生物炭强化有机废弃物厌氧发酵技术研究

2019-08-19赵立欣姚宗路申瑞霞

冯 晶,荆 勇,2,赵立欣,姚宗路,申瑞霞

生物炭强化有机废弃物厌氧发酵技术研究

冯 晶1,荆 勇1,2,赵立欣1※,姚宗路1,申瑞霞1

(1. 农业农村部规划设计研究院农村能源与环保研究所,农业农村部农业废弃物能源化利用重点实验室,北京 100125; 2. 东北林业大学工程技术学院,哈尔滨 150036)

厌氧发酵是中国有机废弃物处理的重要技术途径,但利用厌氧发酵技术在高负荷条件下处理有机废弃物过程中,因有机酸、氨氮等抑制性物质作用,易导致厌氧发酵运行不稳定,处理效率不高等问题。生物炭是生物质材料在无氧或缺氧条件下经高温热解形成的多孔径碳质材料,具有比表面积高,孔隙结构复杂,表面活性基团丰富和导电性强等特性,并被广泛用于厌氧发酵技术研究。近年来国内外研究表明,生物炭能有效强化厌氧发酵,提高厌氧发酵过程中有机废弃物的处理效率。然而,对于生物炭强化厌氧发酵技术途径,目前仍未见系统的梳理和报道。该文对生物炭材料的化学组成、孔隙结构、表面官能团关键因素及生物炭强化厌氧发酵技术的重要途径进行了系统分析和归纳,从生物炭材料的理化性质出发,阐述了生物炭对于厌氧发酵技术的强化效果及强化途径,强化途径主要包括:提升系统缓冲能力、微生物载体作用和强化电子传递等,在此基础上提出了今后生物炭强化有机废弃物厌氧发酵技术的重点研究内容和方向,为开发厌氧发酵强化技术提供指导。

废弃物;发酵;生物炭;强化技术;研究进展

0 引 言

据统计,中国每年约产生21亿t林业废弃物和农副产物[1],约38亿t畜禽粪污[2]。当前,中国仍有大量农林废弃物没有得到有效利用,秸秆田间无序焚烧、粪污散乱排放等问题在部分地区仍然存在。

厌氧发酵技术被认为是处理农林废弃物的重要途径。农林废弃物经过厌氧发酵可用于生产清洁能源沼气,发酵剩余的沼渣、沼液也可作肥料还田。近年来,中国在农林废弃物资源化利用领域普遍采用湿法厌氧发酵技术,尤其是全混式厌氧发酵技术。然而,随着中国规模化沼气的迅速发展,农村沼气工程转型升级的持续推进,发现全混式厌氧发酵过程易受高浓度氨氮及挥发性脂肪酸等的抑制,存在产气效率低、发酵不稳定等问题[3-4],这也是中国规模化沼气工程运行效果差的重要原因。

生物炭作为一种新兴炭材料,是农林废弃物高温热解的产物[5],一般具有比表面积高、孔隙结构复杂、表面活性基团丰富、导电性强等特性[6-7],近年来在厌氧发酵系统中的添加、应用已经成为当前的研究热点。众多研究发现,生物炭的添加可有效保持厌氧发酵过程的稳定性,提高厌氧发酵产气效率[8-10],然而,目前对添加生物炭强化厌氧发酵机理仍不清晰,该技术的工程化应用也受到一定限制。本文拟通过对当前生物炭强化厌氧发酵的众多研究进行梳理和总结,为开展厌氧发酵过程中生物炭作用机理研究,进一步开发生物炭强化厌氧发酵技术提供一定的借鉴。

1 生物炭理化特性

1.1 化学组成

生物炭是由含碳量丰富的生物质在无氧或限氧的条件下高温热解而得到的一种细粒度、多孔性的碳质材料[11],一般由无定形碳、芳香族碳和灰分组成[12],其主要组成元素包括C、H、O、N及灰分中的Si、Al、Fe、Ti、P、Ca、Mg、Na、K和S等[13-14]。生物炭表层分布着各种官能团、无机及金属离子,其中含O、N、S的官能团比较丰富[7]。生物炭中Na、K、Mg、Ca 等碱土金属元素常以氧化物或碳酸盐的形式存在,溶于水后呈微碱性,具有一定的酸碱缓冲特性[15]。

不同种类生物炭组分存在一定差异,如粪肥源生物炭一般含有较高的N、P元素,木材源生物炭的碳和挥发性物质含量一般高于农业废弃物制备的生物炭[16],灰分、N、P、K、Ca、Mg等含量却相对较低[17],且同温条件下,一般有机质含量较高的污泥、粪便等生物炭灰分含量依次高于农业废弃物生物炭、木材源生物炭等[14-15]。不同来源与种类的生物炭化学组成具体见表1。

表1 不同生物质原料、热解温度及生物炭化学成分

1.2 孔隙结构

生物质经热解后,组成物质受损,结构收缩形成更为致密的生物炭孔隙结构[26]。根据孔径尺寸的不同,可分为微孔(<0.8 nm)、小孔(0.8~2 nm)、中孔(>2~50 nm)和大孔(>50 nm)。复杂多样的孔隙结构使生物炭具有较大的孔容和比表面积,其中微孔对生物炭的比表面积贡献最大[27]。

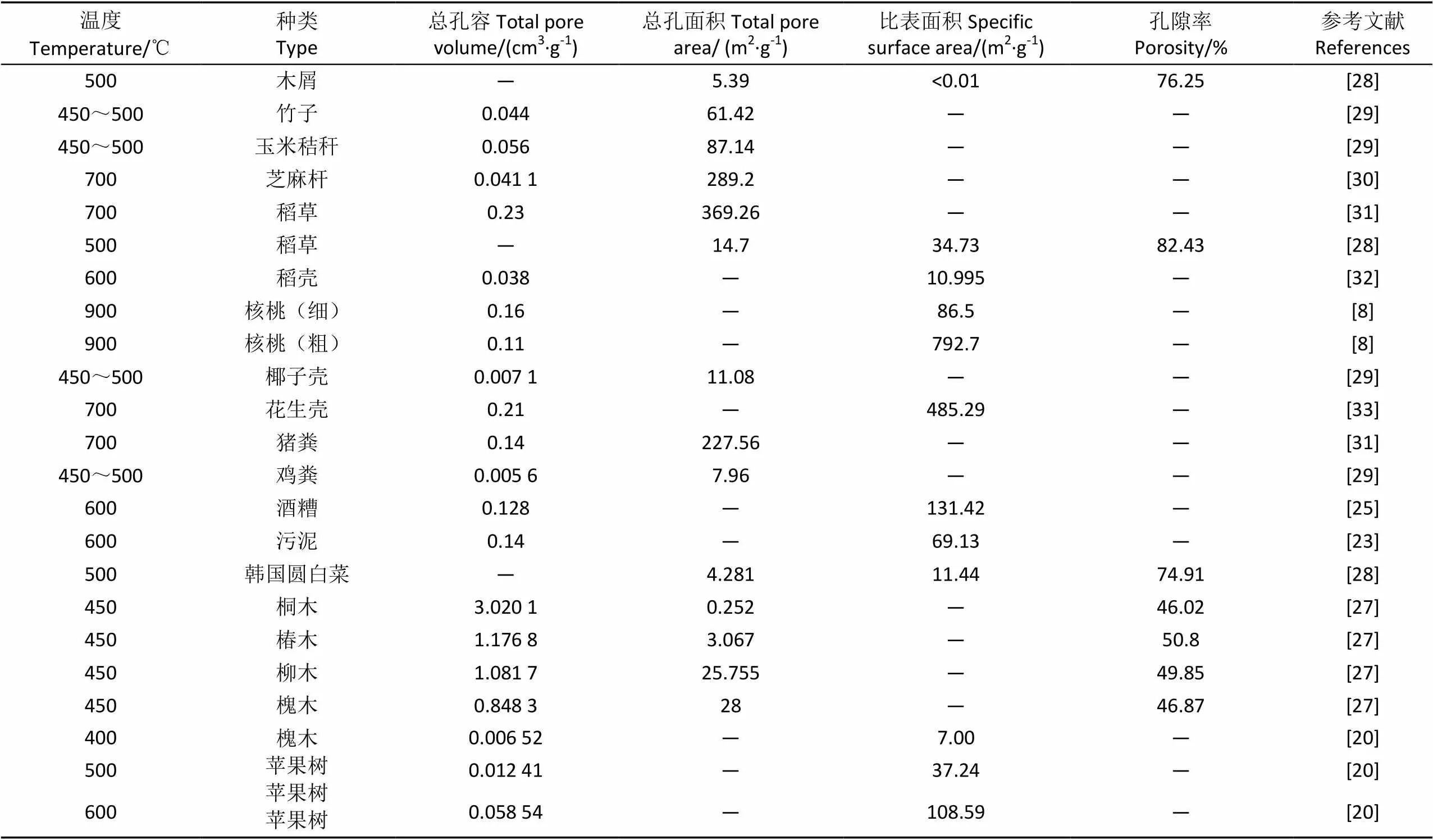

不同的生物质原料及热解温度对生物炭孔隙结构影响比较大(见表2)。如DD Sewu等[6,30-31]研究发现,相同条件下木屑生物炭的孔隙率介于稻草生物炭和韩国圆白菜生物炭之间,其比表面积却远小于农业废弃物、污泥和粪便等原料热解所得生物炭。一般生物炭的比表面积随着温度的升高而增大,温度越高生物质内部挥发性物质消耗的越多,生物炭表面越粗糙,孔隙结构越复杂[17-18]。但温度过高也会影响孔隙结构的多样性,如炭化温度逐渐升至700~800 ℃时,生物炭中微孔和中孔数量反而减少[20,25],其原因主要在于较高的温度使更多的挥发性物质被消耗,造成了微孔和中孔的损失。

表2 不同生物质原料及热解温度下生物炭孔隙结构特征

1.3 表面官能团

生物炭表面分布着丰富的官能团,如De等[34]研究发现,生物炭在3 200~3 600 cm-1(O-H)伸缩振动处对应的峰值最高,在2 850~3 000 cm-1(C-H)、1 550~1 640 cm-1(酰胺)、1 350~1 480 cm-1(-C-H)、1 000~1 300 cm-1(酯)、600~800 cm-1(卤代烷基)处也具有较强的峰。Chen等[31]发现,生物炭表面官能团波峰主要发生在3 436 cm-1(-OH)、1 591 cm-1(芳香C=O,C=C)、1 400 cm-1(C-O)和1 050 cm-1(SiO32-)处。一般生物炭表面含氧、氮、硫的官能团较丰富,大多为负电荷且电荷分布密集,有助于加强生物炭表面极性及与外界物质的阳离子交换能力[14,35]。

不同种类的生物炭表层官能团种类或数量会存在一定的差异。如韩国圆白菜(Korean cabbage)废弃物生物炭和木屑生物炭均在C-C、O-H、C=O、C=C-C芳香环和苯基处有特征峰,而稻草秸秆生物炭在C=O(COOH)、C=C-C(芳香环)、C-O和苯基处也存在特征峰,但相对较少[28],而花生壳和松木生物炭官能团种类差异不显著,但同种官能团的丰富度略有差异[36]。此外,生物质热解炭化工艺,尤其是温度对生物炭表面官能团量具有十分重要的影响。热解过程中,生物质材料中大量的挥发性物质丢失,H、O、N等元素也存在部分丢失,导致生物炭表面的官能团部分损失[18],温度越高损失越多。

2 生物炭强化厌氧发酵的效果及途径

2.1 生物炭强化厌氧发酵的效果

生物炭凭借其良好的生物理化性能,对厌氧发酵起到显著的强化作用。目前,生物炭对厌氧发酵效果的提升研究主要集中在批式试验,而在连续式厌氧发酵试验方面的报道较少。

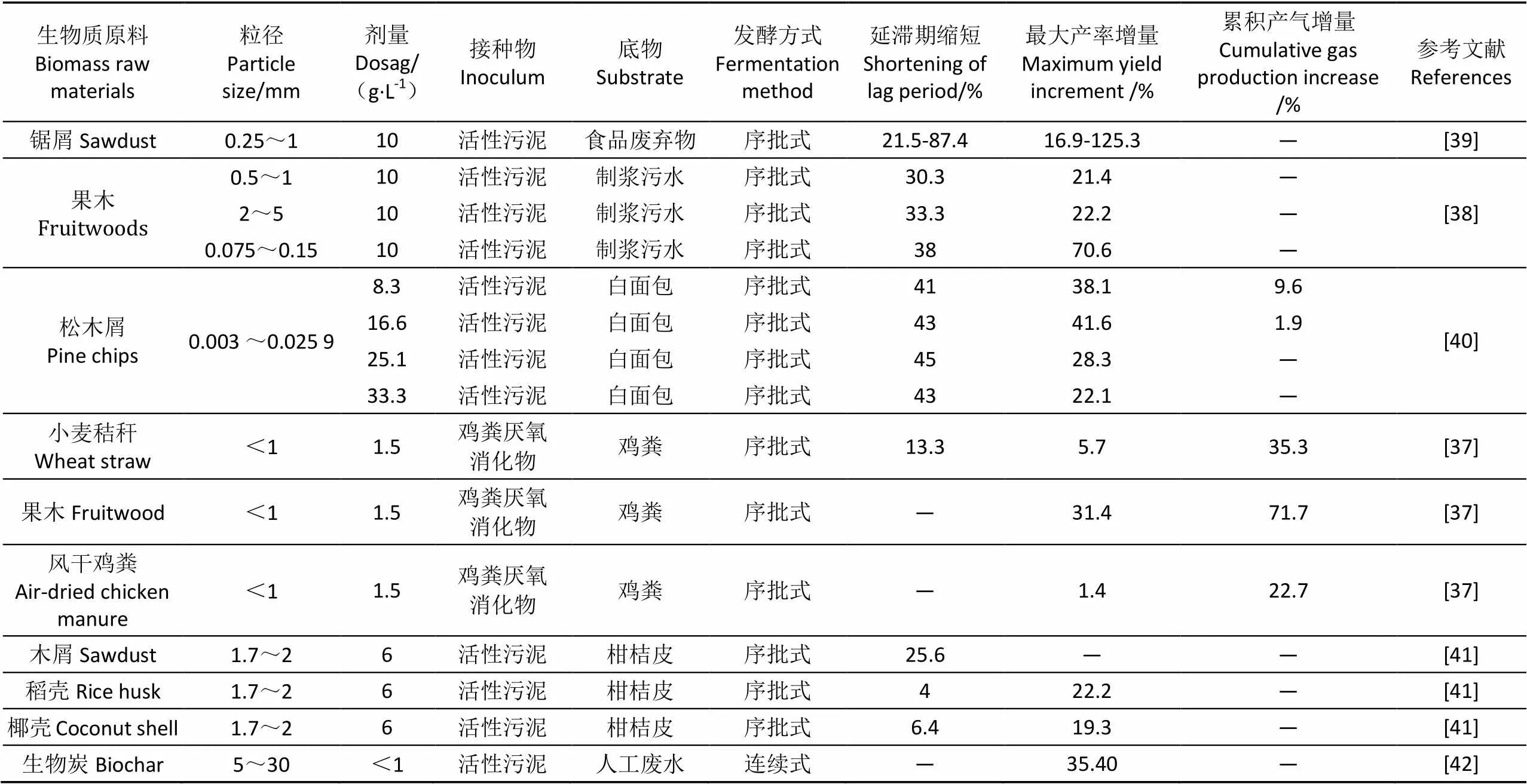

从批式试验的结果来看,生物炭对于厌氧发酵强化效果主要体现在缩短延滞期、提升最大产率以及提高累积甲烷产量等方面[37-38]。批式试验结果表明(见表3),生物炭投加后可缩短延滞期4%~87.4%,提高最大产率1.4%~70.6%,提高累积产甲烷体积分数1.9%~71.7%。

表3 不同生物质原料生物炭产气效果

不同生物炭种类、粒径及添加剂量对于产气效果的提升也存在一定差异[39]。在添加同种生物质原料的生物炭条件下,甲烷的最大产率及延滞期的缩短量与生物炭粒径大小成负相关[40],并随生物炭添加量在一定范围内呈现出先上升后逐渐下降的趋势[3,37],即粒径越小,添加剂量越大,延滞期则越短,最大甲烷产率则越高,当添加剂量达到一定值后,随着生物炭剂量的增加,厌氧发酵强化效果逐渐降低[39]。不同生物炭种类相比,木屑源生物炭比稻壳、秸秆源生物炭对缩短延滞期效果更加显著,同时提高最大甲烷产率及累积甲烷产量也受木屑种类的限制,但一般比稻壳、秸秆、鸡粪源等生物炭提高最大甲烷产率显著[41-42]。生物炭的添加,缩短了厌氧发酵的延滞期,使甲烷的产量及产率得到很大的提升,此效果也被Zhao等通过连续式厌氧发酵所证明[43]。

2.2 生物炭强化厌氧发酵的途径

生物炭对于厌氧发酵效果的提升作用主要是通过提升系统缓冲能力[15]、微生物载体作用[40]、强化电子传递等途径[30],目前已经成为研究的热点。

2.2.1 提升系统缓冲能力

生物炭具有丰富的孔隙,高的比表面积,同时炭表层也含有比较丰富的官能团,大量含氧、氮、硫等形式的官能团使表面具有很强的极性[44],这些性质决定了生物炭具有较强的吸附能力。一般而言,生物炭的吸附途径主要包括静电吸引、沉淀、表面络合、离子交换[14]、范德瓦尔力及生物炭表面与环境中各种基团、物质形成氢键等[45]。如Meng等[19,34]研究发现,通常生物炭在液体环境中会溶解析出各种水溶性化合物,形成水溶性阴离子(SO42-、PO43-等)和阳离子(Ca2+、Mg2+等),使生物炭表面具有一定量电荷,进一步增强生物炭表层的静电吸引力及与外界的离子交换能力。同时,生物炭中含有较多的碱和碱土金属元素[18],在液体环境中呈碱性,有助于促进厌氧消化中二氧化碳向碳酸氢盐或碳酸盐的转化,灰分含量越高碱度越大,提升厌氧发酵系统的缓冲能力越显著[20,46]。

在厌氧发酵系统中添加生物炭,通过碱度的提升及对沼液中有机酸的吸附,可有效提升发酵系统的缓冲能力,保证厌氧发酵过程的稳定运行。一般生物炭对厌氧消化系统中的酸抑制具有显著的缓解作用,生物炭中丰富的碱土金属元素,缓解了厌氧发酵体系乙酸、丙酸、丁酸等VFAs大量生成导致的过度酸化[24],使溶液pH值下降有一定的延迟,有效缩短了滞后时间(约27.5%~64.4%),提高了甲烷最大产量(约22.4%~40.3%),这也直观的表现了生物炭对VFAs的缓冲能力[3]。

在厌氧发酵系统中添加生物炭,通过碱度的提升及对沼液中氨氮等抑制性物质的吸附,可有效提升发酵系统的缓冲能力,保证厌氧发酵过程的稳定运行。生物炭对于氨氮的吸附能力一般在10 mg/g以上,且不同类型生物炭的吸附能力也有所差异,如木素含量越高氨氮吸附量相对越小,宋婷婷等[47]对各类生物炭氨氮吸附能力进行了评价,其中花生壳炭(16.22 mg/g)>玉米秆炭(12.64 mg/g)>竹炭(10.86 mg/g)>杨木屑炭(10.15 mg/g)。Chen等[29,48]对生物炭吸附氨氮的研究结果也表明玉米秸秆炭的吸附效果强于木炭,稻壳炭的吸附效果强于山核桃壳炭和竹炭等。

生物炭对VFAs和氨氮的吸附及抑制缓解能力受各种因素的影响,如pH值、温度、生物炭粒径和剂量等。针对以上因素国内外学者进行了大量试验探索,结果表明,一定条件下随着厌氧发酵系统中生物炭剂量的提升,丙酸的降解得到加强,其质量分数降低到70%~85%,VFAs浓度也呈下降趋势,且生物炭质量浓度每增加2 g/L,VFAs浓度平均下降100 mg/L[9]。刘项等[49]通过氨氮的吸附等温线、吸附动力学研究发现,高温条件下制得的生物炭吸附速率较低温条件下更高(700 ℃> 500 ℃> 300 ℃),但吸附容量较低温条件下制得的生物炭差(300 ℃>500 ℃>700 ℃),且生物炭对氨氮的吸附容量一般在近中性时较好,偏酸或碱吸附能力都会有所降低,Dang等[50-51]的研究与此相同,并发现在pH值为6.5时吸附容量最好。生物炭粒径对生物炭的吸附能力也有着很大的影响。一般生物炭粒径越小,吸附能力越强,滞后期的减小越显著,对厌氧发酵系统的缓冲效果越好[40,52]。

同样的,生物炭对厌氧发酵系统缓冲能力的提升作用,更多建立在批式厌氧发酵试验结果基础上,而缺少在连续式厌氧发酵系统中的验证与研究,同时在连续厌氧发酵系统中,如何控制生物炭的使用条件以实现对缓冲能力进一步强化,仍需开展更深入的研究。

2.2.2 微生物载体作用

生物碳具有丰富的孔隙结构,添加生物炭于厌氧发酵体系中,在一定程度上为微生物提供了稳定的载体,促进了微生物的生存、生长和繁殖,提高了微生物的数量和种群结构的多样性[53]。通过电子显微镜及微生物群落分析发现,生物炭表面富集了大量产甲烷古细菌,其中以甲烷杆菌()、 甲烷鬃菌属()、甲烷八叠球菌属()为主,且超过古生菌总数的90%[40]。这一点Yang等[54]研究与此相同,并发现,厌氧发酵过程中生物碳的添加有效提升了丙酸盐向乙酸盐转化的速率,间接促进了甲烷的生成。

生物炭理化性质对生物炭的载体作用有着重要的影响。生物炭复杂的孔隙结构、高的比表面积,有助于吸附周围环境的可溶性有机物、气体和无机营养物,同时生物炭表层易分解的碳、氮物质也可为微生物生长提供有效的碳源和氮源[55-57]。如陈志良等[16]对比分析了农林业废弃物生物炭与粪肥源生物炭对微生物的富集作用,结果表明粪肥源生物炭由于表层含有较高的营养元素更有利于微生物的附着。另外,一些细菌可在生物炭表层孔隙深处生存,对过酸环境表现出一定的抵抗力。然而,生物炭表层微量的重金属元素、吸附周围环境的金属离子、生物炭表层的生物质焦油中所含的各类化合物等,可能会通过化学阻断的方式抑制底物的利用,导致生物炭表层的酶活性发生改变,从而对表层微生物表现出一定的选择性[55,58-59]。

生物炭具有很好的载体作用,使大量微生物得到富集,有效强化了厌氧发酵的性能及产气能力。然而生物炭富集微生物的条件及机理仍不明确,生物炭表层微生物菌群种类及其多样性、微生物分布方面虽有大量研究,但微生物间的联系仍不够清晰,需结合微生物菌群特性通过高通量测序、宏基因组手段等作更深入的研究与探索。

2.2.3 强化电子传递

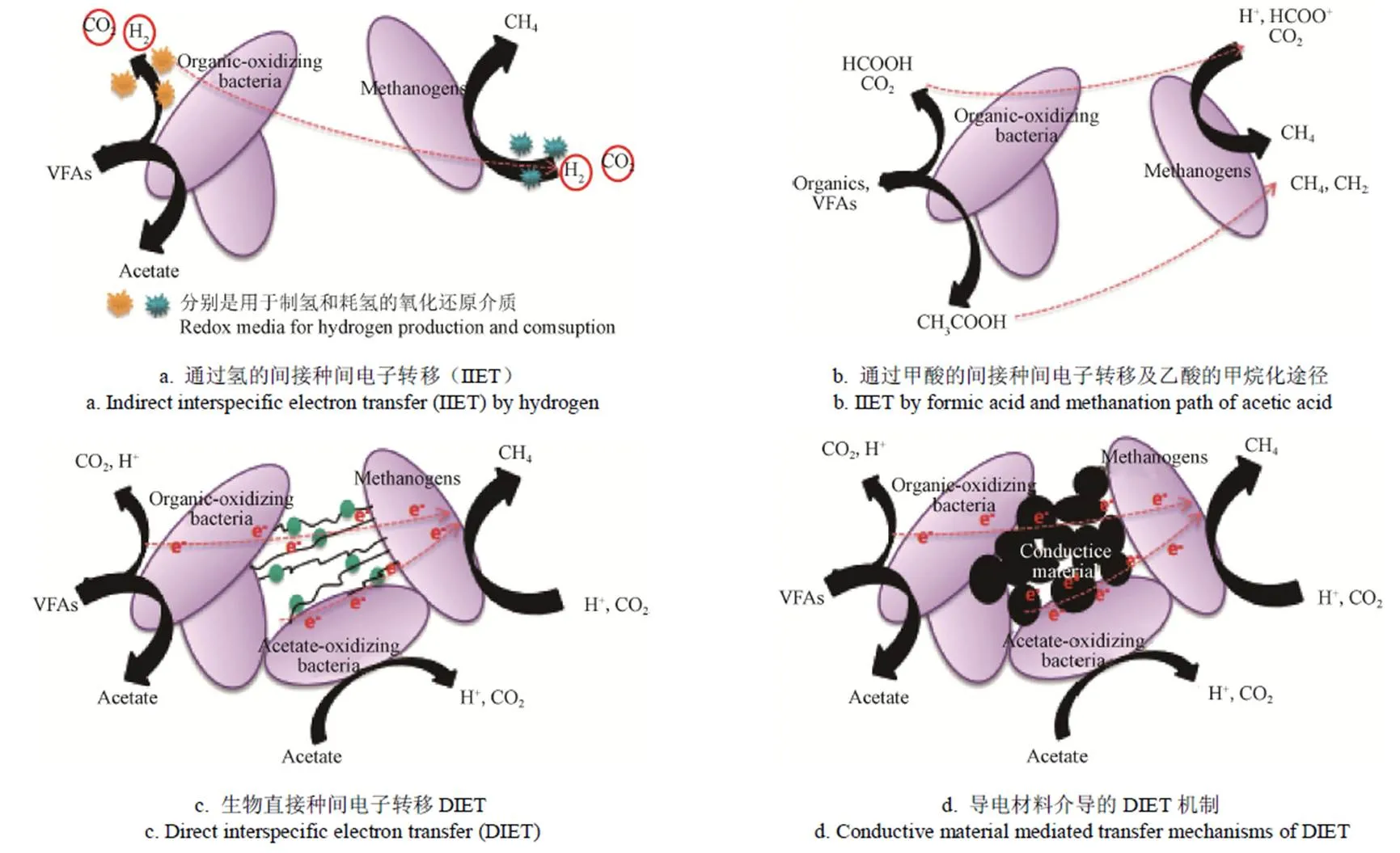

厌氧发酵中挥发性脂肪酸氧化细菌和产甲烷菌之间稳定且快速的跨物种电子转移,包括传统的H2、甲酸途径和直接种间电子转移(direct interspecific electron transfer,DIET)等[60-61],是甲烷生成的重要途径[62],具体见图1。H2是氢型产甲烷菌还原 CO2生成甲烷的直接电子供体,对厌氧发酵的进行具有至关重要的作用,由于产甲烷菌的耗 H2及产H2过程主要与NAD+/NADH、FAD/FADH2,Fd(ox)/Fd(red)(,铁氧化还原蛋白)或辅酶 F420/F420-H2等氧化还原中间体的相互转化相偶联[63],所以耗氢型产甲烷途径具有一定的限制。有时,甲酸亦可替代H2承载电子转移的任务(见图1b)。适当提高H2分压和甲酸浓度,能有效促进H2、甲酸途径电子的转移,加快有机质的降解和甲烷的产生。

厌氧微生物的直接种间电子转移(DIET)机制,即电子不需要借助H2和甲酸等媒介直接从一种微生物直接传递给另一种微生物,已经被证明存在于硫还原地杆菌()和金属还原地杆菌()的共培养体系中[62],且DIET可能是生物电化学系统产甲烷的重要机制也被Zhao等[43]通过焦磷酸测序、FISH等手段首次揭示。同时,通过有效富集土杆菌及产生生物电的细菌也为DIET的强化提供了一种新方法。

图1 微生物种间电子转移的途径[62-64]

近年来,在生物炭强化厌氧发酵技术的研究中,已经有学者发现生物炭的添加可以促进厌氧发酵体系中DIET机制的形成,进而促进厌氧发酵效率的提升。生物炭添加至厌氧发酵系统后,在一定程度上为微生物提供了稳定的载体,各种微生物(如产氢、甲酸及利用CO2的氢营养产甲烷菌等微生物)得到富集[3],利用电子显微镜发现大量微生物无序的附着于生物炭表面而非完全以严格的物理接触形式聚集在一起[10],微生物群落分析表明,碳材料可富集氢利用产甲烷菌、致电菌、等可直接进行种间电子转移的产甲烷菌,由于生物炭的高导电性,在一定程度上能提供效率更高的微生物电子传递路径,使电子供体通过生物炭将电子更高效的转移到电子受体上,增强了互营菌与产甲烷菌之间的电子交换,实现了直接种间电子转移(DIET)的潜在增强[54,65],此观点也被Liu等[66-67]利用产甲烷菌和不能产生H2或甲酸的通过共培养研究所证明。

微生物种间电子传递效率随着电导率的提升而增强[68],在厌氧发酵过程中添加生物炭提高了固液体系的电导率,可增强互营菌与产甲烷菌之间的电子交换,从而促进了厌氧发酵体系中底物的降解及挥发性脂肪酸的生成。同时,生物炭添加,也提高了丙酸的降解速率,并加快乙酸向甲烷的转化等[65],进一步缓解了厌氧发酵的酸化程度,提升了甲烷的产量及产率。生物炭富集微生物的同时,强化了微生物种间电子传递的效率,但目前对氢/甲酸途径和直接种间电子转移途径对厌氧发酵的贡献率及主导性还不清晰,未来还需要更深入的研究。

3 结论及展望

生物炭作为一类新型厌氧发酵酸化缓冲功能材料,具有较高的比表面积,复杂的孔隙结构,丰富的元素成分和表面活性基团,也具有很强的吸附结合能力等,可有效提升对厌氧发酵系统酸、氨等抑制物质的缓冲能力。生物炭表面复杂的孔隙结构与丰富的碳、氮等营养元素为厌氧微生物提供良好的生长载体,并提高了厌氧发酵系统内微生物的丰富度。且生物炭具有良好的导电性能,可作为潜在的厌氧微生物种间电子传递的介质,为厌氧发酵系统在高浓度VFAs条件下保持稳定产气提供了新的途径。以上3点是生物炭投加对厌氧发酵系统的主要促进方式。同时生物炭来源广泛、成本较低,其在厌氧发酵领域的应用前景光明。目前,国内外关于生物炭在厌氧发酵中的应用研究已有很多,但仍不够深入,需在以下几个方面进一步开展工作:

1)厌氧消化过程中氨氮与挥发性脂肪酸共存,两者对厌氧发酵具有协同拮抗作用,而生物炭对两者竞争吸附、共吸附及解吸的效果和机理仍待研究。

2)生物炭可富集厌氧微生物,但其表面富集微生物的群落结构及其对厌氧发酵过程的促进作用仍不清晰。

3)生物炭的添加导致的微生物种间电子传递机制仍需要进一步阐明,对应的应用技术的研发仍需进一步深入。

4)生物炭对厌氧发酵具有一定的强化作用,但生物炭通过何种强化途径对厌氧发酵性能更具有主导性仍不清晰,需要在连续厌氧发酵试验中进行研究与验证。

5)目前,生物炭强化厌氧发酵的研究仍依赖于实验室规模的小试试验,在中试规模乃至工程运行中如何实现生物炭强化厌氧发酵效果仍需要进行验证,并对生物炭强化厌氧发酵性能以及技术经济性进行评价研究。

[1] 陈卫红,石晓旭. 我国农林废弃物的应用与研究现状[J]. 现代农业科技,2017(18):148-149. Chen Weihong, Shi Xiaoxu. Application and research status of agriculture and forestry waste in China[J]. Modern Agricultural Science and Technology, 2017(18): 148-149. (in Chinese with English abstract)

[2] 王火根,黄弋华,张彩丽. 畜禽养殖废弃物资源化利用困境及治理对策:基于江西新余第三方运行模式[J]. 中国沼气,2018,36(5):105-111. Wang Huogen, Huang Yuhua, Zhang Caili. Difficulties in the utilization of livestock and poultry breeding resources and countermeasures: Based on the third party operation mode of Jiangxi Xinyu[J]. China Biogas, 2018, 36(5): 108-114. (in Chinese with English abstract)

[3] Wang G, Qian L, Xin G, et al. Synergetic promotion of syntrophic methane production from anaerobic digestion of complex organic wastes by biochar: Performance and associated mechanisms[J]. Bioresource Technology, 2018, 250: 812.

[4] Fuchs W, Wang X, Gabauer W, et al. Tackling ammonia inhibition for efficient biogas production from chicken manure: Status and technical trends in Europe and China[J]. Renewable and Sustainable Energy Reviews, 2018, 97: 186-199.

[5] Xiu S, Shahbazi A, Li R. Characterization, modification and application of biochar for energy storage and catalysis: A review[J]. Trends in Renewable Energy, 2017, 3: 86-101.

[6] Shen Y, Linville J L, Ignacio-De Leon P A A, et al. Towards a sustainable paradigm of waste-to-energy process: Enhanced anaerobic digestion of sludge with woody biochar[J]. Journal of Cleaner Production, 2016, 135: 1054-1064.

[7] 陈静文,张迪,吴敏,等. 两类生物炭的元素组分分析及其热稳定性[J]. 环境化学,2014,33(3):417-422. Chen Jingwen, Zhang Di, Wu Min, et al. Analysis of elemental composition and thermal stability of two types of biochar[J]. Environmental Chemistry, 2014, 33(3): 417-422. (in Chinese with English abstract)

[8] Linville Jessica L, Shen Yanwen, Ignacio-de Leon Patricia A, et al. In-situ biogas upgrading during anaerobic digestion of food waste amended with walnut shell biochar at bench scale. [J]. Waste Management & Research: The Journal of The International Solid Wastes and Public Cleansing Association, ISWA, 2017, 35(6): 669-679. (in Chinese with English abstract)

[9] Xu J, Mustafa A M, Lin H, et al. Effect of hydrochar on anaerobic digestion of dead pig carcass after hydrothermal pretreatment[J]. Waste Management, 2018, 78: 849-856.

[10] Gómez X, Meredith W, Fernández C, et al. Evaluating the effect of biochar addition on the anaerobic digestion of swine manure: application of py-gc/ms [J]. Environmental Science & Pollution Research, 2018, 25: 1-12.

[11] 孙媛媛. 芦竹活性炭的制备、表征及吸附性能研[D]. 济南:山东大学,2014. Sun Yuanyuan. Preparation, Characterization and Adsorption Properties of Activated Carbon from[D]. Jinan: Shandong University, 2014. (in Chinese with English abstract)

[12] 张千丰,王光华. 生物炭理化性质及对土壤改良效果的研究进展[J]. 土壤与作物,2012,1(4):219-226. Zhang Qianfeng, Wang Guanghua. Research progress in physical and chemical properties of biochar and its effects on soil improvement[J]. Soil and Crops, 2012, 1(4): 219-226. (in Chinese with English abstract)

[13] 卜晓莉,薛建辉. 生物炭对土壤生境及植物生长影响的研究进展[J]. 生态环境学报,2014,23(3):535-540. Xiaoli Bu, Jianhui Xue. Research progress on the effects of biochar on soil habitat and plant growth[J]. Acta Ecologica Sinica, 2014, 23(3): 535-540. (in Chinese with English abstract)

[14] Shen Yanwen, Jessica L Linville, Meltem Urgun-Demirtas, et al. Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn stover biochar with in-situ CO2removal[J]. Applied Energy, 2015, 158: 300-309.

[15] 谢祖彬,刘琦,许燕萍,等. 生物炭研究进展及其研究方向[J]. 土壤,2011,43(6):857-861. Xie Zubin, Liu Qi, Xu Yanping, et al. Research progress and research direction of biochar[J]. Soil, 2011, 43(6): 857-861. (in Chinese with English abstract)

[16] 陈志良,袁志辉,黄玲,等. 生物炭来源、性质及其在重金属污染土壤修复中的研究进展[J]. 生态环境学报,2016,25(11):1879-1884. Chen Zhiliang, Yuan Zhihui, Huang Ling, et al. Research progress on the source and properties of biochar and its remediation in heavy metal contaminated soils[J]. Acta Ecologica Sinica, 2016, 25(11): 1879-1884. (in Chinese with English abstract)

[17] 高继平,隋阳辉,霍轶琼,等. 生物炭用作水稻育苗基质的研究进展[J]. 作物杂志,2014(2):16-21. Gao Jiping, Sui Yanghui, Huo Yiqiong, et al. Research progress of biochar as a substrate for rice seedlings[J]. Crops, 2014(2): 16-21. (in Chinese with English abstract)

[18] Ho Shih-Hsin, ChenYidi, Yang Zhongkai, et al. High-efficiency removal of lead from wastewater by biochar derived from anaerobic digestion sludge[J]. Bioresource Technology, 2017, 246:142-149.

[19] Meng Jun, Wang Lili, Liu Xingmei, et al. Physicochemical properties of biochar produced from aerobically composted swine manure and its potential use as an environmental amendment[J]. Bioresource Technology, 2013, 142(Complete): 641-646.

[20] Zhao Shixiang, Ta Na, Wang Xudong. Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material[J/OL]. Energies, 2017, 10: 1293. doi: 10.3390/en10091293.

[21] Park Cho, Ok Kim, Heo Delaune Seo. Comparison of single and competitive metal adsorption by pepper stem biochar[J]. Archives of Agronomy and Soil Science, 2016, 62(5): 617-632.

[22] Chen H, Lin G, Wang X, et al. Physicochemical properties and hygroscopicity of tobacco stem biochar pyrolyzed at different temperatures[J/OL]. Journal of Renewable & Sustainable Energy, 2016, 8(1): 013112. doi:10.1063/1.4942784.

[23] Li Chunxing, Wang Xingdong, Zhang Guangyi, et al. A process combining hydrothermal pretreatment, anaerobic digestion and pyrolysis for sewage sludge dewatering and co-production of biogas and biochar: Pilot-scale verification[J]. Bioresource Technology, 2018, 254: 187-193.

[24] Wang D, Ai J, Shen F, et al. Improving anaerobic digestion of easy-acidification substrates by promoting buffering capacity using biochar derived from vermicompost[J]. Bioresour Technol, 2017, 227: 286-296.

[25] Zheng Xuebo, Yang Zhiman, Xu Xiaohui, et al. Characterization and ammonia adsorption of biochar prepared from distillers' grains anaerobic digestion residue with different pyrolysis temperatures[J]. Journal of Chemical Technology & Biotechnology, 2017, 93 (1): 198–206.

[26] 吴志丹,尤志明,江福英,等. 不同温度和时间炭化茶树枝生物炭理化特征分析[J]. 生态与农村环境学报,2015,31(4):583-588. Wu Zhidan, You Zhiming, Jiang Fuying, et al. Physical and chemical characteristics of carboniferous tea branches at different temperatures and time[J]. Journal of Ecology and Rural Environment, 2015, 31(4): 583-588. (in Chinese with English abstract)

[27] 申卫博,张云,汪自庆,等. 木材制备生物炭的孔结构分析[J]. 中国粉体技术,2015,21(2):24-27,31. Shen Weibo, Zhang Yun, Wang Ziqing. Pore structure analysis of biochar prepared from wood[J]. China Powder Technology, 2015, 21(2): 24-27, 31. (in Chinese with English abstract)

[28] Divine D Sewu, Patrick Boakye, Seung H Woo. Highly efficient adsorption of cationic dye by biochar produced with Korean cabbage waste[J]. Bioresource Technology, 2017, 224: 206-213.

[29] Chen Wei, Liao Xindi, Wu Yinbao, et al. Effects of different types of biochar on methane and ammonia mitigation during layer manure composting[J]. Waste Management, 2017, 61: 506-515.

[30] Park Jeong-Hoon, Kang Hyun-Jin, Park Kang-Hee, et al. Direct interspecies electron transfer via conductive materials: A perspective for anaerobic digestion applications[J]. Bioresource Technology, 2018, 254: 300-311 .

[31] Chen Tingwei, Luo Ling, Deng Shihuai, et al. Sorption of tetracycline on H3PO4modified biochar derived from rice straw and swine manure[J]. Bioresource Technology, 2018, 267:431-437.

[32] Kizito S, Wu S B, Kirui W K, et al. Evaluation of slow pyrolyzed wood and rice husks biochar for adsorption of ammonium nitrogen from piggery manure anaerobic digestate slurry. [J]. Science of the Total Environment, 2015, 505: 102-112.

[33] 丁文川,朱庆祥,曾晓岚,等. 不同热解温度生物炭改良铅和镉污染土壤的研究[J]. 科技导报,2011,29(14):22-25. Ding Wenchuan, Zhu Qingxiang, Zeng Xiaoyu, et al. Study on the improvement of lead and cadmium contaminated soil by different pyrolysis temperature biochar[J]. Science and Technology Review, 2011, 29(14): 22-25. (in Chinese with English abstract)

[34] De D, Santosha S, Aniya V, et al. Assessing the applicability of an agro-industrial waste to engineered bio-char as a dynamic adsorbent for fluoride sorption[J]. Journal of Environmental Chemical Engineering, 2018, 6(2): 2998-3009.

[35] 张华. 柚皮基活性炭制备及吸附应用机理研究[D]. 南宁:广西大学,2013. Zhang Hua. Study on Preparation and Adsorption Mechanism of Pomelo-Based Activated Carbon[D]. Nanning: Guangxi University, 2013. (in Chinese with English abstract)

[36] 周丹丹,吴文卫,赵婧,等. 花生壳和松木屑制备的生物炭对Cu2+的吸附研究[J]. 生态环境学报,2016,25(3):523-530. Zhou Dandan, Wu Wenwei, Zhao Jing, et al. Adsorption of Cu2+by biochar prepared from peanut shell and pine wood chips[J]. Acta Ecologica Sinica, 2016, 25(3): 523-530. (in Chinese with English abstract)

[37] Pan Junting, Ma Junyi, Liu Xiaoxia, et al. Effects of different types of biochar on the anaerobic digestion of chicken manure[J]. Bioresource Technology, 2019, 275: 258-265.

[38] Luo C, Fan L, Shao L, et al. Corrigendum to “Application of eco-compatible biochar in anaerobic digestion to relieve acid stress and promote the selective colonization of functional microbes”[J]. Water Research, 2015, 68: 710-718.

[39] Li Q, Xu M, Wang G, et al. Biochar assisted thermophilic co-digestion of food waste and waste activated sludge under high feedstock to seed sludge ratio in batch experiment[J]. Bioresour Technol, 2017, 249: 1009-1016.

[40] Nms S, Zhu M, Zhang Z, et al. Effect of biochar addition on hydrogen and methane production in two-phase anaerobic digestion of aqueous carbohydrates food waste[J]. Bioresource Technology, 2016, 219: 29-36.

[41] Fagbohungbe M O, Herbert B M J, Hurst L, et al. Impact of biochar on the anaerobic digestion of citrus peel waste[J]. Bioresource Technology, 2016, 216: 142-149.

[42] Zhao Zhiqiang, Zhang Yaobin, Woodard T L, et al. Enhancing syntrophic metabolism in up-flow anaerobic sludge blanket reactors with conductive carbon materials[J]. Bioresource Technology, 2015, 191: 140-145.

[43] Zhao Zhiqiang, Zhang Yaobin, Wang Liying, et al. Potential for direct interspecies electron transfer in an electric anaerobic system to increase methane production from sludge digestion[J]. Scientific reports, 2015. doi:10.1038/srep11094

[44] Matthew Essandoh, Bidhya Kunwar, Charles U. Pittman, et al. Sorptive removal of salicylic acid and ibuprofen from aqueous solutions using pine wood fast pyrolysis biochar[J]. Chemical Engineering Journal, 2015, 265: 219-227.

[45] Kangkan Roy, Kapil Mohan Verma, Kumar Vikrant, et al. Removal of patent blue (V) dye using indian bael shell biochar: Characterization, application and kinetic studies[J]. Sustainability, 2018, 10(7): 2669. doi:10.3390/su10082669.

[46] 蒋旭涛,迟杰. 铁改性生物炭对磷的吸附及磷形态的变化特征[J]. 农业环境科学学报,2014,33(9):1817-1822. Jiang Xutao, Chi Jie. Adsorption of phosphorus by iron modified biochar and changes of phosphorus forms[J]. Journal of Agro-Environment Science, 2014, 33(9): 1817-1822. (in Chinese with English abstract)

[47] 宋婷婷,赖欣,王知文,等. 不同原料生物炭对铵态氮的吸附性能研究[J]. 农业环境科学学报,2018,37(3):576-584 Song Tingting, Lai Xin, Wang Zhiwen, et al. Adsorption properties of different raw materials biochar for ammonium nitrogen[J]. Journal of Agro-Environment Science, 2018, 37 (3): 576-584. (in Chinese with English abstract)

[48] 索桂芳,吕豪豪,汪玉瑛,等. 不同生物炭对氮的吸附性能[J]. 农业环境科学学报,2018,37(6):1193-1202. Suo Guifang, Lü Haohao, Wang Yuxi, et al. Adsorption of nitrogen by different biochars[J]. Journal of Agro-Environment Science, 2018, 37(6): 1193-1202. (in Chinese with English abstract)

[49] 刘项,南红岩,安强. 刺桐生物炭对水中氨氮和磷的吸附[J].农业资源与环境学报,2018(1):66-73. Liu Xiang, Nan Hongyan, An Qiang. Adsorption of ammonia nitrogen and phosphorus in water by prickly ash biochar[J]. Journal of Agricultural Resources and Environment, 2018(1): 66-73. (in Chinese with English abstract)

[50] Dang Y, Sun D, Woodard T L, et al. Stimulation of the anaerobic digestion of the dry organic fraction of municipal solid waste (OFMSW) with carbon-based conductive materials[J]. Bioresource Technology, 2017, 238: 30-38.

[51] Zhang Y, Yu F, Cheng W, et al. Adsorption equilibrium and kinetics of the removal of ammoniacal nitrogen by zeolite X/activated carbon composite synthesized from elutrilithe[J/OL]. Journal of Chemistry, 2017. doi:10.1155/2017/1936829.

[52] Fan Lü, Cheng Luohao, Mingshao Li, et al. Biochar alleviates combined stress of ammonium and acids by firstly enrichingand then[J]. Water Research, 2016, 90: 34-43.

[53] Zhao H Q, Liu Q, Wang Y X, et al. Biochar enhanced biological nitrobenzene reduction with a mixed culture in anaerobic systems: Short-term and long-term assessments[J]. Chemical Engineering Journal, 2018, 351: 912-921.

[54] Yang Yafei, Zhang Yaobin, Li Zeyu, et al. Adding granular activated carbon into anaerobic sludge digestion to promote methane production and sludge decomposition[J]. Journal of Cleaner Production, 2017, 149: 1101-1108.

[55] 韩光明. 生物炭对不同类型土壤理化性质和微生物多样性的影响[D]. 沈阳:沈阳农业大学,2013. Guangming Han. Effects of Biochar on Physical and Chemical Properties and Microbial Diversity of Different Types of Soil[D]. Shenyang: Shenyang Agricultural University, 2013. (in Chinese with English abstract)

[56] 李喜凤. 稻壳炭与有机肥配施对苹果园土壤有机碳组分及微生物活性的影响[D]. 杨凌:西北农林科技大学,2016. Li Xifeng. Effects of Combined Application of Rice Husk and Organic Manure on Soil Organic Carbon Fraction and Microbial Activity in Apple Orchard[D]. Yangling: Northwest A&F University, 2016. (in Chinese with English abstract)

[57] Preeti Sharma, Uma Melkania. Biosurfactant-enhanced hydrogen production from organic fraction of municipal solid waste using co-culture ofand Enterobacter aerogenes[J]. Bioresource Technology, 2017, 243: 566-572.

[58] Johannes Lehmann, Stephen Joseph. Biochar for Environmental Management: Science, Technology and Implementation[M]. 2 nd Edition. Lonclon: Taylor 8. 2015.

[59] Vrieze J D, Devooght A, Walraedt D, et al. Enrichment of Francis Group Methanosaetaceae, on carbon felt and biochar during anaerobic digestion of a potassium-rich molasses stream[J]. Applied Microbiology & Biotechnology, 2016, 100(11): 5177-5187.

[60] Zhao Zhiqiang, Zhang Yaobin, Dawn E. Holmes, et al. Potential enhancement of direct interspecies electron transfer for syntrophic metabolism of propionate and butyrate with biochar in up-flow anaerobic sludge blanket reactors[J]. Bioresource Technology, 2016, 209: 148-156.

[61] Shen Liang, Zhao Qingchuan, Wu Xuee, et al. Corrigendum to: “Interspecies electron transfer in syntrophic methanogenic consortia: From cultures to bioreactors” [J]. Renewable and Sustainable Energy Reviews, 2016, 54: 1358-1367.

[62] Baek G, Kim J, Lees C, et al. Role and potential of direct interspecies electron transfer in anaerobic digestion[J/OL]. Energies, 2018, 11(1): 107. doi:10.3390/en11010107

[63] 张杰,陆雅海. 互营氧化产甲烷微生物种间电子传递研究进展[J]. 微生物学通报,2015,42(5):920-927. Zhang Jie, Lu Yahai. Research progress in inter-species electron transfer between oxidized methanogenic microorganisms[J]. Bulletin of Microbiology, 2015, 42(5): 920-927. (in Chinese with English abstract)

[64] 黄玲艳,刘星,周顺桂. 微生物直接种间电子传递:机制及应用[J]. 土壤学报,2018,55(6):1313-1324. Huang Lingyan, Liu Xing, Zhou Shungui. Direct interspecific electron transfer of microorganisms: Mechanism and application[J]. Acta Pedologica Sinica, 2018, 55(6): 1313-1324. (in Chinese with English abstract)

[65] 张文亚. 铁及活性炭对污水厌氧处理的强化[D]. 大连:大连理工大学,2017. Zhang Wenya. Strengthening of Anaerobic Treatment of Wastewater by Iron and Activated Carbon[D]. Dalian: Dalian University of Technology, 2017. in Chinese with English abstract)

[66] Liu Fanghua, Amelia-Elena Rotaru, Pravin M Shrestha, et al. Promoting direct interspecies electron transfer with activated carbon[J]. Energy & Environmental Science, 2012, 5(10): 8982-8989

[67] Chen Shanshan, Amelia Elena Rotaru, Pravin Malla Shrestha, et al. Promoting interspecies electron transfer with biochar[J]. Sci Rep, 2014, 4: 5019. Doi: 10. 1038/srep05019.

[68] Liu Yuhao, He Pinjing, Shao Liming, et al. Significant enhancement by biochar of caproate production via chain elongation[J]. Water Research, 2017, 119: 150-159.

Research progress on biochar enhanced anaerobic fermentation technology of organic wastes

Feng Jing1, Jing Yong1,2, Zhao Lixin1※, Yao Zonglu1, Shen Ruixia1

(1.,,,,100125,; 2.,,150036,)

Anaerobic fermentation is an important technical way to deal with organic wastes in China. However, in the process of treating organic wastes under high load conditions by anaerobic fermentation technology, it is easy to cause anaerobic fermentation operation unstable and the efficiency of organic waste treatment is not high due to the inhibitory substances such as the high concentration of organic acid and ammonia nitrogen. Biochar is a multi-aperture carbonaceous material formed by high-temperature pyrolysis of biomass materials under the anaerobic or anoxic conditions. Biochar has many excellent properties, such as the high specific surface area, good conductivity, mass transfer and heat transfer performance. At the same time, biochar also contains a lot of ash, and the abundant ash contains a lot of elements such as calcium and magnesium, which makes the biochar have good adsorption and ion exchange performance. As an additive for anaerobic fermentation, it can effectively improve the pH value, alkalinity and the acid buffer capacity of the anaerobic fermentation system, and alleviate the inhibition of the excessive production of methane by the volatile fatty acids during the lag period. It can cause the adhesion of microorganisms and had a certain microbial carrier effect. Addition of biochar can effectively solve the problems of the low efficiency of gas production and unstable fermentation in current anaerobic fermentation, and biochar is now widely used in anaerobic fermentation technology research. In recent years, the research status of domestic and foreign showed that biochar could effectively strengthen anaerobic fermentation under certain conditions and improve the treatment efficiency of organic wastes in anaerobic fermentation process. However, for the biochar-enhanced anaerobic fermentation technology approach, there were still no systematic reviewed and reported. In this paper, the chemical composition, surface pore structure, key factors of surface functional groups and important ways of biochar-enhanced anaerobic fermentation technology of biochar materials were systematically analyzed and summarized. Based on the physical and chemical properties of biochar materials, biochar was described. For example, the effects of different types, different particle sizes and different amounts of additive biochar on anaerobic fermentation. And the intensive pathways of anaerobic fermentation technology mainly included: Biochar could effectively improve the buffer capacity of the system, it had a certain microbial carrier function, and it could strengthen the interspecific electron transport of microorganisms. On this basis, the focus of research on anaerobic fermentation technology of organic wastes in the future was proposed. At the same time, it also provided support for the in-depth development of biochar enhanced anaerobic fermentation technology.

wastes; fermentation; biochar; strengthening pathway; research progress

2018-12-30

2019-06-10

现代农业产业技术体系专项资金资助

冯 晶,博士,高级工程师,研究方向为有机废弃物资源化利用技术研究。Email:fengjing0204@sina.com

赵立欣,博士,研究员,主要从事农业废弃物能源化研究。Email:zhaolixin5092@163.com

10.11975/j.issn.1002-6819.2019.12.031

X71;X72

A

1002-6819(2019)-12-0256-09

冯 晶,荆 勇,赵立欣,姚宗路,申瑞霞. 生物炭强化有机废弃物厌氧发酵技术研究[J]. 农业工程学报,2019,35(12):256-264. doi:10.11975/j.issn.1002-6819.2019.12.031 http://www.tcsae.org

Feng Jing, Jing Yong, Zhao Lixin, Yao Zonglu, Shen Ruixia. Research progress on biochar enhanced anaerobic fermentation technology of organic wastes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(12): 256-264. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.12.031 http://www.tcsae.org