Development of alpha surface contamination monitor based on THGEM for contamination distribution

2019-10-18SiMinXiaoZhiPingLuoQianLiuGuoJunYuanHongChaoPangYangLiuJinFengHuangShiChen

Si-Min Xiao · Zhi-Ping Luo · Qian Liu · Guo-Jun Yuan · Hong-Chao Pang ·Yang Liu · Jin-Feng Huang · Shi Chen

Abstract In cases of high radiation emergencies, we propose a surface contamination monitor (SCM) that can quickly measure and pinpoint the contamination distribution in the affected population. Thick gaseous electron multiplier(THGEM)has several advantages,including fast response time and good spatial resolution. Based on new THGEMs, a two-dimensional imaging detector was developed for alpha detection, with a position resolution greater than 3 mm.The detector design and test results are described in this paper.Fast radiation imaging SCMs,with a 40 mm × 40 mm sensitive area, are currently under development.

Keywords THGEM detector · Surface contamination distribution·Alpha particle·Position resolution·Imaging detector

1 Introduction

Surface contamination monitor (SCM) is an important device in nuclear equipment monitoring, environmental radioactive pollution investigation, and evaluation and monitoring of emergency nuclear accident events. Traditional alpha detectors, for contamination monitoring, usually provide the level of contamination. New monitoring equipment, based on thick gaseous electron multipliers(THGEMs), can be used for locating contamination and is discussed in this paper. Such type of SCM can quickly measure the count rate and generate positional imaging of alpha radiation contamination. We are currently in urgent need of such a device, for monitoring the spread of contamination by local residents and nuclear plant workers,in the event of an emergency. In such situations, rapid measurement and precise details of radiation contamination regions are vital for assessing medical or other assistance needs [1-3].

In the probe of the traditional alpha SCMs,the detectors are usually gaseous, scintillation, or semiconductor detectors. Scintillation detectors are usually composed of a photomultiplier tube (PMT), with scintillators such as CsI(Tl) and ZnS(Ag). Radioactive contamination of a scintillation material plays a key role to reach a low background level. Scintillation SCMs are mainly used to measure weak alpha radioactivity because the spatial resolution at the sub-centimeter level does not meet the requirements [4-6]. Semiconductor detectors are mainly used for to accurately measure the energy spectra of alpha particles and heavy charged particles. The Si(Au) surface barrier detector has good spatial resolution(less than 1 μm)and high detection efficiency (approximately 100%).However,semiconductor detectors have poor anti-radiation ability [7, 8] and are significantly expensive for large-area production.

THGEMs are a type of micro-pattern gaseous detector(MPGD) developed by A. Breskin et al. in 2004, which have fast response time (~10 ns), high counting rate (up to 106/mm2), radiation resistance, and good spatial resolution (sub-mm) [9-11]. The THGEM detector detects radiation on the basis of the gas-ionizing action of radiation. It is suitable for a variety of applications including photon detection, such as the ring imaging Cherenkov(RICH) detector [12, 13], or charged particle detection,such as the Digital Hadron Calorimeter(DHCAL)[14,15].The critical characteristics of THGEM detectors are efficient monitoring for ionizing radiation and relative positioning of radiation contamination, after irradiation.Therefore, the THGEM detector is expected to be one of the most useful monitors for major radiation emergencies.The THGEM (as shown in Fig. 1) developed by the University of Chinese Academy of Sciences (UCAS) has 20 cm × 20 cm effective area and is 400 μm thick,and the diameter of the hole is 400 μm with a pitch of 1 mm.

Fig. 1 THGEM

The aim of this research is to develop large-area, fast radiation imaging detectors with moderate spatial resolution. In the following sections, we first present the design of the detector. Then, we describe the performance requirement for the alpha detector, including detection efficiency, spatial resolution as well as long-term stability.Finally, the components of the SCM are described.

2 Detector design

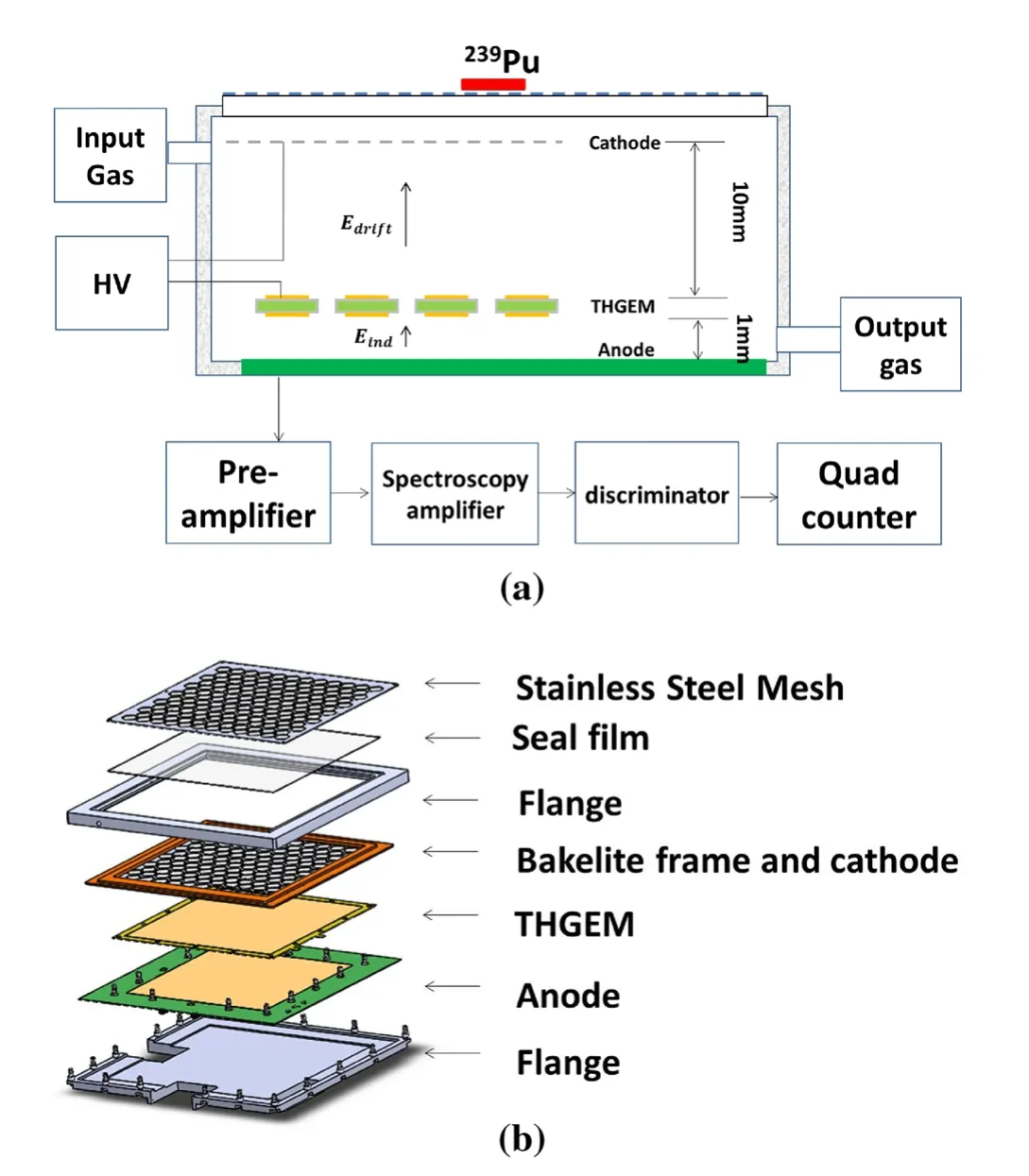

Figure 2a shows the sealed gaseous detector based on a THGEM.The drift region is defined as the area between the cathode mesh and the THGEM,with 10 mm,in which alpha particles ionize the gas and create primary electrons.Primary electrons are amplified in the THGEM,which is defined as the amplifier region.The induction region is defined as the region between the THGEM and the anodes with 1 mm.The avalanche of electrons induces detectable signals on the readout anode as they drift toward it.

Each part of the sealed detector is shown in Fig. 2b.The design is straightforward.The chamber is sealed by flanges,tightly connected to the anode, with O-rings. An ultrathin film of polyvinylidene chloride (PVDC) is used as the window(thickness of approximately 5 μm),and a stainless steel mesh (thickness of approximately 100 μm) is placed on the window. The dimension of the detector is 23 mm × 302 mm × 302 mm.

Fig. 2 Structure of the THGEM detector

An alpha source239Pu of 650 Bq was used in this experiment. The source was calibrated by the Metrology and Testing Department of the China Institute of Atomic Energy.Alpha particles of 5.157 MeV are emitted into the drift region with a solid angle of 2π.The Ar:iC4H10(97:3)is continuously flushed with a flow rate of 150 ml/min.The gas is precisely controlled with an Alicat MC-Series Mass flowmeter. The high voltage is provided by a CAEN NDT1471 HV programmable power supply.

Fig.3 Detection efficiency versus THGEM voltage for different film thickness

Fig. 4 a Geant4 model for a THGEM detector with a 239Pu source and b the simulation result of different thicknesses of seal film. The detector efficiency changes with energy of alpha particle

Fig. 5 a Detection efficiency dependence on Vdrift under constant Vind =100 V and ΔVTHGEM =650 V. b Detection efficiency dependence on ΔVTHGEM under constant Vind =100 V and Vdrift =350 V.c Detection efficiency dependence on Vind under constant Vdrift =350 V and ΔVTHGEM =650 V

Fig. 6 a Readout anode board and b scheme of the readout

3 Detector performance

3.1 Detection efficiency

3.1.1 Transmission efficiency of the window film

The alpha particles have to pass through the mesh and the thin film to reach the drift region of the detector.For the mesh, it is straightforward to perform a calibration by considering its optical transmittance, which is roughly 81%. However, the film thickness must be considered carefully. A thinner film leads to better alpha detection.However,the gas seal is also important.Therefore,we have used different film thicknesses and studied the detection efficiency. Figure 3 shows the result from measurements with the239Pu alpha sources. As expected, detection efficiency decreases as the thickness of the film increases.Additionally, the detection efficiency reaches a plateau as the THGEM is fully operated with Vdrift=350 V and Vind=100 V.The detection efficiencies are 48%,27%,and 5% for 5 μm, 10 μm, and 15% μm films, respectively.

Fig. 7 Imaging of surface contaminate

Geant4 Monte Carlo simulation is employed to study the transmission efficiency of the window film. Figure 4a shows a snapshot of the propagation of alpha particles from a239Pu source. The particles passing into the ionization region are recorded. The blue layer represents the detector window film, and the gray layer represents ionization region;the solid lines represent the tracks of alpha particles released from the radioactive source.

The results are shown in Fig. 4b.It can be seen that the transmission efficiencies are close to the detection efficiency, which indicates that the detection efficiency decreases owing to the window film.

3.1.2 Alpha detection efficiency studies

Fig. 8 Distribution of strip number in X and Y directions

Fig. 9 Long-term stability of the detector

The detection efficiency will be affected by the drift electric field(ΔEdrift),the induced electric field(ΔEind),and the THGEM electric field (ΔETHGEM). Figure 5 shows the results of the detection efficiency under different electric field configurations.

With increasing Vdrift, the recombination effect reduces.This is caused by the primary electrons, which are accelerated by the high drift electric field and bombarded onto the upper surface electrode of the THGEM instead of drifting into the THGEM holes to be amplified. The Vdriftwas optimized to be 350 V.

The detection efficiency increases with increasing induction voltage Vind. This is due to the small portion of amplified electrons that are collected by the bottom layer of THGEM. This portion decreases and thus increases Vind.Vindwas optimized to be 100 V.

3.2 Imaging and position resolution measurement

Fig. 10 Diagram of the SCM

The THGEM detectors are read out by two-dimensional strips and are shown in Fig. 6a. There are 64 channels in each direction. Those signals are fed to the GASTONE ASIC Chip which offers 64 channels of charge-sensitive preamplifier-shaper circuits and then discriminates those signals with 4 tunable thresholds [16-18]. The digitized signals are then daisy-chained and packaged by a Xlinx FPGA and then sent to a computer for online data analysis.The scheme is shown in Fig. 6b.

3.3 Long-term stability

To study the long-term stability of the detector, we continuously operated the system for a half-month while recording data every 5 min. The detector was set to ΔVTHGEM=650 V, Vdrift=350 V, and Vind=100 V. The result is shown in Fig. 9. The detection efficiency shows a good stability, which varies about 3.2% over 16 days.

4 Surface contamination monitor

The SCM (Fig. 10) was designed to precisely measure the position of a surface where alpha contamination might have occurred.For instance,it can be used at nuclear plants to check whether workers’ hands are contaminated. The SCM is divided into three parts:the probe unit,the display unit, and the controller unit. The probe unit contains two alpha detectors with an effective area of 20 cm × 20 cm.The controller unit contains an 8 L gas cylinder,HV power supply, and a mass flowmeter. The display unit is a thinclient industrial computer.

Online software has been developed in C programming language, based on multi-thread architecture. The gas flowmeter and the HV modules are automatically monitored by a slow-control thread.Data acquisition,as well as the online analysis, and plots display are validated.

5 Conclusion

In summary, a THGEM-based SCM prototype has been successfully developed. A 48%239Pu alpha detection efficiency has been achieved.The thickness of the window film was optimized to 5 μm.The spatial resolution was less than 3 mm. The system was in operation for almost half a month and showed good stability performance.

杂志排行

Nuclear Science and Techniques的其它文章

- Study of Sallen-Key digital filters in nuclear pulse signal processing

- Advanced topics on RF amplitude and phase detection for lowlevel RF systems

- Feasibility analysis of 60Co production in pressurized water reactors

- Recovery of saturated signal waveform acquired from high-energy particles with artificial neural networks

- Assessment of self- and cross-absorbed SAF values for HDRKman using GEANT4 code: internal photon and electron emitters

- Single-event effects induced by medium-energy protons in 28 nm system-on-chip