Application Research of Card-Model-Based Systems Engineering in the Development of Smart Dragon 1

2019-04-05ZHANGZijunWANGYaoNIANYongshangGAOFengLIBingweiGONGMinZHANGDong

ZHANG Zijun,WANG Yao,NIAN Yongshang,GAO Feng,LI Bingwei*,GONG Min,ZHANG Dong

China Academy of Launch Vehicle Technology,Beijing 100094

Abstract:Rapid development of Chinese commercial launch vehicles brings new challenges under the traditional systems engineering (TSE)working method.A new model-based systems engineering (MBSE)working method was proposed for Smart Dragon 1 (SD-1),which is a low-cost commercial launch vehicle developed by the China Academy of Launch Vehicle Technology (CALT).Based on the characteristics of a commercial launch vehicle,the system model based on information cards was established.Through a problem-oriented working method,risk identification and management,the process of Card-MBSE was utilized and verified by the success of the maiden flight of SD-1.This paper introduces a new method and reference for the development of low-cost and high-reliability launch vehicles.

Key words:SD-1,commercial launch vehicle,card model,MBSE,application research

1 INTRODUCTION

Today,space industry develops rapidly and new demands are required for launch vehicles.As a result of SpaceX demonstrating the deployment of cost effective commercial launch vehicles which feature agile-development and a fast-launch capability,satellite operators favor this approach which gradually is being adopted by the commercial space market.The Smart Dragon 1 (SD-1)launch vehicle is a commercial rocket developed by the China Academy of Launch Vehicle Technology(CALT),designed to serve the international launch market for small satellites.

In order to reduce the development cost,SD-1 used streamlined and simplified technical design ideas in the development process.With streamlined development ideas,it often brings great technical risks to the rocket,and several commercial launch missions failed before the maiden flight of SD-1.Under multi-dimensional constraints of time,space and cost,one of the major problems for commercial launch vehicles is how to manage the risk while improving the reliability.

SD-1 provides remarkable access to space with a reduced preparation period and a higher injection accuracy compared with other Chinese commercial launch vehicles.On August 17,2019,SD-1 conducted its maiden flight and launched three satellites accurately into their preset sun-synchronous orbits of 550 km,as shown in Figure 1.

The completion of SD-1 maiden flight approved that the innovative application of systems engineering and risk management method for the commercial launch vehicle under multi-dimensional constraints was successful.In this paper,the cardmodel-based systems engineering (Card-MBSE)applied in the development of SD-1 is introduced,and three component processes are introduced as well.This paper proposes a new systems engineering concept based on the“card model”as a new MBSE working method,which can provide a reference for the development of commercial spacecraft and launch vehicles.

2 A BRIEF OVERVIEW OF MBSE APPLIED IN AEROSPACE ENGINEERING

As an organization management technology,systems engineering includes two key aspects:system modeling technology and organization management technology[1,2].Traditional Systems Engineering (TSE,also referred to as Text-Based Systems Engineering)has been in existence since its inception and the modeling language has changed little[3-6].With the increasing complexity of space systems,TSE faces several disadvantages[7].The scale and complexity of space engineering is increasing year by year,while the growth of our engineering ability to deal with complex system problems cannot keep up with the growth of system complexity.Meanwhile,it is difficult to maintain inheritance between various stages in the system project.

In order to solve the problems faced by TSE,Wymore[1]proposed the concept of MBSE.He proposed various states in the systems engineering process based upon strict mathematical expressions,the method of abstract expression of elements,and also established the connection between various state elements in systems engineering under a mathematical model system,which is the prototype of the model description method for systems engineering.

MBSE is a formal application of modeling methods to support system requirements,design,analysis,test and validation activities,starting with the conceptual design phase,continuing through design development and all subsequent life cycle phases[8].MBSE has made a major change in modeling language,modeling ideas,and modeling tools[9-14].A brief review of the MBSE working method is shown in Figure 2.

Figure 1 The image of SD-1 (left)and the images from the camera onboard (right)

3 CARD MODEL DESCRIPTION OF SD-1

During the development process of SD-1,constraints due to cost,schedule and resource were faced by the engineers and designers.To apply MBSE concepts,it is necessary to combine the technical and management characteristics in the development process,then identify the design priorities,shorten iterative chains and improve work results.Therefore,based on the application of MBSE,taking the characteristics of commercial rockets into consideration,the Card-MBSE was proposed.Compared with traditional MBSE applications,Card-MBSE has the following unique characteristics.

1)Verification method based on virtual-real co-design

The utilization of a virtual-real co-design eliminates the boundary between the virtual and the real models,which effectively resolves the contradiction between cost and risk,and achieves an optimized system.

2)Refinement and representation of the system model

Traditional MBSE takes information as the main body of the system,while the Card-MBSE applied in SD-1 introduces personnel as the carrier of information.The experience of designers is fully utilized,so the system model is more refined and firm,which solves the disparity that system model is not equal to the actual situation,and improves efficient problem handling.

3)Technology and management information adoption in SD-1

Based on the general quality characteristics of the product,a three-dimensional modeling collaborative platform and a general quality characteristics collaborative working platform were constructed,thereby improving the adoption of the information level of technology and management.Technology and management were effectively integrated in the card model through the information interaction,which shortened the development chain and reduced development costs.

4)Integrating multi-disciplinary chains of SD-1

The system holistic and top-level information was described through Card-MBSE,and integrated multi-disciplinary professional models,from the technical position,by means of data,model transformation and encapsulation.MBSE served as a hub for multidisciplinary design in the systems engineering process,and realized multidisciplinary design through the card model for the different systems of SD-1.Through MBSE concepts,the gap between different disciplines was filled and the design blind spots avoided.

Figure 2 MBSE model conversion process for system definition and interface definition

3.1 Card Model Definition of SD-1

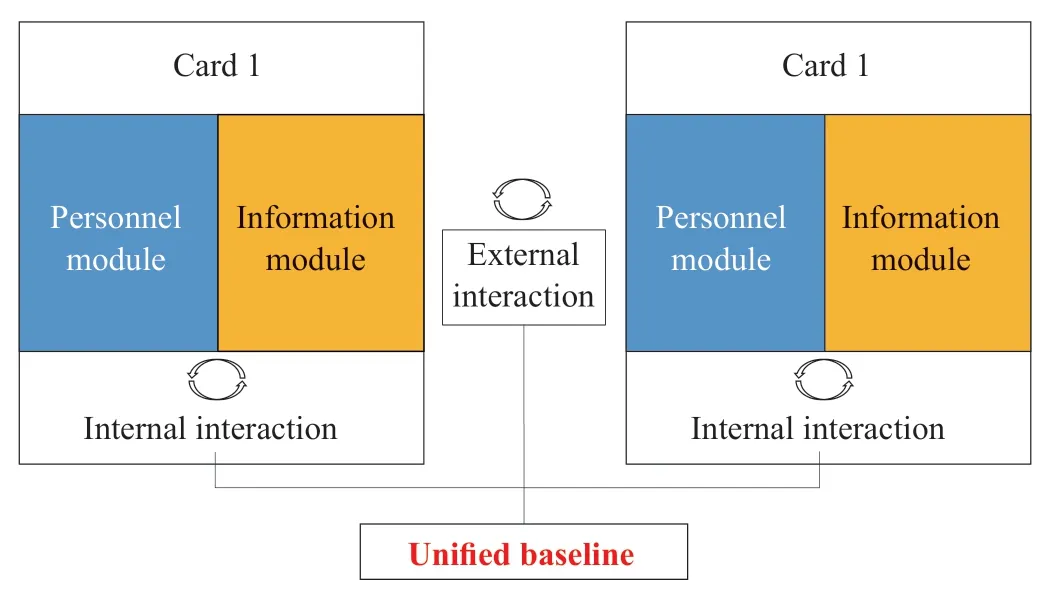

The card model used in SD-1 was derived from the“Element Model”proposed by Wymore[2].Unlike the“element”mentioned under conventional MBSE,the card model contains more nuances,and each card itself contains two components:personnel and information.

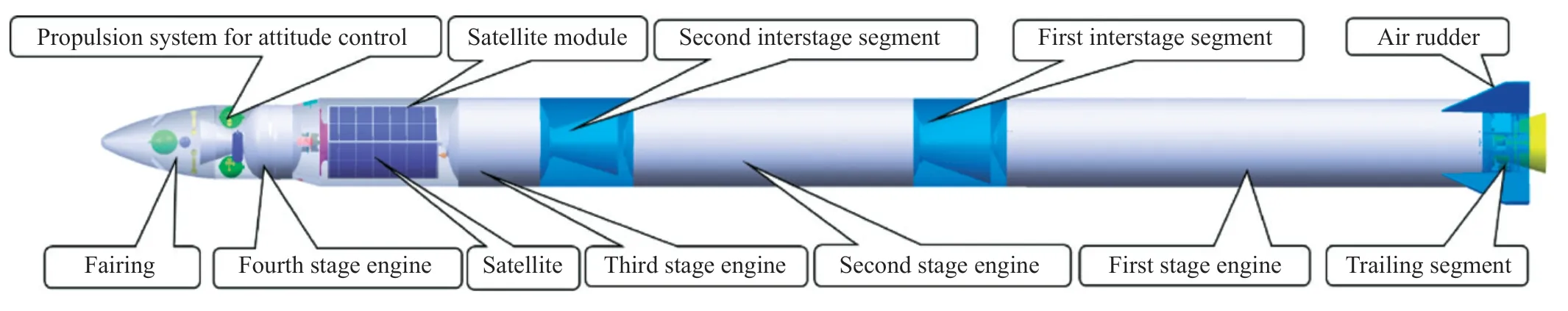

Card model of the SD-1 is shown in Figure 3,which contains eight aspects:requirement,product,interface,environment,activity,timeline,space-domain,and influence.The form of the card model is unified,and each includes two modules:

1)Personnel module includes the corresponding professional personnel in designer team and related professional experts (to maximize the application of design experience).

2)Information module includes various types of documents,drawings,3D models,simulations and test results corresponding to the card title.

Figure 3 Card model description for the commercial launch vehicle system

Figure 4 The structure card of SD-1

An example of the card model is shown in Figure 4,in which the structure of SD-1 is illustrated and the information of the structure is kept in a central database for the conveniently use of different cards.

3.2 Dynamic Interaction of Different Cards

The card model itself is a dynamic model that includes the interaction of personnel and information:the personnel collect,process,and use the information.There also exists an external interaction between different cards.In the development process of SD-1,information was transferred between different specialists to solve certain special problems.Through this exchange and discussion,information was transferred and utilized in a timely and reasonably manner between different cards.

As shown in Figure 5,whether it is by internal interaction or external interaction,the baseline is unified,which forms the 3D model of the product or the development process of the product.

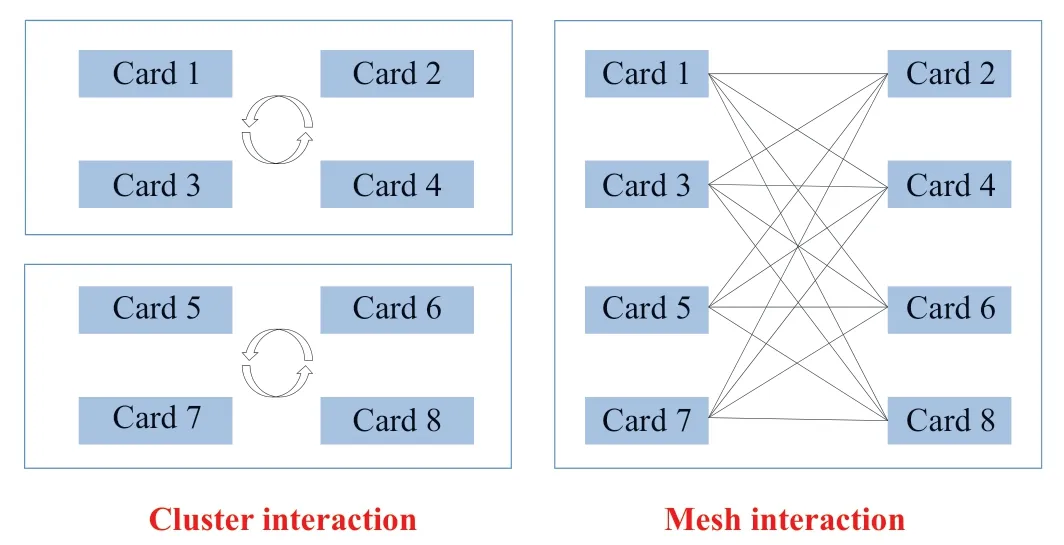

On the other hand,the external interaction for SD-1 between cards may be considered a cluster interaction of fixing cards or a mesh interaction of all cards,as shown in Figure 6.

Figure 5 Unified card model

Figure 6 Two typical forms of external interaction

4 APPLICATION OF CARD-MBSE IN SD-1

Taking the characteristics and the multi-dimensional constraints (time,space,cost and so on)of the commercial launch vehicle into consideration,the application of Card-MBSE was carried out based on answering the following three questions:

1)How to solve problems under a variety of constraints through Card-MBSE in the development of SD-1?

2)How to identify and control technical risks as early as possible through Card-MBSE in the development of SD-1?

3)How the Card-MBSE covers the entire process during the SD-1 development?

4.1 Problem-oriented Systems Engineering

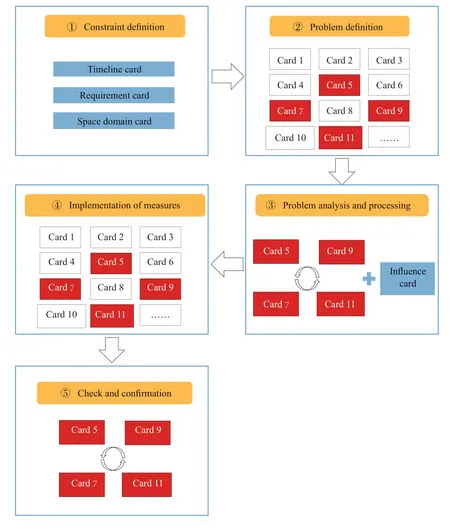

In the development process of SD-1,systems engineering philosophy oriented to problems and risks was used.Problem-oriented systems engineering includes five stages of work,as shown in Figure 7.

Step1:Constraint deflnition

Define the external constraints that are encountered during the processing of the problem.Generally,the constraints come from the requirements,timeline and space-domain cards.

Step2:Problem deflnition

Define all the features in the problem and select the appropriate cards.Define the boundaries and establish the minimum cut-set of the cards which related to the problem.Through the idea of“minimum cut-set”,strong-correlated cards were selected out,so that the problem-solving process can be more efficient.

Step3: Problem analysis and processing

Conduct analysis of the external and internal interactions of strong-correlated cards,then propose problem-solving measures and analyze the influence.This step focuses on the problem-solving scheme and the influence brought about by the problem-solving process.An update of one card may have an influence on a large number of other cards,so this step requires a review of those weak-correlated cards.

Step4: Implementation of measures

Draw up comprehensive measures to resolve the problem.This step was limited in the strong-correlated cards,but the information change was updated in time on the unified technical baseline.

Step5: Check and conflrmation

Conduct simulation and test verification to confirm whether the problem resolution measures are in place.The verification needs the participation of all cards,in order to avoid a gap between different disciplines.

Through the practice of problem-oriented systems engineering,the work-points in the development process are highlighted,the problem-solving processes are streamlined,and the waste of resource caused by an“all-in”method was avoided.

Figure 7 Problem-oriented systems engineering workflow

4.2 Pre-recognition and Closedloop Control of Risk

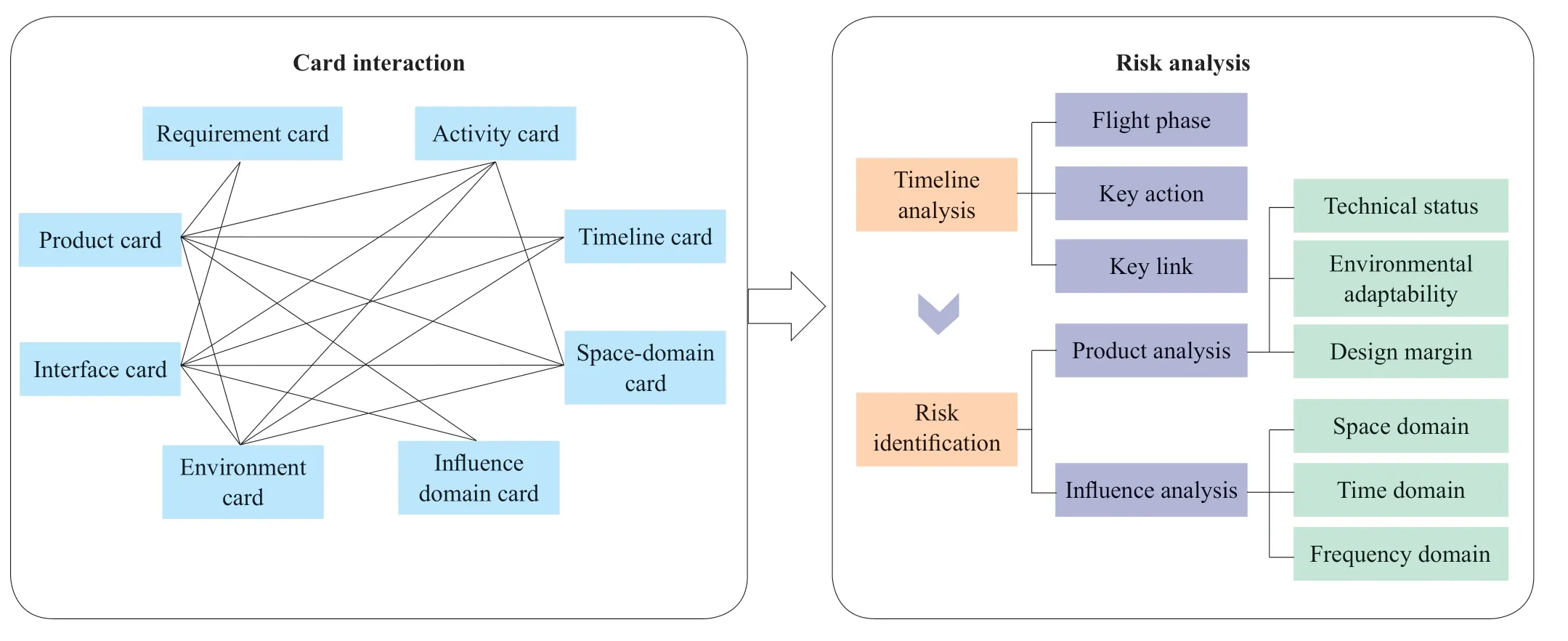

Through the application of the card model in SD-1,risk identification and control were carried out in the early stage of development.As shown in Figure 8,the risk identification was carried out through card interaction.At the same time,as the development process progressed,the internal information was updated and the risk identification was dynamically carried out,so that the technical risk was exposed and resolved first time around.

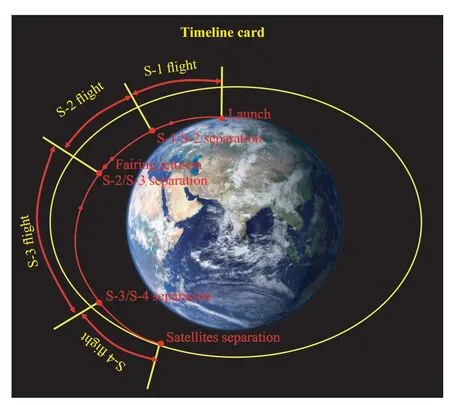

In the development of SD-1,the risk pre-recognition was taken through a timeline-based analysis process.As shown in Figure 9,the risk pre-recognition was conducted along the timing action of the launch vehicle during its planned flight.For every timing action,a coupling analysis was carried out by the experts in different disciplines.In the working process,the interaction between different cards occurred and a problem-oriented systems engineering working method was applied.

Figure 8 Risk analysis based on card model

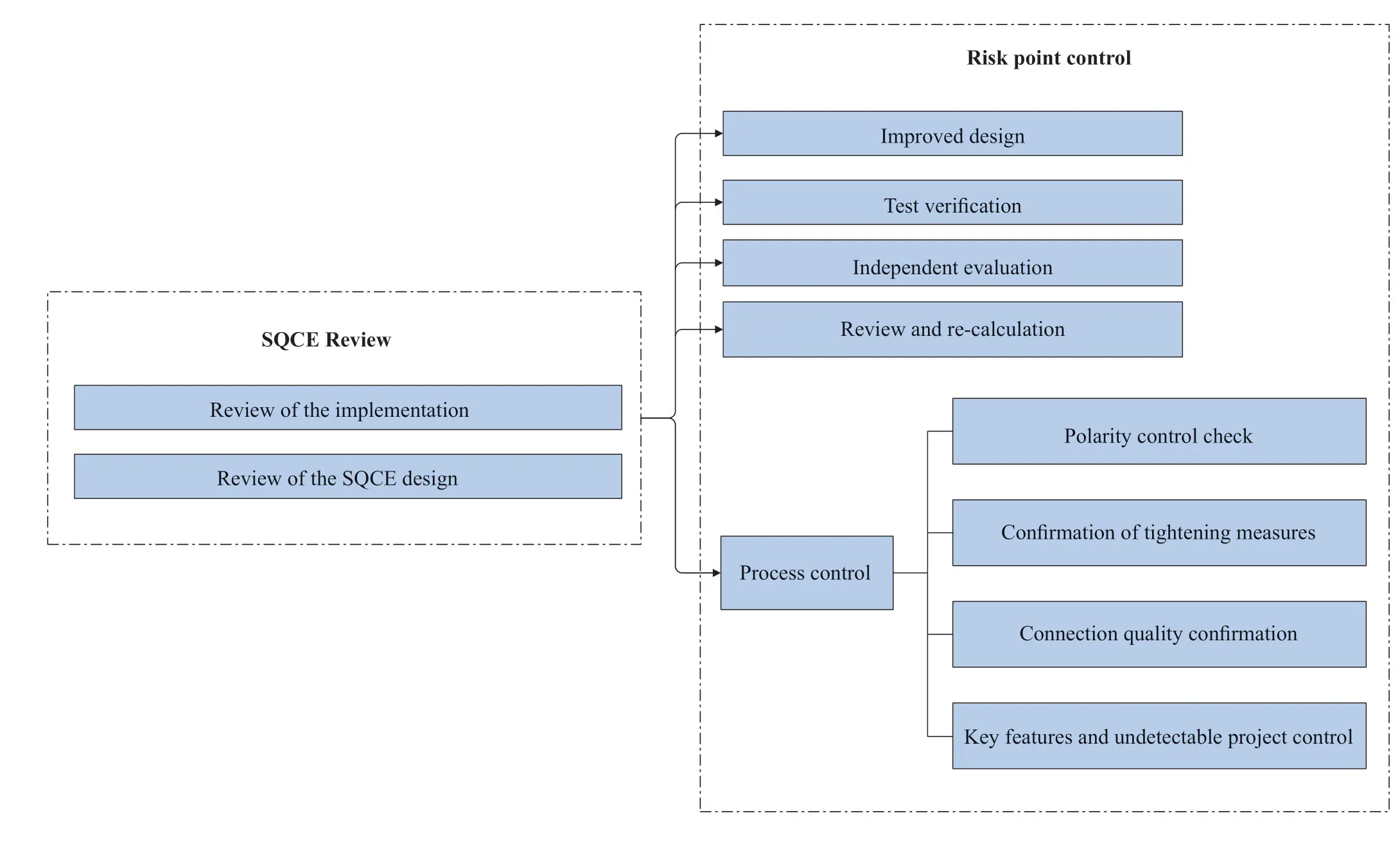

On the basis of identifying risks,the development of risk mitigation measures and closed-loop control of risks was carried out.Subjected to the multi-dimensional constraints of time,space and cost,the technical analysis method of the general six quality characteristics (reliability,safety,supportability,maintainability,testability,environmental adaptability)engineering(SQCE)was used.From the perspective of assessing risk,using the SQCE design method,products were designed with the weak-link in mind,and finally using the SQCE review method to ensure closed loop risk management and control,as shown in Figure 10.

Figure 9 Timeline based risk analysis applied on SD-1

4.3 Systems Engineering Implementation Process Based on Card Model

In the development process of SD-1,a three-dimensional model CAD collaborative design platform and a general quality characteristic work platform were combined to conduct the establishment and application of the Card-MBSE.The development process of SD-1 based on Card-MBSE is shown in Figure 11.

5 SUMMARY

This paper outlined the Card-MBSE process used in the development of SD-1.The advantages of this application are as follows:

1)The dynamic card model of the system was constructed,the technical baseline of the commercial launch vehicle system was unified,and the description of the system was unified,so as to avoid design blind spots caused by gaps between different engineering disciplines.

2)Reasonable use of the card model for problem analysis,focusing on strong-correlated cards interaction,minimized the professional cut-off of the problem involved,thus shortening the iterative chain,improving processing efficiency and reducing development costs.

Figure 10 Risk control through SQCE engineering

Figure 11 Systems engineering implementation process based on card model

3)Risk analysis was conducted based on card interaction.SQCE design and analysis methods were used to carry out risk management and control.Pre-recognition of risk in design stage were realized,so as to avoid design and work recurrence caused by discovering risks in the later stage of product production.

Through the practice of Card-MBSE,the contradiction between low-cost and high reliability requirements of SD-1 was properly managed,which laced a solid foundation for the rapid development and market roll-out.The method proposed in this paper can provide some reference for the development of commercial launch vehicles and commercial spacecraft systems engineering going forward.

杂志排行

Aerospace China的其它文章

- Relative Navigation of Long-Range Non-Cooperative Targets Based on Monocular Sequence Images

- Analysis of International Commercial Space Market and Policy

- Reflection on Small Satellite Constellation Operations from the Commercial Space Perspective

- Practice and Enlightenment for International Cooperation on Chang’e 4 Mission

- A LM-4B Launched China-Brazil Earth Resource Satellite into Orbit

- Twin BeiDou Satellites Launched Aboard a LM-3B/Yuanzheng 1