Study on the Law of the Development Height of Water Flowing Fractured Zone in Shaanxi Guojia River Coal Mine

2018-05-13YangGuodong

Yang Guodong

(Shanxi Guojia River Coal Industry Limited Liability Company,Baoji,Shaanxi 721505)

Abstract: The fully mechanized sublevel caving mining in Huanglong Jurassic coalfield is threatened by water inrush from roof sandstone's“separated layer”.Studying the Law of the development height of water flowing fractured zone in the mining process is of great significance for the further study of the water source,channel and mechanism of mine water inrush,taking reasonable and effective prevention and control measures for dealing with“separated layer”water inrush,and guiding future water prevention and control work.Taking Shaanxi Guojia River Coal Industry Limited Liability Company as an example,they use two main methods of the drilling fluid leakage observation and downhole television technology to determine the maximum development height of water flowing fracture zone.Compared with domestic and neighboring mines,it further verifies the accuracy of the measured data and accords with the actual situation on site,which is of great significance for guiding the mine to take reasonable and effective measures to prevent and control water inrush from“separated layer”.

Keywords: two belts;water flowing fracture zone;delamination;water inrush;water prevention

I.Introduction

Guojia River Coal Mine is located in the northern part of Linyou county of Yonglong Mining Area of Jurassic coalfield in Huanglong,Shaanxi Province.The maximum coal thickness of the mine is about 20 meters,with an average thickness of 11.57 meters.Mining method is fully mechanized sublevel caving by long-wall mining.In the process of construction and production in recent years, the phenomenon of“separated layer”water inrush in some parts of the mine is serious,which has a great impact on the safe production of the working face.Especially,coal seam roof in Luohe formation of Cretaceous system of this mining area has a large sedimentary thickness,which poses a great threat to coal mining.Studying the development height and law of water flowing fractured zone during mining is important to accurately evaluate the influence degree of underground water in coal mine on safe mining.The further study of the water source,channel and mechanism of mine water inrush is vital for people to take effective prevention and control technical measures to deal with“separated layer”water inrush.These measures are of great significance to guide future water prevention and control work.

II.Working Face Profile

1302 working face is the seventh working face in Guojia River Coal Mine,which is the joining face of 1307 working face.The working face has an available mining length of 1325m,a dip length of 270m,and a recoverable area of 3.5775×105m2.The coal seam thickness of the working face is 3.0 ~13.1 m,with an average of 8.0m.The elevation of coal seam floor is+720 ~+810 m,the highest height difference is 90m,and the fluctuation of coal seam floor is large.The distance between the coal seam roof and the Cretaceous system floor is 218 ~232 m,and gradually increases from the air return gateway to the drawing gateway of the working face.

III.“Two Zones”Exploration

The development height of water flowing fractured zone is mainly determined by two methods:the drilling fluid leakage observation and downhole television technology.The exploration was carried out 2-7 months after mining,and the location of the exploration hole was 40m in the working face near the adjacent goaf side along the trough to the working face,and it was located near the syncline axis(coal thickness is 9m),which can represent the maximum height of the development of water flowing fractured zone.

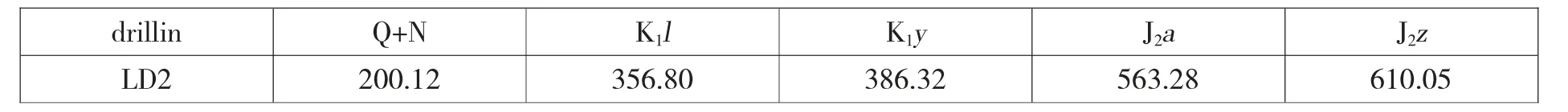

Exploration Hole Statistic Table of the Stratigraphic Boundary Information (unit:m)

IV.Comprehensive Determination of the Height of Roof water flowing fractured zone

(i)Observation and analysis between drilling flushing fluid consumption and water flowing fracture zone height.

During the drilling process,from 0m to 211.79 m,and the consumption of flushing fluid is about 0.1~0.45m3/h,which is the normal consumption during the drilling process.The flushing fluid would leakage to nothing from 211.79m to 216.78 m.After plugging the part in 216.78m and continue drilling to 341.86m,during which the consumption of flushing fluid is about 0.15 ~0.45m3/h,which belongs to normal consumption range.341.86 m ~343.28 m,flushing fluid lost again.Plugging again and drilling to 353.34m,all flushing fluid was lost again.After repeated plugging and drilling operations(353.34 m~357.3 m,361.85 m ~365.77 m,372.77 m ~373.79 m flushing fluid all leak out,other positions can continue to drill after plugging),when it reaches 396.17m,plugging cannot be carried out,and top leakage drilling construction reaches 610.05m (to the top of the coal seam roof).After conventional logging and downhole observation,the probe cannot be normally lowered into the bottom of the hole.After through the hole for many times,the conventional logging is blocked in 580m, and downhole observation is blocked in 387m.

When the loess layer is being constructed this time,the consumption of flushing fluid belongs to the normal consumption in the production process,which indicates that the water flowing fractured zone has not yet developed into the loess layer, but several fractures have been found on the surface,which indicates that the stratum is within the scope of“bending subsidence zone”in the upper“three zones”.During the construction of bedrock section,the construction can be continued after 353.34m~396.17m parts are blocked,and all flushing fluid below 7 is lost,which indicates that the formations of Yijun Formation, Anding Formation and Zhiluo Formation have been disturbed and damaged to varying degrees since the bottom of Luohe Formation.

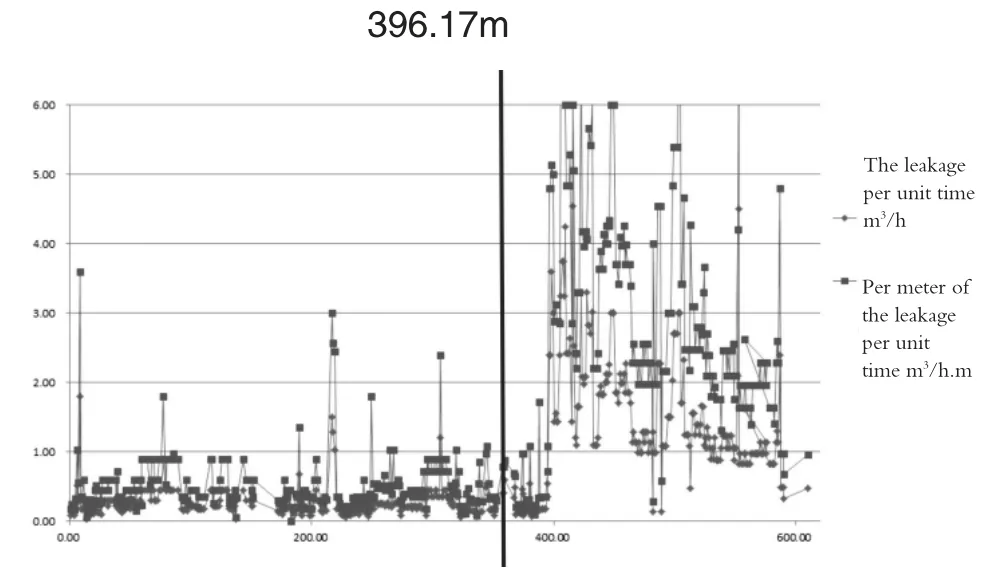

During the construction, the consumption of drilling flushing fluid was observed in detail,and according to the observation a relevant curves were made as shown in the figure.

Starting from 396.17m, the consumption of flushing fluid suddenly changed from 1.08 m3/h.m to 4.8 m3/h.m,and after which the circulation of flushing fluid was interrupted.From this,it can be inferred that the stratum has been affected by the coal mining disturbance of the working face,and the top of the water flowing fractured zone is about 396.17m,which is located at the upper part of Anding Formation stratum.

Curves of Water Level Variation with Hole Depth in Borehole

Calculation of height of water flowing fractured zone:

After comprehensive analysis, it can be determined that the water-conducting fractured zone has developed to Anding Formation,and 396.17m deep hole is selected as the vertex of the water-conducting fractured zone this time.

Therefore,the height of water flowing fractured zone is:

H导=H-M-h+W

Where:H导——Maximum height of the water flowing fractured zone;m

H——Vertical depth of coal seam floor from orifice;(615.00m)

M——Average mining thickness of coal seam;(Take the average mining thickness as 9.0m).

h——Vertical depth of apex of water flowing fracture zone from orifice;(396.17m).

W——Compression value of rock stratum in fracture zone during drilling observation(since it is a post-mining hole,it is taken W=0m here).

According to calculation,the maximum height of water flowing fractured zone H导=209.83m,which is about 23.31 times of mining thickness.

(ii)Observation and analysis between downhole television observation and water flowing fracture zone height.

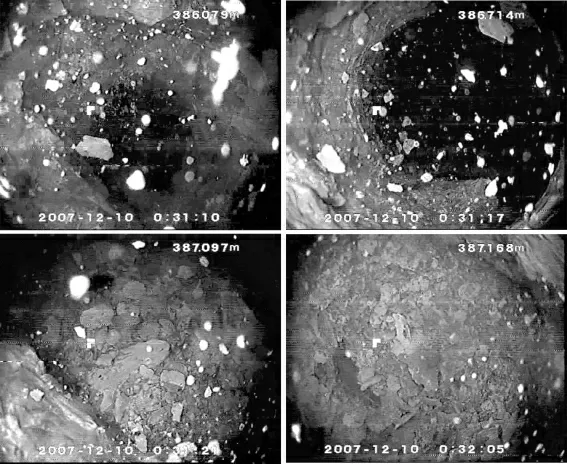

Downhole television observation: about 7 months after the working face was pushed and mined;a downhole television observation was conducted on the hole,and the situation in the hole of 0~387.00m section was clearly peeped,of which 0 ~200.12 m section was loess layer retaining sleeve,258.60m section was the water level,the hole wall of 200.12 ~385 m section was relatively regular,358m,362m,366m and 376m section had transverse cracks,and no obvious vertical cracks were found in the whole hole.From 386m to 387m, there was obvious collapse.

According to the core logging results,the bottom of Luohe formation is 356.8m,and the bottom of Yijun formation is 386.32m.Analysis shows that several transverse fissures at 358m to 376m are formed due to uneven settlement caused by different rock strength.Below 386m, the bottom of Yijun formation and the soft and hard joints in the lower part do not exclude the possibility of delamination space development.See as the following figure.

Drilling TV Image

(iii)Calculation of Height of Water Conducted Fracture Zone in Coal Seam Mining

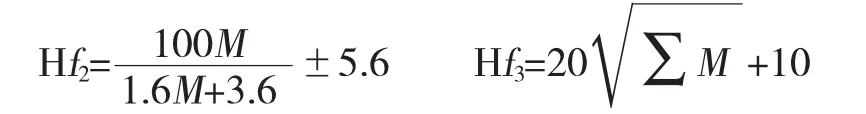

The calculation formula of roof water flowing fractured zone provided by the“Regulations for Coal Pillar Retention and Coal Mining in Buildings,Water Bodies,Railways and Main Tunnels”is as follows:

However, this formula is suitable for single-layer mining thickness of 1~3m and cumulative mining thickness of no more than 15m.There was no fully mechanized caving mining method as the formula was confirmed.Coal seam mining was basically in the shallow area of 300m,and the strata studied were mainly in the Carboniferous-Permian coalfields.Therefore, the calculation formula has certain limitations.It is not suitable for the prediction of the height of water flowing fractured zone in overlying rock roof of fully mechanized caving mining.The calculation results are only for reference.

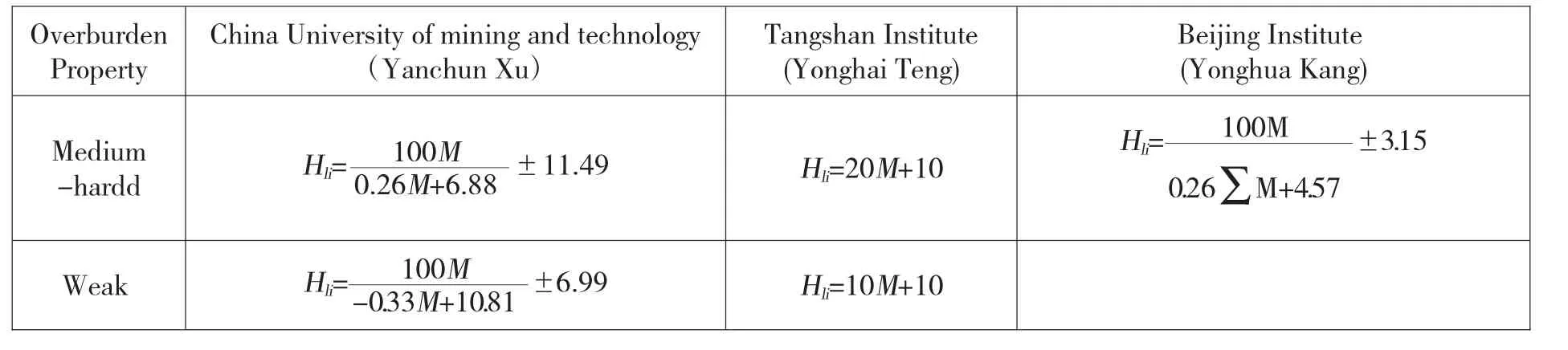

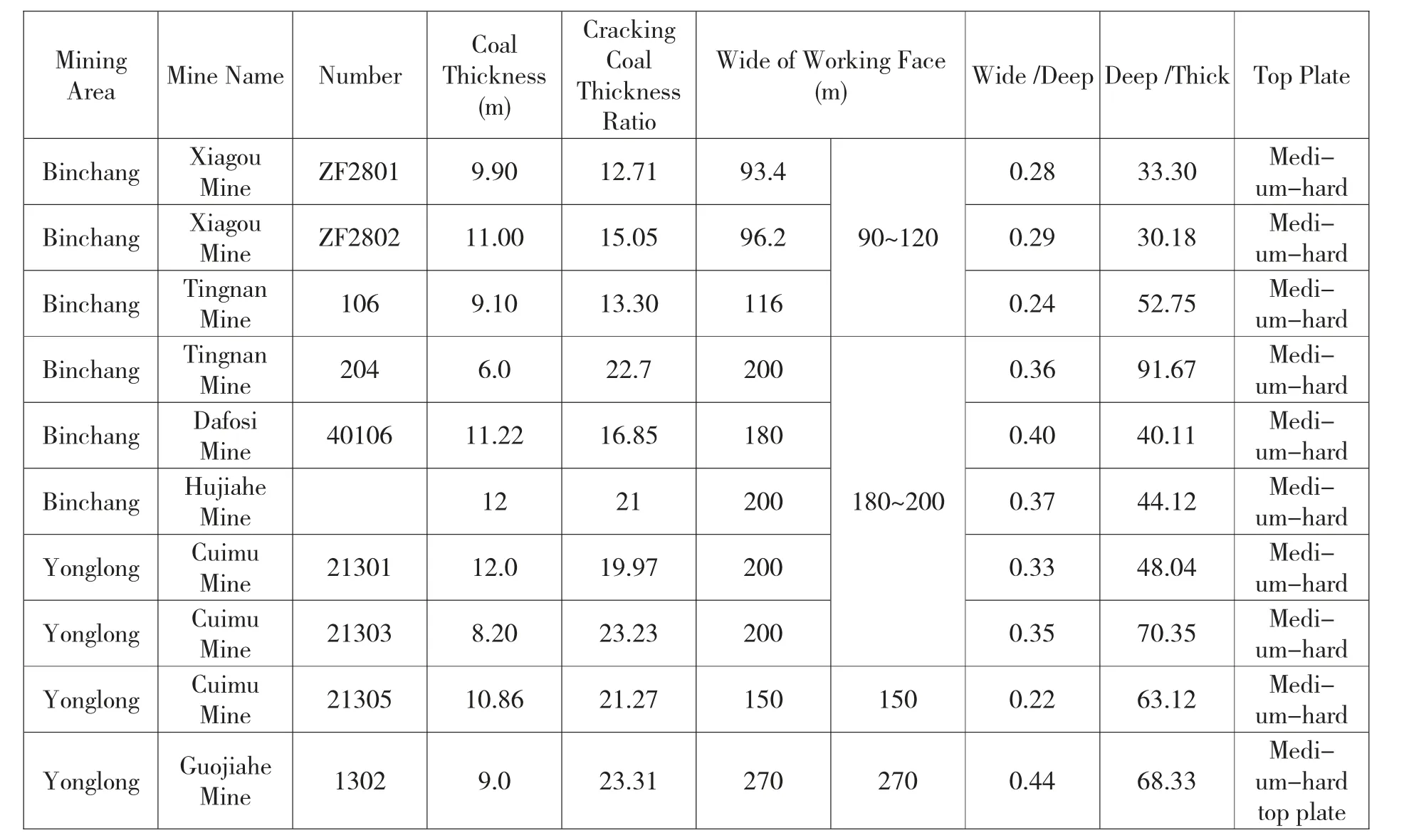

According to domestic published papers, at present,there are more than 40 mines in China that have carried out actual measurement of roof water flowing fractured zones under fully mechanized caving conditions.Relevant scholars have preliminarily summarized the occurrence of overlying rock water flowing fractured zones under medium hard and weak roof conditions.At present, the applicability of the formula for calculating the height of education needs to be further tested.Table 1 is the relevant calculation formula.Table 2 and Table 3 are the domestic measured data and the measured data in this area.

Table 1 Relevant Calculation Formula of Fully Mechanized Sublevel Caving Demands and“Two Zones”Exploration

Table 2 Statistics of Domestic Fully Mechanized Caving Crack Height-Mining Thickness Ratio

Table 3 Measured Data of Binchang Mining Area and Adjacent Area

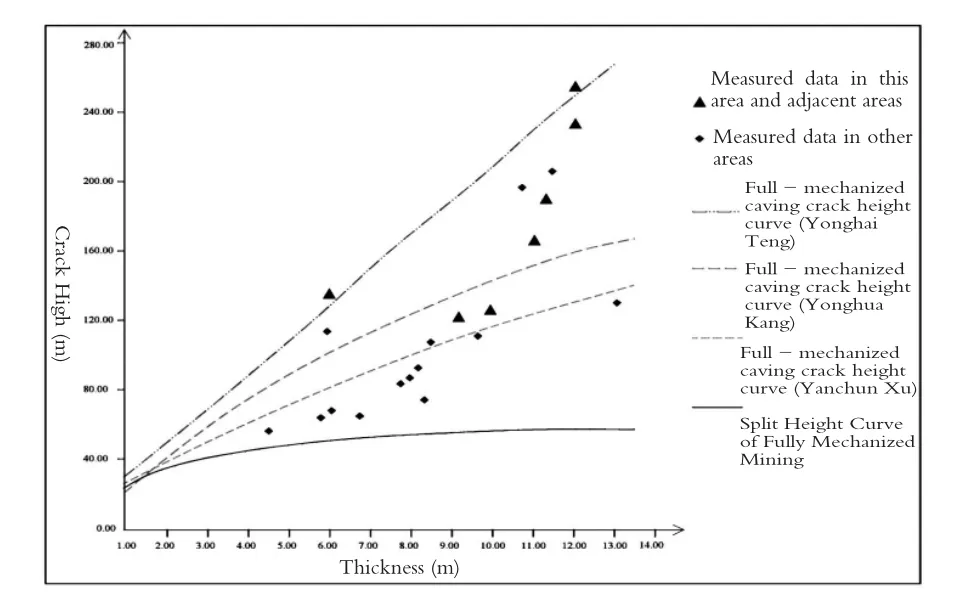

The superposition of measured crack height data and crack height curves of various calculation formulas under the condition of hard overburden roof in domestic fully mechanized top-coal caving mining is shown in the figure below

Comparison Diagram of Crack Height Curves of Various Formulas and Measured Crack Height

From the figure,it can be seen that the crack height predicted by using the“Three Times”Coal Mining Regulation thick coal seam layered mining calculation formula is less than the measured crack height value,and the gap between the measured value and the mining thickness increases,indicating that the layered fully mechanized mining crack height calculation formula is not suitable for predicting the crack height under the condition of fully mechanized caving.Xu Yanchun[1-2]based on the calculation formula of fully mechanized top-coal caving crack height summarized from the domestic measured data,when the mining thickness is less than 9.0m,it accords with the measured crack height value to a higher degree, and when the mining thickness is more than 9.0m,the predicted crack height value is quite different from the measured value.Kang Yonghua[3-4]uses the calculation formula summarized from the research data in XinglongVillage of Yanzhou proves that the date accord with the measured crack height relatively well when the mining thickness is more than 8.0 m.The formula recommended by Teng Yonghai[5]of calculating the crack height of fully mechanized top-coal caving mining tells us that when there is no measured data,the predicted value of the crack height is mostly higher than the measured value that indicates the predicted result has certain value.

V.Conclusion

(i)The development height of water flowing fractured zone is not only related to coal seam mining thickness,mining method,roof management method,overburden lithology and post-mining time process,but also related to the layout of working face.According to the actual situation of the mining area and the adjacent area and the arrangement width of the working face,the development height of the water flowing fractured zone is divided into two situations,the first one is the width of the working face〈120m and the second one is the width of the working face〈120 m.

When the working face is 90~120m,the average ratio of crack height to mining thickness is 13.69 times.

When the width of the working face is 180~200m, the average ratio of crack height to mining thickness is 20.13 times.

(ii)This time,through the observation method of drilling flushing fluid consumption and downhole television technology method, the comprehensive analysis shows that the height of the water flowing fractured zone in the 1302 working face of Guojia River Coal Mine is about 209.83m,which is about 23.31 times of the mining thickness,and the height of the fractured zone is developed to the top of Anding Formation.

(iii) The fully mechanized sublevel caving mining in Huanglong Jurassic coalfield is threatened by water inrush from roof sandstone's“separated layer”.Taking Shaanxi Guojia River Coal Industry Limited Liability Company as an example,they use two main methods of the drilling fluid leakage observation and downhole television technology to determine the maximum development height of water flowing fracture zone.Compared with domestic and neighboring mines,it further verifies the accuracy of the measured data and accords with the actual situation on site, and confirms the law of the development height of water flowing fractured zone in the mining process.All of this is of great significance for the further study of the water source,channel and mechanism of mine water inrush and taking reasonable and effective prevention and control measures to deal with“separated layer”water inrush problem.This paper has great significance for guiding future water prevention and control work.

杂志排行

中阿科技论坛(中英文)的其它文章

- 中国天眼模型结构的技术探究

- 基于应用技术实现语言处理研究

- Technical Research on Model Structure of Chinese“Sky Eye”

- 宁夏枸杞产业的SWOT 分析与发展策略

- The Potentials,Challenges and Path for Achieving Science and Technology Cooperation between China and Arab States under the Background of the Belt and Road Initiative

- SWOT Analysis and the Development Strategy of Goji Berry Industry in Ningxia