最正宗的西湖藕粉原来在这里

2019-01-09柏建斌

柏建斌

三家村藕粉還真有其特点,它色泽呈微红,贮藏时间很久不会变质,而且口感独特。资料显示,三家村藕粉一直是“风靡两京”的食品,借助京杭大运河,远销苏州、上海、南京等地。这在《随园食单》及《杭州府志》等古籍中都有记载。

冠名杭州西湖的美食不多,印象中除了大名鼎鼎的西湖醋鱼,还有西湖莼菜,再有就是西湖藕粉了。

说来也是奇怪,这些冠名西湖的名菜名点,却并不生长于西湖之中。比如做西湖醋鱼的鱼,原本都是蒋村一带抓来的,莼菜则生长于双浦水田。至于用来制作藕粉的老莲藕,却以杭州余杭崇贤街道三家村的为最佳。

走秋石高架,过半山隧道,经过连绵的高楼大厦和新建小区,车子转入一条村道,忽然大片荷塘出现,一下就豁然开朗了。

杭州最正宗的藕粉,就藏在这里。

为啥这里的藕粉最正宗

荷塘一会在左,一会在右,虽然数量不多,规模却不小。可以想象,藕粉出名于此,是有些渊源的。

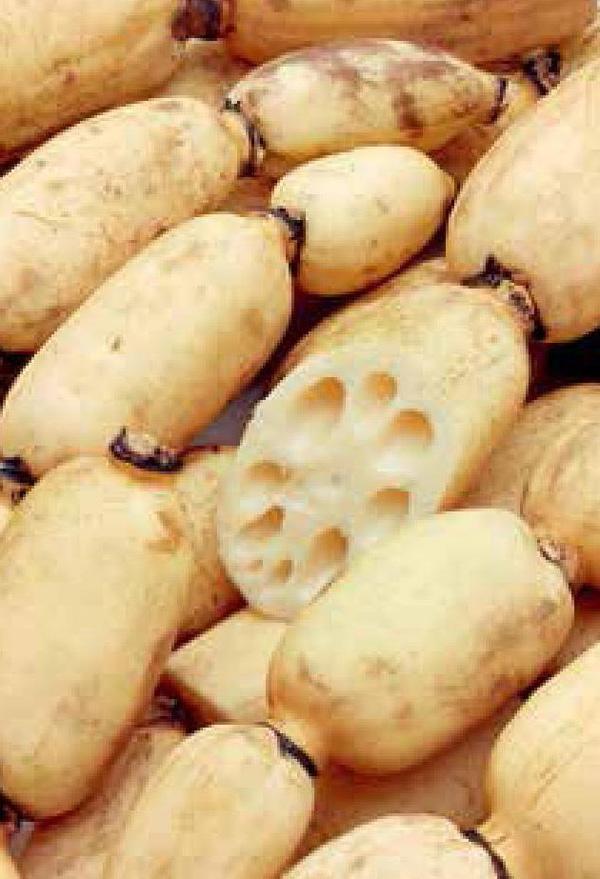

“这是一早挖的,都是老藕,这会儿一斤要将近5元了。”要去的范家角56号不好找,站在57号边,还是得打电话让人带。

走到56号,几个大竹匾已放满了刚削出来的藕片,一位阿姨仍在忙着削藕片。村民老范指着一堆正用水冲洗的莲藕说,上午就做这些。

阿姨忙完手中最后那点藕粉团,开始打理那些冲洗干净的生藕。反复搓去莲藕表面的泥锈,还要切去藕节以及周边的根系,这些深色的杂物都会影响最后藕粉的质量。

再次清洗,包括去掉一些孔里的泥土。

洗净之后,便开始“舂藕”。老范的工具简单实用,就是一个自制的金属多孔刨子,不断将莲藕在刨子上来回搓,碾碎藕节后成为粉渣状的莲藕泥。

范家角是现在的地名,这个自然村曾是当年三家村的一部分。这几个村地势低,原先河港交叉,内塘特多。“最主要的原因是这儿的塘泥深而肥沃,一般都会超过一米深,老底子的时候大家都种藕。”老范说,现在村民住户多了,藕塘少了许多,反而是外埠藕粉制作量大了。

百多斤的老藕很快刨完,这个时候整个桶里都是藕泥了。“这个过程其实和做番薯粉条一样,主要是过滤出淀粉。”老范说,藕浆磨得越细越好,因为磨得越细,出粉率越高。

为了多出粉,他还得在桶里加水,不断搓揉,这个过程叫洗粉。

再就是过滤了,土办法是在桶上面放几层纱布,然后将搓揉后类似浆一样的料倒入纱布。这样,渣滓和一些其他杂质就被过滤出来,流到纱布下的便是比较纯净的浆水了。

老范说,过滤需要多次,这个过程繁复却不能省,目的是为了确保藕粉的纯净和细腻。

三家村藕粉声名远播,除了因为当地藕的质地上佳,也许更是因为这种传统的工序。清光绪《唐栖志》关于藕粉的记载写道:“藕粉者,屑藕汁为之,他处多伪,掺真膺各半,唯唐栖三家村业此者以藕贱不必假他物为之也。”

说起这里的藕粉,老范非常自豪地提起了美国前总统尼克松当年品尝的故事。“我没有见到,但当时都在说这个事,讲周恩来总理让尼克松吃了三家村精制藕粉,尼克松赞赏不绝,还作为礼物带回国。”

神秘手艺传媳不传子

反复过滤后的藕浆水自然越来越多,因此它的沉淀过程也就更长了,按照一般经验,大约要3个小时左右。

3个小时后再看木桶,上面的水基本是清澈的,倒去上层清水,底下可见实实的,便是尚没有完全干透的“藕粉”团。

让这沉淀出来的“藕粉”团进一步沥干水分有很多办法,比如放在草木灰之中等等,但最好的办法还是让它自然失去水分。

接下去的那一道工序,可以说是三家村女子的亮点。“一直以来,这个削藕粉的技术,在我们这儿是只传给媳妇的。”正忙的时候,隔壁一位老太太走了过来,将近80岁的老人显得十分白净,她说自己也姓范,从小长在这个村。“做姑娘的时候我们会在边上看,学学也蛮快的。”老太太的意思是:没做人家媳妇的时候先学着,嫁人了,再学起来就方便了。

“老底子村里还会进行削藕粉比赛,一大个竹匾两个人搭档,一人一边,自愿组合,最后两人一组决出胜负。”老人说,那个时候,往往是快的和快的搭在一起,胜负早就看出来了。

“藕粉是削出来的,晒干的成品呈片状,其实不是粉。”拿着沥干水分的藕粉团,一位阿姨弯腰在大竹匾上左右来回摇晃,藕片像雪花一样,落在竹匾上。“关键要做到厚薄均匀,不然的话晒起来把不准时间,有的干了,有的还有水分。最后泡的时候,也会因为厚薄不匀起小疙瘩。”

三家村藕粉“风靡两京”

老范说,三家村藕粉还真有其特点,它色泽呈微红,贮藏时间很久不会变质,而且口感独特。资料显示,三家村藕粉一直是“风靡两京”的食品,借助京杭大运河,远销苏州、上海、南京等地。这在《随园食单》及《杭州府志》等古籍中都有记载。

“现在是吃藕的好时节,大节的鲜藕每斤要卖四五元。但每100斤鲜藕只能制成六斤左右藕粉,而时价藕粉每斤也才卖50元左右。”老范说,这个时候他只能挑选那些小的、大约1元1斤的头尾小节来加工,不然会亏本。

尽管如此,老范还是坚持传统制作,从这个时候开始到明年4月之前,用成熟莲藕为原料,制作出一袋袋的“古法纯藕粉”。

其实,是否古法藕粉,从冲泡方法上也可以看出。“我们这种传统藕粉的冲泡,先要用少许凉水将其调匀,大概调到牛奶状,然后加入开水,碗中立刻涌现出微红晶莹的冻体。”老范说,三家村的藕粉,哪怕不放糖也好吃,它清香扑鼻、沁人心脾,自带淡淡的甜味。

“谁碾玉玲珑,绕磨滴芳液。擢泥本不染,渍粉讵太白。铺奁暴秋阳,片片银刀画。一撮点汤调,犀匙溜滑泽。”这是清代钱塘诗人姚思勤的《藕粉》诗,藕粉的制作和最后的品尝,都蕴含在这诗作中了。

(本文图片摄影:视范影像 朱莉莉)

“West Lake lotus root powder” is a famed delicacy of Hangzhou. The best-known West Lake lotus root powder is made at Sanjiacun (literally, a village of three families), a village in Yuhang, which is now a district in the north of Hangzhou. The production history can be traced to the Southern Song Dynasty (1127-1279), which was housed in present-day Hangzhou. In ancient times, it was shipped to the north through the Grand Canal of China that connects Hangzhou to Beijing.

The other day, I visit Sanjiacun to take a look the ancient procedure these lotus root powder makers still follow faithfully.

The journey I take to get there includes a long way on an elevated expressway and a long tunnel. After high buildings and new residential communities disappear, I turn into a village road. There are lotus ponds, now a pond on the right and now a pond on the left. All of a sudden, the sky is low, broad and open.

I have no idea where Old Fans home is though I have his address. I phone him and he comes to fetch me. We reach his home. A middle-aged woman is cutting the wet powder dough in her hand into flakes onto a broad flat bamboo tray to dry. “Thats what we have done today,” explains Old Fan.

The woman soon completes cutting what is left in her hand and begins to clean some lotus roots. I learn that cleaning is the first step of lotus root powder making. First of all, all the lotus roots must be cleansed repeatedly. The tubers are cut open so that the mud inside holes inside can be removed. Unnecessary parts such as links between tubers and the tough ends of tubers are all chopped off.

After the cleaning, all root tubers are grated on a kitchen grater. The result is a thick paste. The crude paste is then ground again and again until it becomes fine. Now and then, Old Fan puts his hands into the bucket to make sure the grinding is fine and he adds some more water into the paste so that all the starch has an opportunity to get out of the grated roots. The fine paste is then placed on a layer of gauze to separate starch from the paste. The paste will be filtered repeatedly to get the greatest amount of starch and remove dregs. Old Fan says that repeated filtering is an important step to ensure quality.

Old Fan says the superior quality of the lotus root powder made in Sanjiacun can be attributable to the quality lotus roots and partly to the traditional procedure. He says proudly that a local history of the Qing Dynasty (1644-1911) remarks that lotus root powder made in Sanjiacun was pure, never adulterated with starches of other plants.

And then Old Fan mentions that American President Nixon sampled the lotus root powder during his visit to Hangzhou in 1972. Fan wasnt there to see the US president sample the lotus root powder, but “everyone was telling the same story,” says Old Fan. “The president appreciated the delicacy and spoke highly of it. The Sanjiacun lotus root powder was among the Chinese gifts he brought back to America.” Old Fans face beams.

After the filtering, the fine starch will be let alone, starch begins to deposit to the bottom. After three hours, starch becomes a thick paste. The water on top is removed. The wet starch will dry naturally. Then, women will slice a relatively dry pasty mess into flakes. In the past, only daughters and daughters-in-law were taught how to make flakes. Flakes are then spread evenly on a wide flat bamboo tray to further dry. An elderly woman explains: the secret is to make even flakes, neither too thick nor too thin so that all the flakes will dry relatively at the same time and there will be no bubbles when powder is made into jelly with boil water. In good old days, Lao Fan says, the village held competitions for women cutters. Usually two good cutters would group together. In some cases spectators could see who the best cutter was shortly after a competition started.

The best lotus roots are big thick ones: they produce better and more starch. But “It is now lotus root season and big ones sell for 8 to 10 a kilo. 50-kilo lotus roots make about 3 to 4-kilo powder, which sells 100 yuan a kilo. In order to keep costs as low as possible, only small lotus roots, about 2 yuan a kilo, will be used simply because they are cheap and are good enough to make good quality powder and make a profit,” Old Fan explains.

The ancient production method the villagers of Sanjiacun faithfully follow is more than something like a recipe. It is also about raw material selection, processing steps, cost control, quality assurance. The production season lasts from October to Qingming Festival in early April next year.

The production procedure of the Sanjiacun lotus root powder has been inscribed onto the directory of intangible cultural heritage of Zhejiang.

The Sanjiacun lotus root powder jelly looks slightly reddish and crystal. The powder comes in flakes roughly the size of sugar in the raw. To prepare, you first mash a spoonful of the powder in cold water to make a milky paste, and then quickly stir while pouring in a cupful of boiling water. As you stir, the opaque powder becomes a transparent jelly. The desired result is a bowl of light brown translucent jelly. The natural flavor is a little bit sweet. “You can enjoy it without adding any sugar,” Old Fan says.