Influence of Interface on Mechanical Properties of Double-base Gun Propellant with RDX

2018-05-17LIUJiaCHENGShanZHANGLihuaMAZhongliangXIAOZhongliang

LIU Jia, CHENG Shan,ZHANG Li-hua, MA Zhong-liang, XIAO Zhong-liang

(1.Jianghe Chemical Technology Co., Ltd., Yichang Hubei 444200,China; 2.School of Chemical Engineering and Environment, North University of China, Taiyuan 030051,China;3.School of Chemical Engineering, Nanjing University of Science and Technology,Nanjing 210094,China)

Introduction

A heterogeneous gun propellant is formed as a heterogeneous mixture by adding energy-contained solid to improve its energy[1]. The solid filler makes it easier to peel or remove the binding agent attached to the gun propellant as it forms an interface between the gun propellant and the binding agent. This interface plays an important role in the properties of the gun propellants as it changes the elasticity modulus, compressive strength and impact strength to some extent.

The degree of change is focused on the interface structure and interface interaction between binding agent and solid filler. The influence of interfacial binding strength on the properties of the gun propellant is hot-spot in composite material field[2-3].

Studies on the mechanical properties of heterogeneous gun propellants are limited to objective evaluation or qualitative analysis, including macroscopic and microscopic methods[4-6]. Compared with the macroscopic method, the microscopic method is more direct, economic and time-saving. In order to improve the interactions of bonding agent and fillers, different bonding agents were used, and their efficiency was analyzed. The position of formed cracks in the specimen and their area have a great influence on the mechanical properties of composite propellants[7]. Besides, the interaction energy between some bonding agent and RDX was calculated by molecular dynamics method, but the difference with experimental results is unknown[8]. Applying interface principle to heterogeneous propellants to study the interface interaction and setting-up a quantitative relationship between micro parameters and macro mechanical properties is an effective way to represent the macroscopic mechanical properties of gun propellants. However, due to the complex interface structure, hardly any quantitative relationship is studied.

Based on these, a new microscopic parameter-adhesive energy per mass RDX and bonding agent(Ed,mJ/g) was defined to represent the relationship of the bonding strength and the content of RDX. The microscopic interface between bonding agent and RDX was characterized by a three-dimensional stereo microscope. The function relationships ofσ-EdandD-Edwere established at 20 and 50℃ based on the compression test, shock test and contact angle measurement. Moreover, the results have certain guiding significance to formulation optimization, interfacial additive study, mechanical properties estimation of heterogeneous gun propellants.

1 Theory Calculation

1.1 Calculation of surface energy by contact angle method

So far, there is not a direct method to measure the surface energy of solid, so some indirect methods were studied. The contact angle method was applied to this study to calculate the surface energy. Principle is as follows:

Young′s equation[9]:

γ2=γ12+γ1cosθ

(1)

Girifalco and good deduced the relationship ofγ1,γ2andγ12[10]:

γ12=γ2+γ1-2φ(γ2γ1)1/2

(2)

In the equation: φ is the molar volume factor and approximate to 1, so the Equation (2) becomes:

γ12=[(γ2)1/2-(γ1)1/2]2

(3)

For the adhesion work (Wa) is[11]:

Wa=γ1+γ2-γ12

(4)

The following equation can be obtained by Equations (3) and (4) :

Wa=2(γ1)1/2(γ2)1/2

(5)

By Equations (1) and (4) , the following equation can be obtained:

Wa=γ1(1+cosθ)

(6)

The polar component and nonpolar component can be added[11], so:

(7)

For every component fits Equation (7) , Equations (3) and (5) respectively becomes:

(8)

(9)

Equations (6) and (9) can deduce Equation (10) :

(10)

The surface energy can be obtained by the following equation:

γ=γd+γp

(11)

So two liquids with known surface tension, polar component and nonpolar component can be dropped on the surface of a bonding agent to measure the contact angle, and using the Equation (10), two binary quadratic equation groups can be obtained. So the polar component and nonpolar component can be calculated, then the surface energy of bonding agent is acquired by Equation (11).

1.2 Calculation of Ed

R. J. Wu[10]using semi-continuous model of energy adduct concept, assuming the force between molecules consist nonpolar parts and polar components, gets an interface energy equation suitable for low surface energy system:

(12)

(13)

2 Experiment

2.1 Materials and devices

RDX (the average diameter of RDX is about 0.0577mm and it is bought from Luzhou Chemical Plant) , double-base tablet (it is produced by Luzhou Chemical Plant) , anhydrous ethanol, ether, diphenylamine, and diiodomethane are all analytically pure, and they are bought from Tianjin Tianda Chemical Reagent Factory; distilled water (it is produced by ourselves)

WSM-10KN electronic universal testing machine (the manufacturer of it is Changchun Intelligent Equipment Co., Ltd.) , drop weight machine (the manufacturer of it is Jiangsu Tianyuan Test Equipment Co.), high-low temperature test chamber (the manufacturer of it is Shanghai Linpin Instrument Co., Ltd.), digital caliper, three-dimensional stereo microscope (the manufacturer of it is Keyence Co., Japan) , contact angle measuring device (the manufacturer of it is Shanghai Zhongchen instrument Co., Ltd.)

2.2 Preparation for double-base gun propellant

Based on the synthetic process of gun propellant[12], the samples with different mass fraction of RDX (0,5%,10%,15%) were obtained to meet the experimental needs.

2.3 Tests and methods

First, the compressive property and shock resistance of these double-base gun propellants with different amounts of RDX were tested at different temperatures (20℃,50℃) . The experimental principle of compressive property testing is referred to reference[12]. The double-base gun propellants were planted on a flat and hard iron. A hammer fell from a certain height onto the samples, but the samples only deformed and must not be broken. The volume deformation impact energy was adopted to estimate the shock resistance[13], and then the contact angles of bonding agent/distilled water and bonding agent/diiodomethane were measured at different temperatures (20℃,50℃) , finally the surface images of these gun propellants were observed by three-dimensional stereo microscope under normal temperature after being impacted. Five samples are tested at every amount of RDX.

3 Results and Discussion

3.1 Surface characterization

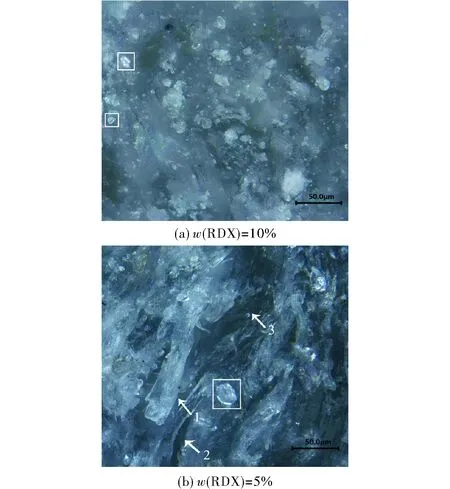

Double-base gun propellants were impacted by the same impact energy, that means the hammer fell from the same height to make the samples broken. The fractured face was observed by three-dimensional stereo microscope, as shown in Figure 1. Double-base gun propellants have good toughness, thus the ones with none or low content of RDX deformed only but cannot be broken. So cracks just in samples with 10% and 15% RDX were observed.

Fig.1 Surface of double-base gun propellants with different contents of RDX after it is impacted

Based on observation from the Figure 1, we can see that the bonding agent peels off the RDX crystals (the crysals ringed in the two pictures) when the samples were impacted. With the same impact energy samples with 15% RDX is damaged more seriously. As in the Figure 1 (b), not only the RDX crystals fall off and exposed completely, but the whole bonding agent produces faults (as the part pointed out by arrow 1) and cracks (the section showed by arrows 2 and 3). Also, in the Figure 1 (a), for RDX crystals only semi-nudity exposed.

This is the case that NC and RDX are two-phase components and incompatible substances, making an interface between the two phases. As the content of RDX increases, the interface between the two phases also increases, and interface failure increases, thus leads stress to focus, and the gun propellants are broken from the interface. As RDX is more, RDX/RDX and RDX/NC strands cannot intertwine as NC/NC strands, so the interaction of interface decreases, resulting in that gun propellants are damaged easily when impacted. In a word, the reason is the interface in the heterogeneous gun-propellants.

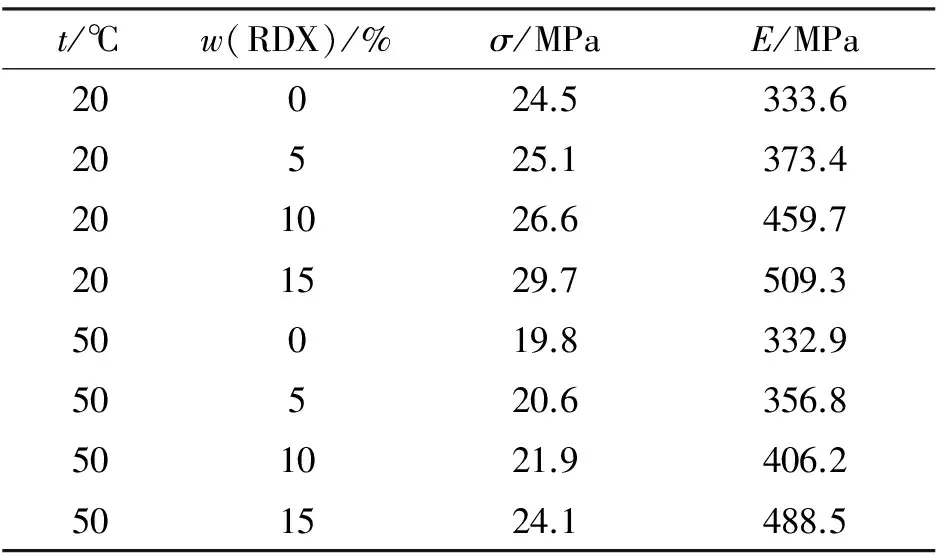

3.2 Mechanical property testing results of double-base gun propellants

The results of compression tests are shown in Table 1, and the results of impact experiments are summarized in Table 2. The average value of the five groups is calculated to be the final result. And the standard deviation is listed following it.

Table 1 Yield stress (σ) and elasticity modulus (E) of double-base gun propellants with different RDX at different temperatures

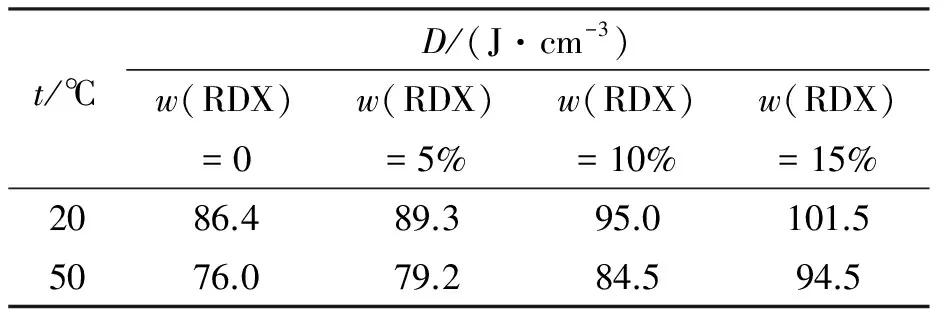

Table 2 Volume deformation impact energy (D) of double-base gun propellants with different content of RDX at different temperatures

From the results we can see that at 20 or 50℃ compressive strength increases, impact resistance decreases with increasing RDX content. Because the RDX added can share the load with the bonding agent, limit bonding agent to deform by mechanical constraints, enhance the polymer binder system, and improve the compressive strength. But the added RDX makes the gun propellants produce more interfaces, and lead stress to focus. Also RDX can peel from the bonding agent, resulting in the decrease of impact resistance.

3.3 Surface energy results of bonding agent

According to the contact angle on the bonding agent with water and diiodomethane,γ,γp,γdof bonding agent can be obtained by Equations. (10) and (11) .γ,γp,γdof water and diiodomethane at 20℃ are referred to reference[11], also the surface tension temperature coefficient of water is -0.16mN/(m·℃) , and of diiodomethane is about -0.1mN/(m·℃) . The obtained results are listed in Table 3. Also the average value of the five group data for the contact angle is calculated here. And the standard deviation is listed following it.

Table 3 Contact angle (θ) , surface energy (γ) , polar component (γp) and nonpolar component (γd) of bonding agent at different temperatures

3.4 Results of Ed

The interface energy of RDX/bonding agent and the adhesive work are calculated by Equations (12) and (4) respectively. The results are presented in Table 4. Due to the average diameter of RDX is about 0.0577mm[14].γ,γp,γdof RDX are referred to reference[14]. The surface tension temperature coefficient is 0.5mN/(m·℃)[10]. Because the shape of RDX is irregular, its surface area is approximately 0.239m2/g. FinallyEdis calculated as Table 4.

Table 4 Adhesive work of binding agent ( , adhesive work of interface (Wa) and adhesive energy per mass of RDX and binding agent (Ed) of gun propellants with different content of RDX at different temperatures

3.5 Relationship between Ed and mechanical properties

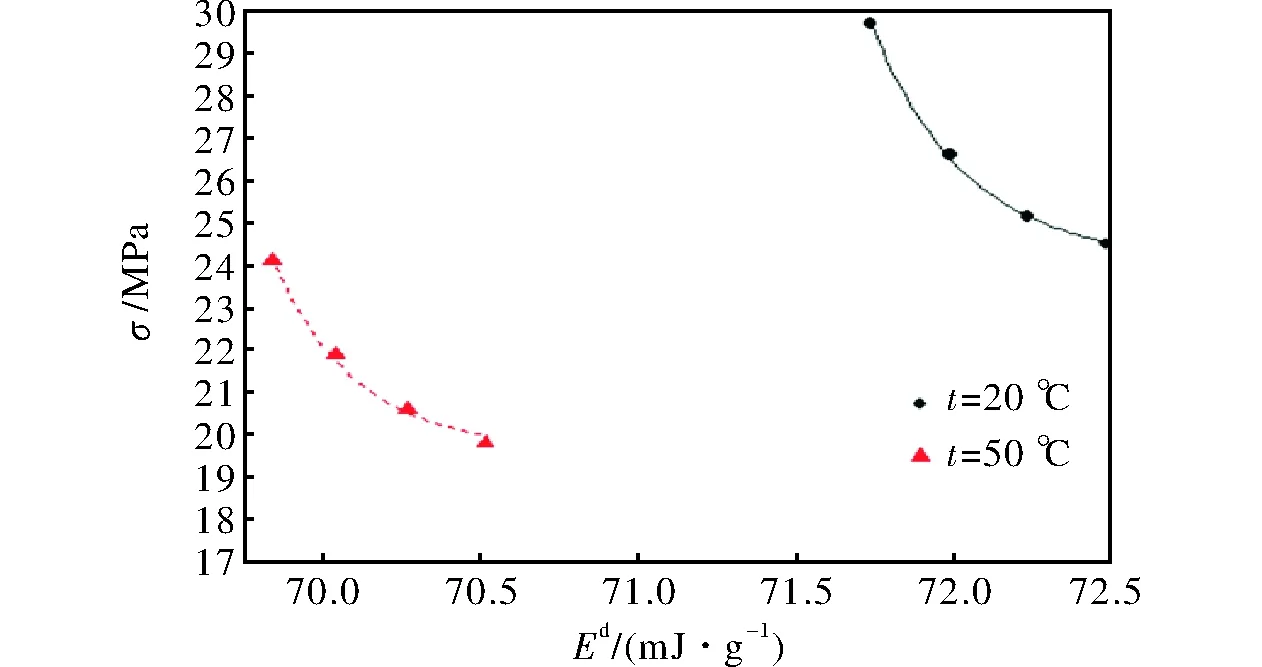

For studying the relationship betweenEdand mechanical properties, discussing whetherEdcan represent mechanical properties, theσ-EdandD-Edcurves are drew as Figure 3 and Figure 4, and the relationship is listed in Table 5.

Table 5 Relationship between σ and Ed or D and Ed at different temperatures

Fig.3 σ vs. Ed curves of double-base gun propellants at different temperatures

Fig.4 D vs. Ed curves of double-base gun propellants at different temperatures

Based on the results, we can see thatσ-EdorD-Edat different temperatures present exponential decay function relationship. With increasing the content of RDX,Eddecreases, butσandDincrease, that is to say, compressive strength increases and impact resistance decreases, which agrees with the macroscopic mechanical properties testing results. So the relationship between macroscopic mechanical parameters and microscopic interface parameter can be quantified. But the meaning and universality of the parameters in the equations should be studied further.

4 Conclusion

(1)With increasing the content of RDX, the compressive strength of double-base gun propellants increases, but the impact resistance decreases and the impacted damage is more serious.

(2)Edis defined to represent the influence of RDX′s content on macroscopic mechanical properties. Exponential decay function relationship (y=a+be-x/t) ofσ-EdorD-Edis obtained at different temperatures(when the RDX is five kind). So it is easier and more convenient to represent macroscopic mechanical properties by usingEdbefore the gun propellants produced. The mechanical properties can be estimated before the gun propellants shaped up.

(3)Edcan represent macroscopic mechanical properties. But the relationship under low temperature and the influence of RDX′s size to mechanical properties is still need to be further studied.

References:

[1] Naya T I, Kohga M. Influences of particle size and content of RDX on burning characteristics of RDX-based propellant[J]. Aerospace Science and Technology, 2014,32(1):26-34.

[2] Iqbal M M, Ch S R, Wang L, et al. Investigation the effect of solid fillers on mechanical and rheological properties of composite propellants[J]. International Journal of Energetic Materials and Chemical Propulsion, 2010,33(4):40-46.

[3] Lan Y H, Zhai J X, Li D H. Multiscale simulation on the influence of dimethyl hydantoin on mechanical properties of GAP/RDX propellants[J]. Propellants, Explosives, Pyrotechnics,2014,39(1):18-32.

[4] Takahashi S J, Koyama M F, Maria T J. Solid polyurethane-based composite propellant: I- influence of the bonding agent[J]. Química Nova,2002,25(1):107-110.

[5] Zhang J B, Ju Y T, Zhou C S. A study of experimental method for mechanical properties of solid propellant under hydrostatic compressive loading[J]. Applied Mechanics and Materials,2013,300:789-793.

[6] Zhang X J, Chang X L, Zhang S Y. Experimental study on low temperature mechanical properties of HTPB propellant[J]. Applied Mechanics and Materials, 2013,310(3):124-128.

[7] Dostanic J, Uscumlic G.The use of image analysis for the study of interfacial bonding in solid composite propellant[J]. Journal of the Serbian Chemical Society,2007,72(10):1023-1030.

[8] Liu Y F, Chen Y, Shi L. Synthesis of three novel laurylamine-derived long-chain alkyl bonding agents and their interactions with RDX[J]. Propellants, Explosives, Pyrotechnics,2012,32(1):69-76.

[9] Giessen A E van, Bukman D J, Widom B. Contact angles of liquid drops on low-energy solid surfaces[J]. Journal of Colloid and Interface Science,1997,192:257-265.

[10] Wu R J. Surface and interface of high polymer[M].Beijing: Science Press,1998:7-45.

[11] Luo Y J, Du M N. The use of inverse gas chromatography (IGC) to determine the surface energy of RDX[J]. Propellants, Explosives, Pyrotechnics,2007,32(6):496-501.

[12] Wang Z S, Han P M, Zhang X Z. Power Experiment[M]. Beijing: Science and Technology of China Press,1992:87-91.

[13] Liu J, Zhang L H, Ma Z L, et al. Study on the mechanical properties of mutiphase gun propellant with RDX[J]. Chemical Propellants & Polymeric Materials, 2013,11(4):87-89.

[14] Du M N, Luo Y J. Effect of particle size and surface free energy of RDX on the mechanical properties of the high-energy nitramine gun propellant[J].Chinese Journal of Explosives & Propellants(Huozhayao Xuebao),2005,28(3):1-3.