WMMP: Vying to be Intelligent Manufacturing Pioneer of Marine Equipment

2019-12-03ChenLu

Chen Lu

Recently, the MIIT intelligent manufacturing new mode application project -- “Digital Workshop of Electromechanical Equipment of Ship and Ocean Engineering” undertaken by the Wuhan Marine Machinery Plant Co., Ltd. (WMMP) successfully passed the acceptance. The industry insiders believe that this marks progress made in the industry's digital transformation and upgrading.

As a backbone enterprise in the marine equipment field and a pioneer of intelligent manufacturing in the industry,WMMP has followed the national strategy in recent years, and based on the technological progress of the industry and the corporate innovation and development,has realized the transformation from introduction of technology to independent R&D, from low-end equipment to high-end equipment, from equipment manufacturing to system integration,and from marine equipment to ocean engineering equipment. Under the guidance of superior departments and industry experts, the company has explored a path of intelligent transformation and upgrading of traditional discrete manufacturing industry, providing a model for reference in the industry.

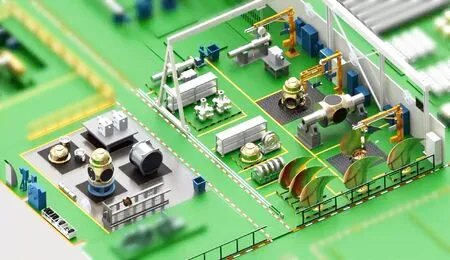

Digital Workshop

Brave to be a Bellwether in Digital Transformation

"Intelligent manufacturing is the objective trend of manufacturing development in the world, is an important means to deal with the complex and volatile market demand and the high quality development of manufacturing enterprises, and is also the only way for us to reshape the industrial system and promote industrial upgrading." Tang Min,master of ship design and deputy general manager of WMMP, said in an interview with our reporter, "As the flagship of scientific research and production of domestic ship supporting industry,WMMP aims at the characteristics of large, complete sets, non-standard and single small batch, individual customization of electromechanical equipment of ship and ocean engineering,through digital, networked and intelligent means, integrated industry advantage resources, and achieved implementation of 'comprehensive digitization and core intelligence'. implemented the integration and development of intelligent manufacturing system, has broken through a number of major technical equipment and key industrial technologies, and has created a leading digital workshop model project for mechanical and electrical equipment of ship and ocean engineering with demonstration significance and reference value. "

What is the digital workshop of the electromechanical equipment of the ship and ocean engineering? We learned that the digital workshop, centering on the whole life-cycle process of the marine product "Design - technology -production -test - service”, takes ERP,PDM and MES as the core, dedicated to pursue the innovation of the whole process of flexible manpower, paperless,transparent and the like, The integration of nine core business systems, such as PDM, MES, and the establishment of the data system, can realize the integration of the design process based on the unified model, the comprehensive management of the workshop production plan, production resources and production status.

a workers is using a terminal equipment to view electronic drawings

In the core manufacture link of large part processing, complex parts assembly,comprehensive product test and the like,WMMP mainly develops an intelligent processing unit with a tool monitoring function, an intelligent assembly unit with a fool-proof and anti-error prevention function, an intelligent storage unit with safety lamp reminder function, an intelligent test unit with virtual and real integration function to ensure the product quality, improve the efficiency of the key process of the product, and improve the working environment. At present, the scheme is applied to the manufacturing process of mechanical and electrical equipment for typical ship and ocean engineering, such as controllable-pitch propeller and cargo oil pump.

In October 2018, the 2018 World Intelligent Manufacturing Conference held in Nanjing issued the “Top Ten Technological Progress of Intelligent Manufacturing in the World'' and “Top Ten Technological Progress of Intelligent Manufacturing in China''. Based on the project of “Digital Workshop of Electromechanical Equipment of Ship and Ocean Engineering” , the “Intelligent Manufacturing System Integration of Electromechanical Equipment of Ship and Ocean Engineering” project extracted and summed up from the former project became the “pass” of WMMP elbowing its way into “Top Ten Technological Progress of Intelligent Manufacturing in China'' , and the company also became the only enterprise in the shipbuilding industry that won the honor that year.

Building a New Mode of Digital Workshop

"The research and development period of WMMP is obviously shortened,and the digital management level of the workshop is obviously improved by the demonstration application of the product of the controllable-pitch propeller and cargo oil pump," said Ma Juyong,chairman of WMMP.

Propeller core component intelligent mosaic unit

From defining the task of intelligent manufacturing construction in 2015 to realizing the pilot launch of digital workshop of controllable-pitch propeller products in 2017, WMMP has gone through six important stages in nearly two years. As of January 2019, the company had 249 PDM online application job numbers and 12 MES online application job numbers, realized the tracking management of more than 30,000 materials and more than 40,000 parts and components in the workshop site.The system with PDM, ERP and MES as the core covers more than half of the employees and all the core business of the whole plant, providing reliable support for the traceability of product process data.

On the basis of deeply summing up the experience of reconstruction of the digital workshop of controllable-pitch propeller products, WMMP took the lead in replicating and popularizing within the company, and created the first "overall,transparent and paperless" digital workshop of liquid cargo products, mainly used in the production and manufacture of high-end liquid cargo products such as cargo oil pumps and immersed pumps.Up to now, the functions of the workshop have been steadily applied online.

During the construction of the digital workshop, the WMMP always insists on the digital application mode dominated by the traction and application of the problem. Ma Juyong concluded that: "By implementing the intelligent manufacturing in the marine equipment sector, the WMMP forms the digital system of “Up and down opening up,right and left linkage, precise execution and data drive”, and builds the ability of the “core business system individualized and the key equipment function intelligent”, and intelligent technology is becoming the new power of the company's high-quality development."

Under the guidance of the new generation of intelligent manufacturing strategy, centering on the high-quality development requirements, the company will continuously improve the top-level architecture of the digital factory and the industrial Internet platform, and continuously promote the application of the intelligent technology, share the experience and the method, confirmedly act as a pioneer in the intelligent technology innovation practice in the industry.

In the aspect of R&D design intelligence, the company will set up a virtual test site for ocean engineering electromechanical equipment, and innovate product design. In the aspect of realizing the process intelligence, the controllable-pitch propeller intelligent manufacturing system is used as a sample project internally, and is popularized and applied to other products; externally, and the whole set of intelligent manufacture construction mode is popularized and applied to other sibling units or other similar discrete manufacturing fields in a non-reserved fashion with the position of the WMMP in the ship and ocean engineering electromechanical equipment industry. In terms of product and service intelligence, build an intelligent equipment system featuring ship-shore integration and multi-sector integration, dock the ship's overall system,and improve capabilities of operation,safety management, regional integration,coordination, health management and maintenance. In the aspect of management decision-making intelligence, dock the knowledge management system, build the large data operation center of the WMMP,realize the sharing and integration of data and knowledge, perform the data mining and decision analysis in a bid to boost the corporate operation optimization and transformation and upgrading.