesLeaf is the main organ for intercepting light energy and performing photosynthesis, and the dry matter accumulation of leaves has an important effect on the formation of rice yield. From Fig.1, it can be seen that the dry matter weight of leaves showed an increasing trend from the tillering stage to the grain filling stage in each treatment, and it showed a decline trend from the grain filling stage to the maturing stage because the large portion of nutrients is transferred to the panicles after the grain filling. Compared with CK treatment, at the tillering stage, the leaf dry matter weight of S and C2 treatments at the tillering stage decreased significantly by 28.14% and 16.45%, respectively, and C1 treatment increased by 2.16%, the difference was not significant; at the jointing stage, the S, C1, and C2 treatments increased by 9.82%, 19.12%, and 5.68%, respectively, and C1 was significantly higher than CK and C2 treatments; at the heading stage, S, C1, and C2 treatments increased by 4.67%, 14.92%, and 4.90%, respectively, and C1 was significantly higher than CK treatment; at the grain filling stage, S, C1 and C2 treatments increased by -9.95%, 3.80%, and -8.78%, respectively, the leaf dry matter of S and C2 treatments decreased significantly, and the difference with C1 was not significant; at the maturing stage, S, C1, and C2 treatments increased by 13.06%, 11.10%, and 7.87%, respectively, and S treatment was significantly higher than CK, the difference between other treatments was not significant. These indicate that the application of straw and high amount of biochar has effects of decreasing the leaf dry matter weight at the tillering stage and grain filling stage, and increasing the leaf dry matter at other stages, while the returning straws to field at low amount of biochar has the positive effect on the leaf dry matter weight in the whole growth stage, especially, it has significantly promotion effect at the jointing stage and heading stage.

Note: different small letters in the figure denote significant difference between different treatments at the same growth stage (P<0.05). The same in Fig.2 and Fig.3.

Fig.1 Effects of returning straws and biochar to field on dry matter accumulation of leaves

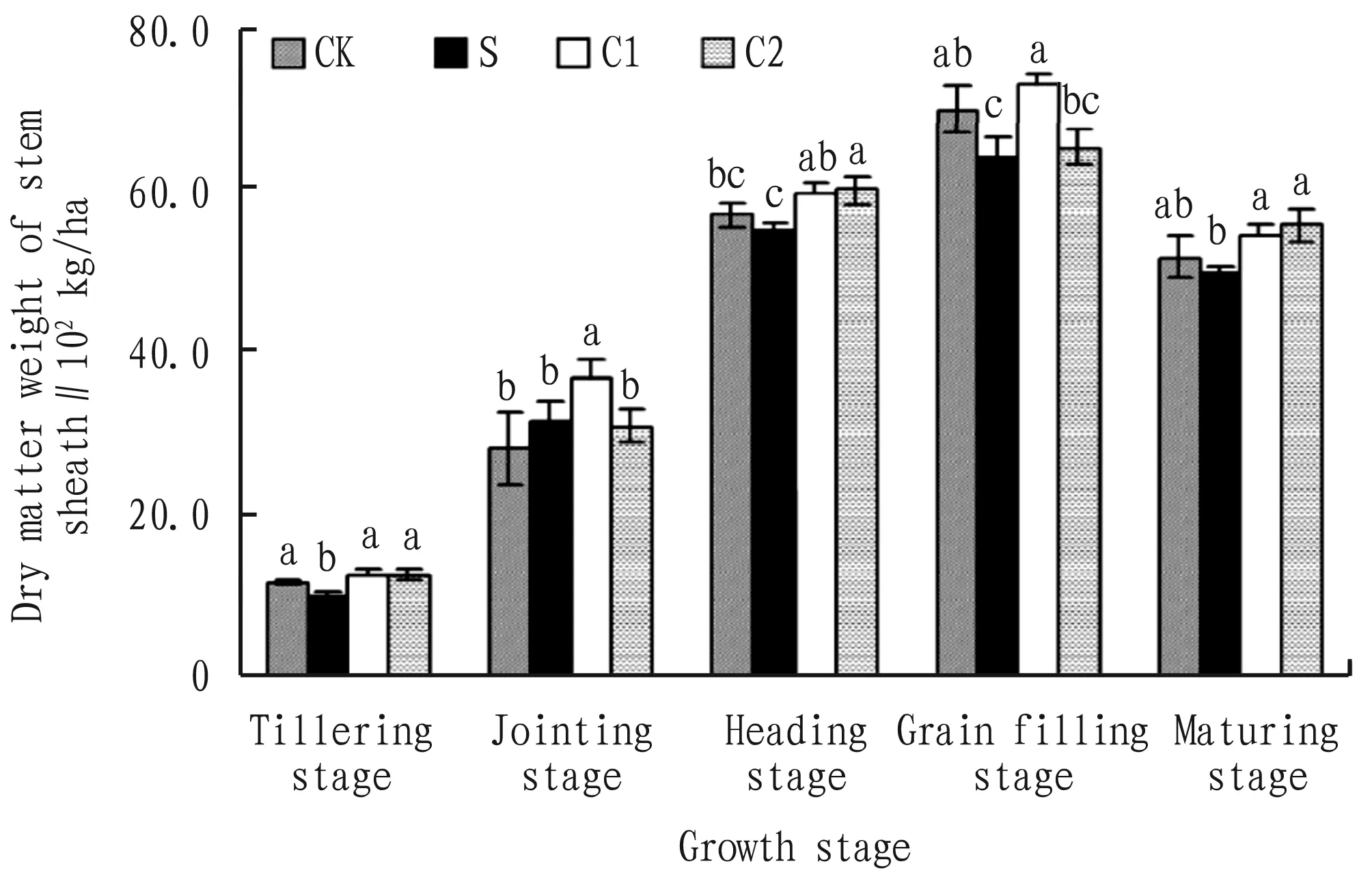

3.2 Dry matter accumulation of stem sheathsAs shown in Fig.2, the dry matter weight of stem sheath under each treatment showed an almost straight line increase trend from the tillering stage to the grain filling stage, then it declined sharply at the maturing stage. Compared with CK treatment, at the tillering stage, the dry matter of stem sheath in S treatment decreased significantly by 15.63%, and the treatment of C1 and C2 increased by 6.78% and 8.26%, respectively, the difference was not significant; at the jointing stage, S, C1, and C2 treatments increased by 11.93%, 31.38%, and 9.79%, respectively, and C1 was significantly higher than CK treatment, and S and C2 treatments were not significantly different from CK treatment; at the heading stage, the S, C1, and C2 treatments increased by -2.99%, 4.47%, and 5.53%, respectively, C2 treatment was significantly higher than the control, and S and C1 treatments did not reach significant level; at the grain filling stage, S and C2 treatments were 8.35% and 6.77% lower than CK treatment, respectively, and C1 treatment increased by 4.53%, the difference between S and CK treatments was significant, and the difference between C1 and C2 treatments was not significant; at the maturing stage, compared with CK treatment, S, C1, and C2 treatments increased by -3.88%, 4.98%, and 7.37%, respectively, and the difference was not significant. These indicate that the return of straws to field at the tillering stage and grain filling stage significantly reduced the dry matter weight of stem sheath, returning straws to field at low amount of biochar at jointing stage had significant promotion effect, while returning straws to field at high amount of biochar can significantly increase the dry matter weight of stem sheath at the heading stage.

Fig.2 Effects of returning straws and biochar to field on dry matter accumulation of stem sheaths

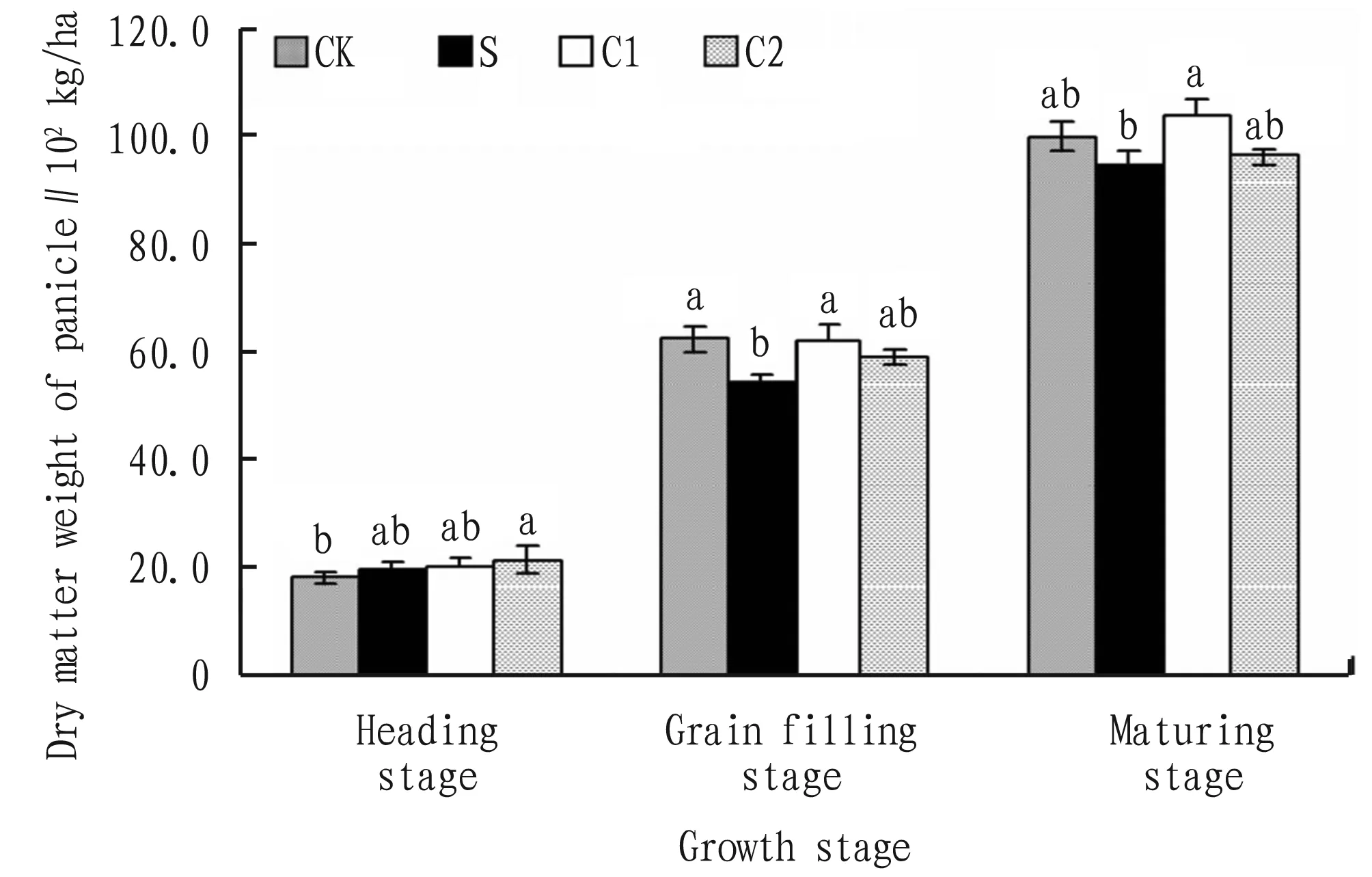

3.3 Dry matter accumulation of panicleFrom Fig.3, it can be seen that with the advance of the growth stage, the dry matter weight of the panicle increases continuously. At the heading stage, S and C1 treatments increased by 8.97% and 10.62%, respectively, and the difference was not significant, while the C2 treatment increased significantly by 18.31% compared with CK treatment; at the grain filling stage, S treatment was significantly lower than CK by 12.67%, while C1 and C2 treatments decreased by 0.05% and 5.13%, respectively, and the difference was not significant; at the maturing stage, S and C2 treatments decreased by 5.23% and 3.68% compared with CK treatment, and C1 treatment increased by 3.67%, but the difference was not significant. These indicate that the return of straws to field at the grain filling stage significantly reduced the dry matter weight of panicle, returning straws to field at low amount of biochar had little effect on the dry matter weight of panicle, while returning straws to field at high amount of biochar could significantly increase the dry matter weight of panicle, but it showed negative effect at the late period of the grain filling stage.

Fig.3 Effects of returning straws and biochar to field on dry matter accumulation of panicle

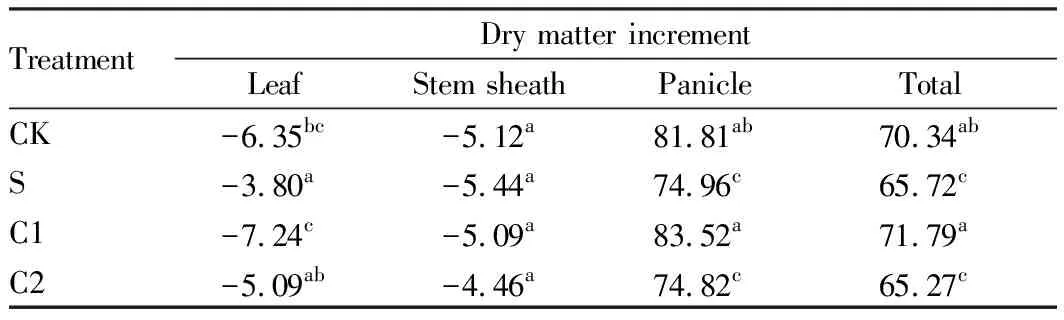

3.4 Dry matter incrementAccording to Fig.2, from the heading stage to the maturing stage, C1 treatment had the highest absolute value of leaf dry matter increment, up to 7.24×102kg/ha, which was significantly higher than S and C2 treatments, but the difference with CK treatment was not significant; S treatment was significantly lower than CK treatment, up to 40.16%, and the difference between C2 treatment and CK treatment was not significant; for the absolute value of stem sheath dry matter increment, S treatment was the highest, up to 5.44×102kg/ha, but the difference between treatments did not reach the significant level; C1 treatment had the highest panicle dry matter increment, up to 83.52×102kg/ha, which was significantly higher than S and C2 treatments, but the difference with CK treatment was not significant, and S and C2 treatments decreased by 8.37% and 8.54% compared with CK treatment; for the total dry matter increment of leaves, stem sheaths, and panicles, the performance was consistent with that of panicle dry matter increment, C1 treatment was significant higher than S and C2 treatments, but the difference with CK treatment was not significant, and S and C1 treatments decreased by 6.57% and 7.21% compared with CK treatment. These indicate that under the condition of return of straws to field, from the heading stage to the maturing stage, the dry matter increment of rice leaves and panicles showed a significant decline trend, while returning straws to field at low amount of biochar had little effect on the leaf and panicle dry matter increment, but significantly reduced the panicle dry matter increment; in terms of the stem sheath dry matter increment, there was no significant difference between each treatment; in terms of the total dry matter increment of leaves, stem sheaths, and panicles, the performance trend was consistent with the panicle dry matter increment.

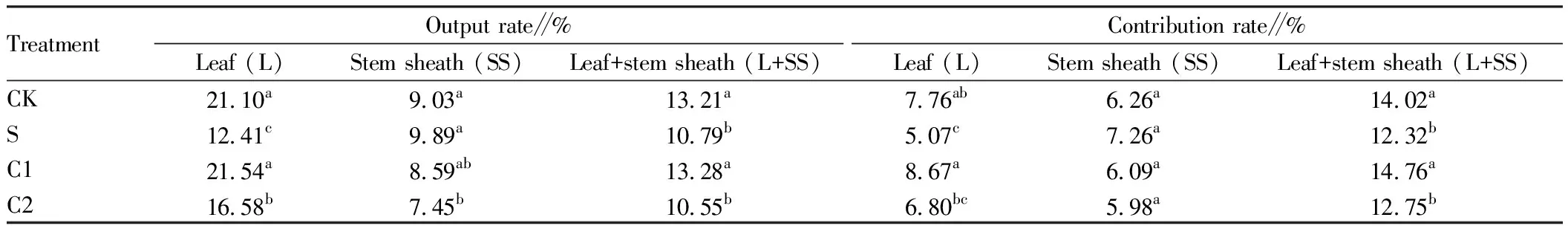

3.5 Output rate and yield contribution rateAccording to Table 3, the leaf output rate of S, C1 and C2 treatments were 41.19%, 2.11% and 21.41% lower than CK treatment, respectively, and S and C2 treatments were significantly lower than CK treatment, and the difference between C1 and CK treatments was not significant; the stem sheath output rate of S and C1 treatments were not significantly different from CK treatment, while C2 treatment was significantly lower than CK treatment by 17.43%; in terms of the overall output rate of leaves and stem sheaths, S and C2 treatments were significantly lower than CK treatment, decreasing by 18.34% and 20.16%, respectively, while the difference between C1 and CK treatments was not significant. These indicate that returning straws at high amount of biochar to field significantly reduced the output rate of leaf, and leaf+stem sheath, while returning straws to field at low amount of biochar had little effect on the output rate of leaf+stem sheath. Besides, returning straws to field at low amount of biochar had little effect on the output rate of stem sheath, while returning straws to field at high amount of biochar significantly reduced the output rate of stem sheath.

Table 2 Difference in dry matter increment from heading stage to maturing stage under return of straws and biochar to field(×102kg/ha)

TreatmentDry matter incrementLeafStem sheathPanicle Total CK-6.35bc-5.12a81.81ab70.34abS-3.80a-5.44a74.96c65.72cC1-7.24c-5.09a83.52a71.79aC2-5.09ab-4.46a74.82c65.27c

Note: different small letters in the same column denote significant difference between treatments (P<0.05). The same as below.

Table 3 Difference in output rate and contribution rate between organs under returning straws and biochar to field

TreatmentOutput rate∥%Leaf (L)Stem sheath (SS)Leaf+stem sheath (L+SS)Contribution rate∥%Leaf (L)Stem sheath (SS)Leaf+stem sheath (L+SS)CK21.10a9.03a13.21a7.76ab6.26a14.02aS12.41c9.89a10.79b5.07c7.26a12.32bC121.54a8.59ab13.28a8.67a6.09a14.76aC216.58b7.45b10.55b6.80bc5.98a12.75b

In terms of the contribution rate of leaf, C1>CK>C2>S, C1 treatment increased by 11.68% compared with CK treatment. The difference between C2 and CK treatments was not significant, and S treatment was significantly lower than CK treatment by 34.69%; in terms of the contribution rate of stem sheath, there was little difference between treatments, and the difference with CK treatment did not reach the significant level; as the the overall contribution rate of leaf and stem sheath, S and C2 treatments were significantly lower than CK treatment by 12.08% and 8.96%, respectively, while C1 treatment was 5.30% higher than CK treatment, but the difference was not significant. These indicate that the return of straws to field significantly reduces the contribution rate of leaf, while returning straws to field at low amount of biochar increased the contribution rate of leaf, but the effect of high amount of biochar was not significant; returning straws at low and high amount of biochar exerted little effect on the contribution rate of stem sheath, but returning straws at high amount of biochar significantly reduced the contribution rate of leaf+stem sheath.

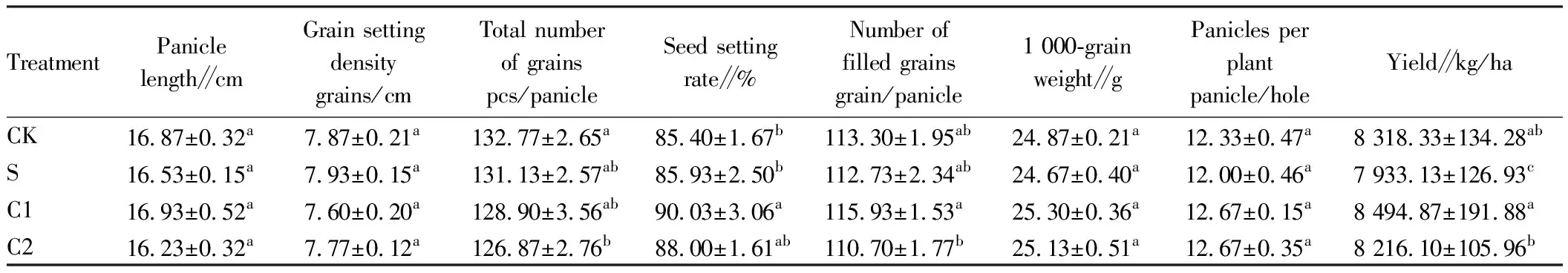

3.6 Yield and difference between yield componentsThe yield of rice is the combined action of the number of filled grains per panicle, 1 000-grain weight, and unit area panicles per plant. Therefore, coordinating the relationship between yield components is the key for realizing high yield of rice. According to Table 4, returning straws and biochar to field had little effect on the panicle length and grain setting density, but reduced the total number of grains per panicle to 125.87-132.77 pcs/panicle, manifested as C2

Table 4 Yield and difference between yield components under returning straws and biochar to field

TreatmentPaniclelength∥cmGrain settingdensitygrains/cmTotal numberof grainspcs/panicleSeed settingrate∥%Number offilled grainsgrain/panicle1 000-grainweight∥gPanicles perplantpanicle/holeYield∥kg/haCK16.87±0.32a7.87±0.21a132.77±2.65a85.40±1.67b113.30±1.95ab24.87±0.21a12.33±0.47a8 318.33±134.28abS16.53±0.15a7.93±0.15a131.13±2.57ab85.93±2.50b112.73±2.34ab24.67±0.40a12.00±0.46a7 933.13±126.93cC116.93±0.52a7.60±0.20a128.90±3.56ab90.03±3.06a115.93±1.53a25.30±0.36a12.67±0.15a8 494.87±191.88aC216.23±0.32a7.77±0.12a126.87±2.76b88.00±1.61ab110.70±1.77b25.13±0.51a12.67±0.35a8 216.10±105.96b

4 Conclusions and discussions

According to studies of other scholars, after the straws are returned to the field, the nutrients released by the straws and some small molecular substances have a great impact on the yield, but the yield increase effect is different due to different regions, farming methods, soil types, water and fertilizer operations, and years of returning to field[9-11]. In the opinion of Pei Penggangetal.[12], the return of straws to field had effects on rice growth and development, manifested as slow growth at the early stage, and rapid growth at the late stage, and tillering was slow but had strong stamina; according to the study of Li Chaosuetal.[13], the return of straws to field could extend the functional period of green leaves after rice flowering stage, which increased the proportion of photosynthetic product accumulation in the formation of yield. According to the experiment of Hanetal.[14], the return of straws to field at 3 t/ha had the most significant effect on yield increase; according to the study of Ye Wenpeietal.[15], the return of straws to field can increase the number of tillering and dry matter accumulation of aboveground part, it can significantly increase the early rice yield by 10.0%-12.9%; according to the study of Zhu Liqunetal.[16], the return of straws to field can reduce the spikelets per panicle, 1 000-grain weight, and yield by 12.1%, 5.7%, and 7.7%. According to the results of this experiment, the return of straws to field at 6 t/ha reduced the dry matter weight of leaves and stem sheaths significantly by 28.14% and 15.63% at the early stage of rice growth; photosynthetic material conversion is limited, and it significantly reduced the dry matter weight of panicle by 12.67% at the grain filling stage, the leaf output rate and contribution rate to yield significantly decreased by 41.19% and 34.69%, respectively, finally reducing the number of filled grains per panicle, 1 000-grain weight, and panicles per plant, leading to decline of the yield, possibly because degradation of straws under flooded anaerobic environment is prone to generate a large amount of harmful gases such as hydrogen sulfide, which is harmful to the growth of rice roots and influences the growth and development of rice[17]. In addition, high C/N value in the straws makes them decompose slowly in the soil, promote the microbes to move rapidly, and compete for nitrogen with the crop growth, resulting in nitrogen deficiency in the early stage of rice, inhibiting rice growth and low dry matter accumulation, but at the middle and late stages of growth, with the decay of straw, the nutrients fixed by microorganisms are gradually released into the soil, which tends to cause excessive supply of nitrogen, causing late maturity and harmful to the rice yield[18-19].

The yield effect of biochar is influenced by many factors such as biochar characteristics, application time, crop and soil types, fertility characteristics, and farmland fertilization management measures. In order to accurately understand the relationship between crop yield and biochar application, Jefferetal.[20]systematically analyzed the correlation between biochar application and crop productivity, and found that the average yield increase after biochar improvement of soil was about 10%, but the fluctuation was large (-28%-39%). The application of biochar is favorable for the growth and absorption of nutrients at the tillering and jointing stages of rice, and tinput of biochar (1.458 t/ha) could increase the yield by 9.78% compared with the single application of fertilizer[21]. According to the experiment carried out by Zhang Weimingetal.[22], application of biochar can increase the rice yield because it increases the panicles per hole, number of grains per panicle, and seed setting rate. Zhang Aiminetal.[23]believed that adding the biochar can increase the panicles and grains per panicle, and accordingly increasing the rice yield. According to the results of this experiment, application of low amount of biochar (2 t/ha) had positive effect on the dry matter accumulation of rice leaves and stem sheaths in the whole growth stage. Especially, at the jointing stage and heading stage, it could increase the dry matter weight of leaf by19.12% and 14.92%, respectively, which laid a foundation for improving the photosynthetic potential of the leaves in the later stage, significantly increased the contribution rate of leaves to yield (11.68%), so as to raising the direct supply capacity of rice photoassimilate product, to increase the dry matter accumulation in the panicle, obtain the suitable panicles, significantly increasing the seed setting rate by 5.42%, increasing the number of filled grains per panicle and 1 000-grain weight by 1.69% and 2.70%, realize the optimal combination of panicles, grains, and weight, accordingly increasing the yield. This is possibly because of the special microporous structure of the biochar surface. On the one hand, it provides an excellent living environment for habitat and reproduction of microorganisms, provides sufficient energy and nutrient sources, reduces competition among microorganisms, and enhances soil microbial function[24]. On the other hand, it can adsorb more nutrient ions and other organic substances to avoid nutrient loss, improve soil fertility and nutrient supply level[25], thus comprehensively coordinating the soil water, fertilizer, gas and heat during the whole growth period of rice. Besides, it can improve the light energy conversion efficiency, potential activity and open ratio of rice PSII reaction center, and improve the photosynthetic function of leaves at the grain filling stage[7].

According to findings of Asaietal.[26], combined application of biochar and nitrogen fertilizer can increase the rice yield; the rice yield increased with the amount of application, but when the application amount reached 16 t/ha, the rice yield would not increase due to lack of nitrogen element. In this experiment, at the application of high amount of biochar (40 t/ha), due to the insufficient dry matter accumulation of leaves at the early stage (decreasing by 16.45%), the leaf output rate decreased by 21.41%; at the late stage, the dry matter accumulation of panicles decreased, the number of grains per panicle significantly decreased, so the yield declined, which was consistent with findings of Deeniketal.[27], possibly because high amount application of biochar into soil led to fixation of soil N element, and reduced the availability of N element[28], which is harmful for absorption and utilization of rice to N elements, shortening the growth period, and accordingly leading to the yield decline. In addition, the biochar is alkaline, thus the high amount application of biochar will greatly increase the pH of the soil, influencing the growth of rice roots and the absorption of nutrients[29], which in turn affects soil microorganisms and crop growth, leading to the decline of rice yield. Moreover, biochar has a large specific surface area and adsorption capacity, thus the high amount application of biochar may lead to the competitive adsorption of nutrients with root systems, accordingly restricting the rice growth.

杂志排行

Asian Agricultural Research的其它文章

- Land Use Regionalization in Poor Counties in Mountainous Areas Based on Targeted Poverty Alleviation

- Effects of Cultivation Method on Seed Yield and Quality of Bitter Gourd

- Progress of Land Engineering Discipline and Comparative Study on Teaching Methods

- Changes in Utilization of Contracted Land in Xundian County of Yunnan Province in the Background of Poverty Alleviation

- Influencing Factors of Determination of Total Arsenic in Soil by Atomic Fluorescence (AFS-9760) Method

- Impacts of Nanchang Metro on Accessibility of Public Transport Network and Fairness of Travel for Indemnificatory Housing Residents