生物质炭催化玉米秸秆热解气重整提质研究

2019-10-10王敬茹姚宗路丛宏斌赵立欣霍丽丽袁艳文

王敬茹,姚宗路,丛宏斌,赵立欣,马 腾,霍丽丽,袁艳文

生物质炭催化玉米秸秆热解气重整提质研究

王敬茹1,2,姚宗路1,丛宏斌1,赵立欣1,2※,马 腾1,霍丽丽1,袁艳文1

(1. 农业农村部规划设计研究院,农业农村部农业废弃物能源化利用重点实验室,北京 100125;2. 黑龙江八一农垦大学工程学院,大庆 163319)

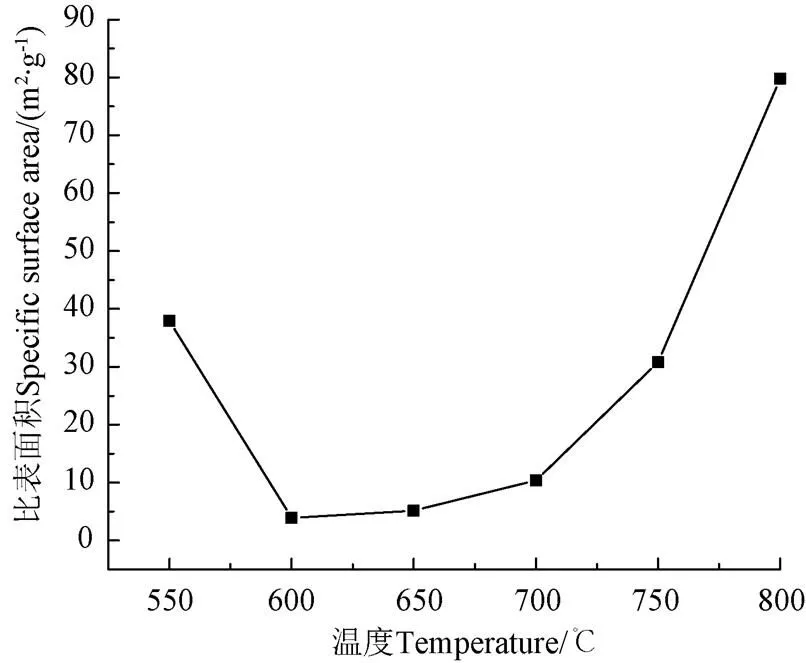

为研究生物炭作催化剂消减焦油提高热解气品质的效果,以玉米秸秆为原料,以焦油转化率、热解气产率和热解气热值为评价指标,研究重整温度、停留时间和生物炭特性对热解气提质的影响,并分析生物炭作为催化剂重整前后比表面积的变化。研究结果表明,与石英砂(高温裂解)相比,生物炭具有较好的催化特性,且稻壳炭、木屑炭和玉米秸秆炭对焦油的转化率分别为79.8%、78.6%、72.6%,热解气产率分别为39.7%、38.6%、37.9%。随着重整温度和停留时间的增加,热解气产率和焦油转化率增加,而热解气热值仅随着温度升高而增加,当温度为800 ℃时,热解气热值为17.6 MJ/m3。800 ℃催化重整后生物炭比表面积为79.81 m2/g,高于550 ℃热解生物炭比表面积37.96 m2/g,生物炭作催化剂时不但可以提高热解气品质,而且生物炭比表面积也有所增加。

秸秆;热解;催化;热解气;生物炭;耦合;焦油;催化重整

0 引 言

生物质热解技术是一种热化学转化技术,利用热解技术可以实现秸秆的回收利用,还能获得生物炭和热解气等高附加值能源产品[1-4]。但在热解过程中,秸秆内还有5%~15%的能量转化进入焦油,热解焦油含有重质有毒组分,低温下黏度大,易引起管道堵塞,阻碍连续热解生产过程[5-7]。因此,需要对热解气中焦油进行消减。消减焦油方法通常分为物理法和化学法,和物理法消减焦油相比,化学法不但能消减焦油,还能提高能源的利用率[8-9],常用的化学法为催化裂解,催化裂解是利用催化剂的作用,降低焦油裂解需要的活化能,以降低裂解气中焦油含量并改善燃气品质[10-11]。目前对催化剂的研究主要以天然矿石和镍基催化剂为主,虽然都具有较高的活性,但天然矿石耐磨性差,镍基催化剂成本较高,且易发生中毒失活[12-16]。

生物质热解得到的生物炭可以为烃类裂解提供活性表面[17],而且含有碱金属和碱土金属元素,两类金属元素对焦油裂解过程具有催化作用[18],在生物质气化工艺中,生物炭目前已被证明可有效脱除和转化合成气中的焦油,但采用生物炭催化裂解热解气中焦油的研究相对较少。孟凡彬等[19]证明了生物炭对热解气中焦油具有良好的催化特性,当温度为1000 ℃时,玉米秸秆炭和木屑炭的产气率为91.98%和94.11%。陈宗定等[20]研究表明生物炭中Fe、Ca等金属体系具有良好的焦油催化裂解效果,并且Ca、Mg在高温下形成MgO-CaO的配合物,使颗粒表面具有吸附焦油分子的极性活性位,降低了C-C和C-H键断裂键能以及烃类与H2O、CO2反应的活化能。马欣欣[21]证明了比表面积能够为催化反应提供更多的活性位点,从而促进焦油的催化转化。

本文在已有研究的基础上,以两段式固定床作为试验平台,以玉米秸秆为原料,生物炭为催化剂,探索应用生物炭催化裂解热解气中焦油时不同工作条件对生物质热解气提质与生物炭比表面积的影响。研究了重整温度、停留时间和生物炭特性对热解气提质和焦油消减的影响,以及催化重整后生物炭性质变化。

1 试验设备与方法

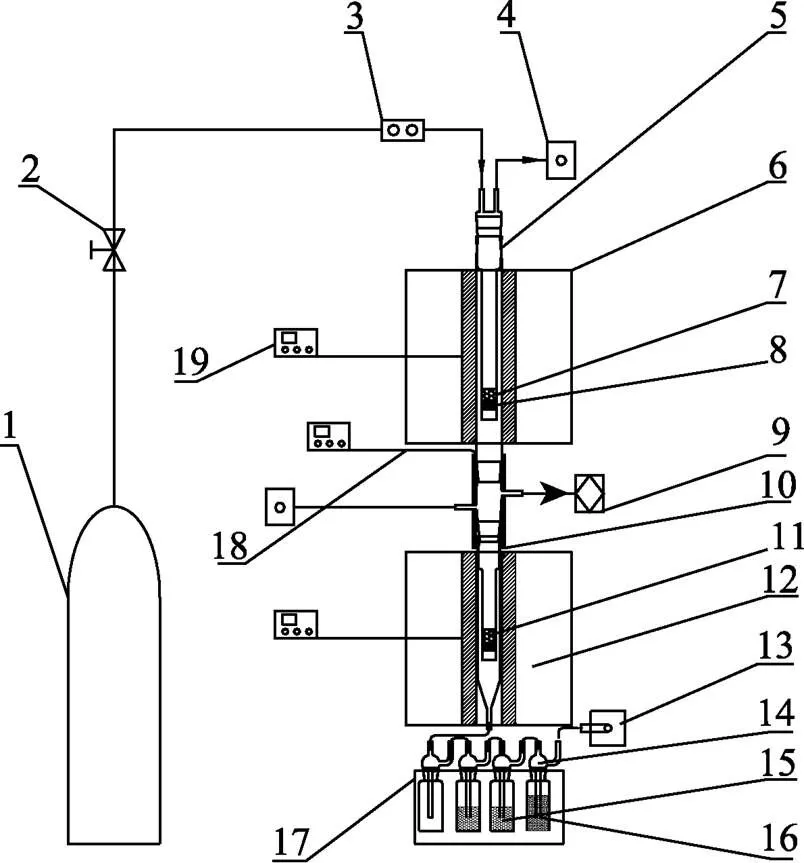

1.1 试验设备

生物质热解气重整试验平台如图1所示,上段为热解系统,下段为催化重整系统,热解反应器和催化重整反应器的中间连接段采用伴热带和保温棉保温,将测温热电偶置于石英管和伴热带的夹层中,将温度控制在320 ℃,保证焦油不会在石英管管壁上面冷凝。产品收集系统由多级冷凝装置和制冷机组成,设定制冷机的冷凝温度为-8 ℃,多级冷凝装置为四级冷凝,为了使焦油完全冷凝,二、三级中装有玻璃珠,四级中装有硅胶[22]。工作时,先将热解炉和催化重整炉升温到设定温度,再通入氮气吹扫(氮气流量为0.3 L/min,吹扫时间为45 min),使物料填装反应管处于绝氧环境,将物料填装反应管放入热解炉中,加热一定时间后,生物质在热解反应器中发生热解反应,生成的焦油和热解气随氮气进入催化重整炉,在高温和生物炭的作用下,焦油发生催化裂解反应,使部分重质焦油裂解为轻质焦油,部分焦油转化为气体。热解气中CO2、水蒸气等组分与生物炭发生气化反应,转化为CO、H2等可燃组分。重整后的热解气和焦油经多级冷凝装置进行油气分离后分别收集,以测得最终的油气产率和气体组成。

1.氮气瓶 2.开关阀 3.气体质量流量计 4.压力表 5.热解反应器 6.热解炉 7.生物质床层 8.筛板 9.蒸汽发生器 10. 催化重整反应器 11.催化剂床层 12.催化重整炉 13.气袋 14.焦油瓶 15.玻璃珠 16.硅胶 17.多级冷凝装置 18.热电偶 19.温度控制仪

1.2 试验原料和催化剂

1.2.1 试验原料

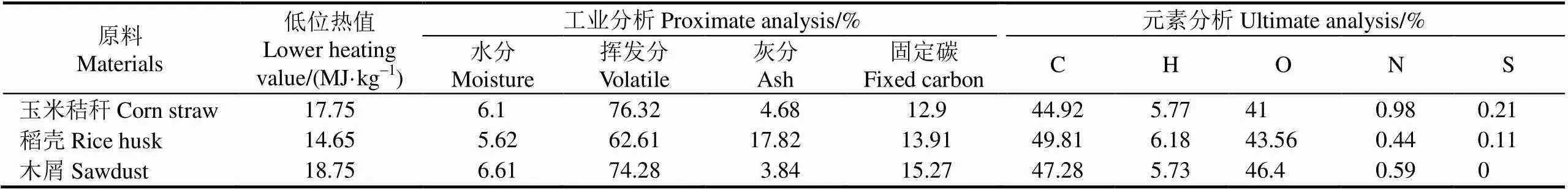

从生产与应用实际出发,选择玉米秸秆、稻壳和木屑作为试验原料,3种原料分别源自山东省肥城市、北京市通州区、河北省邢台市,分别采用国际GB 28731-2012方法和Vario EL III型元素分析仪分析3种原料的理化性质,如表1所示。

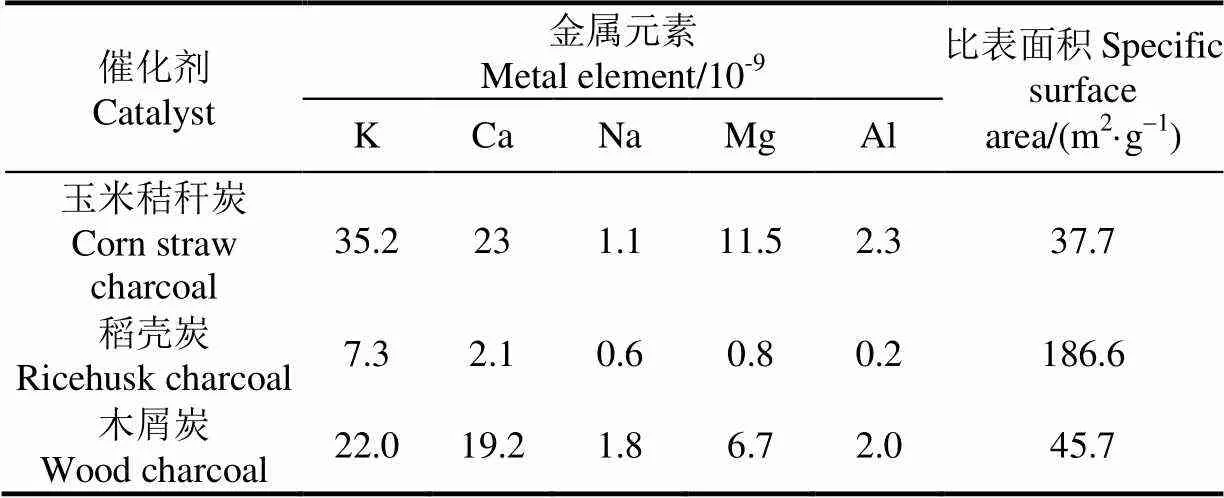

1.2.2 催化剂制备

催化剂制备在热解炉内完成,试验原料为玉米秸秆、稻壳和木屑,每次试验取10 g原料。热解条件:热解温度550 ℃、N2流量0.1 L/min、试验时间为70 min,以确保生物质有充分时间热解。并采用JW-BK112比表面及孔径分析仪检测生物炭比表面积,用电感耦合等离子体发射光谱(ICP-AES; Thermo Elemental,USA)测量生物炭催化剂碱金属和碱土金属(AAEMs)含量,测量结果见表2。玉米秸秆炭K、Ca含量相对较高,但比表面积低于稻壳炭和木屑炭,而稻壳炭的金属含量较低,比表面积较高。

表1 试验原料的理化特性

注:工业分析样品为空气干燥基,元素分析样品为干燥无灰基,O元素计算采用差减法。

Note: Samples in air dry base, dry and ash free base were used for proximate analysis and ultimate analysis respectively, and O was calculated by difference.

表2 三种生物炭的主要金属元素含量和比表面积

1.3 试验条件与测试指标

热解气提质工艺中涉及的试验因素包括重整温度、停留时间和催化剂,玉米秸秆原料质量为10 g,催化重整温度分别为600、650、700、750和800 ℃;停留时间是热解气穿过生物炭床层的时间,保证载气流量0.1 L/min不变,N2吹扫时间为70 min,通过改变床层高度调节停留时间分别为0.2、0.6、1.0、1.4和1.8 s;催化剂分别为空白对照组(无催化剂)、玉米秸秆炭、稻壳炭、木屑炭。单因素试验时,固定(预试验确定)催化重整温度为800 ℃、停留时间为0.2 s、催化剂为玉米秸秆炭。

相同条件下3次重复试验结果取平均值,并在平均值的基础上,加上统计学方差分析,以保证试验结果可靠。

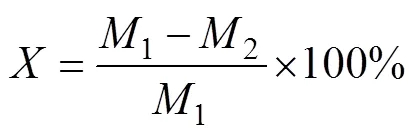

本研究涉及的相关测试指标,包括焦油转化率、热解气产率、热值等。焦油转化率是指重整反应转化为热解气的焦油占热解反应产生焦油的总量之比,其计算公式为

式中为焦油转化率,%;1为热解焦油质量,g;2为催化重整后焦油质量,g。

通过多级冷凝装置收集热解与催化重整焦油并离心后称取质量,下层液体质量定义为焦油质量。

热解气产率是指重整冷凝后的不可凝气体与原料质量之比[23],其计算公式为

式中gv为体积产气率,m3/kg;gm为质量产气率,%;为产生热解气标准体积,m3。

热解气热值是指单位体积的热解气在标况下所含有的化学能[24],利用气袋收集气体后采用气相色谱仪(浙江福立9 790A)分析不可凝气体组分,并根据气体组分以及单一气体热值计算热解气热值,其中,催化重整气体产物中的可燃气体组分主要包括H2、CH4、CO和CnHm(不饱和碳氢化合物)。

2 结果与分析

2.1 催化重整温度对热解气重整的影响

2.1.1 催化重整温度对热解气提质的影响

图2为不同催化重整温度对热解气产率、热值和气体组成的影响。温度的升高,一方面提高了催化剂催化活性,另一方面也为焦油裂解提供了能量。

注:玉米秸秆炭作催化剂、玉米秸秆原料用量为10 g、停留时间0.2 s。图上不同小写字母表示同一指标不同处理之间差异显著,下同。

从图2中可知,随着重整温度由550 ℃升高到800 ℃,热解气热值由13.0 MJ/m3升高至17.6 MJ/m3,热解气产率由21.0%增加到37.9%。由于温度的升高促进了催化裂解反应[19],使H2和CH4的体积分数随着温度升高而增加。随着重整温度由550 ℃升高到800 ℃,H2体积分数由11.7%增加到21.8%,CH4体积分数由13.5%增加到18.2%。CO2体积分数由40.2%降低到24.3%。CO体积分数变化不明显,由31.4%下降到30.6%。

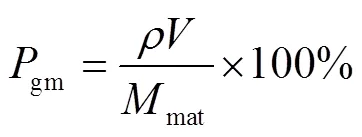

2.1.2 催化重整温度对焦油消减的影响

图3为催化重整温度对焦油消减的影响,如图3所示,550 ℃热解焦油产量为0.84 g,随着催化重整温度由600 ℃增加到800 ℃,焦油产量从0.64 g下降到0.23 g,焦油转化率从23.8%增加到72.6%,其中600~650 ℃之间焦油转化率变化较大,焦油转化率提升了29.8%。这表明,随着催化重整温度增加,焦油的裂解反应增强,焦油中重质组分部分转化为轻质组分和不可凝气体[25-26]。

注:玉米秸秆炭作催化剂、玉米秸秆原料用量为10 g、停留时间0.2 s。

2.2 停留时间对热解气重整的影响

2.2.1 停留时间对热解气提质的影响

载气流量不变,通过增加生物炭质量改变床层高度,通过测量生物炭质量2 g时,床层高度为3 cm。图4为不同停留时间对热解气产率、热值和气体组成的影响。从图4中可知,随着停留时间由0.2 s增加到1.8 s,热解气产率由37.9%增加到54.3%,热解气热值由17.6 MJ/m3降低到16.8 MJ/m3。由于延长热解气焦油组分穿过生物炭床层的停留时间,促进焦油催化裂解反应[27]。从气体组成图中可知,随着停留时间由0.2 s增加到1.8 s,H2体积分数由21.8%增加到32.7%,CH4体积分数由18.1%下降到13.6%,且与H2相比,CH4的热值相对较高,所以导致热值下降[28-29]。

2.2.2 停留时间对焦油消减的影响

图5为停留时间对焦油消减的影响,从图5中可知,随着停留时间增加,焦油产量下降,焦油转化率增加,是由于停留时间增加,促进了水煤气反应,以及焦油组分在生物炭表面矿物质组分活性位点上的催化转化[30],从而引起焦油产量下降。当停留时间由0.2 s增加到0.6 s时,焦油转化率由72.6%增加到74.4%,当停留时间由0.6 s增加到1.4 s时,焦油转化率由74.4%增加到78.6%,焦油产量下降为0.19 g,停留时间为1.8 s时,焦油转化率为79.8%。

注:玉米秸秆炭作催化剂、玉米秸秆原料用量为10 g、温度800 ℃。

注:玉米秸秆炭作催化剂、玉米秸秆原料用量为10 g、温度800 ℃。

2.3 催化剂对热解气重整的影响

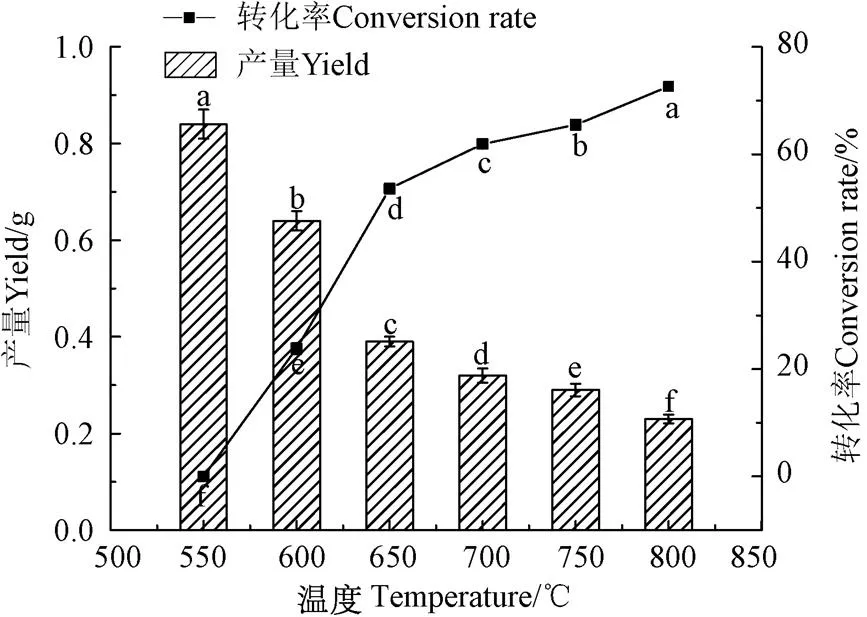

2.3.1 催化剂对热解气提质的影响

图6为催化重整温度800 ℃时,3种不同生物炭催化剂和填充材料石英砂对热解气产率、热值和气体组成的影响,由于石英砂为惰性材料,其对焦油裂解几乎没有催化作用[31-32],在本文仅用来研究高温裂解对热解气提质的影响,从图6中可知,550 ℃热解时,热解气产率为21%,高温裂解时(石英砂)热解气产率为33.8%,热值为18.0 MJ/m3,木屑炭、稻壳炭、玉米秸秆炭的热解气产率为38.6%、39.7%和37.9%,热值为17.7、17.8和17.6 MJ/m3。相比之下,石英砂的热解气产率较低,但热值较高,是由于高温促进裂解反应,生成热值较高的CO,而生物炭催化剂虽然能使H2产率升高,但CO体积分数降低。由表2中可知玉米秸秆炭中K、Ca等元素含量高,有利于促进焦油转化,但其催化效果较低,这说明生物炭比表面积的影响要高于金属元素的影响,当然也可能与生物炭结构和金属元素存在形式有关。不同生物炭催化剂对热解气产率影响效果:稻壳炭>木屑炭>玉米秸秆炭,而对热解气热值催化效果大致相同。

注:停留时间0.2 s、玉米秸秆原料用量为10 g、催化剂温度800 ℃。

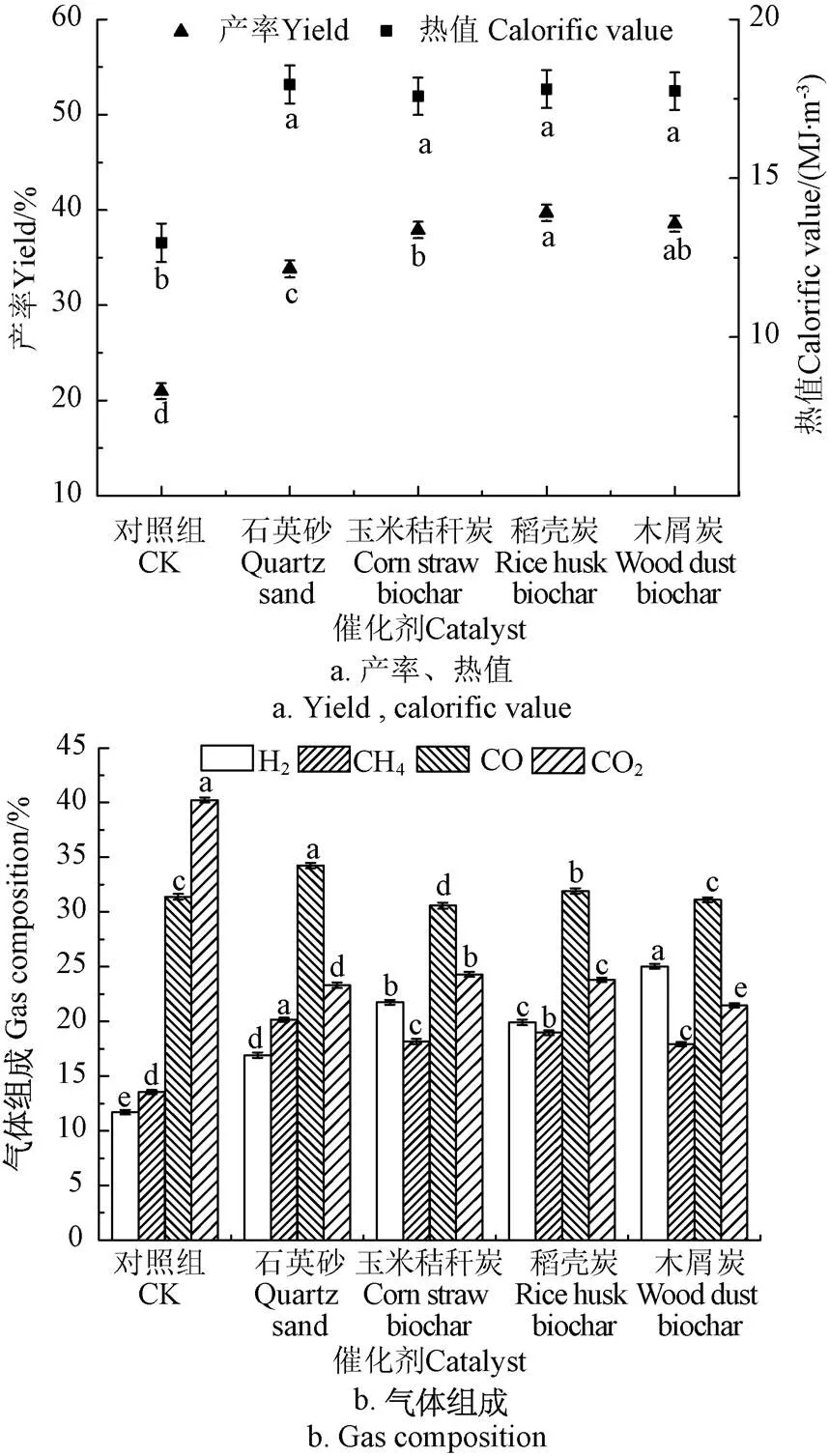

2.3.2 催化剂对焦油消减的影响

图7为催化剂对焦油消减的影响,从图7中可知,550 ℃热解产生的焦油产量为0.84 g,高温裂解时,焦油产量为0.30 g,转化率为64.3%,是由于石英砂具有较高的比热容,蓄热量大,增强了反应器内的热量传递,使通过石英砂的气体温度迅速升高,促进了焦油裂解[33]。和高温裂解相比,木屑炭、稻壳炭、玉米秸秆炭的催化重整焦油转化率为78.6%、79.8%和72.6%,提高了8.3%~15.5%,是因为生物炭颗粒的表面具有极性活化位,使π形电子云被破坏而失去稳定,使C-C键、C-H键断裂,促进了裂解反应。如表2所示,生物炭中K、Ca等元素虽然有利于焦油催化裂解,但其催化效果低于稻壳生物炭,是由于稻壳炭比表面积186.6 m2/g高于木屑炭比表面积45.7 m2/g和玉米秸秆炭比表面积37.7 m2/g,增大了催化剂的接触面积和催化活性。

注:停留时间0.2 s、玉米秸秆原料用量为10 g、催化剂温度800 ℃。

2.4 催化重整前后生物炭比表面积变化

图8为催化重整前后玉米秸秆炭比表面积变化,从图8中可知,热解温度550 ℃的玉米秸秆炭比表面积为37.96 m2/g,600 ℃催化重整后比表面积下降到3.88 m2/g,是由于生物质热解产生的焦油附着在生物炭表面,产生积碳,使生物炭比表面积降低。由600 ℃升高到800 ℃时,生物炭比表面积逐渐增加,重整温度为800 ℃时,生物炭比表面积为79.81 m2/g,高于热解生物炭比表面积,一方面是由于温度的增加,促进焦油催化裂解反应,避免了生物炭被焦油附着,另一方面是由于热解产生的水蒸气与炭发生气化反应,消耗表面覆盖积碳,同时在生物炭催化剂上形成多孔[34]。生物炭作催化剂时,不但可以提高热解气品质,而且可提高生物炭比表面积。

图8 催化重整前后玉米秸秆炭比表面积变化

3 结 论

1)随着重整温度、停留时间增加,热解气产率和焦油转化率增加,但热解气热值只随着温度升高而升高,当重整温度为800 ℃时,热解气热值为17.6 MJ/m3。

2)通过生物炭与石英砂比较,说明生物炭具有较好的催化特性,玉米秸秆炭虽然K、Ca元素含量较高,但其催化效果较低,说明生物炭比表面积对裂解焦油的影响高于金属元素。其中生物炭催化特性:稻壳炭>木屑炭>玉米秸秆炭。

3)800 ℃催化重整后玉米秸秆炭比表面积为79.81 m2/g高于550 ℃热解玉米秸秆炭比表面积37.7 m2/g,生物炭作催化剂时不但可以提高热解气品质,也可提高生物炭比表面积。

[1] 胡二峰,赵立欣,吴娟,等. 生物质热解影响因素及技术研究进展[J]. 农业工程学报,2018,34(14):212-220. Hu Erfeng, Zhao Lixin, Wu Juan, et al. Research advance on influence factors and technologies of biomass pyrolysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(14): 212-220. (in Chinese with English abstract)

[2] 刘标,陈应泉,何涛,等. 农作物秸秆热解多联产技术的应用[J]. 农业工程学报,2013,29(16):213-219. Liu Biao, Chen Yingquan, He Tao, et al. Application of cogeneration technology of gas-liquid-solid products pyrolyzed from crop straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(16): 213-219. (in Chinese with English abstract)

[3] 丛宏斌,姚宗路,赵立欣,等. 自燃连续式生物质热解炭气油联产系统燃气净化分离技术工艺研究[J]. 可再生能源,2015(9):1393-1397. Cong Hongbin, Yao Zonglu, Zhao Lixin, et al. Research on gas separation and purification technology forcontinuous pyrolysis system with biomass spontaneous combustion[J]. Renewable Energy Resources, 2015(9): 1393-1397. (in Chinese with English abstract)

[4] 刘荣厚,袁海荣,徐璐,等. 玉米秸秆热解反应动力学的研究[J]. 太阳能学报,2007,28(5):527-531. Liu Ronghou, Yuan Hairong, Xu Lu, et al. Kinetic study of maize straw pyrolysis[J]. Journal of Solar Energy, 2007, 28(5): 527-531. (in Chinese with English abstract)

[5] José Corella. Biomass gasification with air in fluidized bed: Reforming of the gas composition with commercial steam reforming catalysts[J]. Ind.eng.chem.res,1998, 37(12): 4617-4624.

[6] Donaj P. Conversion of Biomass and Waste Using Highly Preheated Agents for Materials and Energy Recovery[D]. Stockholm: Doctoral Disse Ration of Royal Institute of Technology, 2011.

[7] 贾吉秀,赵立欣,孟海波,等. 生物质热解焦油燃烧试验系统设计与试验[J]. 农业机械学报,2018,49(12): 334-339. Jia Jixiu, Zhao Lixin, Meng Haibo, et al. Design and experiment on biomass pyrolysis Tar combustion System[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(12): 334-339. (in Chinese with English abstract)

[8] 仉利,赵立欣,姚宗路,等. 生物质燃气燃烧器技术研究进展[J]. 中国农机化学报,2017,38(1): 111-115. Zhang Li, Zhao Lixin, Yao Zonglu, et al. Research progress of biomass gas burner technology[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(1): 111-115. (in Chinese with English abstract)

[9] 袁晓涛,胡建杭,张凤霞,等. 铜渣载镍催化剂催化气化松木屑的实验研究[J]. 化工进展,2018,37 (10): 3919-3927. Yuan Xiaotao, Hu Jianhang, Zhang Fengxia, et al. Experimental study on the catalytic gasification of pine sawdust over nickel catalyst supported by copper slag[J]. Chemical Industry and Engineering Progress, 2018, 37 (10): 3919-3927. (in Chinese with English abstract)

[10] 周劲松,王铁柱,骆仲泱,等. 生物质焦油的催化裂解研[J]. 燃料化学学报,2003,31(2): 144-148. Zhou Jinsong, Wang Tiezhu, Luo Zhongyang, et al. Catalytic cracking of biomass tar[J]. Journal of Fuel Chemistry and Technology, 2003, 31(2):144-148. (in Chinese with English abstract)

[11] Thangalazhy-Gopakumar S, Adhikari S, Ravindran H, et al. Physiochemical properties of bio-oil produced at various temperatures from pine wood using an auger reactor[J]. Bioresource Technology, 2010, 101(21): 8389-8395.

[12] 李贤斌,姚宗路,赵立欣,等. 生物质炭化生成焦油催化裂解的研究进展[J]. 现代化工,2017,37(2): 46-50. Li Xianbin, Yao Zonglu, Zhao Lixin, et al. Research progress of catalytic pyrolysis of biomass tar[J]. Modern Chemical Industry, 2017, 37(2): 46—50. (in Chinese with English abstract)

[13] 姜建国,张卫杰,孙荣峰,等. 生物质气化过程中焦油脱除技术研究进展[J]. 山东科学,2019,32(1): 127-134. Jiang Jianguo, Zhang Weijie, Sun Rongfeng, et al. Research progress on tar removal technology in biomass gasification process[J]. Shandong Science, 2019, 32 (1): 127-134. (in Chinese with English abstract)

[14] 金亮,童瑞明,周劲松,等. 生物质燃气焦油产率及其净化[J]. 农业工程学报,2010,26(增刊2): 259-263.Jin Liang, Tong Ruiming, Zhou Jinsong, et al. Tar character and cleaning of biomass gasification gas [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(Supp.2): 259-263. (in Chinese with English abstract)

[15] 周中仁,吴文良.生物质能研究现状及展望[J].农业工程学报,2005,21(12):12-15.Zhou Zhongren, Wu Wenliang. Status quo and prospects of biomass energy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2005, 21(12): 12-15. (in Chinese with English abstract)

[16] Lopamudra Devi, Krzysztof J Ptasinski. A review of the primary measures for tar elimination in biomass gasification processes[J]. Biomass and Bioenergy, 2003, 24(2): l25-140.

[17] 刘殊远,汪印,武荣成,等. 热态半焦和冷态半焦催化裂解煤焦油研究[J]. 燃料化学学报,2013,41(9):1041-1049. Liu Shuyuan, Wang Yin, Wu Rongcheng, et al. Research on coal tar catalytic cracking over hot in-situ chars[J].Journal of Fuel Chemistry and Technology, 2013, 41(9):1041-1049. (in Chinese with English abstract)

[18] 李欢欢. 典型热解焦炭对热解气中焦油模化物的催化裂解研究[D]. 杭州:浙江大学,2018. Li Huanhuan. Study on Catalytic Cracking of Model tar Species in Pyrolysis Gas by Typical Pyrolysis Char[D]. Hangzhou: Zhejiang University, 2018. (in Chinese with English abstract)

[19] 孟凡彬,孟军. 玉米秸秆炭和木屑炭催化裂解焦油的试验研究[J]. 沈阳农业大学学报,2017,48(4): 472-476. Meng Fanbin, Meng Jun. Experimental study on catalytic cracking of tar with corn stalk charcoal and sawdust charcoal[J]. Journal of Shenyang Agricultural University, 2017, 48(4): 472-476. (in Chinese with English abstract)

[20] 陈宗定,张书,王芳杰,等. 活化前后半焦原位催化重整褐煤热解焦油研究[J]. 煤炭科学技术,2014,42(11):105-110. Chen Zongding, Zhang Shu, Wang Fangjie, et al. Study on in-situ catalytic reforming of coal tar from pyrolysis of brown coal by activated and inactivated char[J]. Coal Science and Technology, 2014, 42(11): 105-110. (in Chinese with English abstract)

[21] 马欣欣. 预处理和焦油催化重整对生物质热解制气性能的影响研究[D]. 北京:北京化工大学,2016. Ma Xinxin. Effect of Impregnation and Catalytic tar Conversion on Biomass Pyrolysis for Gas Production[D]. Beijing: Beijing University Chemical Technology, 2016. (in Chinese with English abstract)

[22] 王敬茹,马腾,丛宏斌,等. 生物质热解气重整试验平台设计与试验[J]. 可再生能源,2019,37(4): 482-487. Wang Jingru, Ma Teng, Cong Hongbin, et al. Design and experimental test for a biomass pyrolysis gas reforming reactor[J]. Renewable Energy Resources, 2019, 37(4): 482-487. (in Chinese with English abstract)

[23] 丛宏斌,赵立欣,姚宗路,等. 玉米秸秆连续干馏条件下能量平衡分析[J]. 农业工程学报,2017,33(7): 206-212. Cong Hongbin, Zhao Lixin, Yao Zonglu, et al. Energy balance analysis of corn straw continuous distillation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE)), 2017, 33(7): 206-212. (in Chinese with English abstract)

[24] 张丹阳. 多孔泡沫陶瓷对生物质气化焦油裂解转化的影响研究[D]. 合肥:合肥工业大学,2017. Zhang Danyang. Study on the Effect of Porous Foam Ceramic on Pyrolysis of Biomass Gasification[D]. Hefei: Hefei University of Technology, 2017. (in Chinese with English abstract)

[25] 王晨光,王铁军,吕鹏梅,等. 整体式催化剂催化重整净化生物质粗燃气性能研究[J].燃料化学学报,2007(3):285-288. Wang Chenguang, Wang Tiejun, Lu Pengmei, et al. Reforming of raw biomass fuel gas over monolith catalyst[J]. Journal of Fuel Chemistry and Technology, 2007(3): 285-288. (in Chinese with English abstract)

[26] 王芳,曾玺,孙延林,等. 两段流化床中半焦催化脱除焦油特性[J]. 化工学报,2017,68(10):3762-3769. Wang Fang, Zeng Xi, Sun Yanlin, et al. Characteristics of char catalytic reforming of tar in two-stage fuuidized bed[J]. CIESC Journal, 2017, 68(10): 3762-3769. (in Chinese with English abstract)

[27] Saxena R C, Goyal H B. Thermo-chemical routes for hydrogen rich gas from biomass: A review[J]. Renewable and Sustainable Energy Reviews, 2008, 12(7): 1909-1927.

[28] 谢玉荣,肖军,沈来宏. 生物质催化气化制取富氢气体实验研究[J]. 太阳能学报,2008,29(7):888-893. Xie Yurong, Xiao Jun, Shen Laihong. Research on biomass catalytic gasification to produce hydrogen-rich gas[J]. Acta Energiae Solaris Sinica, 2008, 29(7): 888-893. (in Chinese with English abstract)

[29] 敦启孟,陈兆辉,皇甫林,等. 温度和停留时间对煤热解挥发分二次反应的影响[J]. 过程工程学报,2018,18(1): 140-147. Dun Qimeng, Chen Zhaohui, Huang Pulin, et al. Influences of Temperature and residence time on secondary reactions of volatiles from coal pyrolysis[J]. The Chinese Journal of Process Engineering, 2018, 18(1): 140-147. (in Chinese with English abstract)

[30] 孙海权,张晓东,陈雷,等. 生物质焦油模型化合物的催化转化[J]. 农业工程学报,2009,25(07):201-203. Sun Haiquan, Zhang Xiaodong, Chen Lei, et al. Catalytic conversion of biomass pyrolysis tar model compound[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(7): 201-203.(in Chinese with English abstract)

[31] 尤占平,由世俊,李宪莉,等. 生物质炭催化裂解焦油的实验研究[J]. 太阳能学报,2011,32(5):718-723. Yu Zhanping, You Shijun, Li Xianli, et al. experimental research on tar catalytic cracking over biomass char[J]. Acta Energiae Solaris Sinica, 2011, 32(5): 718-723. (in Chinese with English abstract)

[32] 王磊,吴创之,赵增立. 热解焦对生物质焦油催化裂解的影响[J]. 太阳能学报,2006(5):514-518. Wang Lei, Wu Chuangzhi, Zhao Zengli. Effect of char on catalytic cracking of tar from biomass gasification gas with toluene as a model compound[J]. Acta Energiae Solaris Sinica, 2006(5): 514-518. (in Chinese with English abstract)

[33] 李旭,由世俊,张欢,等. 生物质炭催化重整焦油的动力学模型研究[J]. 太阳能学报,2014,35(6):949-954. Li Xu, You Shijun, Zhang Huan, et al. Study on kinetic model of tar catalytic reforming reaction over biomass char[J]. Acta Energiae Solaris Sinica, 2014, 35(6): 949-954. (in Chinese with English abstract)

[34] 吴小飞,巴玉鑫,王惠惠,等. 无热载体蓄热式旋转床生活污泥热解技术研究[J]. 环境工程,2016,34(S1):707-710,714. Wu Xiaofei, Ba Yuxin, Wang Huihui, et al. Pyrolysis technology of sewage sludge in regenerative heat -carrier- free rotating bed [J]. Environmental Engineering, 2016, 34(S1): 707-710, 714. (in Chinese with English abstract)

Upgrading biomass pyrolysis gas from corn stalk by charcoal catalytic reforming

Wang Jingru1,2, Yao Zonglu1, Cong Hongbin1, Zhao Lixin1,2※, Ma Teng1, Huo Lili1, Yuan Yanwen1

(1.,,,100125; 2.,,163319,)

Biomass pyrolysis technology is a thermochemical conversion technique. Through the pyrolysis technology, straw recycling can be realized, and high value-added energy products such as biochar and pyrolysis gas can be obtained. However, the tar produced in the pyrolysis process contains heavy poisonous components, and the low temperature viscosity is high, which easily causes pipeline blockage. In order to study the effect of biochar as catalyst for reducing tar and improving pyrolysis gas quality, taking corn stalk as raw material, the tar conversion rate, pyrolysis gas yield and pyrolysis gas heat value were selected as index. The effects of reforming temperature (550, 600, 650, 700, 750, 800 ℃), residence time (0.2, 0.6, 1.0, 1.4, 1.8 s) and biochar characteristics (corn straw charcoal, rice husk, wood charcoal) on pyrolysis gas quality were studied. The changes of specific surface area of biochar catalysts before and after reforming were analyzed. The results showed that at high temperature cracking, the pyrolysis gas yield was 33.8%, and the pyrolysis gas heat value was 18.0 MJ/m3, biochar had better catalytic properties than quartz sand (high temperature cracking), and its catalytic properties were: rice husk charcoal > wood charcoal > corn straw charcoal, indicating that the catalytic properties of rice hull carbon were better. The pyrolysis gas yields of rice husk charcoal, wood charcoal and corn straw charcoal were 39.7%, 38.6%, and 37.9%, respectively, and the tar conversion rates were 79.8%, 78.6% and 72.6%, the calorific values were 17.8, 17.7 and 17.6 MJ/m3, respectively. When the reforming temperature was increased from 550 to 800 ℃, the pyrolysis gas yield increased from 21.0% to 37.9%, the tar conversion rate increased from 23.8% to 72.6%, and the pyrolysis gas calorific value increased from 13.0 to 17.6 MJ/m3, which was due to the increase of temperature to promote the cracking reaction of tar. The tar heavy components were partially converted into light components and non-condensable gases. As the residence time increased from 0.2 to 1.8 s, the pyrolysis gas yield increased from 37.9% to 54.3%, and the tar conversion rate increased from 72.6% to 79.8%. The pyrolysis gas heat value was reduced from 17.6 to 16.8 MJ/m3. It was due to the increase in residence time, which promoted the catalytic conversion of the tar component on the active site of the mineral component on the surface of the biochar, resulting in an increase in the yield of the pyrolysis gas. At 800 ℃, the specific surface area of biochar after catalytic cracking was 79.81 m2/g, which was higher than the specific surface area of pyrolysis biochar of 37.96 m2/g. In summary, as the reforming temperature and residence time increased, the pyrolysis gas yield and tar conversion rate increased, and the pyrolysis gas heat value increased only as the reforming temperature increased. Although biochar can increase pyrolysis gas yield and tar conversion rate, the calorific value was low. Biochar can not only improve the quality of pyrolysis gas, but also increase the specific surface area of biochar at 800 ℃, indicating that the interaction between biochar and pyrolysis gas can not only improve the quality of pyrolysis gas, but also increase the specific surface area of biochar.

straw; pyrolysis; catalyzation; pyrolysis gas; biochar; coupling; tar; catalytic reforming

2019-03-19

2019-07-30

国家玉米产业技术体系任务委托协议资助项目(CARS-02-31)和农业农村部规划设计研究院自主研发项目(2018ZZYF0203)

王敬茹,研究方向为生物质热解。Email:807838914@qq.com

赵立欣,研究员,主要从事生物质能资源开发利用技术与政策研究。Email:zhaolixin5092@163.com

10.11975/j.issn.1002-6819.2019.16.029

TK6

A

1002-6819(2019)-16-0258-07

王敬茹,姚宗路,丛宏斌,赵立欣,马 腾,霍丽丽,袁艳文.生物质炭催化玉米秸秆热解气重整提质研究[J]. 农业工程学报,2019,35(16):258-264. doi:10.11975/j.issn.1002-6819.2019.16.029 http://www.tcsae.org

Wang Jingru, Yao Zonglu, Cong Hongbin, Zhao Lixin, Ma Teng, Huo Lili, Yuan Yanwen. Upgrading biomass pyrolysis gas from corn stalk by charcoal catalytic reforming[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(16): 258-264. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.16.029 http://www.tcsae.org