强电、强磁场对钢箱梁跨越磁浮快线轨道顶推落梁施工的影响

2019-12-20姜早龙刘晓君金波张志军刘正波赵嘉祺李园

姜早龙 刘晓君 金波 张志军 刘正波 赵嘉祺 李园

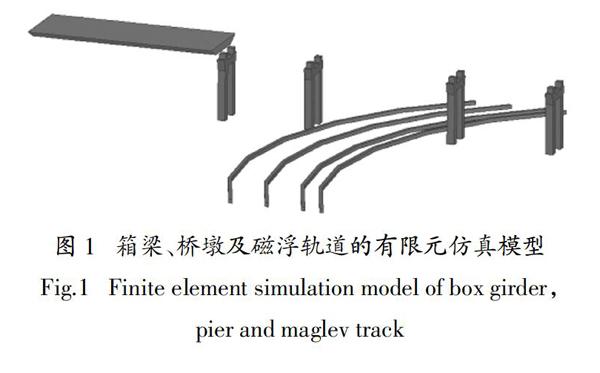

摘 要:中低速磁浮快线轨道通电时会使周围的电场和磁场发生强烈的变化,形成强电、强磁场效应,是上跨磁浮快线轨道钢箱梁顶推及落梁施工的重大安全隐患. 以长沙黄花国际机场大道工程为案例,研究强电、强磁场对钢箱梁跨越磁浮快线轨道顶推落梁施工的影响. 采用大型有限元分析软件ANSOFT,对磁浮快线轨道产生的强电、强磁场进行有限元分析及数值计算,假定钢箱梁推进过程中磁浮轨道电流保持不变,通过改变钢箱梁相对于轨道的位置,研究不同工况下强电、强磁场对钢箱梁顶推落梁产生的影响,并对每一个工况进行静态分析及计算,得出相应的施工安全范围,为今后类似工程提供具有参考价值的理论和经验.

关键词:钢箱梁;顶推施工;有限元;电场;磁场

中图分类号:F407.9 文献标志码:A

Influence of Steel Electromagnetic Field on Pushing and Falling

Construction of Steel Box Girder over Maglev Track

JIANG Zaolong1,2,4,LIU Xiaojun1,JIN Bo2,ZHANG Zhijun3,LIU Zhengbo2,ZHAO Jiaqi2,LI Yuan2

(1. College of Civil Engineering,Xi' an University of Architecture & Technology,Xi'an 710055,China;

2. College of Civil Engineering,Hunan University,Changsha 410082,China;

3. The Third Engineering Co Ltd of China Railway Seventh Group,Xi'an 710032,China;

4. Hunan Huda Construction Supervision Co Ltd,Changsha 410082,China)

Abstract: The surrounding electromagnetic fields will be changed greatly when the track of medium and low speed maglev is electrified. The generated effect of strong electromagnetic field has a great impact on the safety of the pushing and falling of the steel box girder over the maglev track.Therefore,taking the construction of Changsha Huanghua International Airport Avenue Project as a practical case,the impact of electromagnetic field on the pushing and falling of the steel box girder over the maglev track is studied.The large finite element analysis software ANSOFT is used to perform finite element analysis and numerical calculation on the strong electromagnetic field of the maglev track.It is assumed that the current of the maglev track remains constant during the advancement of the steel box girder. By changing the position of the steel box girder relative to the track,the impact of the strong electromagnetic field generated by the maglev track on the launching and falling of the steel box girder under the different working conditions is studied. After performing the static analysis and calculation for each working condition,the corresponding construction safety scope is obtained. The conclusion of the study provides references and suggestions for similar projects in the future.

Key words: steel box girder;pushing construction;finite element;electric field;magnetic field

隨着世界桥梁建设领域的快速发展,桥梁的结构形式与受力特性日益复杂[1],交叉跨越、临水临电、跨山跨河等现象不断增多,增加了桥梁施工与管理的难度. 顶推落梁、BIM、快速施工、静力拆除等技术持续创新、相互融合,逐渐突破桥梁施工的局限性,施工工艺不断改进,监管效率不断提高[2-4]. 顶推法构思源于钢箱梁纵向拖拉法,采用若干个千斤顶替代卷扬机滑车组,板式滑动设备替代滚筒,将梁体顶推向[5],具有快速、安全、经济、优质、受外界干扰较小和占用场地少等优势. 当桥梁施工需要跨越深谷、且有交通线路(铁路、公路、河道)或难以拆迁的既有建筑物(名胜古迹、地下设施等)时,采用顶推施工法从空中完成跨越作业,是一种比较理想的方法. 自1959年在奥地利阿革尔桥中成功应用后,顶推施工工艺不断创新,在国内外各类大跨径桥梁施工中相继运用[6],建成了多座预应力混凝土连续梁桥,得到了快速的发展[7-8]. 1977年,我国首次采用单点顶推法施工建成了预应力混凝土连续梁桥——狄家河

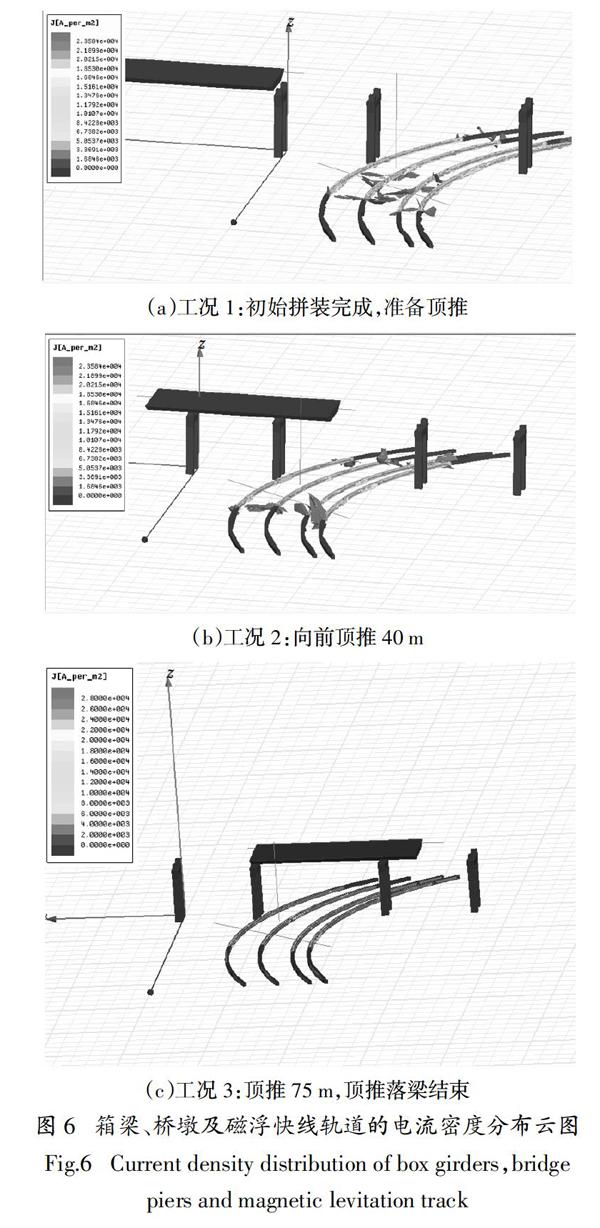

仿真結束后,对整体模型进行电流密度云图求解,可得箱梁、桥墩及磁浮快线轨道周围的磁感应强度,如图6所示. 以3条直线为例,分别建立3条线上电流密度云图分布曲线图,3条直线位置及最不利情况分析见表6.

4.2 各工况下电流密度分析

3种工况下第1条直线电流密度分布曲线如图7(a)(b)(c)所示. 第1条直线上电流密度有4个峰值,每个峰值位置都位于4条轨道附近,电流密度由4条轨道向外递减. 对其大小与相应距离进行分析,第1条直线上电流密度峰值与对应距离的关系如表7所示,可以发现离两条外侧轨道大约0.7 m附近电流密度小于人体安全限值(≤10 mA/m2). 对比3个工况可知,3工况下轨道附近电流密度大小无明显差异,说明当钢箱梁通过磁浮快线轨道上方时,对轨道附近电场无影响.

第2条直线电流密度分布曲线,如图7(d)(e)(f)所示. 第2条直线电流密度随距离变化较为规律,磁浮快线轨道内部电流密度最大,从轨道向箱梁表面电流密度逐渐递减. 第2条直线上电流密度与对应距离的关系如表8所示,可以发现只有磁浮快线轨道内部电流密度较大. 因此,只要施工人员不触碰磁浮快线轨道,轨道电场就不会对施工人员的安全产生影响.

第3条直线电流密度分布曲线,如图7(g)所示,通过数据显示,发现箱梁表面上的电流密度几乎为0,可见电场分布对箱梁表面的影响很小,施工人员可正常施工.

5 电磁场仿真结论

5.1 磁场研究结论

1)系统磁场分布主要集中在磁浮快线轨道位

置,距离磁浮快线轨道越远磁场强度越小且磁场衰减越快.

2)距离磁浮快线两条外轨3.5 m以内,磁感应强度超过国家安全标准值(≤100 μT). 为保证安全,距离两条外轨附近3.5 m的施工人员应配备绝缘工器具.

3)距离磁浮快线轨道正上方2.5 m以内,磁感应强度超过国家安全标准值(≤100 μT). 但当落梁完成时,梁底附近施工人员离轨道大约4.2 m,为最接近轨道的情况,且磁浮公司采取了相应的防护措施,导致磁场强度实测值小于理论值. 因此,施工人员受磁场影响较小.

4)磁浮快线轨道在箱梁表面产生的磁场强度几乎为0,故箱梁表面施工人员可以正常施工.

5)现场施工时应严格避免金属物品掉落到轨道附近,防止造成磁浮快线轨道损坏或磁浮快线运行事故.

5.2 电场研究结论

1)系统电场分布主要集中在磁浮快线轨道内以及各轨道之间,最大电流密度高达2 500 A/m2,极易造成触电死亡等意外事故. 因此,在列车通电运行时磁浮快线轨道附近严禁施工人员靠近.

2)距离磁浮快线两条外轨0.7 m以内,电流密度超过人体电流密度安全限值(≤10 mA/m2),为保证安全,两条外轨附近0.7 m以内严禁施工人员靠近.

3)磁浮快线轨道在箱梁表面产生的电场几乎为0. 因此,箱梁表面施工人员可以正常施工.

参考文献

[1] 张建,王永光,孔祥韶,等. 九堡大桥主桥顶推施工模型试验研究[J]. 中外公路,2017,37(5):94—99.

ZHANG J,WANG Y G,KONG X S,et al. Experimental study on the push construction model of the main bridge of Jiubao bridge [J]. Sino-foreign Highway,2017,37(5):94—99. (In Chinese)

[2] 杜亚江,宗海. 曲线钢箱梁桥顶推施工新方法[C]//2010年全国桥梁学术会议论文集. 北京:中国公路学会桥梁和结构工程分会,2010: 425—430.

DU Y J,ZONG H. New construction method of curved steel box girder bridge jacking [C]//Proceedings of 2010 National Bridge Academic Conference. Beijing: Bridge and Atructural Engineering Branch,China Highway Society,2010: 425—430. (In Chinese)

[3] 姜早龙,李园,张志军,等. BIM技术在跨越磁悬浮轨道桥梁工程施工中的应用研究[J].施工技术,2018(24):58—63.

JIANG Z L,LI Y,ZHANG Z J,et al. Research on the application of BIM technology in the construction of trans-maglev railway bridge [J]. Construction Technology,2018(24): 58—63. (In Chinese)

[4] 张志军,万钰,姜早龙,等.承插型键槽式钢管支架在城市高架桥施工中的应用研究[J].公路工程,2018,43(6):15—21.

ZHANG Z J,WAN Y,JIANG Z L,et al. Research on application of spigot type steel pipe support in urban viaduct construction [J]. Highway Engineering,2008,43(6):15—21. (In Chinese)

[5] 蘇魁. 钢箱梁斜拉桥顶推施工关键问题研究[D]. 上海:同济大学土木工程学院,2006:2.

SU K. Research on key problems of steel box girder cable-stayed bridge jacking construction [D]. Shanghai: College of Civil Engineering,Tongji University,2006:2. (In Chinese)

[6] ZELLNER W,SVENSSON H. Incremental launching of structures [J]. Journal of Structural Engineering,1983,109(2):520—537.

[7] 赵人达,张双洋.桥梁顶推法施工研究现状及发展趋势[J].中国公路学报,2016,29(2):32—43.

ZHAO R D,ZHANG S Y. Research status and development trend of bridge jacking construction [J]. China Highway Journal,2016,29(2):32—43. (In Chinese)

[8] 张晓东. 桥梁顶推施工技术[J]. 公路,2003(9):45—51.

ZHANG X D. Construction technology of bridge jacking [J]. Highway,2003(9):45—51. (In Chinese)

[9] 汤俊生. PC梁顶推施工技术的回顾与展望[J]. 桥梁建设,1996(1):11—14.

TANG J S. Review and prospect of PC beam jacking construction technology [J]. Bridge Construction,1996(1):11—14. (In Chinese)

[10] 邵厚坤,周以诚. 用顶推法施工的狄家河连续梁桥设计[J]. 铁道标准设计,1979(8):7—14.

SHAO H K,ZHOU Y C. Design of Dijiahe continuous girder bridge constructed by push method [J]. Railway Standard Design,1979(8):7—14. (In Chinese)

[11] 陈青. 连续梁桥的顶推施工技术[J]. 中外公路,1998(1):22—25.

CHEN Q. Jacking construction technology of continuous beam bridge [J]. Sino-foreign Highway,1998(1):22—25. (In Chinese)

[12] 陈勤. 桥梁钢箱梁顶推施工过程受力分析及施工对策[D]. 重庆:重庆大学土木工程学院,2013:1.

CHEN Q. Force analysis and construction countermeasures in the process of bridge steel box girder jacking construction [D]. Chongqing:College of Civil Engineering,Chongqing University,2013:1. (In Chinese)

[13] 马如岭. 跨铁路线78m钢桁梁顶推施工[J]. 铁道建筑,2006(2):15—16.

MA R L. Jacking construction of 78m steel truss beam across railway line [J]. Railway Construction,2006(2):15-16. (In Chinese)

[14] MARTINKOVIC B,IVANKOVIC A M,ILIC K. Competitiveness and progress in application of incremental bridge launching[C]// Proceedings of IABSE Symposium. Madrid,2014:823—830.