Preparation of Alkalisoluble Pachymaran Rice Wine

2019-09-10HongyuanTANZhaoyueSHENG,MingjieTIANFuyaoTANZhiyueWANGPengWU

Hongyuan TAN Zhaoyue SHENG, Mingjie TIAN Fuyao TAN Zhiyue WANG Peng WU

Abstract [Objectives] This study was conducted to determine the optimum process conditions for the preparation of alkalisoluble pachymaran rice wine.

[Methods] A new type of alkalisoluble pachymaran rice wine was prepared by mixing and fermenting alkalisoluble pachymaran and glutinous rice as raw materials. The sensory score was used as the evaluation index to investigate the effects of three factors including the amount of alkalisoluble pachymaran, inoculation amount and fermentation temperature on the quality of the alkalisoluble pachymaran rice wine. The fermentation process of the rice wine was then optimized by an orthogonal experiment.

[Results] With the proportion of the alkalisoluble pachymaran added of 0.4%, the inoculation amount of 0.6% and the fermentation temperature at 30 ℃, the sensory score of the prepared rice wine was the highest, which was 93.5 points. The alkalisoluble pachymaran rice wine prepared under above conditions was rich in flavor and tasted sweet and sour.

[Conclusions] The production of the new rice wine and the understanding of the development history of rice wine will provide reference for the future development of rice wine industry, and provide research directions for the development of new health drinks.

Key words Rice wine; Fermentation; Alkalisoluble pachymaran; Single factor

Received: August 13, 2019Accepted: November 6, 2019

Supported by Youth Project of Hubei Education Department (03201718402); Huanggang Normal University Highlevel Cultivation Project (04201711903).

Hongyuan TAN (1999-), female, P. R. China, devoted to research about food biotechnology and processing and storage of agricultural products.

*Corresponding author. Email: 115479165@qq.com.

Poria is a funguslike traditional Chinese medicine that tastes sweet and mild and mainly parasitize on the roots of Pinaceae plants[1]. It has the effect of eliminating edema and strengthening heart spleen. The main effective ingredient in poria is the pachymaran, which can enhance immunity and resist tumor, and is widely used in medical care and thus have a broad market prospect[2-3].

Rice wine is a traditional fermented food made from glutinous rice by adding a certain amount of distillers yeast[4]. It is rich in nutrients, can effectively maintain the nerves, digestion and circulatory systems of human body. After drinking, it has the functions of promoting appetite, nourishing yin and tonifying kidney, and nourishing qi and blood. The distillers yeast in wine is an important factor affecting the flavor of rice wine[6], so it is called "the bone of wine".

In order to improve the fermentation process of traditional rice wine, and develop rice wine that is more in line with the market and the public taste, this study developed a new rice wine: alkalisoluble poria polysaccharide rice wine based on the traditional fermentation process. Singlefactor and orthogonal design experiments were carried out to determine the optimal technical conditions for the preparation of the alkalisoluble pachymaran rice wine by changing such three main influencing factors as the amount of alkalisoluble pachymaran added, inoculation amount and fermentation temperature, which fully demonstrated the advantages of the new rice wine[11]. Reviewing relevant literatures and works and studying the development characteristics of rice wine in different periods can help to better understand the changes of rice wine, and provide some reference for the future development and trend of rice wine industry[12].

Materials and Methods

Materials and equipment

Materials: Highquality glutinous rice (commercially available); alkalisoluble poria polysaccharides (laboratory); distillers yeast: Angel Yeast Co., Ltd.

Equipment: HZQF250A highlow constant temperature incubator: Beijing Kewei Yongxing Instrument Co., Ltd.; YX280B pressure steam sterilizer: Shenan Medical Devices; JD2003 electronic level:Shenyang Longteng Electonic Co., Ltd.

Experimental methods

Process flow and operation points

The process was started from soaking of goodquality glutinous rice, followed by steaming, cooling, addition of distillers yeast, addition of alkalisoluble pachymaran, stirring and fermentation, and completed by sterilization, giving the finished product[13].

Pretreatment of glutinous rice: The glutinous rice was soaked in water for 24 h[14], followed by drainage. The soaked rice was subjected to steaming during which the rice was sprinkled with hot water in small quantities for 2-3 times. A small amount of warm water was sprinkled into the steamed rice to make it cool quickly. The rice should be cooled as fast as possible to prevent the rice from being contaminated by bacteria and starch, which would affect the saccharification and fermentation[15].

Inoculation and fermentation of rice wine: Distillers yeast was mixed into glutinous rice in proportion, and then alkalisoluble pachymaran was added in different proportions for constant temperature fermentation for 48 h.

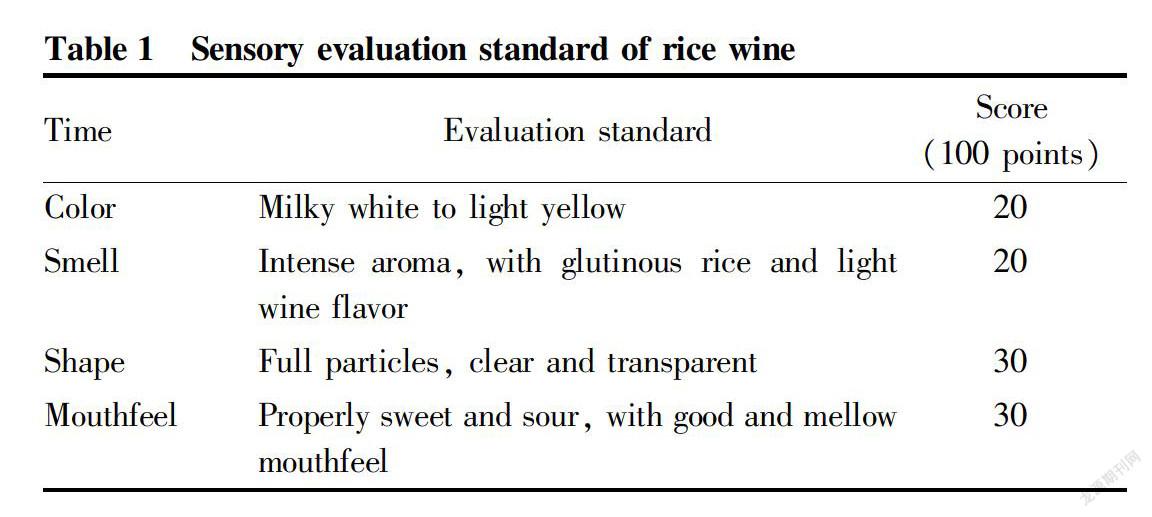

Determination of sensory evaluation indexes

A scoring group consisting of 10 people performed sensory evaluation on the prepared alkalisoluble pachymaran rice wine from such four aspects as color, smell, shape and mouthfeel, and the scores were averaged. The specific scores are shown in Table 1.

Single Factor Experiment

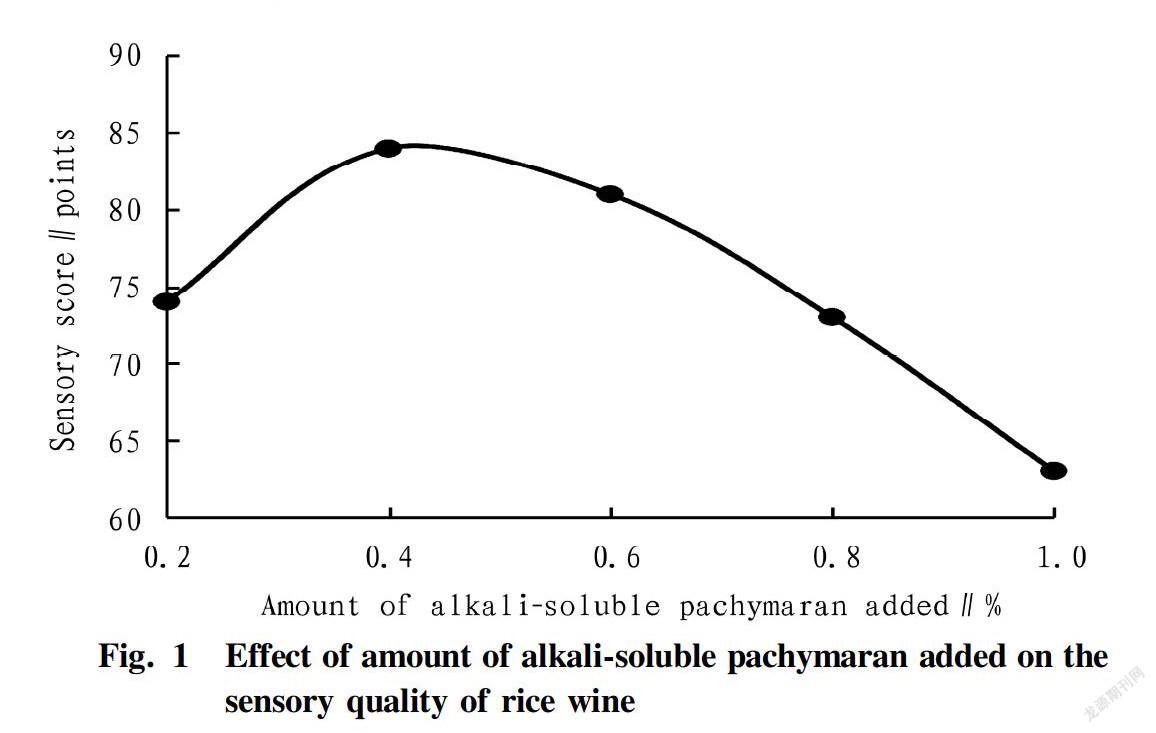

Determination of the amount of alkalisoluble pachymaran added

A certain amount of glutinous rice (50 g) was accurately weighed and mixed with distillers yeast at a proportion of 0.6%, and then, alkalisoluble pachymaran were added at proportions of 0.2%, 0.4%, 0.6%, 0.8% and 1.0%, respectively. Fermentation was carried out at a temperature of 30 ℃ for 48 h, and the finished product was subjected to sensory evaluation.

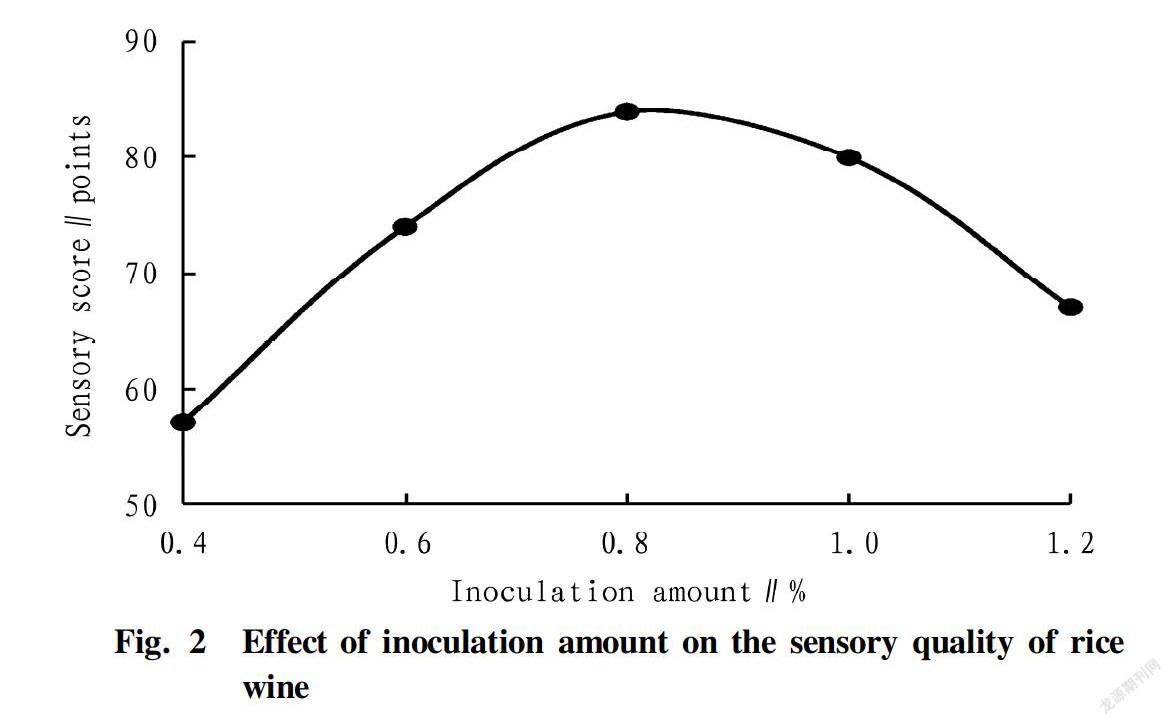

Determination of inoculation amount

A certain amount of glutinous rice (50 g) was accurately weighed and mixed with alkalisoluble pachymaran at a proportion of 0.4%, and distillers yeast was added at proportions 0.4%, 0.6%, 0.8%, 1.0% and 1.2%, respectively. Fermentation was carried out at a temperature of 30 ℃ for 48 h, and the finished product was subjected to sensory evaluation.

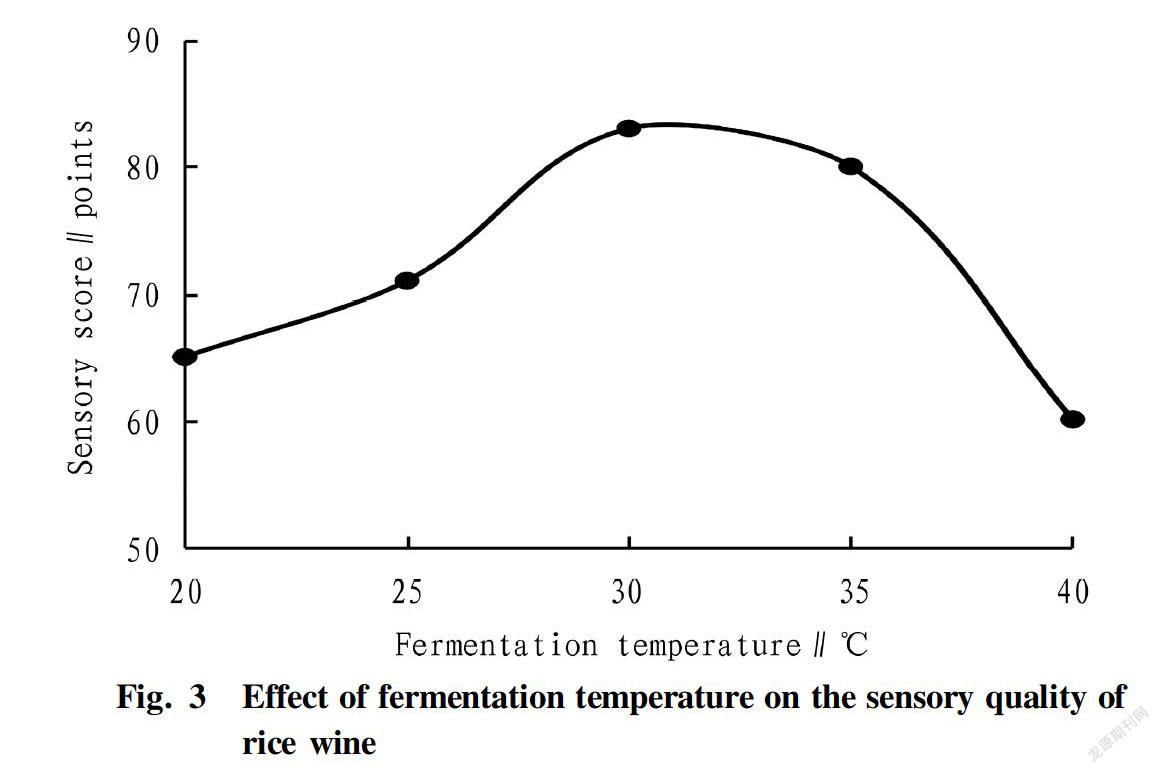

Determination of fermentation temperature

A certain amount of glutinous rice (50 g) was accurately weighed and mixed with alkalisoluble pachymaran at a proportion of 0.4% and distillers yeast at a proportion of 0.6%. Fermentation was carried out at temperatures of 20, 25, 30, 35 and 40 ℃, respectively, for 48 h, and the finished product was subjected to sensory evaluation.

Orthogonal experiment

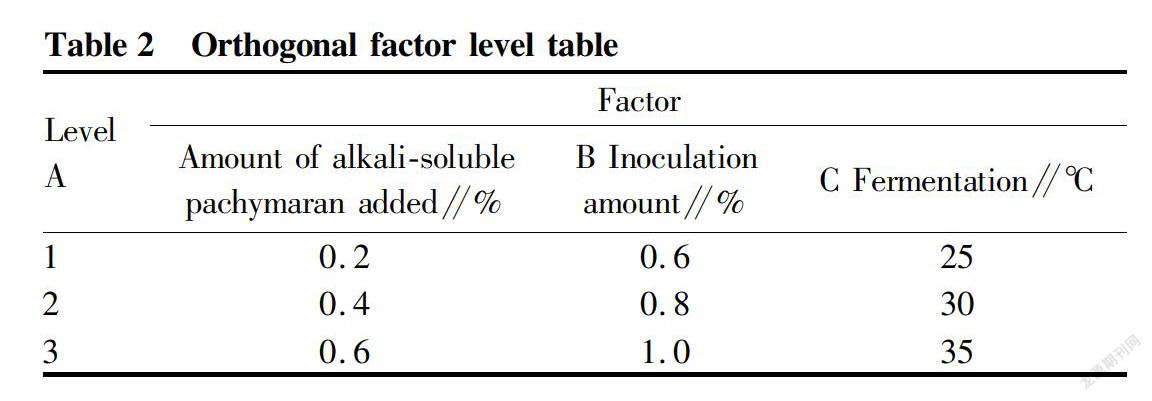

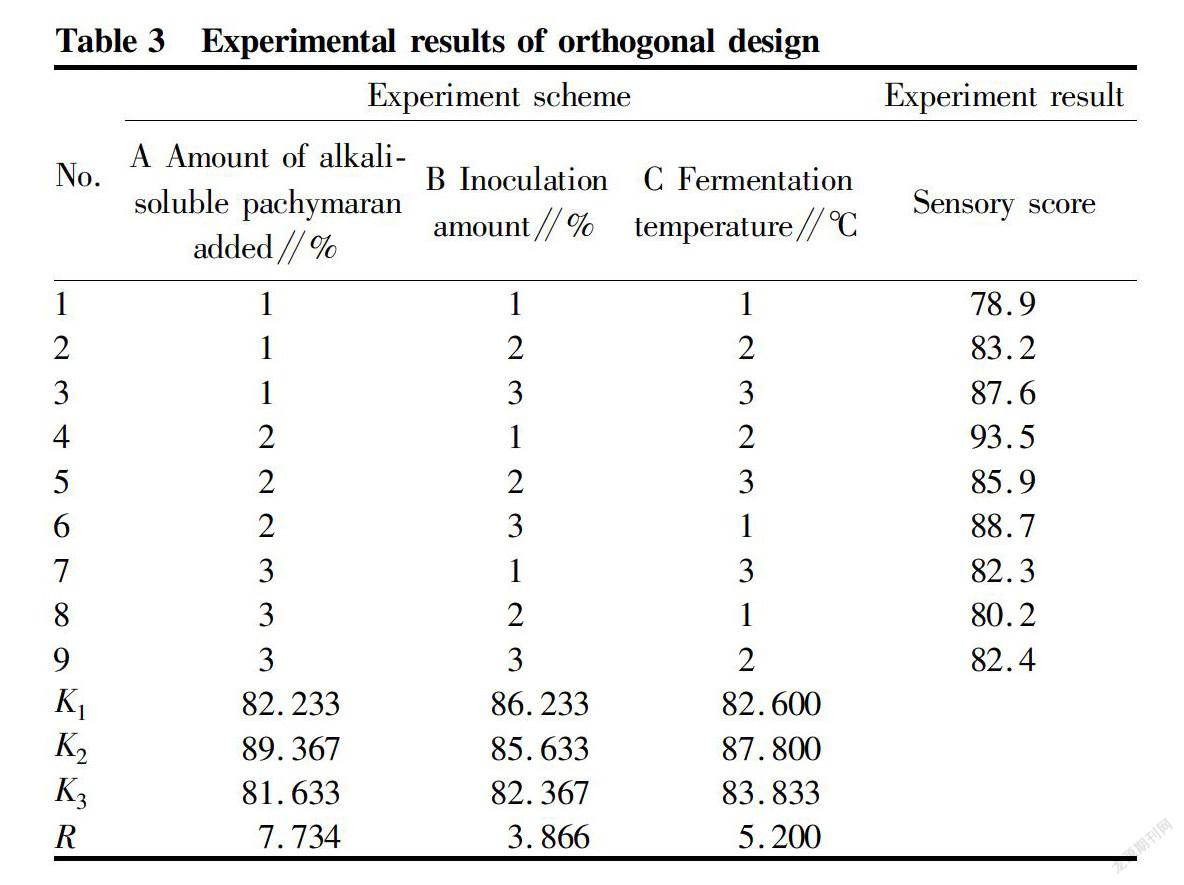

On the basis of the single factor experiment, the amount of alkalisoluble pachymaran added, inoculation amount and fermentation temperature were taken as three factors, and each factor was set with three levels. The L9 (34) orthogonal table was selected for the experiment. The factor level table is shown in Table 2.

Results and Analysis

Single factor experiment

Effect of the amount of alkalisoluble pachymaran added on the sensory quality of rice wine

As shown in Fig. 1, as the amount of alkalisoluble pachymaran added continued to increase, the sensory score of the alkalisoluble pachymaran glutinous rice wine showed a trend of increasing first and then decreasing. When the amount of alkalisoluble pachymaran added was small, the taste of poria was not obvious, the overall effect on the alkalisoluble pachymaran rice wine was not great, and an appropriate amount of alkalisoluble pachymaran could enhance the flavor of the rice wine. When the amount of alkalisoluble pachymaran added got more and more, the taste of poria was prominent and covered the glutinous rice aroma and wine taste of the rice wine itself, and the overall taste of the alkalisoluble pachymaran rice wine was affected to a certain extent, i.e., the flavor of the rice wine was rather reduced. When the content of the alkalisoluble pachymaran was 0.4%, the taste of the rice wine was suitable.

Effect of inoculation amount on the sensory quality of rice wine

As can be seen from Fig. 2, when the proportion of the inoculation amount was less than 0.8%, the sensory quality of rice wine increased with the increase of the inoculation amount. When the proportion of distillers yeast added in a suitable range can promote the fermentation of rice wine, the aroma and taste of rice wine are not too faint, and as the amount of distillers yeast increases, the rice wine gradually becomes rich and mellow[17]. After the inoculation amount exceeded 0.8%, the wine tasted too heavy and even pungent, which seriously deteriorated the taste of the rice wine. When the inoculation amount was 0.8%, an alkalisoluble pachymaran rice wine which tasted sweet and sour properly and had an appropriate wine taste, could be obtained.

Effect of fermentation temperature on the sensory quality of rice wine

As can be seen from Fig. 3, the sensory quality of the alkalisoluble pachymaran rice wine had a trend of rising slowly and then decreasing with the increase of the fermentation temperature. When the fermentation temperature was lower than 30 ℃, the aroma of the alkalisoluble pachymaran rice wine became gradually rich with the increase of the temperature, the taste gradually became mellow, and the sensory quality of the rice wine gradually increased with the increase of the temperature; and when the fermentation temperature reached 30 ℃, the alkalisoluble pachymaran rice wine was more harmonious, with a sweet and sour taste and a strong aroma. When the fermentation temperature exceeded 30 ℃, the flavor of rice wine decreased with the increase of the temperature. This is because when the temperature of fermentation was too high, the growth of some fungi in distillers yeast was inhibited, resulting in poor taste of rice wine[18]. When the fermentation temperature was 30 ℃, an alkalisoluble pachymaran rice wine having a good taste could be obtained.

Development of orthogonally optimized alkalisoluble pachymaran rice wine

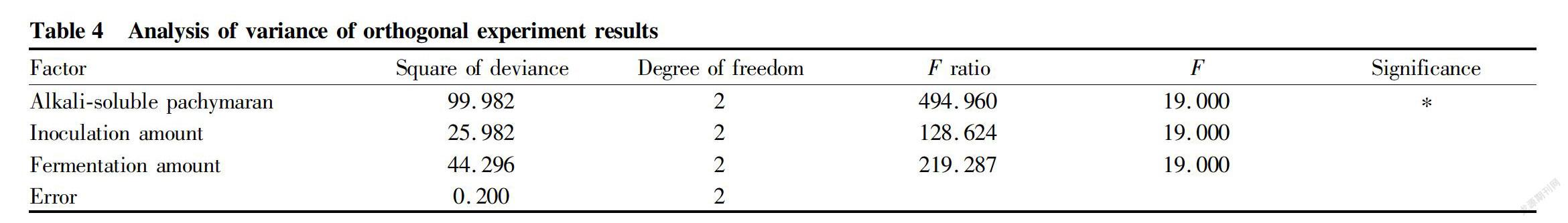

After the single factor experiment, we obtained the effects of A (alkalisoluble pachymaran added), B (inoculation amount) and C (fermentation temperature) on the flavor of alkalisoluble pachymaran rice wine. In order to further optimize the process, these three factors were tested by an orthogonal design experiment. The results are shown in Table 3.

From Table 3, it can be concluded that the R values corresponding to various factors were different. The larger the R value, the greater the influence of this factor on the alkalisoluble pachymaran rice wine. The effects of factors on the sensory score of the alkalisoluble pachymaran rice wine followed an order of A>C>B, that is, in the development of alkalisoluble pachymaran rice wine, the most important factor affecting the flavor was the amount of alkalisoluble pachymaran added, followed by the fermentation temperature, and the inoculation amount had the least effect.

The evaluation index of the orthogonal experiment was the sensory evaluation score. The higher the sensory score, the better the quality of the alkalisoluble pachymaran rice wine produced. Therefore, a larger Ki value of each factor in Table 3 was better, and it was concluded accordingly that the optimal combination was A2B1C2, i.e., the optimal conditions developed for the alkalisoluble pachymaran rice wine were the addition amount of alkalisoluble pachymaran of 0.4%, the inoculation amount of 0.6%, and the fermentation temperature at 30 ℃.

Agricultural Biotechnology2019

As can be seen from Table 4, the F ratio was greater than the F threshold, indicating that factor A was significant at the significance level of 0.05. The factor with most effect on the alkalisoluble pachymaran rice wine was the amount of alkalisoluble pachymaran added, and the one with the least effect was the inoculation amount.

Verification test

From the results of the orthogonal experiment in Table 3, the optimal process parameters for the development of the alkalisoluble pachymaran rice wine can be obtained as follows: the addition amount of alkalisoluble pachymaran of 0.4%, the inoculation amount of 0.6%, and the fermentation temperature at 30 ℃. According to the results obtained from the experiment, three sets of parallel experiments were carried out, and the sensory evaluation was conducted. The sensory score of the alkalisoluble pachymaran rice wine was 93.5, and the alkalisoluble pachymaran rice wine prepared under the conditions had rich aroma and tasted good. The production process was obviously optimized, and the data were accurate and reliable.

Conclusions

In this study, the optimal level range of three main factors affecting alkalisoluble pachymaran rice wine was determined by single factor experiment. Then the orthogonal experiment was carried out to optimize the production process of alkalisoluble pachymaran rice wine, and the best parameters were determined. It was finally obtained that with the amount of the alkalisoluble pachymaran added of 0.4%, the inoculation amount of 0.6% and the fermentation temperature at 30 ℃, the obtained alkalisoluble pachymaran rice wine had the best taste. In the process of rice wine fermentation, the changes in acidity, alcohol content and total sugar content of rice wine are closely related to microorganisms[19]. The organic acids in rice wine can increase the flavor of rice wine, and they are not only important precursor substances of aroma substances, but also important components of wine body substances[20]. This study provides a theoretical and experimental basis for the indepth development of rice wine resources.

References

[1] LEE HYUNKYUNG, CHA HWA JUN. Poria cocos Wolf extracts represses pigmentation in vitro and in vivo[J]. Cellular and Molecular Biology (NoisyleGrand, France), 2018, 10(2): 80-84.

[2] WU SL, SHAO CG, TANG SJ, et al. Antibacterial and antitumor activities of Poria cocos spent culture fluid[J]. Acta Edulis Fungi, 2016, 23(1): 63-66. (in Chinese)

[3] ZHU XG, LI YQ. Advances in immunomodulatory effects of alkalisoluble pachymaran[J]. Swine Industry Science, 2018, 35(6): 80-81. (in Chinese)

[4] WEI XL, LIU SP, YU JS, et al. Innovation Chinese rice wine brewing technology by biacidification to exclude rice soaking process[J]. Journal of Bioscience and Bioengineering, 2017, 123(4): 460-465.

[5] WU GF. Guide of fermentation engineering experiment[M]. Beijing: Higher Education Press, 2006. (in Chinese)

[6] YANG L, CHENG TY, HUANG ZG. Application of distillers yeast produced by multiple bacterial strains in the production of Luzhouflavour liquor by distilled grains/distillers grains[J]. LiquorMaking Science & Technology, 2018, 6(8): 124-127. (in Chinese)

[7] LIU Q, GUO TT, XING XX, et al. Research progress on beneficial components of asian rice wine[J]. Agricultural Science&Technology and Equipment, 2016, 15(12): 67-68. (in Chinese)

[8] TAN F. Effect and safety of mifepristone combined with Cassia twig poria capsule on the treatment of uterine fibroids[J]. World Latest Medicine Information, 2019, 19(32): 132-133. (in Chinese)

[9] ZHANG N, ZHANG ZX, LI J, et al. Research advances on chemical constituents and bioactivities of Poria cocos (Schw.) Wolf[J]. Modernization of Traditional Chinese Medicine and Materia MedicaWorld Science and Technology, 2019, 21(2): 220-223. (in Chinese)

[10] LI YQ, HOU XH, WANG YF, et al. The inhibition effect study of sulfated derivatives polysaccharides from sclerotium of Poria cocos for nude mice gastric adenocarcinoma[J]. Journal of Clinical Medicine in Practice, 2012, 16(15): 1-4. (in Chinese)

[11] HUANG YY, LIU KY, WANG Q, et al. Optimization for fermentation of red bean rice wine using response surface methodology[J]. Food and Fermentation Industries, 2018, 44(5): 130-134. (in Chinese)

[12] LI FH, LI M, LI JC, et al. Study on the development of traditional rice wine under O2O+C mode——A case study on the selfproduced rice wine in South Sichuan[J]. Market Modernization, 2018, 32(6): 24-25. (in Chinese)

[13] YU ZM. Study on the manufacturing process of Xiaogan rice wine with sufficient γaminobutyric acid[J]. Journal of Hubei VocationalTechnical College, 2018, 21(4): 103-105. (in Chinese)

[14] GE XY, TIAN HZ, LIANG YX. Zymurgy[M]. Beijing: Higher Education Press, 2005. (in Chinese)

[15] TIAN YH, WANG WJ, JIA CH. Study on fermentation process of sweeten glutinous rice wine and changes regularity of components during fermentation[J]. Food Science and Technology, 2008, 12(6): 37-39. (in Chinese)

[16] WANG AQ, WANG DY, ZHU YZ, et al. Correlation between sensory and instrumental quality characteristics of stewed chicken[J].Meat Research, 2019, 33(4): 19-23. (in Chinese)

[17] SU C, HU SW. Development of Avena chinensis rice wine[J]. The Food Industry, 2018, 39(7): 175-177. (in Chinese)

[18] MEI X, WANG SH, CAI F. Development of konjak rice wine[J]. Science and Technology of Cereals,Oils and Foods, 2016, 24(5): 10-13. (in Chinese)

[19] WU YJ, XIAO M, ZHOU JR. Influence factors of pitaya fruit wine fermentation and the pilot scale application[J]. China Brewing, 2017, 36(5): 192-196. (in Chinese)

[20] FAN WL, GONG SB, XU Y. Organic acid spectrum of Baijiu[J]. Liquor Making, 2019, 46(1): 37-42. (in Chinese)

杂志排行

农业生物技术(英文版)的其它文章

- Observation on Cardiac Opening of the Inferior Vena Cava in Goat Fetuses

- Evaluation on Application and Spraying Effect of AirAssisted Sprayer in Apple Orchard with Dwarfing Rootstocks

- Problems in the Development of Traditional Chinese Medicinal Materials Planting Industry in Shiyan City and Countermeasures

- Study on Practical Mature Age of Individual Pinus thunbergii×P. densiflora

- Effects of Different Densityreducing Methods on Canopy Microenvironment, Tree Growth and Fruit Quality in Closed Apple Orchard

- Development of Whole Potato Flour Fish Noodles