Tribological Behavior of Graphene Strengthened Lithium Grease

2019-09-12,,,,,,,,

, ,,, , , , ,

(1.School of Mathematics and Physics, Changzhou University, Changzhou 213164, China; 2.Jiangsu Province Cultivation Base for State Key Laboratory of Photovoltaic Science and Technology, Jiangsu Collaborative Innovation Center for Photovoltic Science and Engineering, School of Materials Science and Engineering, Changzhou University, Changzhou 213164, China; 3.Micro/Nano Science and Technology Center, Jiangsu University, Zhenjiang 212013, China; 4.State Key Laboratory of Tribology, Tsinghua University, Beijing 100084, China)

【Abstract】 Owing to unique structure and particuar physical and chemical properties, graphene has been attracting much attention to be as an environment friendly lubricating candidate. Graphene was synthesized by the solution-exfoliation method, and subsequently characterized by many advanced techniques, e.g. Raman spectroscopy, and X-ray photo-electron spectroscopy, ect. The as-prepared graphene as an additive could be well dispersed in the lithium grease through a series of grinding/homogenization steps. Tribological behavior of the as-obtained grease was studied using a friction tester and a noncontact interferometric microscope. It is found that graphene-strengthened lithium grease (graphene grease) provides the best tribological properties with the lowest friction coefficient and the least wear loss. Compared with that of pure lithium grease, the wear volumes of the worn surfaces lubricated by the graphene grease are decreased by 68~83%. Furthermore, the worn surfaces lubricated by the graphene greases containing 0.015wt% and 0.02wt% of graphene have the least wear volumes. These benefits are ascribed to the laminated structure and good dispersion of graphene in grease.

【Key words】 graphene; lithium grease; lubricating additive; lubrication; tribology

1 Introduction

Lubricating grease gives protection to the bearings and other rolling elements against wear and reduces friction in many applications. Owing to its semi-solid character, greases could effectively protect the moving mechanical parts[1]. It is beneficial if the grease could maintain its anti-wear and anti-friction properties for a long time to keep moving mechanical parts working[2]. In particular, lithium grease has been found to effectively decrease friction and wear and extends the lifetime of mechanical parts[3]. Thus, lithium grease has found applications in transports, machine tools, instruments and many others involving moving mechanical parts[4].

However, poor mechanical stability and continuous mechanical forces result in degradation or leakage of grease or even failure of the machines[1,5]. Therefore, researchers have been focusing on the searching for lubricants that could effectively improve the tribological properties in many applications. It has been found that some nanomaterials added into the lubricating oil/grease could effectively improve the thermal stability, corrosion resistance, anti-wear ability, and overall tribological property[6-13]. However, most of the reported lubricating additives contain phosphorus, sulphur atoms or heavy metal elements, which may pollute the environment and cause corrosion problems[14]. In addition, the application of solid nanomaterials has been limited due to the poor dispersion and aggregation in lubricants. Therefore, researchers have made great efforts to develop green lubricants with high performance, which are environment friendly and could provide low tribological wear and self-repairing capability. Due to the excellent properties including the high chemical stability and high load-bearing capacity, carbon-based materials have aroused much concern as promising lubricating additives used in lubricating oil and water[15]. They have been found to reduce friction and have anti-wear property[3,16-17]. Kobayashi studied the carbon nanohorn as additive in grease and found that it could improve the load carrying capacity and anti-wear property[17]. Mohamed found that only 1wt% of CNTs adding into grease could also increase the load carrying capacity and decrease the wear loss[3].

Graphene is a two-dimensional honeycomb-structured carbon crystal with atom-scaled thickness[18]. Owing to its unique structure and particular chemical and physical properties, graphene has attracted much attention in many applications over the recently years[19-20]. In particular, the high thermal conductivity, good chemical stability, strong mechanical strength and low shear strength of graphene make it an attractive, environmentally friendly lubricating candidate[20]. Lin reported that only 0.075wt% of modified graphene platelets adding into lubricating oil clearly improved the anti-wear property and load-carrying capacity of machines[21]. Wu prepared the graphene and found that the as-prepared graphene as an additive could improve the tribological properties of base oil[22]. Fan studied the effect of multi-layered graphene as a solid additive on the tribological and anti-wear ability of lubricating greases[23]. Therefore, graphene is expected to improve the tribological properties of lithium grease. However, few reports have been found to study the effect of the adding of graphene on the tribological behavior of lithium grease.

Therefore, in this study, unmodified graphene was added into lithium grease with a good dispersion in order to explore its effects on the friction-reducing and anti-wear performance. The effects of concentration, types of additives and load on the tribological behavior were systematically researched.

2 Experimental

2.1 Materials

Graphite powders were used to prepare graphene. N-methyl-2-pyrrolidone (NMP), Sodium tauroglycocholate (98%), Lithium grease. All other analytical-grade reagents were used without further purification. Ultrapure water was used for rinsing.

2.2 Preparation of the graphene and additive-containing lithium greases

Graphite powders were used to synthesize the graphene according to the solution-exfoliation method[24]. Graphite powder (5g) was added into a beaker. Then 20mL NMP and a little sodium tauroglycocholate were added one by one. The as-obtained solution in the beaker was stirred at a desired speed and maintained for 60min. The as-prepared precipitate was collected through filtration and washed with ethanol until the pH value was about 6-7 before the last filtration, and dried at 90℃. Finally, the graphene sheets were obtained.

The as-prepared graphene was mixed with ethanol and then the obtained solution was uniformly mixed into the lithium grease. Then the ethanol was evaporated and the lithium grease was left. The graphene-containing lithium grease (hereinafter referred to as graphene grease) was obtained after a series of fine grinding/homogenization steps. The amount of 0.01wt%, 0.015wt%, 0.02wt%, 0.03wt% and 0.05wt% graphene were added into the lithium grease, respectively and they were denoted as graphene-1 grease, graphene-2 grease, graphene-3 grease, graphene-4 grease and graphene-5 grease for short, respectively. It can be clearly seen that the as-obtained graphene could be uniformly dispersed in the lithium grease and the more the graphene was added, the darker the graphene grease is, as shown in Fig.1. In addition, the amount of 0.02wt% graphite was also mixed into the lithium grease in the same procedure as described for that of graphene for comparison. After a series of grinding/homogenization procedures, the graphite-containing lithium grease (graphite grease as abbreviated form) was also obtained.

Fig.1 Optical images of lithium grease. (a) added with graphene with different mass fraction; (b) added with different additives with mass fraction of 0.02wt%

2.3 Characterization

The surface morphologies of the as-prepared graphene were characterized by a field emission scanning electron microscopy (FE-SEM, SUPRA) and an atomic force microscope (AFM, Nanoscope IIIa) in the tapping scanning mode. The information of chemical compositions and phase identification of the as-prepared graphene was obtained using a Raman spectroscope with 532nm laser excitation (Lab JY-HR800) and an X-ray diffractometer (XRD, DMax-RA). The surface chemical composition of the as-prepared graphene was examined with a PHI-5702 multifunctional X-ray photo-electron spectroscope (XPS), using Mg Ka radiation as the excitation source, and the binding energy of contaminated carbon (C1s:284.8eV) was used as reference.

Tribological performances of the lubricating greases were assessed on an Optimal-SRV-I friction tester (Optimal) in the ball-on-block reciprocation mode. The commercially available upper AISI 52100 steel ball with a diameter of 10 mm (hardness of 710 HV) slid against the stationary lower AISI 52100 steel disks (hardness of 664 HV) at the amplitude of 1 mm. The applied loads of 100-300 N and sliding frequency of 30 Hz were employed for all the tests each for 30min. Before the tribological tests, about 1 g grease was added into the ball-block contact area. Plots of the friction coefficient versus time were recorded automatically by a computer connected to the Optimal-SRV tester. The wear loss of the lower disk was calculated by a MicroXAM-3D noncontact interferometric microscope. The extreme pressure property of the graphene greases was evaluated on an Optimal-SRV-IV friction tester in the ball-on-block reciprocation mode. The tests were conducted sequentially from 100 to 600 N stepped by 50 N with a sliding frequency of 30 Hz, an amplitude of 1 mm and a duration of 3min for each load.

3 Results and Discussion

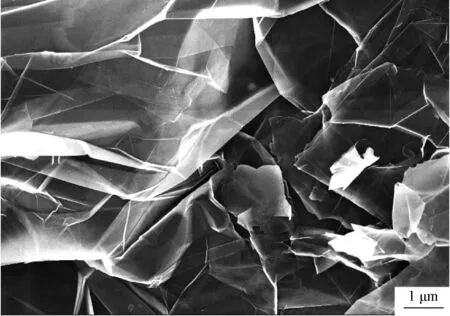

Figure 2 shows the FESEM image of the as-prepared graphene powder. It can be seen that the as-prepared graphene disorderly piled together with lamellar structure. The sheets have different size and the shape is irregular.

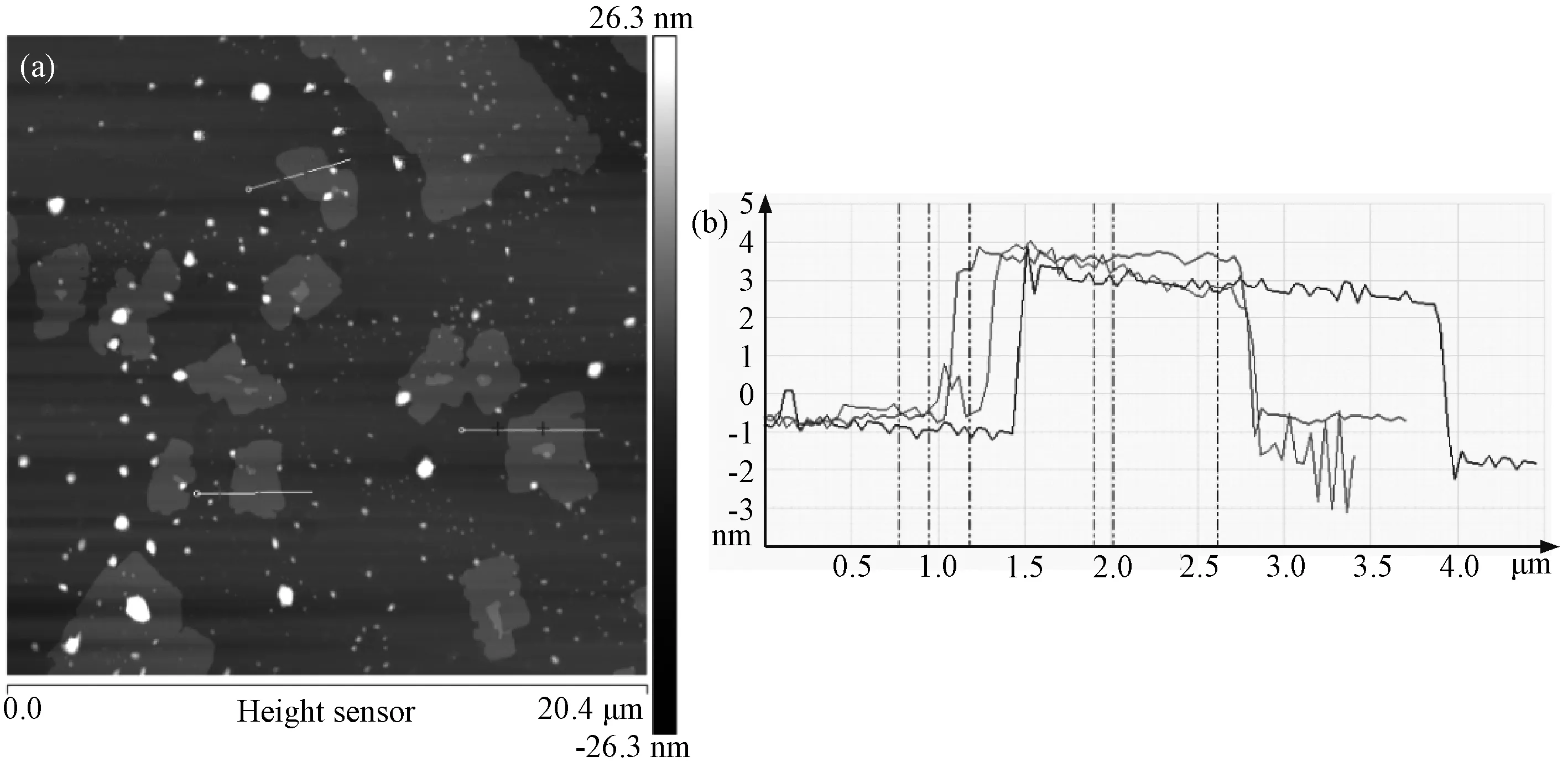

Figure 3 shows the surface morphological information of the as-obtained graphene on bare silicon, which was measured by AFM. It can be clearly observed that there are several irregular sheet-like graphene scattering on the bare Si surface, as shown in Fig.3a. The section analysis shown in Fig.3b indicates that the sheet-like graphene has an average thickness of about 5nm, which is larger than the typical value of 0.34nm for a single-layered graphene, indicating the as-prepared graphene are multi-layered[25-26].

Fig.2 FESEM image of the as-prepared graphene

Fig.3 Surface morphological information of the as-prepared graphene on bare silicon (a) AFM image, (b) Two dimensional cross section

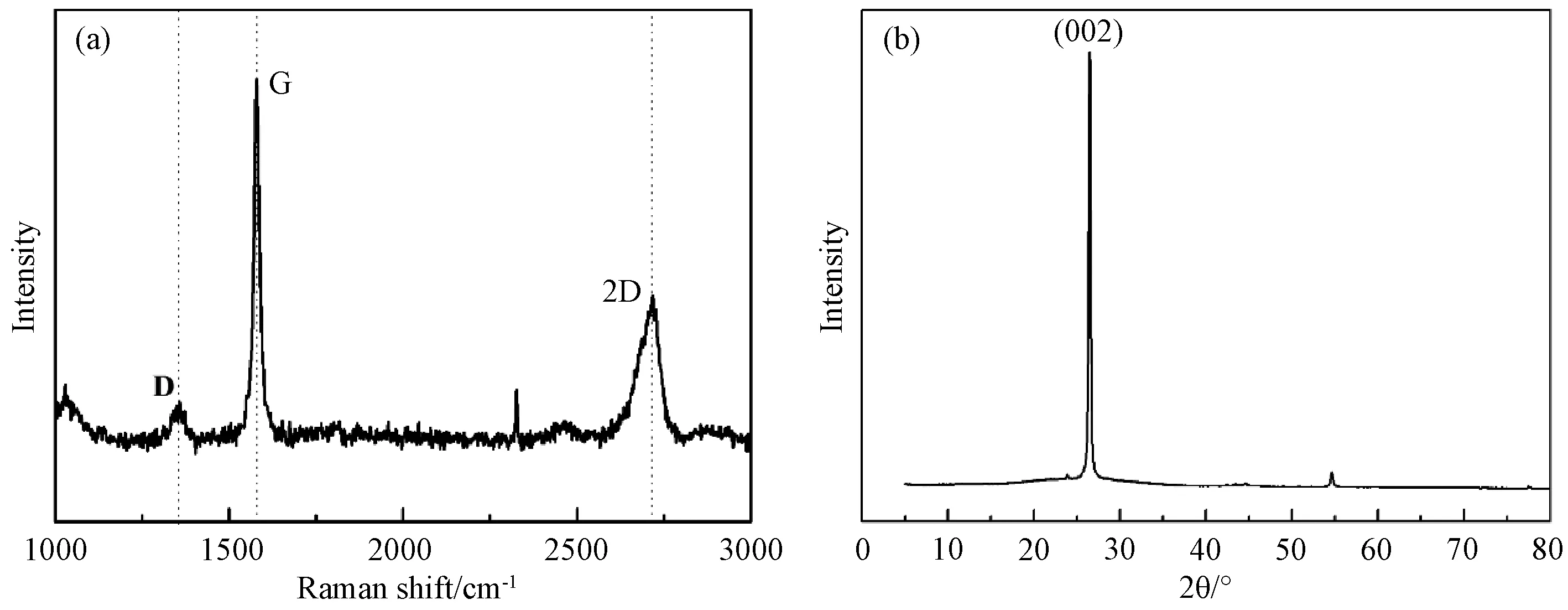

Raman spectrum of the as-prepared graphene was also obtained and was shown in Fig.4a. It can be seen that there are two typical and most intense peaks of graphene, which are the G band (1578cm-1) originated from the in-plane vibration of sp2carbon atoms and 2D band (2716cm-1) originated from two-phonon double-resonance Raman scattering process[27]. The existence of the D band (1354cm-1) indicates that there are some defects existing at the sample edge. Furthermore, the ratio of I2D/IG(much<1) suggests that the as-prepared graphene is multi-layered[28], which is consistent with the results obtained from AFM. XRD pattern in Fig.4b shows a strong (002) diffraction peak at about 26°, indicating that the as-prepared graphene has a well ordered crystalline structure[29].

To further clarify the defects existing at the as-prepared sample, XPS spectra of the as-prepared graphene were shown in Figure 5. It can be clearly observed that there are a strong C1s peak and a weak O1s peak, as shown in Fig.5a. The C1s spectrum shown in Fig.5b indicates that two typical peaks are observed. The peak at 284.8eV is formed by the sp2hybridized carbon while the peak at 286.8 eV corresponds to sp3hybridized carbon atoms due to the functional group containing the carbon-oxygen single bond[30].

Fig.4 Spectra of the as-prepared graphene (a) Raman spectrum; (b) XRD pattern

Fig.5 XPS survey spectrum (a) and the deconvoluted C1s XPS spectrum (b) of the as-prepared graphene

Figure 6 displays the coefficients of friction of as-obtained lithium grease added with graphite or graphene as a function of the time under the load of 300N with the sliding rate of 30 Hz, compared with that of pure lithium grease. It can be clearly seen that pure lithium grease has the highest coefficients of friction. While the coefficients of friction decrease to different extents after the adding of graphite or graphene, indicating that both graphite and graphene added into lithium grease could effectively reduce the coefficients of friction. Compared with that of the graphite grease, the graphene grease could obviously reduce the coefficient of friction by 4.1%~8.6%. This is because that graphene exhibits better dispersion in lithium grease and the sheet-like structure of the graphene possesses a better adsorption on the contacting surfaces, which effectively improves the tribological property and wear resistance.

Fig.6 Variation in coefficients of friction of lithium greases adding with different additives with time at applied load of 300N and a sliding velocity of 30Hz

The lower disks were cleaned with petroleum ether to remove the grease and wear debris, and dried with N2after the friction test. Then the worn surface was examined by a 3D noncontact interferometric microscope. The 2D section analysis of the wear tracks of the lower disk lubricated with different lubricating greases under an applied load of 300 N and a sliding rate of 30 Hz is shown in Fig.7. It can be observed that the worn surfaces lubricated by the pure lithium grease or graphite grease show deeper wear grooves, indicating abrasive wear is dominant. While the graphene grease-lubricated worn surface is smoother and displays a lower wear groove. Compared with that of pure lithium grease, the wear losses of the worn surfaces lubricated by the graphene grease containing only 0.01wt%~0.05wt% of graphene are decreased by 68%~83% throughout the testing processes, as shown in table 1. Moreover, the worn surfaces lubricated by graphene-2 grease and graphene-3 grease containing only 0.015wt% and 0.02wt% of graphene, respectively, have the lowest wear volumes. The results show that graphene grease improves better the tribological and anti-wear properties than that of pure lithium grease or graphite grease, and the amount of added graphene had a best value or value range. Moreover, compared with the literatures’ value, only adding less amount of graphene (one to two orders of magnitude less than the amount of literatures’) into the lithium grease could significantly reduce the wear losses of the worn surfaces and improve the tribological properties[31-35]. It may be suggested that graphene has a good dispersion in lithium grease after a series of fine grinding/homogenization steps.

Fig.7 2D section analysis of the wear tracks of the lower disk lubricated with different lithium greases under the applied load of 300N and the sliding rate of 30Hz for 30min

Table 1 Wear volume of steel disks lubricated with different lithium greases after rubbing testing under load of 300N with the sliding rate of 30 Hz for 30min

Fig.8a displays the extreme pressure property and tribological curves of the graphene grease, respectively. It can be observed that the graphene grease added with only 0.01wt% of graphene maintains a low friction coefficient (below 0.13) before the applied load raising to 600N, which could be ascribed to the outstanding mechanical performance and the good dispersion of the grapheme(Fig.8a). In addition, the friction coefficient of the graphene grease-lubricated surface slightly decreases when the applied load increases. To further certify it, the tribological curves of the grapheme-2 grease were obtained under 100N and 300N with the sliding rate of 30Hz for 30min, as shown in Fig.8b. It is true that the coefficients of friction of the surface lubricated by grapheme-2 grease under 300 N is lower than the one under 100N. However, the wear loss of the grapheme-2 grease-lubricated surfaces under 300N (1.87×108μm3) is larger than that under 100 N (3.69×107μm3).

Fig.8 (a) Extreme pressure property of grapheme-1 grease; (b) Variation in coefficients of friction of the grapheme-2 grease with time at the sliding rate of 30 Hz for 30min

4 Summary

Graphene was synthesized by the solution-exfoliation method. The as-prepared graphene is multi-layered and has a crystalline structure. The as-prepared graphene is uniformly dispersed in the lithium grease through a series of grinding/homogenization steps, and provides better tribological performance and higher wear resistance than graphite otherwise the same. Compared with additive-free lithium grease, the wear losses of the worn surfaces lubricated by the 0.01wt%~0.05wt% graphene-containing greases are decreased by 68%~83%. Furthermore, the lithium greases added with 0.015wt% and 0.02wt% of graphene has the lowest wear volumes. This excellent tribological property and wear resistance of graphene-containing greases attribute to the good dispersion of graphene, as well as the particular laminated structure. Graphene as an environment friendly solid lubricating additive could effectively improve the tribological performances and exhibits great potential for a wide-ranging applications.