Effect of Heat Moisture Treatment Combined with Sodium Alginate on Physicochemical Properties of Normal Corn Starch

2020-01-08WANGYushengMEIXuanweiCHENHaihuaCHENJiangang

WANG Yusheng, MEI Xuanwei, CHEN Haihua,, CHEN Jiangang

(1. College of Food Science and Engineering, Qingdao Agricultural University, Qingdao 266109, China;2. Editorial Department of Journal of Qingdao Agricultural University, Qingdao 266109, China)

Abstract: The effects of heat moisture treatment (HMT) combined with sodium alginate (AG) on pasting properties, thermal properties, crystalline structures, and gel properties of normal corn starch (NCS) were investigated. NCS was subjected to HMT alone or in combination with AG (HMT-AG) under the following conditions: moisture content of 15%~ 35%,temperature of 80~120 ℃, and time of 1~15 h. The results showed that HMT-AG increased the pasting temperature of NCS,but significantly decreased its breakdown value, setback value, and gelatinization enthalpy (P < 0.05). Either treatment did not change the crystalline pattern of NCS. At moisture content above 25% (P < 0.05), HMT obviously decreased the relative crystallinity (RC) of NCS (P < 0.05) whereas the opposite was observe with HMT-AG. Under the conditions of moisture content of 25%, temperature of 120 ℃, and time of 6 h, HMT-AG resulted in more significant decreases in the viscosity,gelatinization onset temperature, and gel hardness of NCS compared to HMT alone (P < 0.05).

Keywords: heat moisture treatment; sodium alginate; gel hardness; pasting properties; thermal properties;crystalline structure

Starch is the most abundant reserve carbohydrate of many plants and it has gained importance as one of the most important material in food, paper, chemical, and pharmaceutical industry[1]. But the native starch has limited use in the industry[2]. At present, starch can be modified by chemical, physical, enzymatic, and genetic methods. Among these methods, the heat moisture treatment (HMT) presents a series of advantages. Heat moisture treatment belongs to physically modified method, which is considered safe for using in food products, and did not produce by-products of chemical reagents[3]. During the process of heat moisture treatment, the starch granules are conditioned to moisture levels below 35% and subjected to temperatures ranging from 84 to 120 ℃ for a certain period time ranging from 15 min to 16 h[3-4]. In addition, HMT is a method that is cost-effective and easy to be applied.

HMT causes the rearrangement of amylose and amylopectin chains in the starch, and therefore may modify its X-ray pattern, crystallinity, swelling power, amylose leaching, pasting and gelatinization properties, as well as its susceptibility to enzymatic or acidic hydrolysis, which also affect the starch rheological properties. As reported,HMT reduced the swelling power and solubility of the rice starch, and got a higher interest for application in foods with lower swelling, lower viscosity, and higher thermal stability[5]. Starches modified by HMT showed higher pasting temperature (PT), lower peak viscosity, and lower gelatinization enthalpy, while breakdown viscosity practically disappeared[6]. Similar observations of the HMT-starch properties have been found in the early reports[3,7].

Modification of starch with ionic gums followed by heating at high temperature for fixed time could be alternative to chemical modification which may improve the final properties and stability of starch-containing foodstuffs[8].We usually use dry heating treatment and hydrothermal treatment because that the temperature and moisture cause property alterations of starch with ionic gums. Chandanasree et al[9]carried out carboxy methyl cellulose along with sodium alginate (AG) followed by dry heating at 130 ℃ to modify cassava starch. Pramodrao et al[8]modified potato,sweet potato starch combined dry heating treatment with ionic gums (carboxy methyl cellulose and AG). Instead of the simple aqueous mixing of starches and gums, processes accompanied by heating such as dry heating[8-9]and heat moisture treatment[10]to provide new functionality to mixture products.

Generally, interest has increased to the effects of high drying temperatures on the physicochemical and functional properties of starch granules. In the presence of hydrocolloids, starches treated with heat modification often exhibited fine quality than native starches. Pramodrao et al[8]studied the properties of potato, sweet potato and taro starches modified by dry heating treatment with ionic gums,and the results showed that the ionic modification of the starch increased the water and oil binding capacities. Using differential scanning calorimeter (DSC), Chandanasree et al[9]concluded that high drying temperatures reduces the gelatinization and thus decreases the onset gelatinization temperature and the enthalpy, this may be due to heat induced disintegration of starch granules. In addition, high drying temperatures increased viscosity, starch can be applied in product where thickening properties are required. Dry heating treatment combined with adding hydrocolloids in starch also has been utilized in the early report[10].

Recently, HMT has been widely applied to modify starch from various sources of starch. However, there are few reports about the effects of heat moisture treatment combined with hydrocolloids on the physicochemical properties of starch. AG, as an ionic gum, was used in the food industry for its low cost, stable properties (such as gelling properties,thickening properties, and anti-retrogradation properties),unique pH sensitivity, and biocompatibility[11]. Shang Mengshan et al[12]used the method of dual heat moisture treatment to modify the molecular structure of the starch and affect the properties of starch.

Therefore, the object of this study was to evaluate the effect of heat moisture treatment conditions (heat moisture content, heat temperature, and heat time) on the physicochemical properties of normal corn starch (NCS) with or without AG addition. The results of this study can provide instructions on application of modified starch.

1 Materials and Methods

1.1 Materials and reagents

AG (the ratio of mannuronic acid to guluronic acid is about 1.17%) Qingdao Bright Moon Seaweed Group Co., Ltd., Shandong, China; NCS (amylose content of 26.2%) Binzhou Jinhui Corn Co. Ltd.,Shandong, China. All other reagents used were analytical grade.

1.2 Instruments and equipments

Model 4D rapid visco analyzer Newport Scientific,Australia; TA-XT Plus texture analyzer Stable Micro Systems Ltd., Surrey, England; DSC-1 differential scanning calorimeter Mettler-Toledo International Inc., Switzerland;Model D8-ADVANCE X-ray diffractometer Bruker AXS,Inc., Germany

1.3 Methods

1.3.1 Heat moisture treatment

The AG-NCS mixture was prepared according to the method of Chen Haihua et al[13]. AG was first dispersed in distilled water, with magnetic stirring for 30 min. Then, NCS was poured into the AG solutions and stirred vigorously. The mixture was dried at 40 ℃ in an oven and ground through 100 meshes, and ready to be used.

HMT with different moisture content: the NCS or AG-NCS mixture was conditioned to 15%, 20%, 25%, 30% and 35%moisture content for subsequent HMT. The amount of water needed to achieve the desired moisture content was added slowly with a burette and was mixed in a glass container at low speed and equilibrated at 25 ℃ for 24 h. Then the samples were heated at 120 ℃ for 6 h.

HMT with different treatment time: the NCS or AG-NCS mixture was conditioned to 25% moisture content for subsequent HMT. Then the samples were heated at 120 ℃for 1, 3, 6, 10, 15 h.

HMT with different treatment temperature: The NCS or AG-NCS mixture was conditioned to 25% moisture content for subsequent HMT. Then the samples were heated at 80,100 and 120 ℃ for 6 h, respectively.

The above treated samples were subsequently dried at 40 ℃ in an oven till moisture content lower than 10% and then ground, sieved with 100 meshes, and ready to be used.

The samples were named as HMT-NCS (NCS subjected to HMT), AG-NCS (NCS with the addition of AG, but without HMT), HMT-AG-NCS (NCS with the addition of AG and subjected to HMT), respectively.

1.3.2 Pasting properties

According to the method of Chen Haihua et al[13], the pasting properties of the samples were performed by using a rapid visco analyzer (RVA).

1.3.3 Gel hardness

According to the method of Shang Mengshan et al[12],gel hardness analysis was performed with a texture analyzer,using a P/0.5 probe (a type of cylinder probe with a 1.27 cm diameter).

1.3.4 Thermal properties

According to the method of Zhao Yang et al[11], the thermal properties of samples were determined by a DSC in the nitrogen flow.

1.3.5 X-ray diffraction

According to Chen Haihua et al[14]and Chen Long et al[15], X-ray diffraction analysis of the samples were performed using an X-ray diffractometer at 40 mA (tube current) and 40 kV (target voltage).

1.4 Statistical analysis

Analytical determinations for the samples were performed at least in triplicate. A comparison of the means was performed by a Tukey's test to a 5% level of significance by analysis of variance (ANOVA), using SPSS 17.0 software.

2 Results and Analysis

2.1 Pasting properties of HMT-NCS without AG addition

Pasting properties can provide information about the interactions between starch granules during heating process[16]. The RVA pasting parameters of NCS before and after HMT were summarized in Table 1-3. HMT had significant effects on pasting properties of NCS. All HMT increased the PT of NCS. The higher PT indicated that the reinforcement of intragranular bonds for the increased interactions between starch granules during HMT results in more heat requirement for structural disintegration and paste formation[17]. The PT of NCS before HMT was 76.3 ℃ and that of NCS after HMT ranged from 76.5 to 89.2 ℃, which increased by 0.2 to 12.9 ℃. The PT increased with increasing HMT moisture content and HMT temperature. But, when HMT time was prolonged, it was increased first (81.0 ℃ after HMT for 3 h) and then kept stable after HMT for more than 3 h. It has been reported earlier that HMT could increase the PT value of Indian water chestnut starch[18], corn starch[19],sweet potato starch[7], organic cassava starch[3], and normal potato starch[16]. The reason of the increase in PT can be ascribed as the partial disruption of the organized chain structure and the rearrangement of the disrupted molecules are promoted by HMT[7].

Table 1 Pasting properties of HMT-treated NCS with different HMT moisture contents

Table 2 Pasting properties of HMT-treated NCS with different HMT times

Table 3 Pasting properties of HMT-treated NCS with different HMT temperatures

After HMT, both the peak viscosity (PV) and final viscosity (FV) values of NCS decreased obviously. The results of lower paste viscosity and higher PT indicated that HMT strengthened the interactions among the starches granules. The lowest PV and FV values were found in HMT-NCS with HMT moisture content of 35%. Both PV and FV values decreased with increasing HMT moisture content,HMT temperature, or prolonging HMT time. When HMT moisture content varied from 15% to 35%, the PV value of HMT-NCS ranged from 214 to 78 RVU (decreased by 3 to 139 RVU as compared to NCS without HMT) and the FV value of HMT-NCS ranged from 223 to 87 RVU (decreased by 3 to 139 RVU) as compared to NCS without HMT. It has been reported earlier that HMT could reduce the PV and FV values of sorghum starch[20], normal potato starch[16], African yam bean starch[21], etc. The reduction in PV value may be ascribed as the increase in hydrogen bonding between starch chains and the degradation of amylose during HMT[22].Another plausible reason may be assumed to the low restricted swelling capacity and low leached amylose content as a result of the reorganization within the starch granules after HMT[18,23].

The breakdown (BD) value is an indication of the stability of starch granules to continuous heating and agitation. The setback (SB) value reflects the tendency of short-term retrogradation[24]. There was considerable decrease in the BD and SB values of NCS after HMT. Both of these two parameters decreased with increasing HMT moisture content and HMT temperature. With prolonging HMT time, the BD value changed slightly, while the SB value increased first and then decreased. The lowest BD and SB values were 0.4 and 10 RVU of HMT-NCS with HMT moisture content of 35% (decreased by 52.6 and 52 RVU as compared to NCS without HMT, respectively). The lower BD value suggested that granules were quite strong and resisted breakdown under shear and heat. The decrease of the BD value might be the increased interaction between starch chains during HMT[16]. The lower SB value suggested that associated tendency of starch chains on cooling had been retarded, which might be the insufficient reassociation of amylose molecules[25]. Another reason for low SB value might be associated with the amylose gelation as well as the presence of rigid swollen granules embedded within the leached amylose network[26]. The third reason of the lower SB value might be the additional interactions between amylose-amylose and/or amylopectin-amylopectin chains were promoted by HMT and resulted in the decrease of leached amylose[5]. These observations are in good accordance with those reported earlier[5,25,27].

2.2 Pasting properties of NCS after HMT-AG

As shown in Table 4-6, HMT-AG could considerably increase the PT of NCS, which was increased with increasing HMT moisture content, HMT temperature, or prolonging HMT time. When HMT temperature and time were constant, the PT of HMT-AG-NCS with HMT moisture content of 35% was 82.7 ℃, which was increased by 6.1 ℃as compared to that of HMT-AG-NCS with HMT moisture content of 15%. When HMT moisture content and temperature were constant, the PT of NCS after HMT-AG for 6 h was 80.1 ℃ and higher than that of AG-NCS without HMT (increased by 3 ℃). When HMT moisture content and time were constant, the PT of NCS after HMT-AG at 120 ℃was increased by 2.9 ℃ as compared to that at 80 ℃.

Table 4 Pasting properties of HMT-AG-treated NCS with different HMT moisture contents

Table 5 Pasting properties of HMT-AG-treated NCS with different HMT time

Table 6 Pasting properties of HMT-AG-treated NCS with different HMT temperatures

The PV, FV, BD and SB values of NCS after HMT-AG decreased with increasing HMT moisture content, HMT temperature, or prolonging HMT time. When the HMT temperature and HMT time were constant, the PV, FV, BD and SB values of NCS after HMT-AG with HMT moisture content of 35% were 146, 165, 0.6 and 19 RVU, respectively,decreased by 90, 95, 21.4 and 28 RVU as compared to those of AG-NCS without HMT. When the HMT moisture content and HMT temperature were constant, the PV, FV, BD and SB values of NCS after HMT-AG with HMT for 6 h were decreased by 65, 77, 14 and 28 RVU as compared to those of the sample without HMT. When the HMT moisture content and HMT time were constant, the PV, FV, BD and SB values of NCS after HMT-AG at 120 ℃ were decreased by 45, 53,10 and 19 RVU as compared to NCS with HMT-AG at 80 ℃,respectively. According to the results in SB value, the short-term retrogradation of NCS might be retarded by HMT-AG. Chandanasree et al[9]reported that heat treatment combined with hydrocolloids could reduce the SB value of starch. The reason of the decrease in SB value may be associated to the formation of ester bonds between the starch and AG molecules when subjected to heat treatment[28].

Moreover, under the same HMT condition, HMT-AG slightly increased the PT of NCS. The BD and SB value of NCS after HMT-AG were obviously lower than that after HMT when HMT moisture content was less than 25%. The viscosity of NCS decreased more obviously after HMT-AG at 120 ℃ for 6 h with HMT moisture content of 25% as compared to that after HMT under the same HMT condition.

2.3 Thermal properties of HMT-NCS without AG addition

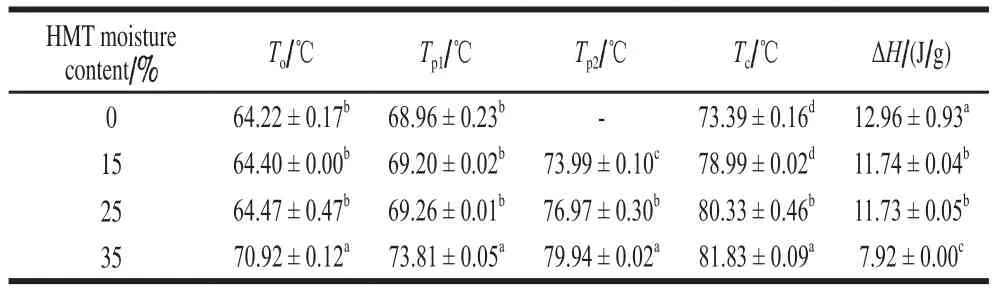

The gelatinization parameters of NCS before and after HMT measured by DSC were listed in Table 7-9. Compared to NCS before HMT, NCS subjected to HMT exhibited two peaks during DSC scanning. This biphasic transition indicated that HMT promotes the formation of new structure with less homogeneous crystals and results in a structural transformation toward an increased thermodynamic stability,which was reported earlier[12,29].

Table 7 Thermal parameters of HMT-treated NCS with different HMT moisture contents

Table 8 Thermal parameters of HMT-treated NCS at different HMT temperatures

Table 9 Thermal parameters of HMT-treated NCS with different HMT times

Gelatinization temperatures were affected by the crystalline region, interaction of starch chains, and amylose content[30]. After HMT, the gelatinization onset (To), peak(Tp), and conclusion (Tc) temperatures of NCS were shifted toward higher values, which exhibited a similar trend as the result of RVA. The Toof HMT-NCS was increased with increasing HMT moisture content, or prolonging HMT time,but changed slightly with increasing HMT temperature.The Tovalues of HMT-NCS were 70.92 and 68.82 ℃ with HMT moisture content of 35% and HMT time of 15 h,respectively, which was increased by 6.70 and 4.60 ℃ as compared to NCS without HMT. The Tp1of NCS changed slightly, while the Tp2and Tcincreased considerably with increasing HMT moisture content, HMT temperature, or prolonging HMT time. When the HMT temperature and HMT time were constant, the Tp2and Tcvalues of HMT-NCS with HMT moisture content of 35% were 79.94 and 81.83 ℃,respectively, increased by 5.95 and 2.84 ℃ as compared to HMT-NCS with HMT moisture content of 15%. When the HMT moisture content and HMT temperature were constant,the Tp2and Tcvalues of NCS after HMT for 15 h were 77.47 and 81.21 ℃, respectively, increased by 3.54 and 3.35 ℃as compared to NCS after HMT for 1 h. When the HMT moisture content and HMT time were constant, NCS with HMT at 80 ℃ only exhibited one endothermic peak, while NCS with HMT at 100 and 120 ℃ exhibited two transition peaks. The Tp2of NCS after HMT at 120 ℃ was 1.96 ℃which was higher than that of NCS after HMT at 100 ℃,and the Tcof NCS after HMT at 120 ℃ was 6.86 ℃which was higher than that of NCS after HMT at 80 ℃.Huang Tingting[7], Wongsagonsup[31], and Li Suling[32]et al also reported the similar trend about the effect of HMT on the gelatinization temperatures of starch. The increase of gelatinization temperature might be ascribed to the interactions between amylose molecules and amylopectin chains present in the branched crystalline regions that reducing the mobility of the amylopectin chains. The above results indicated that HMT may increase the stability of the crystallites and make more inter and intra helical hydrogen bonds formation.

The gelatinization enthalpy (ΔH) reflected the amount of unravelling and melting of double helices during gelatinization[1,4]. The ΔH value of NCS subjected to HMT exhibited a slight decrease over its native counterpart. A decrease in the ΔH value of the HMT starch also has been reported in the earlier studies[4,7]. The gelatinization enthalpy of HMT-NCS decreased with increasing HMT moisture content, HMT temperature, or prolonging HMT time. When the HMT temperature and HMT time were constant, the ΔH value of HMT-NCS with HMT moisture content of 35% was decreased by 5.04 J/g as compared to NCS without HMT. It was in good accordance with the earlier results[7]. The result of the decrease in ΔH value indicated that HMT disrupted some of the double helices and hydrogen bonds presented in crystalline and non-crystalline regions of the starch granules[4], which resulted in fewer double helices unravelling and melting during gelatinization of HMT starches.

2.4 Thermal properties of HMT-AG-NCS

The gelatinization parameters of AG-NCS before and after HMT measured by DSC were listed in Table 10-12.Unlike thermal properties of HMT-NCS, AG-NCS before and after HMT showed only one transition peak during DSC scanning.

Table 10 Thermal parameters of HMT-AG-treated NCS with different HMT moisture contents

Table 11 Thermal parameters of HMT-AG-treated NCS with different HMT times

Table 12 Thermal parameters of HMT-AG-treated NCS at different HMT temperatures

After HMT-AG, the To, Tp, and Tcvalues of NCS were shifted toward higher values, but the gelatinization enthalpy of NCS changed slightly after HMT-AG as compared to that of AG-NCS without HMT. The To, Tp, and Tcvalues of HMT-AG-NCS were increased with increasing HMT moisture content, HMT temperature, or prolonging HMT time. When the HMT temperature and HMT time were constant, the To, Tp, and Tcvalues of HMT-AG-NCS with HMT moisture content of 35% were increased by 11.50, 9.09 and 5.65 ℃ as compared to HMT-AG-NCS with moisture content of 15%. However, the results for gelatinization temperature were contrary upon modifications for cassava starch as reported by Chandanasree et al[9].

The gelatinization enthalpy of HMT-AG-NCS was lower than that of HMT-NCS when HMT moisture content was less than 25%. Under the same HMT condition with HMT moisture content less than 25%, HMT time ranged in 1-15 h,and HMT temperature of 120 ℃, the Tovalue of HMT-AG-NCS obviously decreased as compared to HMT-NCS. This result was in accordance to that of RVA.

2.5 X-ray diffraction patterns of HMT-NCS and HMT-AG-NCS

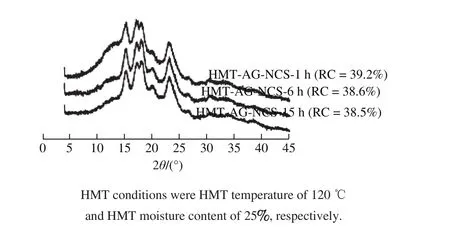

The X-ray patterns and RC of NCS after HMT were depicted in Fig. 1-3, and those after HMT-AG were depicted in Fig. 4-6. The X-ray pattern of NCS and AG-NCS before and after HMT exhibited a typical A-type crystalline pattern,with a strong doublet-centered diffraction peak at 2θ values of 17.4° and 18.2°, and two single peaks at 2θ values of 15.3° and 23.1°. This phenomenon was also found by other researchers[2,29]. Both HMT and HMT-AG did not alter the inherent diffraction pattern of NCS. Previous researchers found that the X-ray pattern of B-type tuber starches could be altered to A-type starches by HMT, whereas the X-ray pattern of A-type cereal starches remained unchanged[4,22].

Fig. 1 X-ray patterns and RC of HMT-treated NCS with different HMT moisture contents

Fig. 2 X-ray patterns and RC of HMT-treated NCS with different HMT times

Fig. 3 X-ray patterns and RC of HMT-treated NCS at different HMT temperatures

Fig. 4 X-ray patterns and RC of HMT-AG-treated NCS with different HMT moisture contents

Fig. 5 X-ray patterns and RC of HMT-AG-treated NCS for different HMT times

Fig. 6 X-ray patterns and RC of HMT-AG-treated NCS at different HMT temperatures

The crystallinity of starch is influenced by the distribution of amylopectin chain-length, double helix orientation in crystalline regions, crystallite size, etc[31]. As shown in Fig. 1-3, the RC of NCS without HMT was 35.4%.HMT reduced the RC of NCS by 0.8%-8.2%. The RC of HMT-NCS decreased with increasing HMT moisture content,or with prolonging HMT time, while changed slightly with increasing HMT temperature. When HMT temperature and HMT time were constant, the RC of HMT-NCS with HMT moisture content of 35% was 29.5%, decreased by 5.9%as compared to NCS without HMT. When HMT moisture content and HMT temperature were constant, the RC of NCS after HMT for 15 h was decreased by 7.4% as compared to NCS after HMT for 1 h. The previous studies also reported the similar trend[2,7,15]. This result was in accordance to the previous reports that HMT decreased the RC of corn starch[33], yam starch[4], and potato starch[34]. It might be the changes in amylose-amylopectin ratio of the starch molecules during HMT[21]. Another reason might be ascribed to the increase in the amorphous area of the semi-crystalline lamella. During HMT, the destruction and rearrangement of starch molecules occurred simultaneously induced by partial or complete gelatinization and double helical movement[15].As shown in Fig. 4-6, HMT-AG exhibited slight influence on the RC of NCS as compared to that of AG-NCS without HMT. The similar trend has also been reported[32].It suggested that HMT could promote the resistance of starch granules. Both HMT-AG and HMT did not change the crystalline pattern of NCS. However, the RC of HMT-AG-NCS was much higher than that of HMT-NCS under the same HMT condition.

2.6 Gel hardness of HMT-NCS and HMT-AG-NCS

A starch gel has a continuous network with liquid phase entrapped[1]. The gel hardness of starch gels before and after HMT was shown in Fig. 7-9. The gel hardness of HMT-NCS ranged in 277-361 g when HMT moisture content varied in 15%-35%, 313-422 g when HMT time varied in 1-15 h,and 361-533 g when HMT temperature varied in 80-120 ℃,respectively, which was higher than NCS without HMT.According to the earlier reports, there was an increase in gel hardness for starches after HMT[1,18,22,35]. It has been reported that the starch paste became shear stable and exhibited marked increases in hardness and adhesiveness[24]. When HMT temperature and HMT time were constant, the gel hardness of HMT-NCS increased first and then decreased with increasing HMT moisture content, and the maximum gel hardness was obtained as HMT with moisture content of 25% (about 361 g). With prolonging HMT time, the gel hardness increased first and then decreased, which reached the maximum as NCS after HMT for 10 h (about 422 g), and was increased by 168 g as compared to NCS without HMT.

Fig. 7 Gel hardness of NCS after HMT and HMT-AG with different HMT moisture contents

Fig. 8 Gel hardness of NCS after HMT and HMT-AG for different HMT times

Fig. 9 Gel hardness of NCS after HMT and HMT-AG at different HMT temperatures

As shown in Fig. 7-9, HMT-AG increased the gel hardness of NCS as compared to that of AG-NCS. With increasing HMT moisture content, the gel hardness of HMT-AG-NCS was increased first, and then decreased. When HMT temperature and HMT time were constant, the gel hardness of HMT-AG-NCS reached its maximum (272 g) at HMT moisture content of 30%. When HMT moisture content and HMT time were constant, the highest gel hardness of HMT-AG-NCS was gotten at HMT temperature of 100 ℃.However, prolonging HMT time slightly altered the gel hardness of HMT-AG-NCS. Qiu Chao et al[30]pointed out that heat treatment might promoted the formation of junction zones through the cross-linking between starch chains and resulted in the increase of gel hardness. As compared to HMT-NCS under the same HMT condition, the gel hardness of HMT-AG-NCS decreased obviously.

3 Conclusion

All HMT and HMT-AG altered the pasting properties,thermal properties, crystalline characteristics and gel behavior of NCS. Both HMT and HMT-AG increased the PT value of NCS, and decreased the PV, FV, BD, and SB values of NCS.The lower paste viscosity and higher PT indicated that HMT strengthened the interactions among the starch granules. NCS subjected to HMT exhibited two peaks during DSC scanning,but AG-NCS before and after HMT showed only one transition peak. After HMT or HMT-AG, the To, Tp, and Tctemperatures of NCS were shifted toward higher values. The higher gelatinization temperature showed that the increased stability of the crystallites. Under the same HMT condition with HMT moisture content of 25%, HMT temperature of 120 ℃, and HMT time of 6 h, the viscosity, Tovalue, and gel hardness of HMT-AG-NCS decreased more significantly than those of HMT-NCS. The X-ray pattern of NCS and AG-NCS before and after HMT exhibited a typical A-type crystalline pattern, which suggested that HMT or HMT-AG did not alter the inherent diffraction pattern of NCS.The RC of HMT-NCS decreased with increasing HMT moisture content, or prolonging HMT time, while changed slightly with increasing HMT temperature.HMT-AG increased the RC of NCS. With the HMT moisture content of 25%, the RC of HMT-AG-NCS increased more significantly than that of HMT-NCS.The gel hardness of NCS after HMT and HMT-AG was higher than NCS without HMT. These results indicated that HMT conditions could affect the physicochemical properties of NCS and AG-NCS.