凹凸棒石对水泥净浆结构构筑和水化的影响

2019-12-10张峰

张峰

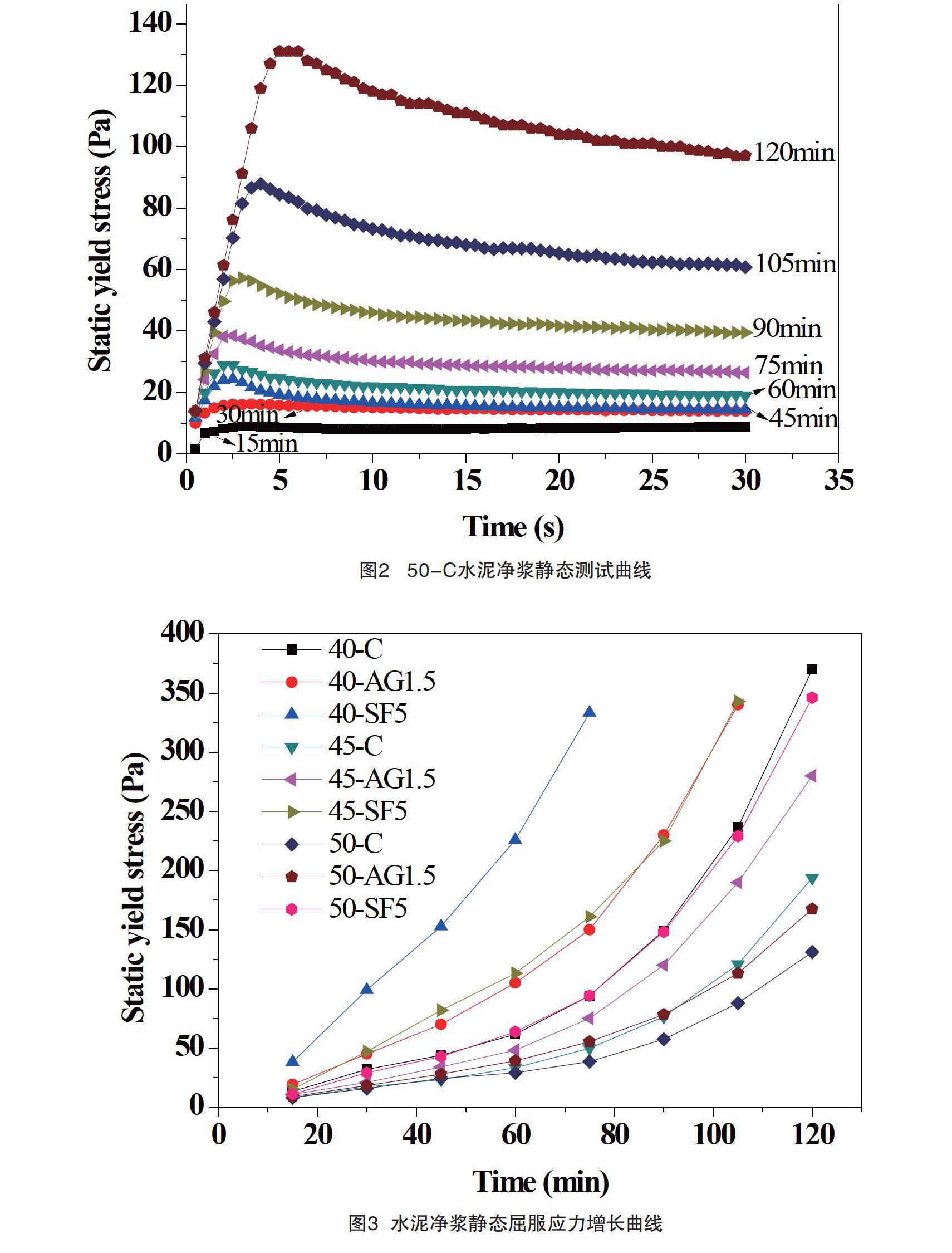

摘 要:凹凸棒石作为无机胶凝材料,具有良好的流变性能,能够在剪切作用下分散良好。将凹凸棒石应用到水泥基材料中,用来改善浆体流变性能,得到越来越多的关注。静态屈服应力是水泥基材料一个重要的流变参数。静态屈服应力增长速率经常被用来表征水泥基材料的触变性/结构构筑,对水泥基材料的稳定性、形状保持能力和分层浇注非常重要。在本文静态屈服应力每15min测试一次,持续120min。同时进行了水化热测试。结果表明随着水灰比的降低,结构构筑速率逐渐增强。掺入凹凸棒石增加了结构构筑速率和CSH机械效率。

关键词:凹凸棒石 结构构筑 水泥 CSH机械效率

中图分类号:TU528.01 文献标识码:A 文章编号:1674-098X(2019)07(b)-0016-06

Abstract: As an inorganic cementitious material, attapulgite has good rheological properties and can be well dispersed under shear agitation. More and more attention has been paid to the application of attapulgite in cement-based materials to improve the rheological properties of paste. Static yield stress is an important rheological parameter of cement-based materials. The growth of static yield stress is often used to characterize the structural build-up/thixotropy of cement-based materials, which is crucial for the stability, shape-holding capacity and multi-layer casting. In this paper, static yield stress was measured every 15 min over 120 min. At the same time, calorimetric curves test was measured. Results showed that with the decrease of water cement ratio, the rate of structural build up increases gradually. The addition of attapulgite increased the structural build up rate and mechanical efficiency of CSH.

Key Words:Attapulgite;Structural build up; Cement; Mechanical efficiency of CSH

凹凸棒石作为一种天然粘土矿物,具有吸附性能、胶体性能、补强性能和载体性能,在化工、医药、农药、建材、石油、环保等领域应用广泛。凹凸棒石作为无机胶凝材料[1],具有良好的流变性能,能够在剪切作用下分散良好。作为一种无机增稠组分,能够有效地增加液体粘度,在高黏剂、钻井液材料、涂料等方面得到了充分的应用。

近年来,传统的建造技术也在不断地突破创新,混凝土已经可以实现无振捣,自动密实的功能,即自密实混凝土[2]。滑模摊铺施工,对于混凝土性能要求更高,需要实现半流动和自密实的功能,且在滑模后,能够迅速固定形状,无坍塌,微变型[3]。在混凝土浇筑方面,尽快实现脱模,有利于模板的流转,减少成本。Billberg 等[4]研究表明加入纳米粘土能够有效减少模板侧压。3D打印混凝土作为建造行业的一个研究热点,需要混凝土挤出成型,在自重和上部荷载作用下,不坍塌,微变形。Soltan 等[5]研究表明掺入凹凸棒石,能够有效提高建造性,在持续剪切的作用下,减少流动性损失。Reiter 等[6]认为将凹凸棒石应用于3D打印混凝土中,可有效的提高混凝土早期结构构筑速率,加快竖向打印速率。结构构筑对混凝土的稳定性,滑模摊铺施工,分层浇筑和3D打印混凝土极为重要[3,4,7-11]。因此本文对比了凹凸棒石和硅灰对结构构筑的影响,通过水化热试验分析水化对结构构筑的作用。

1 原材料及试验方法

1.1 原材料

水泥(PC)采用P·Ⅱ 52.5南宁华润水泥;凹凸棒石(AG)由常州鼎邦矿产品科技有限公司提供;硅灰(SF)由山东博肯硅材料有限公司提供,活性指数为115,平均粒径0.15μm。凹凸棒石、水泥和硅灰物理和化学参数见表1。凹凸棒石和水泥的粒度分析见图1。水为咸阳市饮用自來水。

1.2 制备

考虑凹凸棒石和硅灰对减水剂吸附的影响,本实验不加入减水剂,分别采用水胶比0.5,0.45和0.40,净浆试验配比见表2。使用NJ-106A型水泥净浆搅拌机搅拌。搅拌方式为:慢搅30s,停30s(刮下锅内壁和叶片上的粉体),快搅90s,最后慢搅30s结束。试验温度保持在25℃。

[5] Soltan D G , Li V C . A self-reinforced cementitious composite for building-scale 3D printing[J]. Cement and Concrete Composites, 2018:S095894651730536X.

[6] Reiter L, Wangler T, Roussel N, et al. The role of early age structural build-up in digital fabrication with concrete[J]. Cement and Concrete Research, 2018: 86-95.

[7] Yuan Q , Zhou D , Khayat K H , et al. On the measurement of evolution of structural build-up of cement paste with time by static yield stress test vs. small amplitude oscillatory shear test[J]. Cement and Concrete Research, 2017.

[8] Kim J H, Beacraft M, Shah S P. Effect of mineral admixtures on formwork pressure of self-consolidating concrete[J]. Cement and Concrete Composites, 2010, 32(9):665-671.

[9] Assaad J J, Khayat K H. Formwork pressure of self-consolidating concrete made with various binder types and contents[J]. Aci Materials Journal, 2005, 102(4): 215-223.

[10]Khayat K H, Sariccoric M, Liotta F, et al. Influence of Thixotropy on Stability Characteristics of Cement Grout and Concrete[J]. Materials, 2002, 99(3): 234-241.

[11]Malaeb Z, Hachen H, Tourbah A, Maalouf T, Zarwi N E, Hamzeh F, 3D concrete printing: Machine and mix design[J], International Journal of Civil Engineering and Technology,2015(6):14-22.

[12]Kawashima et al. [21] reported that purified attapulgite clays significantly increased the structural build-up rate of pastes, especially at early ages.

[13]H.F.W. Taylor. Cement chemistry. London: Thomas Telford Publishing; 1997.

[14]S. Gauffinet Garrault, The Rheology of Cement During Setting, in Understanding the Rheology of Concrete, Woodhead Publishing, 2012.