Research on Technical Route of Production Data Management Based on Group Technology

2019-12-25FengLeiGuoJun

Feng Lei Guo Jun

【Abstract】It is necessary to manage product data in industry production during the information era .Group technical can classify similar elements into one group ,which makes efficiency of parts production of small quantities is as many as mass production. This paper presents a production data management system that is allopathic, collateral by means of Internet and grouped.

【Key Word】group technology; production data management; technical route; ASP.NET

【作者簡介】Feng Lei,Lanzhou Institute of Technology;Guo Jun,Beijing University of Technology.

Ι. Introduction

Part information management system utilize group technology to mate feature of shape, size, blank, material and process requirement with the corresponding technological equipment, adopt appropriate arrangement form of machine tool to organize group classification production, which make parts production of small quantities incorporate into mass production . As a result, efficiency of small quantities is as many as mass production. According to manufacturing method, feature can be divided into casting, forging, welding, machining, injection molding and so on; According to types of parts, feature can be divided into shaft plate, plate, box, free surface and other characteristics. In a word, from the integration point of design and manufacturing, we can classify feature according to the standard: each kind of feature is the basic functional unit of the parts design, and its processing method and manufacturing method are identical. For shaft parts, for example, can be divided into internal and external cylinder, transverse trough, slotting, thread, tooth, chamfering and so on; For plate parts,for example, can be divided into groove, hole , concave cavity, bumps, steps, transition edge and so on.

The classification and coding of parts give regulated digital symbol of parts to show parts structure feature information (such as part name, function, structure, shape, etc.) and process feature information, The divided parts have similar process or similar structural.

We code parts and give parts barcode, computer can easily recognize parts.Encoded barcode parts can convenience electronic parts data. Via group technology sorting parts feature, part information management system can improve the processing quality, shorten the production cycle, improve production efficiency, reduce part cost, improve operation and management, make design more reasonable and reduce wip.

Ⅱ. Part Information Management System

Because of listing file generated by CAD/CAM software is the Hypertext Markup Language (HTML, Hypertext Markup Language), it is a mark language for describing web documents.

These file involved in list, machine tools, the starting point, model, blank, function parameters, cutting tool, tool path, NC data which is a key part of the product information, It is possible that Internet can read and modify data in another place in parallel. These data can be storaged and called by computer. Utilize computer technology such as ASP.NET, ADO.NET to establish the database for part information management system. We choose database software according to the number of part information, small amount of parts with Microsoft Office Access, moderate parts number with SQL, large parts number with ORACLE.

Ⅲ. The Interface and Function of The Parts Information Management System

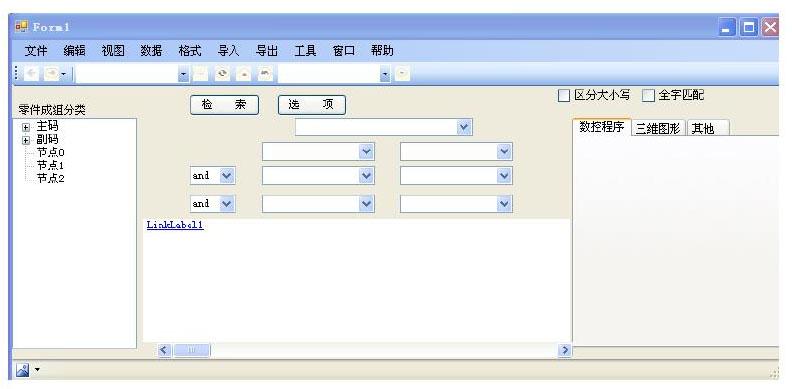

Figure 1 the interface of the part information management system

Interface of the part information management system is composed of three parts1 part features classifications column 2parts data search column 3 parts data preview column.

As shown in figure 1 is the interface of the part information management system. The first column is shape feature classification by group technology,and encode parts, parts barcode information convenience electronic parts information. The second column of the search function have exactly match search, similarity search( for knowledge production and variant route sheet), bar code search (for computer recognize part information) and so on. Those who eventually can be converted into data described and stored by computer. Part information management system can be in charge of all data, for instance: the product structure and configuration, data definition and design, CAD drawing files, engineering analysis and validation data, making plans and specifications, NC programming, image file (photo, modelling, scans, etc.), product manuals, software products (such as procedure, libraries, function “parts”), a variety of electronic report, cost accounting, product annotations, project planning books, multimedia audio and video products, hard copy documents, and other electronic data. The third column are major parts data preview column, due to the parts data diversity, can not include everything, only provide preview of the NC program, 3D graphics and process list.

Ⅳ Integration of Parts Information Management and Enterprise Information

Parts information management system can be seen as an integrated framework, a variety of applications ( EDA, OA, CAPP, MRP...)will be on a variety of ways, ( application interface, development (size))and so on, as one object can be integrated directly, make all parts highly integration, coordination, information sharing, all product development process can be highly optimized or restructuring.

Ⅴ Conclusion

Part information management can be widely used in various industrial fields. But every field has its own characteristics and requirements,the level of the application and the level of requirements is different, so there is no universal part information management system.

References:

[1]Yan Jun qi; Luo Lin hua Shanghai Jiao tong University. Research on combination an planning of processing units under CIMS condition. Chinese Journal of Mechanical English

[2]Gang Xian yue; Chai Shan. An Optimal Load Balancing Leveling Method for Multi-leg Flexible Platforms.2013-04-09 09:52

[3]寧汝新.CAD/CAM技术.2版[M].北京:机械工业出版社,2011.

[4]王隆太.机械CAD/CAM技术.3版[M].北京:机械工业出版社,2012.

[5]杨叔子.网络化制造与企业集成[J].中国机械工程,2000.11.(1-2):45-48.

[6]别传爽.机电专业英语[M].北京:北京理工大学出版社,2010.

[7]HUANG G Q, YEE W Y, MAK K L. Development of a Web-based system for engineering change management[ J].Robotic and Computer Integrated Manufacturing, 2001,17(3): 255- 267.

[8]T E, LOVE P E D. The impact of enterprise application information system lifecycles [J] . Information & Management, 2003, 41(2): 177- 187.ECK T B, KUMAR A S, SUBRAMAN IAN V. A CAD integrated analysis of flatness in a form tolerance zone [J].Computer-Aided Design, 2001(33): 853- 965.

[9]HUANG Ying, CHUN Jen y a o. A Web services-based framework for business integration solutions[ J]. Electronic Commerce Research and Applications, 2003, 2(1): 15- 26.