Optimization of Fermentation Process of Carrot Juice by Probiotics and Analysis of Aroma Components

2019-02-18,U,,,,,

, U, , , , ,

1. Qilu University of Technology, Jinan 250353, China; 2.Jinan Fruit Research Institute, All China Federation of Supply and Marketing Co-operatives, Jinan 250014, China

Abstract Carrot juice was fermented by probiotic Lactobacillus casei (CTCF-LC1) and Lactobacillus reuteri (CTCF-LT1) with sensory score as the main evaluation index, and the fermentation process was optimized by single factor and response surface experiments. The optimum ratio of fermentative strains CTCF-LC1∶CTCF-LT1 was 1∶1, fermentation time was 8 h, inoculum size was 3.1% and fermentation temperature was 26.6℃. Under the optimum conditions, the sensory score of fermented carrot juice was 91.3, pH was 4.50, total acid content was 3.73 g/L, total sugar content was 54.25 g/L, and reducing sugar content was 28.41 g/L. The carrot juice has bright orange color and stable state. It not only has the fresh flavor of fruit and vegetable juice, but also has the unique aroma from lactic acid bacteria fermentation, as well as soft and even taste, moderate acidity and sweetness. The changes of aroma components of carrot juice before and after fermentation were analyzed by headspace solid phase microextraction (HSPME) coupled with gas chromatography-mass spectrometry (GC-MS). After fermentation, substances with medicinal flavor components were reduced, and a lot of floral and fruit-scented substances were produced, such as methyl myristate, β-pinene, phenylethanol, and geraniol. Therefore, the results of this study can provide a theoretical basis for the development of fermented fruit and vegetable juice products with unique flavor substances.

Key words Lactic acid bacteria, Carrot juice, Response surface methodology, Aroma components, Gas chromatography-mass spectrometry

1 Introduction

Carrot, also known as small ginseng, is one of the most commonly eaten vegetables. It is rich in nutrients, and every 100 g carrot contains about 0.6 g protein, 0.3 g fat and 7.6-8.3 g carbohydrate. In addition, carrots also contain a large number of dietary fibers and carotenoids, and so on[1-2]. Studies have shown that carotene supplementation through fruits and vegetables may benefit the body’s immunity and cardiovascular function[3-4]. But because carrots contain unpleasant taste[5-6], it will be rejected by consumers, especially children.

Lactic acid bacteria are a kind of non-spore, gram-positive bacteria which can ferment sugar to produce lactic acid. As a safe microorganism[8], lactic acid bacteria have been widely used in fermentation production[9-10], food preservation[11], medical and health care[12]and so on. And lactic acid bacteria are also widely used in improving food flavor and controlling nutrition of products[13]. In this experiment, carrot was used as the main raw material andLactobacilluscaseiandLactobacillusreuteriwere mixed to ferment carrot juice. The effects of fermentation temperature, fermentation time, inoculum size and different inoculation proportion on the sensory score of carrot juice were studied. The fermentation process was optimized, and the flavor substances of carrot juice were compared and analyzed. The purpose of this study is to develop a kind of carrot fermentation juice with fresh and pleasant taste, so as to provide a theoretical basis for the further processing and fermentation of carrot by microorganisms and the development of new probiotic carrot fermentation juice.

2 Materials and methods

2.1MaterialsandreagentsCarrots, bought from local supermarket;LactobacilluscaseiCTCF-LC1 andLactobacillusreuteriCTCF-LT1, selected and preserved in the Fermentation Technology Laboratory of Jinan Fruit Research Institute; MRS broth medium, bought from Qingdao Binder Biotechnology Co., Ltd; compound stabilizer (food-grade), bought from Hefei Siyou Food Industry and Trade Co., Ltd.

2.2InstrumentsandequipmentTRACE 1300 gas chromatograph-mass spectrometer, Thermo Company; solid-phase microextraction device (manual injector and 50/30 μm DVB/CAR/PDMS extraction head), Qingdao Zhenzheng Analytical Instrument Co., Ltd.; vertical autoclave, Shanghai Boxun Industrial Co., Ltd.; constant temperature incubator, Shanghai Zhiyu Analytic Instrument Manufacturing Co., Ltd.; electronic analytical balance, Mettler Toledo Instruments (Shanghai) Co., Ltd.; pH meter, Shanghai INESA Scientific Instrument Co., Ltd.; vertical ultra-clean worktable, Suzhou Antai Airtech Co., Ltd.; beater, Jiuyang Co., Ltd.; high-speed shearing machine, IKA (Guangzhou) Instrument and Equipment Co., Ltd.

2.3TestmethodsThe carrot juice fermentation process can be seen in Fig. 1. Carrot juice preparation: choose fresh, disease-free carrots; wash and remove dirt and impurities, remove carrot skin and non-edible parts; cut carrots into small pieces of 5-10 mm, and mix with water according to the ratio of 1∶1 for beating using a beater; take carrot juice after filtering, and add stabilizer according to a certain proportion, following heating to 85℃, and 10 000 r/min high-speed shearing for 12 min; conduct high temperature and high pressure sterilization at 121℃ for 15 min.

Preparation of seed solution: add the preserved strains CTCF-LC1 and CTCF-LT1 to MRS broth medium, respectively and activate it twice; culture it for 12 h in 100 mL of sterilized carrot juice according to the ratio of 3%, so that the concentration of bacteria reached 108-109cfu/mL, as seed solution.

Fig. 1Carrotfermentationprocessflow

2.4Single-factoroptimizationexperimentSingle factor test was carried out by using single factor variable control method, to study the effect of the fermentation temperature (24℃, 27℃, 30℃, 33℃, 36℃), fermentation time (6 h, 8 h, 10 h, 12 h, 14 h), inoculum size (1%, 2%, 3%, 4%, 5%), CTCF-LC1∶CTCF-LT1 (1∶0, 2∶1, 1∶1, 1∶2, 0∶1) on the sensory score of fermented carrot juice.

2.5OptimizationoffermentationconditionsbyresponsesurfacemethodologyBased on the results of single factor experiments, according to the principle of Box-Behnken design[14-15], the 3-factor and 3-level response surface experiments of fermentation temperature, fermentation time and inoculum size were carried out with sensory score (Y) as response value. Experimental factors and levels are shown in Table 1.

Table1Optimizationoffermentationprocessfactorsandlevelsbyresponsesurfacemethodology

LevelA Fermentationtime∥hB Inoculumsize∥%C Fermentationtemperature∥℃-172240832719430

2.6SensoryevaluationmethodsTen experts in fermented fruits, vegetables and beverages were asked to evaluate the samples by sense, and sensory evaluation was carried out from four aspects: color, structure, aroma and taste[16]. The sensory evaluation criteria are shown in Table 2.

Table2Sensoryevaluationcriteria

ColorCriteriaScorepointsStructureCriteriaScorepointsAromaCriteriaScorepointsTasteCriteriaScorepointsOrange-yellow, brightlycolored11-15The structure is uniform and no solid precipitates out15-20Fresh carrot aroma, characteristic fermentation aroma, no odor18-25Soft, tasty, pure sour taste, without mixed smell30-40Orange-yellow, brightlycolored6-10The structure is uniform and a small number of solids precipitate out8-14The aroma of carrot and fermen-tation is light, no peculiar smell10-17The taste is pure, slightly sour or light, without mixed smell16-30Abnormal and dark color0-5Uneven structure with solid pre-cipitation0-7No aroma of carrot and fermenta-tion, with peculiar smell0-9Poor taste, too sour or light taste, with mixed smell0-15

2.7DeterminationofphysicalandchemicalindicatorsThe total acid content was determined by pH potentiometric method in GB/T 12456-2008DeterminationofTotalAcidinFood. The total sugar and reducing sugar content was determined by GB 5009.7-2016DeterminationofReducingSugarinNationalFoodSafetyStandard. The pH of fermented carrot juice was measured by pH meter.

2.8Determinationofaromacomponentsofcarrotjuicebeforeandafterfermentation

2.8.1 Sample treatment. 5 mL of unfermented carrot juice and carrot juice under the optimum fermentation conditions were accurately measured, respectively and put into the headspace injection flask, and 1 g of sodium chloride was added. The sample injection flask was balanced for 30 min at 40℃. Then the aged extraction head was inserted into the injection bottle, the headspace was adsorbed for 30 min, and then desorption was carried out.

2.8.2 Conditions for gas chromatography and mass spectrometry. Chromatographic column: HP-5 capillary column (30×0.25 μm, 1 μm); the heating program: the initial temperature was 50℃ for 3 min, then rose at 4 ℃/min to 120℃ for 1 min, and rose at 15 ℃/min to 250℃ for 5 min; the (He) flow rate of carrier gas was 1.2 mL/min and the pressure was 7.652 2 psi; the injection volume was 1 μL; it was splitless injection[17-18].

EI source; electron energy of 70 eV, mass scanning range ofm/z35-450, 0.2 scans/s; transmission line temperature of 280℃ and the ion source temperature of 280℃.

2.8.3 Data processing. The data were collected and analyzed by NIST MS search 2.0, and the flavor substances were determined by CAS number and proportioning degree.

3 Results and analysis

3.1Resultsofsingle-factoroptimizationexperiments

3.1.1 Effect of strain proportion on sensory score of fermented carrot juice. As can be seen from Fig. 2, the sensory score of fermented carrot juice was greatly affected by different strain proportion. With the increase of the proportion of CTCF-LT1, the sensory score of carrot juice increased gradually and reached the maximum at 1∶1. After that, with the decrease of CTCF-LC1 content, the sensory score of carrot juice decreased gradually. Therefore, CTCF-LC1∶CTCF-LT1 was set to be 1∶1.

Fig. 2Effectofstrainproportiononsensoryscoreoffermentedcarrotjuice

3.1.2 Effect of fermentation time on sensory score of fermented carrot juice. As can be seen from Fig. 3, the sensory score of carrot juice increased gradually with the increase of fermentation time, and reached the highest at 8 h, then the sensory score of carrot juice gradually decreased with the prolongation of fermentation time. This was due to the fact that in the early stage of fermentation, carrot juice had low acidity, light taste and lacked fermentable flavor substances; after fermentation time reached 8 h, the acidity was suitable and the taste was good; after fermentation time reached 10 h, the amount of acid production was too much, leading to heavily sour and poor taste of carrot juice. Therefore, the selected fermentation time was 8 h.

Fig. 3Effectoffermentationtimeonsensoryscoreoffermentedcarrotjuice

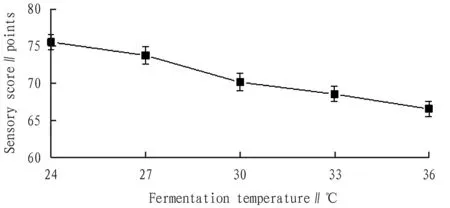

3.1.3 Effect of fermentation temperature on sensory score of fermented carrot juice. It can be seen from Fig. 4 that the sensory score of fermented carrot juice gradually decreased with the increase of fermentation temperature, and the sensory score of carrot juice would be approximately the same at 24℃ and 27℃. This is because with the increase of fermentation temperature, the activity of lactic acid bacteria increased, and the amount of acid production increased, which made the proportion of sourness and sweetness in fermentation carrot juice out of balance, and the taste poor. The selected fermentation temperature was 27℃.

Fig. 4Effectoffermentationtemperatureonsensoryscoreoffermentedcarrotjuice

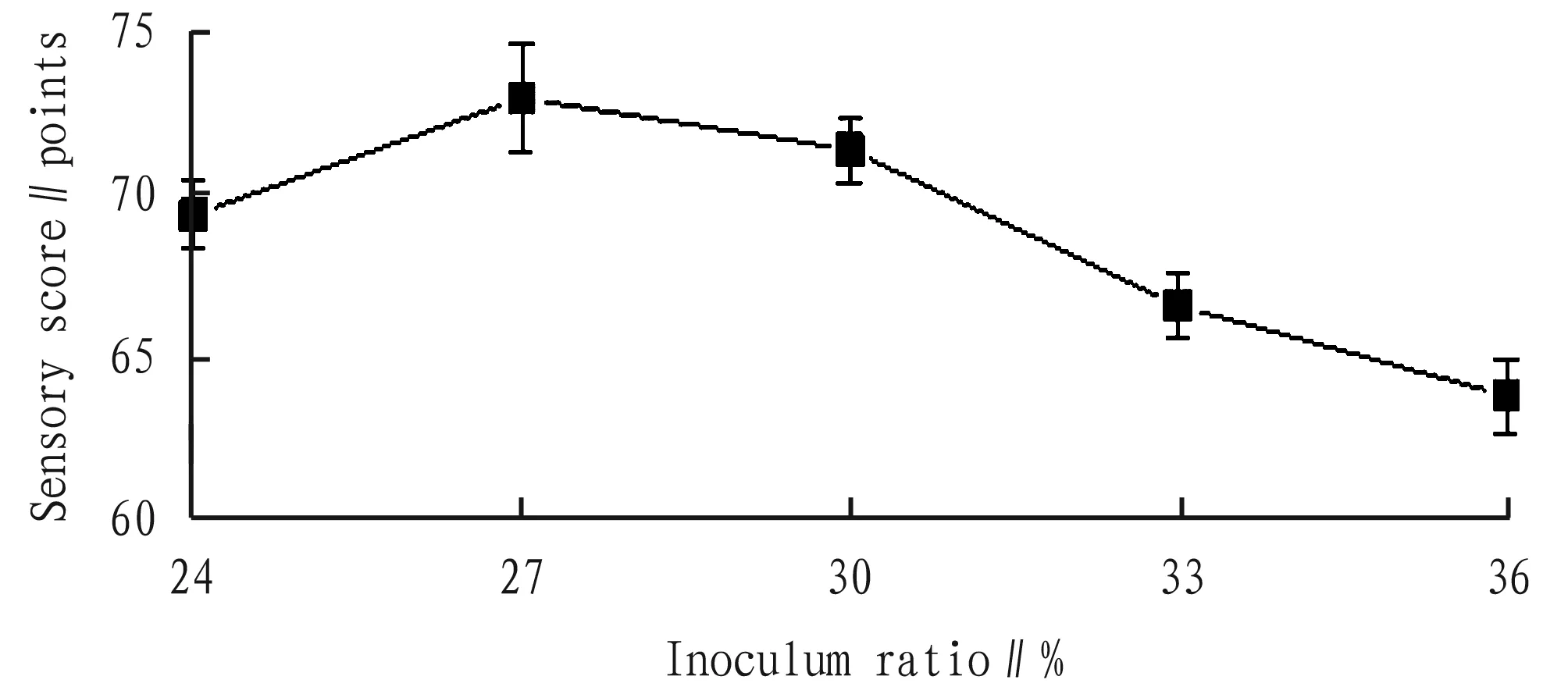

3.1.4 Effect of inoculum size on sensory score of fermented carrot juice. As can be seen from Fig. 5, when the inoculum size was 1%, carrot juice was light because of the small inoculum size and the low fermentative power; when the inoculum size was 2%, the fermented carrot juice with suitable taste was obtained; after the inoculum size reached 3%, carrot juice would be excessively acid. Comprehensively considering the fermentation time, the fermentation time at this point was 10 h. If the fermentation time was 8 h, the inoculum size should be increased properly. As a result, the inoculum size of 3% was selected.

Fig. 5Effectofinoculumsizeonsensoryscoreoffermentedcarrotjuice

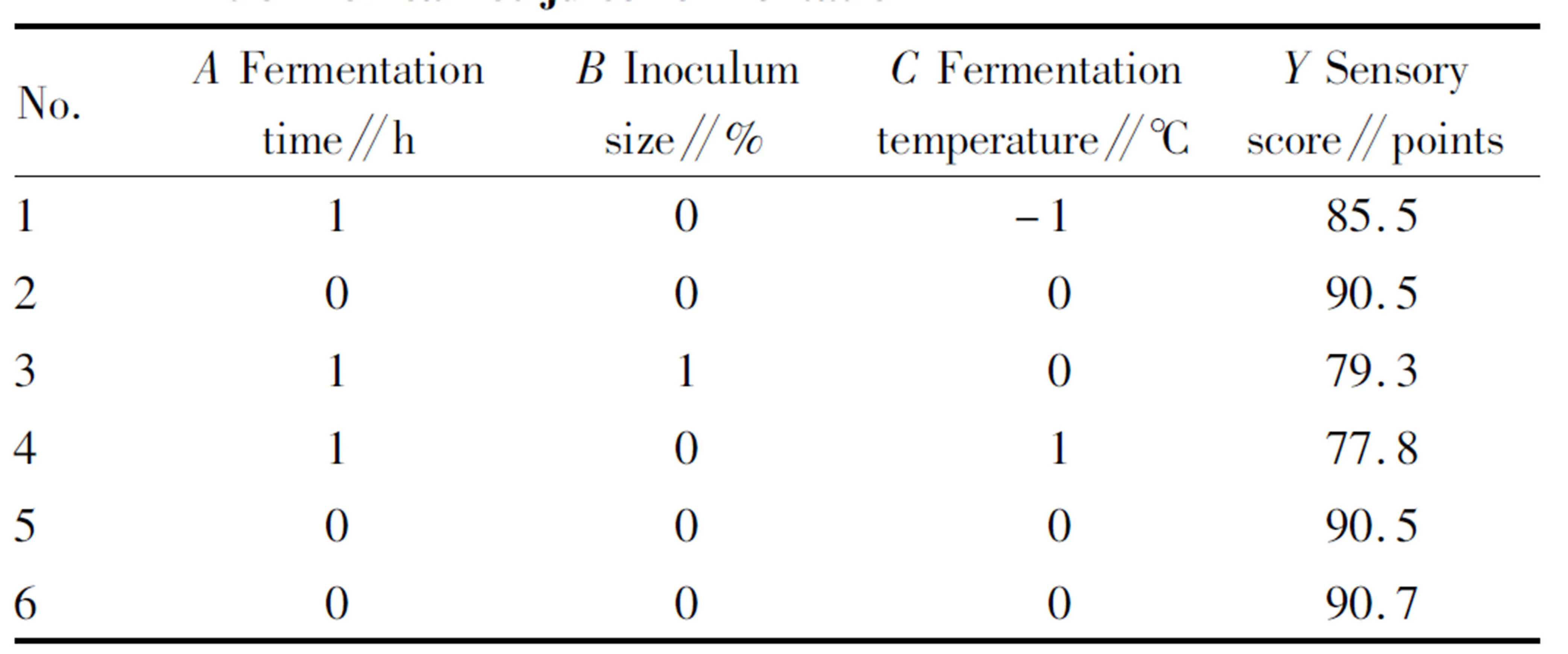

3.2ResultsofresponsesurfaceexperimentforcarrotjuicefermentationIn order to optimize the fermentation process of carrot juice, the experiment principle of Box-Behnken central combination design was applied on the basis of single factor. The fermentation time, inoculum size and fermentation temperature were selected as independent variables, and the sensory score of carrot juice was used as the response value. The experiment of three factors and three levels was designed. The experimental results are shown in Table 3.

Table3Experimentaldesignandresultsofresponsesurfaceoptimizationforcarrotjuicefermentation

No.A Fermentationtime∥hB Inoculumsize∥%C Fermentationtemperature∥℃Y Sensoryscore∥points110-185.5200090.5311079.3410177.8500090.5600090.7

(To be continued)

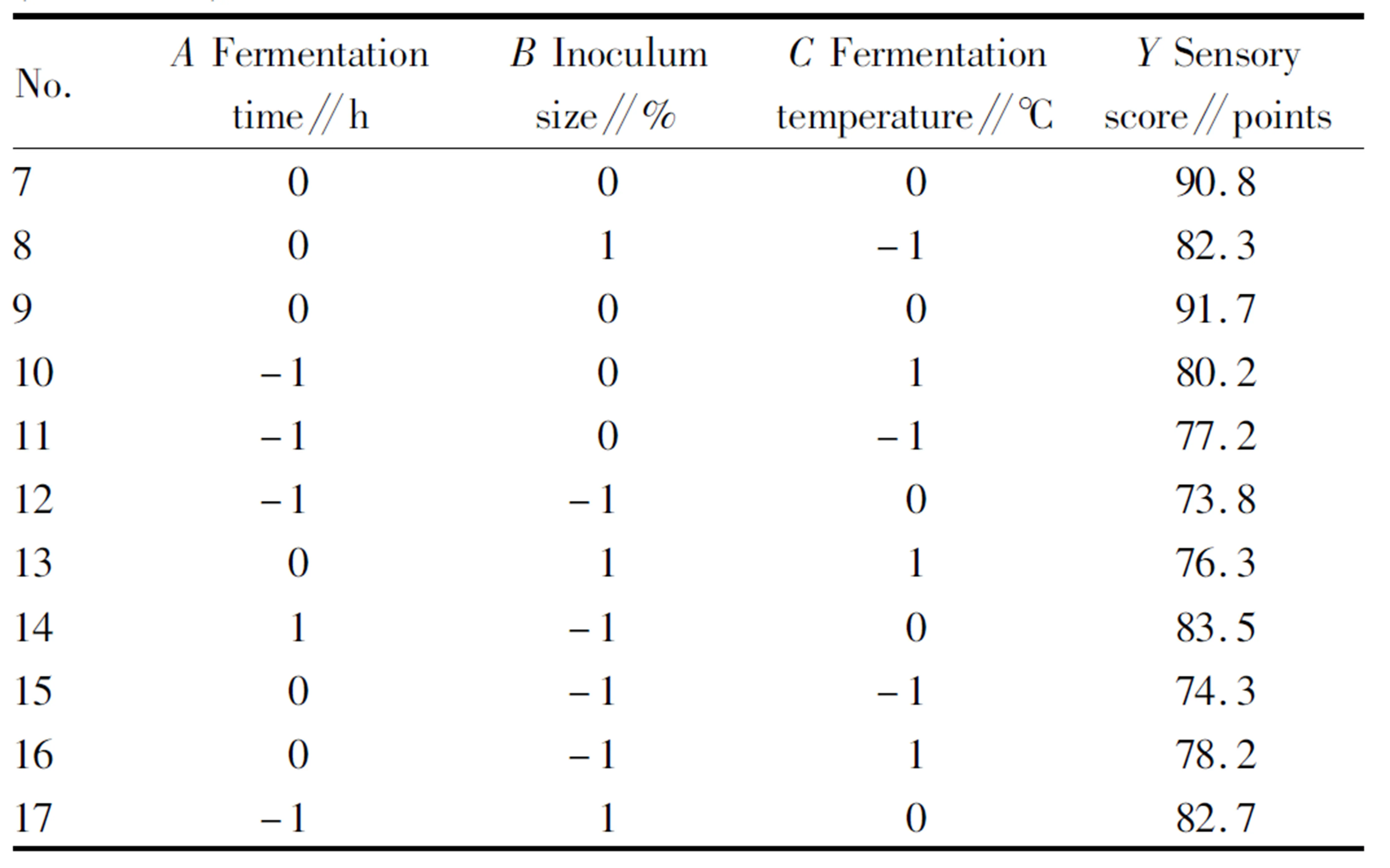

(Continued)

No.A Fermentationtime∥hB Inoculumsize∥%C Fermentationtemperature∥℃Y Sensoryscore∥points700090.8801-182.3900091.710-10180.211-10-177.212-1-1073.81301176.3141-1083.5150-1-174.3160-1178.217-11082.7

Design Expert 8.0.6 was used to analyze the experimental data (Table 4), and the quadratic multiple regression equation model was obtained as follows:

Y=90.80+1.62A+1.25B-0.87C-3.50AB-2.75AC-2.50BC-4.02A2-6.77B2-6.53C2.

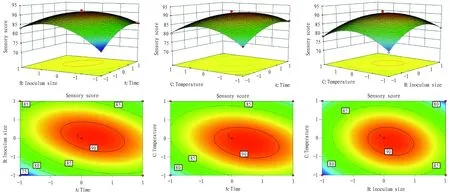

Design Expert 8.0.6 software was used to draw response surface and contour maps based on regression equations, as shown in Fig. 6. The interaction between inoculum size and fermentation time, the interaction between fermentation temperature and fermentation time, and the interaction between fermentation temperature and inoculation size all had significant effects on sensory score. The response surface was steepest along the fermentation time, which indicated that the fermentation time had the most significant effect on sensory score. When other factors were not changed, the response value increased at first and then decreased with the increase of factor value. Response surface analysis showed that the optimum fermentation conditions of carrot juice were fermentation time of 8 h, inoculum size of 3.06% and fermentation temperature of 26.63℃. Under this fermentation condition, the sensory score of carrot juice was 91.07 points. In order to facilitate practical operation, the fermentation conditions were revised as follows: fermentation time of 8 h, inoculum size of 3.1%, and fermentation temperature of 26.6℃. Under these conditions, the average sensory score of carrot juice was 91.3 points, which was close to the predicted value of 91.07 points. This showed that the model was able to better reflect the relationship between sensory score and fermentation time, fermentation temperature, or inoculum size.

Table4ANOVAofregressionmodel

SourceSum of squaresdfMeaan SquareF-ValueP-ValueModel619.20968.80168.74< 0.000 1Significant A-Time17.50117.5042.930.000 3∗∗B-Inoculum size14.67114.6735.980.000 5∗∗C-Temperature5.0115.0112.300.009 9∗∗AB39.06139.0695.80< 0.000 1∗∗AC28.44128.4469.76< 0.000 1∗∗BC26.69126.6965.47< 0.000 1∗∗A273.83173.83181.08< 0.000 1∗∗B2188.311188.31461.83< 0.000 1∗∗C2176.761176.76433.50< 0.000 1∗∗Residual2.8570.41---Lack of fit1.9130.642.700.181 0Not significantPure error0.9440.24---Cor total622.0616- - --CV=0.77%;Adeq Precision=34.372R2=0.995 4;Adj R-Squared=0.989 5;Pred R-Squared=0.948 5

Note:*indicates significant difference whenP<0.05;**indicates extremely significant difference whenP<0.01.

Fig. 6Responsesurfaceandcontourofeffectoftheinteractionbetweenvariousfactorsonthesensoryscoreoffermentedcarrotjuice

3.3ResultsofphysicochemicalanalysisoffermentedcarrotjuiceThe optimized carrot juice was detected and analyzed. The results showed that it was orange-yellow, brightly colored; the structure was uniform; it had fresh aroma and fermentative flavor of fruit and vegetable juice; it had pure and refreshing taste, and suitable sweetness and sourness. The pH was 4.50±0.30, the total acid content was 3.73±0.34 g/L, the total sugar content was 54.25±3.56 g/L, and the reducing sugar content was 28.41±2.18 g/L.

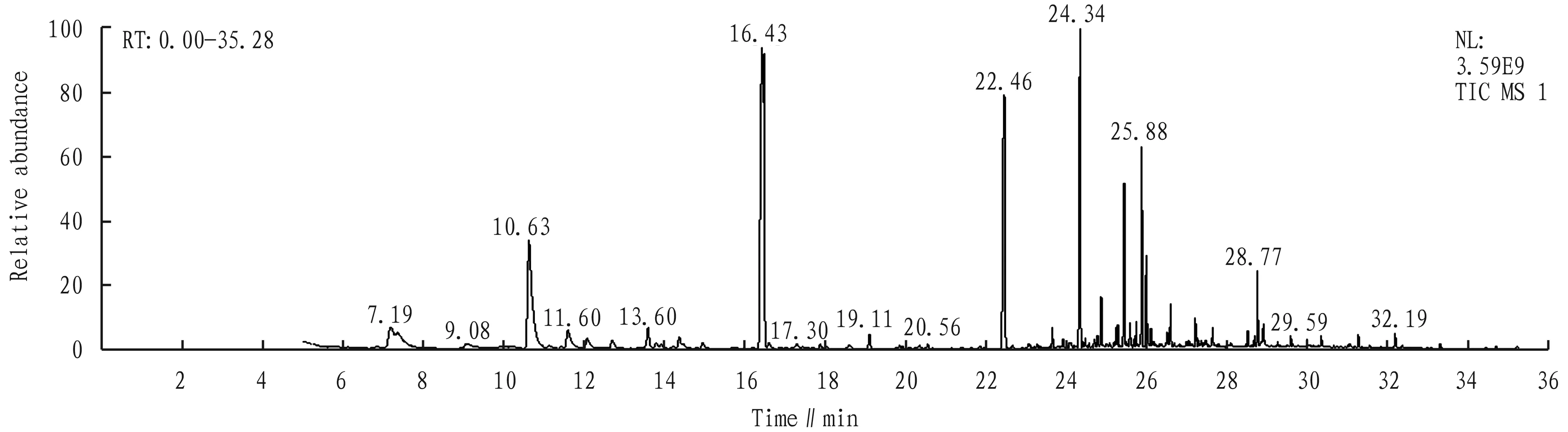

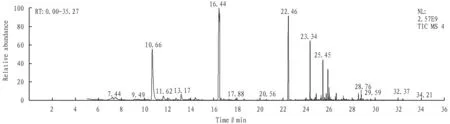

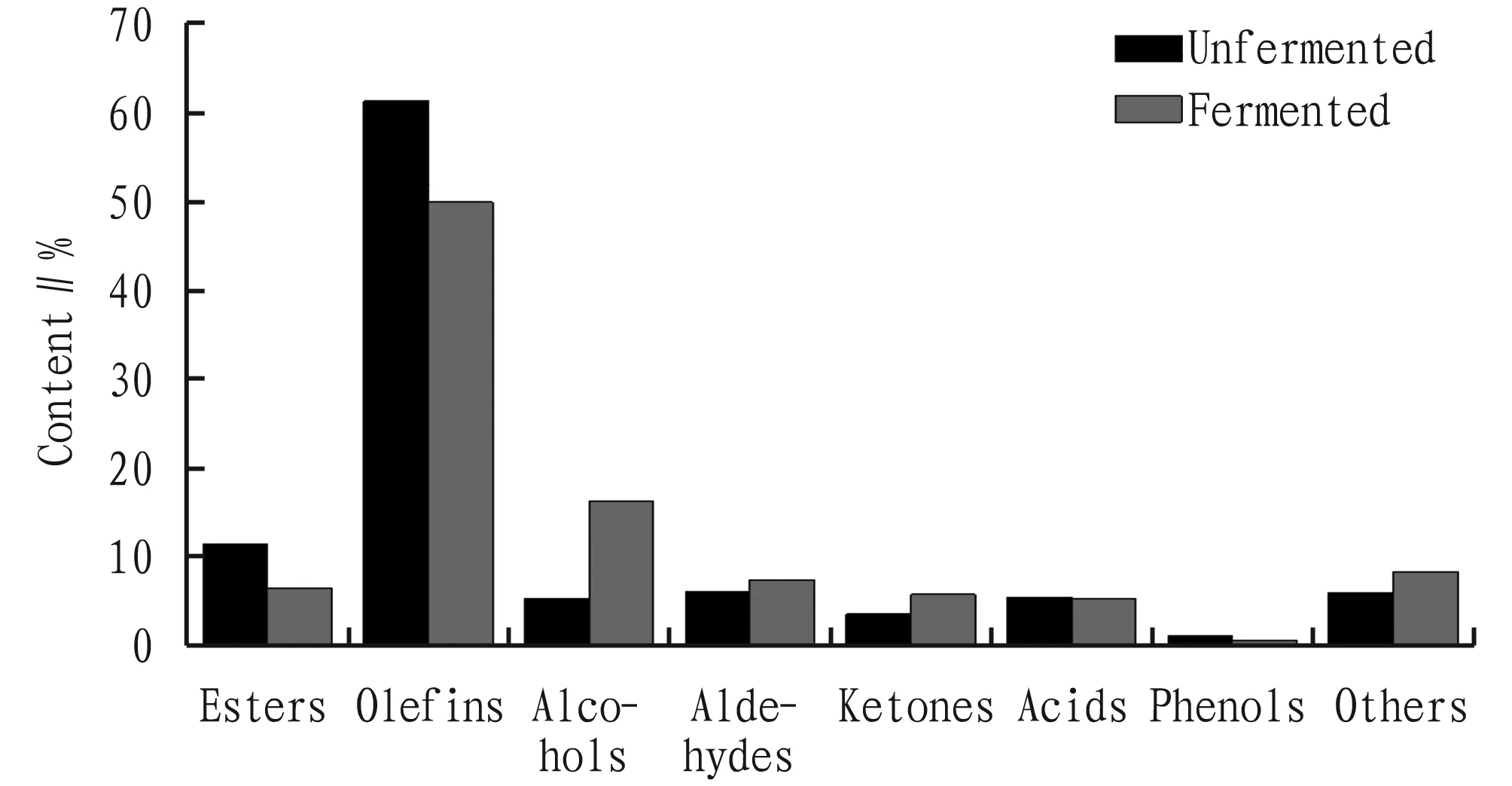

3.4AnalysisofaromacomponentsofcarrotjuicebeforeandafterfermentationFig. 9 showed that there were obvious changes in aroma components of carrot juice before and after fermentation. Among them, the contents of esters and olefins decreased obviously, from 11.381% to 6.492% in esters and from 61.305% to 49.892% in olefins. The contents of alcohols and ketones increased, from 5.308% to 16.286% in alcohols and from 3.546% to 5.750% in ketones. Further analysis showed that 51 aroma components were detected before carrot juice fermentation, including 10 esters, 11 olefins, 9 alcohols, 6 aldehydes, 4 ketones, 4 acids, 2 phenols and 5 others. After fermentation, 56 aroma components were detected, including 7 esters, 10 olefins, 17 alcohols, 6 aldehydes, 5 ketones, 2 acids, 2 phenols and 7 others. After fermentation, some alkanes, acids, esters and olefins disappeared, such as 1-ethynyl-1-tetrahydrobenzene, 4-ethylbenzoate, 2-propyltetrahydropyran-3-ol, octanoic acid, undecane, undecaldehyde, nonanoic acid, 2-methoxy-4-allylphenol, capric acid, α-curcumene, 5, 8, 11-trienoate, decyl sulfide acetate, phytolaccate, nonadecanol, tetradecyl benzoate, pentadecyl benzoate and hexadecyl benzoate. And it produced a lot of new substances, mainly alcohols and esters, such as methyl myristate, benzyl oleate, angelic acid, 2, 6-dimethylpyrazine, β-pinene, benzaldehyde, N-benzyl-methyl 2-aminooctanoate, phenyl-β-D-glucoside, 2,4, 4-trimethyl-2-cyclohexene-1-ol, n-octanol, linalool, phenylethanol, 1-nonanol, 4-terpene alcohol, α,α,4-trimethylbenzyl alcohol, α-terpineol, geraniol, cis-2-isopropyl-5-methylcyclohexane-1-ol, theaspirane, methyl eugenol, α-ionone, and falcipariol.

Fig. 7Gaschromatogramofaromacomponentsofcarrotjuicebeforefermentation

Fig. 8Gaschromatogramofaromacomponentsofcarrotjuiceafterfermentation

Fig. 9Typesandcontentsofaromacomponentsofcarrotjuiceundertheoptimumfermentationconditions

4 Conclusions

In this study, single factor experiment and response surface methodology were used to optimize the fermentation conditions of carrot juice. The results showed that the optimum fermentation conditions of carrot juice were as follows: strain ratio CTCF-LC1∶CTCF-LT1=1∶1, fermentation time=8 h, inoculum size=3.1%, fermentation temperature=26.7℃. Under these conditions, the sensory score of carrot juice was 91.07 points, pH was 4.50±0.30, the total acid content was 3.73±0.34 g/L, the total sugar content was 54.25±3.56 g/L, and the reducing sugar content was 28.41±2.18 g/L. Color, aroma, and taste are in line with the needs of the vast number of consumers.

The fermentation of carrot juice by lactic acid bacteria was mainly lactic acid fermentation. The oxidation reaction, esterification reaction and alcoholization reaction took place to different degrees. The decomposition of proteins and polysaccharides produced amino acids and oligosaccharides; alkenes were oxidized to form alcohols, aldehydes, ketones and acids; organic acids combined with some alcohols to form new esters and so on. This changed the proportion of flavor substances in carrot juice. This change in the proportion of the aroma components broke the original composition of carrot juice, making its aroma components change[19]. Among them, cyclopentyl 4-ethylbenzoate, tetradecyl α-curcumenyl benzoate and pentadecyl benzoate abounding in unfermented carrot juice disappeared, and α-caryophyllene, 2, 6-dimethyl-6-(4-methyl-3-pentenyl) bicyclohepten-2-ene, α-humulene, caryophyllin and 6-methoxylysine in unfermented carrot juice decreased greatly, which weakened the drug flavor of carrot juice. Among the new substances produced, methyl myristate had the aroma of honey, β-pinene had the aroma of rosin, and phenylethanol and geraniol had the fragrance of sweet rose. Others, such as benzyl oleate, dahuric acid, 2, 6-dimethylpyrazine, benzaldehyde, N-benzyl-methyl 2-aminooctanoate, n-octanol, linalool, 1-nonanol, 4-terpene alcohol, α-terpinol, theospirane, methyl eugenol, α-ionone, had their own unique aroma. These flavor substances fused with each other to form the unique aroma of fermented carrot juice. At present, this kind of pure fermented fruit and vegetable juice products are rare in the market. Therefore, it can provide important experimental basis and technological basis for this kind of nutritional and health products.

杂志排行

Asian Agricultural Research的其它文章

- Research Progress of Adansonia digitata

- Overlapped Tray Seedling Raising Model for Mechanical Transplanting of Rice

- Reform of Rural Planting Structure in China since the Reform and Opening-up and Its Main Problems

- Effects of Different Seedling Raising Substrates on Quality of Rice Seedlings

- Cucumber Downy Mildew: Research Progress and Registered Fungicides

- Safety Assessment and Distribution Characteristics of Heavy Metal Pollutants in Livestock and Poultry Meat from Different Regions of China