Vertex angles effects in the energy absorption of axially crushed kenaf fibre-epoxy reinforced elliptical composite cones

2018-08-25MohmedAlkteSpunLemnIshkMohmmdJwid

Mohmed Alkte,S.M.Spun,,c,*,Z.Lemn,M.R.Ishk,Mohmmd Jwid

aDepartment of Mechanical and Manufacturing Engineering,Universiti Putra Malaysia,43400 UPM,Serdang,Selangor,Malaysia

bLaboratory of Bio Composite Technology,Institute of Tropical Forestry and Research Products(INTROP),Universiti Putra Malaysia,43400 UPM,Serdang,Selangor,Malaysia

cAerospace Manufacturing Research Centre(AMRC),Universiti Putra Malaysia,43400 UPM,Serdang,Selangor,Malaysia

dDepartments of Aerospace Engineering,Universiti Putra Malaysia,43400 UPM,Serdang,Selangor,Malaysia

Keywords:Kenaf fibres Composite materials Elliptical cone Vertex angle Collapsible Energy absorption

A B S T R A C T Experimental quasi-static crushing tests were conducted by using a universal testing machine format kenaf-epoxy composite elliptical cones.The work focused on the vertex angle's effects on energy absorption capability;the vertex angles vary from 0°to 24°in 6 increments.The failure modes of the kenaf fibre epoxy composite elliptical cones were observed utilising delegate photos taken during the quasistatic crushing test.Load-deformation curves and deformation histories of typical specimens are presented and discussed.Moreover,the effects of cone vertex angles on the load carrying capacity and the energy absorption capability are also discussed.The results show that the energy absorption abilities significantly influence the ellipticity vertex angle as the load carrying capacity.We concluded that the quasi-static axial crushing behaviour of elliptical mat laminated composite cones is strongly affected by their structural geometry and the specific energy absorbed by the composite elliptical cones with vertex angles of 6°,12°,18°,and 24°,which is more than an elliptical cone with the vertex angle of 0° (the elliptical tube)at any given deformation.However,the specific energy absorption for the elliptical composite cone showed a positive correlation,i.e.,the more the angle increased,the more energy was absorbed.In this regard,an elliptical composite cone with a 24°angle exhibited the best energy absorption capability.

1.Introduction

Crash worthiness is an important element of transport design for automobiles,railroad vehicles,aeroplanes,etc.This is related to the structural integrity of the vehicle and its ability to absorb high energy impacts and provide assurance to passengers and cargoes in the event of crash or collision[1].In the past century,extensive and reliable research has demonstrated the high competitiveness of composites in the field of foldable energy absorbers.Fiber reinforced composite materials are used now in automobiles industry[2],to provide the best crash worthiness with using lightweight materials[3].

Natural fibres[4-6]used as reinforcements in polymer composites are proven to be suitable substitutes for conventional fibres,such as glass fibres in a selected application[7],through the integration of physical and mechanical performance and because they are environmentally friendly materials,recyclable and biodegradable[8],that are generally extracted from sustainable,natural resources.Natural fibre composite has the potential towidely apply in energy absorbing structures[9-12].The properties of polymers reinforced with natural fibre composite materials are governed by fibre and matrix properties,compatibility between the compounds,processing of the fibres and manufacturing process of the composite material.In order,to achieve innovations and wide enhancements in manufacturing technology fields,it is necessary to strengthen and innovate manufacturing technology,assembly of fibre reinforced polymer composite structure to achieve objectives of cost and performance to enables wider adoption in many fields.

Also,Structures with excellent crash worthiness performance are required to maintain critical control in a controlled and stable route to allow the vehicle to stop without exposing its passengers to extreme decelerations,to overcome these negative problems and providing requirements for higher fuel efficiency,continuous studies and attempts to use composite materials in advancing impact mitigation materials and designs[13].Summary definitions utilise composites materials as part of impact resistant applications include the ability to change properties with higher quality and strength,resistance to consumption,and tolerance of interconnected loads.Despite frustrating fragility,composite materials have demonstrated the ability to retain important safety capacity during vehicle crash[14,15].

Recent studies have reported the several parameters which can be effective on crash worthiness of these energy-absorbing composites such as wall thickness[16],geometry shape[17],hybrid material[18],boundary conditions[19],and fibre reinforcement type[20,21], fibre alignments[22-25], filler materials[26],and test velocities[27].Researchers found that high energy absorption can be obtained during the progressive crushing of composite tubes under axial loading.

Mahdi et al.[28],tested four different categories of tube crosssectional geometric properties under quasi-static crushing.The results showed that reinforcing the circular tube with radial GFRP webs could improve both the load-carrying capacity and the specific energy-absorption capability.Elgalai et al.[29],studied the influence of fibre type and corrugation angle on their crash worthiness performance.The results showed that the crush behaviour of the composite corrugated tube was sensitive to changes in corrugation angle and fibre type.The use of natural fibres in a polymeric matrix has led to preferences in the alternative fibres normally incorporated into composites such as glass fibres,including ease of application,degradability,low density,and lower energy usage[30-32].

Recently few studies reported crash worthiness parameters in composite material tubes using natural fibres had been carried out.Ismail et al.[33],studied the effect of fibre orientations,the number of layers,crushing behaviour and performance.The authors found that crushing mechanisms are strongly dependent on the fibre orientation and the number of layers that altered the mode of failure and energy absorption.

Shekeil et al.[34],investigated the effects of fibre content(at 20,30,40 and 50%by weight)on tensile,impact properties and flexural of kenaf bast fibre reinforced TPU composites were investigated.Composite samples were prepared using the melt mixing and compression moulding methods.Sample with a fibre content of 30%had the highest tensile strength,and tensile modulus increased with fibre content.There was an improvement in the flexural strength and modulus as the fibre content increased,the fibre content increasing caused a decrease in the impact strength.

Bartosz et al.[35],studied the compressive behaviour of natural fibre composite,the study aimed at the development of sustainable natural fibre composites(NFC)for civil engineering,the work focused on the compressive behaviour in an elastic region and postcollapse behaviour of NFC tubes.Experimentally investigated deformation behaviour and fracture behaviour and analysed the influence of reinforced arrangement and tube design on mechanical performance.Correlation between reinforced arrangement,material compressive strength and fracture mode was established.The results showed the compressive modulus,and ultimate stress of NFCs increased with the reinforcement orientation angle.Finally,the highest stress and modulus was observed for the reinforcement oriented at 10°to the main axis;it was four times that of the transversely oriented reinforcement.

Fuming Chen et al.[36],studied the effect of laminated structure design on the mechanical properties of bamboo-wood hybrid laminated veneer lumber.These findings suggest that the high stiffness laid-up laminated structure on the surface layer can improve the performance of natural fibre reinforced composites called Cizhu bamboo.Afterwards,they were moulded into uniform veneers using a one-piece veneer technology.Eight types of laminated structure were designed for the BWLVL.The results indicated that as the contribution of bamboo bundle increased in a laminated structure,especially laminated on the surface layers,the MOE,MOR and SS increased.

Eshkoor et al.[37],reported that different trigger configurations could cause significant differences in crash worthiness parameters and failure patterns of silk epoxy composite tubes.Ataollalhi et al.[38],studied the compression response of natural silk/epoxy composite square tubes and the effect of wall length on the failure mode.They found that decreasing tube length increased specific energy.The thin-walled tube has a good geometrical high strength to-weight ratio and energy absorption capability.However,natural fibre composite materials need the application potential of a wide energy absorbing structure[39-43].

From the above short review,it is shown that research on crash worthiness properties of natural fibre epoxy composites has been performed in the past by studying different aspects,such as fabrication process,geometry,hybridisation,and testing.No research is found to investigate the loading behaviours due to the very cone vertex angles.It is a new exploration to find out the potential applications of natural fibre-reinforced composites.The main objective of this study investigates the vertex angle's(vertex angles vary from 0°to 24°in 6 increments)effects of mat kenaf/epoxyel liptical composite cones on the energy absorption capability.

2.Experimental program

2.1.Preparation of mandrels

The first step in planning the test sample processing began with the calculation of the necessary values and then conversion into mandrels of paper and pumice.Next,the moulds were made into steel for use in the manufacture of the samples.The second step involved fabrication of elliptical cone mandrels using steel and steel sheets.The steel sheets were cut to dimensions equal to the size of the elliptical cone.Then,the sheets were bent and welded to form the elliptical cone shape.Solid steel was put inside these hollow elliptical cone mandrels for support.The mandrels were made for easy extraction after completion of each filament winding process(as shown in Fig.1).

2.2.Material and fibre preparation

Mat kenaf fibre was supplied by(IPSB)Innovative Pultrusion Sdn.Bhd.,Seremban,Malaysia.Kenaf(mat)originally has a mat shape.According to[44],the density of kenaf bast is 134.3kg/m3.In the current study,the value of kenaf mat density is 0.17 g/cm3 with a thickness of 4mm based on a study carried out by Ref.[45].The matrix used was a combination of D.E.R.™331™liquid epoxy resin and Joint Mine 950-3S as Hardener/curing.

2.3.Fabrication of hollow elliptical cones

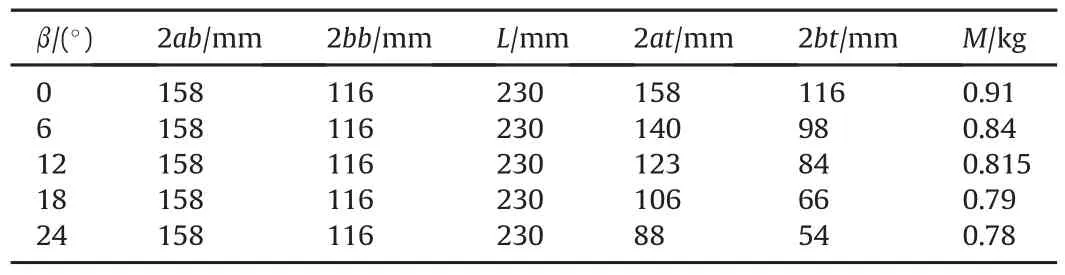

The hollow elliptical cones composites were fabricated using the hand lay-up techniques.For the fabrication of the composites,a specific mould was prepared with the required dimension of the composites.The investigated structure is elliptical conical shells with vertex angles varies from 0°to 24°in 6 increments.Dimensions of the conical bottom end(i.e.major inner radius(ab=79 mm),inner minor radius(bb=58 mm))are fixed.Different cone vertex angles(β)of an elliptical cone result in different dimensions of cone top end(i.e.major inner radius(at),inner minor radius(bt)).The fifteen specimens were fabricated.All the specimens were of 230 mm high,and 9mm thick,their details are tabulated in Table 1.

For the fabrication,weight%of non-woven kenaf fibre and polymer resin were taken(30/70 by weight),and for the curing process,epoxy per hardener was used and mixed at a ratio of 2:1 according to the supplier recommendations and technical data sheets.After that,resin mixture was mixed thoroughly using an electric mixer,and homogenous mixer resin was used.A similar procedure was followed for all the composites fabricated.The wet winding process was used to fabricate the non-woven wound laminated composite elliptical cones specimens.During the winding process,the fibre was passed through a resin bath to impregnating them,used the manual rollers to compressed for reduce the void content in the sample.This is followed by the application of impregnated wet fibre to the mandrels to get the shape of theelliptical cones in tow layers.After that,the roller was pressed and rolled over the composite to get the suitable thickness built-up.The winding paramours,i.e.the winding tension,resin content and resin mixing are maintained at a constant level during the fabrication process.Next,we continued to follow-up and rotate the sample for 30-60 min,after which it was left for 24-48 h at room temperature(30°C).for completely cured,it was removed from the mandrel then leaving it to drycompletely.Fifteen specimens were a fabrication.The last stage involves the finishing sample per the required dimensions.The weight of the fibre mat was recorded as warped and divided by the final composite's weight to find the fibre loading.Despite the advantages of hand lay-up technology,controlling porosity and void content is difficult,the surface quality depends on the technician's skill,and product uniformity is difficult to maintain.So,there are drawbacks to the method[46].The fabricated specimens are presented in Fig.2.

Table 1 Specification of elliptical cones test specimens.

2.4.Test procedure

A total of fifteen test samples were prepared and manufactured as wrapped laminated elliptical cone-shaped shells(Fig.3).They were then subjected to the crushing test(quasi-static compressive load).The length of every sample was 230 mm,resulting in various layers delivered at 9 mm of the thickness of the wall,and likewise,it introduced base distances across the measurements after 158 mm and 116 mm.The vertex point change brought about higher base differences contingent upon the cone vertex edge(Table 1 and Fig.4 show a typical elliptical cone under investigation).In the quasi-static axis crush test,we began(INSTRON MTS 810)with a capacitive load of 25 tonnes using a universal testing machine(UTM).As shown in Fig.4,the load platens were set parallel to each other before the start of the test.The entire specimen was loaded from compression by stroke control at a speed of 20 mm/min.Load and displacement were recorded using an automatic data collection system.

3.Results

The results of load-deformation and specific energy absorption capability of the compression testing and that of vertex angles of elliptical cone geometry in the axially crushing process of matkenaf fibre-reinforced elliptical composite cones samples are presented under the headings that follow.It is imperative to quickly clarify some variables that were used for energy absorption capability,in addition to heap-conveying the limit of the composite elliptical cones.All these factors will be highlighted.

3.1.Assessing factors of energy absorption capability and the load carrying capacity of the composite elliptical shells

3.1.1.Crush force efficiency(CFE)

Crush force efficiency is the ratio between the average crush load and the initial crush failure load.It is useful in measuring the performance of an absorber.It is calculated as Eq.(1)

Where,PiandPmare the initial and the average crushing loads,respectively.This ratio should be as close to 100%as possible,which is difficult to achieve in practice,but an ideal absorber is said to exhibit a crush force efficiency of 100%.

3.1.2.Stroke efficiency(SE)

The relative deformation of the absorber is referred to as the stroke efficiency(SE)of the absorber.This can be calculated as

whereuandHrepresent the stroke and the total height of the structure,respectively.

3.1.3.Initial failure indicator(IFI)

The ratio between initial crush load and critical crush load are calculated as

wherePiis the initial crushing load,andPcris the critical crushing load.

3.1.4.Specific energy absorption ES

Specific energy absorption(Es)is defined as the energy absorbed per unit mass of material.The total work is done,or energy absorbedWt,in the crushing of composite specimens for the area under the load-displacement curve is

whereWtis the total energy absorbed in the crushing of the composite tube specimen,and the more characteristic property of progressive crushing mode is

whereSbandSiare the crush distances,andPmis the mean crush load as indicated.

3.1.5.Volumetric energy absorption capability

The volumetric energy absorption capability(i.e.,energy absorbed per unit volume)is also an essential parameter for an energy absorbing system design,where space is a restraint factor.The volume occupied by kenaf fibre reinforced elliptical epoxy composite cones before crushing can be calculated as

The energy absorbed per unit volumeEVcan be calculated as

4.Kenaf fibre reinforced elliptical epoxy composite cones under quasi-static axial crushing load

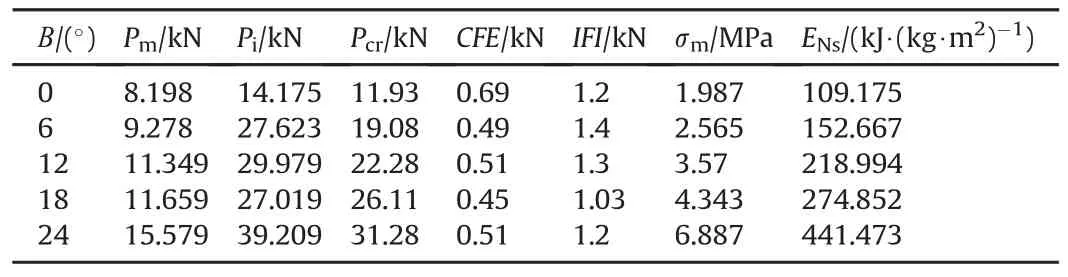

Figs.5-12 show important results from semi-static compression tests.The crash worthiness parameter is expressed by the relationship between its energy absorption capacity and load capacity.It is defined as the energy absorbed per unit mass of material.Experimental data from the measured load-displacement response are summarised in Table 2.

The failure modes were macroscopically investigated using photographs taken during sample crushing as shown in Figs.6-10.The photographs from the experiment were made during the test.Thus,the photograph shows the sample at different crushing distances.The calculated results were taken as the average of at least three specimens for each case.

4.1.Load-displacement curves

The load-displacement curves of kenaf fibre reinforced composite elliptical cones with different conical vertex angles served as an indicator of when and how force and moment changed(Fig.5).Then,this was used to determine the local energy required for the design of vehicle structure and material selection.On the other hand,the matrix material(epoxy)is strong compared to the matte kenaf fibre,and the matrix and fibre mat prevent local microbuckling at low load levels.On the other hand,when the load directed is perpendicular to the fibres,failure can most likely be initiated at stress levels corresponding to the shear stress of the matrix.In this context,the load is characterised by inelastic and non-linear behaviour until reaching its first peak value;no stiff reduction is considered here due to matrix failure.This is because transverse matrix cracks alone usually do not have a significant effect on the laminate stiffness.The micro crush failure mode resulted in local structural instability in the crush zone,which leads to a local surface layer failure mode,and deformation is repeated sequentially until the crush load increases sharply.At this stage,the crushed specimen behaves as a rigid body due to the densification stage of the material.The latter type of failure mode reduces flexural rigidity in the failure zone and results in different resistance drop magnitudes depending on the elliptical cone vertex angle.As the cone vertex increases,so do the size of the first droplet and the general load capacity.Thus,a gradual local buckling or crimping mechanism with a first buckle formed away from the crushed end dominates the post-crushing stage.These sequential deformations are repeated until the crushing load sharply increases.At this stage,the crushed specimen behaves as a rigid body due to the densification stage of the material.

4.2.Failure modes

4.2.1.Mode I

Mode I exhibits the first progressive crushing made at the dropoff of the load capacity,which follows immediately near to the damaged area.The load drop-off in most cases is larger than information mode I(the same type of unstable crack).This does not propagate to the entire periphery because it causes a slight lowering of the load.Apparently,the load after the fracture zone(Fig.6)has passed the damaged area will be restored to the steady state level.Failure starts at the top end of the tube and the tube wallcollapse matrix,and the cracking is followed by splaying mode in the transverse direction(Fig.6).The load-deformation curve shown for the specimen(kenaf/epoxy composite elliptical cone with 0°vertex angle)almost remains in stable condition until 0.6 h deformation,where the curve drops gradually.Finally,they behave as a rigid body after full compression that makes the curve increase.

Table 2 Measured crash worthiness parameters of kenaf fibre reinforced elliptical epoxy composite cones.

4.2.2.Mode II

Multi-failure modes of the grinding process initiated by matrix cracking are a combination of the progressive failure mode and the local buckling mode cracks(Figs.7 and 8).The first progressive failure mode occurs after being developed from both ends due to shear fragmentation and the lateral matrix(Fig.7).At this stage,the main energy absorbing mechanism was observed to be destroyed in the bundles(step is stable load)characterised by the displacement curve(Fig.8).After the failure mode of the regular progressive,one experienced the change of the crushing failure mode of the test piece.These began to crush in local buckling in a position closer to the centre face of the cone(Figs.7 and 8).

4.2.3.Mode III

In the initial stages of compression,the tube behaved as its edges are fixed because of the square end faces and the influence of the friction between the surfaces in contact.As loading progressed,radially inward forces were generated by the circumferential expansion of the radially outward moving parts of the tube.Symmetric collapse mode consisted of a series of radial displacements along the length of the tube that leads to a sharp drop in tube resistance axial load.As the tube compressed,its walls tended to move outwards away from the axis of symmetry due to Poisson's effect and the crack propagation.Typical failure modes are shown in Fig.9.

4.3.Effect of cone vertex angles

4.3.1.Load carrying capacity

The load-deformation curves for kenaf fibre reinforced elliptical epoxy composite cones with different cone vertex angles(0 to 24°)are shown in Fig.5.From this Figure,the effect of the cone vertex angle on the crash worthiness of a composite elliptical cone,or the crush load,is normalised concerning the cross-sectional area of the cone.Crash stress was chosen to eliminate the influence of different cross-sections so that the effect of the cone vertex angle remained.It is clear that the load capacity at the post-crash failure stage was very sensitive to the cone vertex angle.

Regarding the vertex angle investigated,a clear or consistent trend was not associated with the fluctuation of crushing stress.In general,it can be inferred that as the vertex angle increases,the average crushing stress increases.Among the specimens tested,the elliptic cone with a conical vertex angle of 24 had a maximum mean crushing stress value of 6.887 MPa,and the elliptical tube with a conical vertex angle of 0°(i.e.,an elliptical tube)recorded the lowest mean crushing stress of 1.987MPa.

4.3.2.Energy absorption capability

Fig.11 shows normalised specific energy deformation curves of a composite elliptical cone having various conical vertex angles.From the energy deformation curve,it is possible to obtain cumulative energy absorbed from the cone at any displacement.It is understood from the drawings that all the cones have a nonlinear energy deformation relationship,and the energy increases as the displacement increases.With initial crushing fail load,no fail is observed,but matrix cracking occurs as the conical load carrying capacity increases.As the crush load increases further,interface response will occur, fibres will not be supported,and fibres will be more compliant and less susceptible to fail by shearing.All the cones with increase energy increase the displacement and the linear behaviour of specific energy absorption of the deformation curves.In the previous initial crush failure load,the load capacity of the damage is the cone,as matrix cracking increases.The outcomes demonstrate that the vitality is consumed by the mat kenaf fibre composite cones with the vertex angle(24°).This is due to the highest normalised specific energy capability from its cross-section area(A)among the other investigated cones types decreases causing the laminar strength of the composite.As the inter-laminar strength is reduced,the inter-laminar cracking energy absorption capability is reduced,which forms at a lower load.Finally,the specific energy absorption of natural fibre composite tubes depends on the tube geometry and fibre reinforcement[47,48].

In Fig.12,the varying cone vertex angles of elliptical conical shells of energy absorption are shown.The increased vertex angle of the cone(marked decreasing the cross-section area)is followed by an increase in capacity of normalised specific energy absorption.It is possible to conclude that the elliptical cone with a vertex angle of 24°showed the highest specific energy capacity(441.473 kJ/kg·m2)compared to other cones.It is also observed from Table 1 and is apparent from Fig.12,that the energy absorption value shows the same behaviour as the energy absorption value and the average load value,with variation vertex angle.

5.Concluding remarks

Kenaf fibre reinforced elliptical epoxy composite cones were fabricated and tested;quasi-static crushing tests were conducted to study the effect of cone vertex angles on energy absorption in this investigation.Based on the test results,the following qualitative conclusions are drawn:

1)The elliptical composite cones with different vertex angle were successfully fabricated.

2)Catastrophic failure mode occurs whenPiis greater thanPcr(FIF>1).

3)The change in the elliptical composite cones vertex angle affects crash worthiness parameters.

Acknowledgements

The authors want to thank the Universiti Putra Malaysia for the financial support for this research programme using HiCoE Grant,Ministry of Higher Education,Malaysia.

杂志排行

Defence Technology的其它文章

- GUIDE FOR AUTHORS

- Defence technology:Special issue on“composite materials in defence technology”

- Thermal,corrosion and wear analysis of copper based metal matrix composites reinforced with alumina and graphite

- Age hardening process modeling and optimization of aluminum alloy A356/Cow horn particulate composite for brake drum application using RSM,ANN and simulated annealing

- A review on machinability of carbon fiber reinforced polymer(CFRP)and glass fiber reinforced polymer(GFRP)composite materials

- Experimental and simulation studies on delamination strength of laminated glass composites having polyvinyl butyral and ethyl vinyl acetate inter-layers of different critical thicknesses