An Optimization Method for a Single Machine Multi-family Scheduling Problem with Qualification Run Constraints

2018-05-07

(School of Mechanical Engineering, Tongji University, Shanghai 201804, China)

1 Introduction

The challenge to achieve a win-win situation where high quality and low cost are both attained has received a broad spectrum of interest from academia and industry, especially in the semiconductor manufacturing that is generally recognized as the most complex system with extremely expensive equipment[1-2].

Jobs of similar types are grouped into a family, which is viewed as a leverage to decrease setup times, reduce lead time as well as increase equipment utilization[3-4]. Various academic achievements have been made to analyze family scheduling problems in semiconductor manufacturing systems. For instance, Chern et al.[5]investigated the effect of applying family-based scheduling rules to wafer fabrication and then presented five family-based rules. Zheng et al.[6]dealt with an unbounded batching machine scheduling problems with family jobs and setup times by developing a generic forward dynamic programming algorithm. Yugma et al.[7]proposed a heuristic algorithm for solving a batching and scheduling problem in semiconductor diffusion.

All the above-mentioned literatures fail to consider the practical production case where machine parameters may drift after a certain quantity of job processing especially in high mixed fabs[8]. To guarantee high quality, a qualification run (qual-run) is regarded as an indispensable operation to evaluate machine status, ensuring that the machine is qualified to process the jobs of a certain family[9-10]. Currently, little attention is paid to considering the qual-run as a significant constraint which may directly affect the scheduling. Li et al.[11]analyzed the impact of qual-run requirements on the scheduling performance and proved through simulation results that more jobs make a greater impact on the performance. Patel[12]proposed four heuristics to solve the problem of scheduling of job families on non-identical parallel machines with qual-run constraints.

As shown above, there are several existing works covering qual-run requirements, however, qual-runs and setups are not taken as two main contradictory constraints. Owing to the fact that taking the qual-run into consideration is important and imperative in real life, a single machine multi-family problem with an objective of minimizing makespan was addressed, which took setups and qual-runs as two closely interactive constraints. Since the problem-solving methods of the abovementioned literatures are inappropriate to figure out the problem, an adaptive catastrophic differential evolution algorithm with depth neighborhood search was proposed. Differential evolution with its advantage of superior global optimization ability and convenient operation is popularly and successfully employed in a wide range of fields[13-16]. The proposed algorithm, preserving these characteristics and making up for the deficiency of easily trapping in local optimum and poor local search ability, demonstrates its exceptional performance in solving the following problem.

2 Problem Description

In this paper, a single machine scheduling problem with multi-family cases where there areMjobs that belong toFfamilies required to be processed on a machine was presented. Switching from one job to another of a different family requires setups, and one effective way to avoid the setup is to process as more jobs as possible in a row, while a qual-run is incurred if jobs of other families have been processed for a predefined limited number since the last time the job of the same family was processed. In other words, if the number of processed jobs that are from other families exceeds a qual-run threshold of the family, a qual-run is triggered. Moreover, it is notable that a qual-run operation usually takes a relatively long time, which makes it economically wise to avoid performing a great number of qual-runs. Given this, the paper strives to strike a balance between the qual-run and setup times with an objective to minimize makespan.

To clearly state the problem, an illustrative example is given in Fig.1 with three scheduling strategies. Assume that there are three familiesA,B,C, the numbers of jobs in them are 6, 5 and 4 with qual-run thresholds being 2, 3 and 3, respectively.

Solution 1 is a regular scheduling mode of processing all jobs of the same family in a successive way without deliberately avoiding qual-runs. Solution 2 goes to great lengths to avert qual-runs and solution 3 is a merger of the first two solutions. It is evident in Fig.1 that Solution 3 performs best among the three solutions. It finds out a balance between setup and qual-run times, instead of blindly avoiding qual-runs or setups alone.

Fig.1 An illustrative example for scheduling with the qual-run

In order to form the precise problem domain, the hypotheses are made as follows: 1) One machine can process at most one job at a time, and preemption of processing is not allowed. 2) Jobs of the same family have the same processing time. 3) All jobs are available at the very beginning in the schedule. 4) The setup time is sequence-independent and no setup is required between jobs of the same family. 5) A setup is executed before a qual-run. 6) A qual-run is unnecessary for the very first job.

To state the problem clearly, the following notations are defined, as shown in Table 1.

Table 1 Notation definition

Based on the assumption and Ref.[10], the mathematical model of the problem is formulated as follows:

minCmax

(1)

(2)

(3)

Pf(j)i-Pf(j)(i-1)≤Sf(j)i,∀f∈F,∀j∈J,∀i∈I

(4)

(5)

Ci-1+Pf(j)i·pf+Sf(j)i·sf+Qf(j)i·qf=Ci,∀i∈I

(6)

Objective 1) represents minimizing makespan. Constraint 2) ensures that a position can process at most one job. Constraint 3) restricts the total number of jobs of each family. Constraint 4) decides whether familyfrequires a setup. Constraint 5) decides whether familyfrequires a qual-run. Constraint 6) guarantees that the job should be processed instantly after the completion of the job in the last position.

The solution that all jobs of the same family are processed in a row meets the above criteria. It is viewed as an original and primitive solution. In this solution, all families except the family of the first job in the schedule are required to execute qual-runs, as we can see, all possible setups are reduced, and the qual-run times of those families are 1. Therefore, the only way to find a better solution is to ensure that the number of qual-runs of each family is not more than one, as shown in Formula (7).

(7)

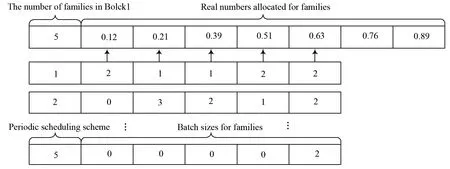

Formula (7) implies that some families are qual-run free, and some have to execute qual-runs. Which certain families to choose from to avoid the qual-run is the pillar and ground of this study. Consequently, a definition is presented.

Definition1Block: Families to be scheduled are spilt into two types of blocks. Batches in Block 1 (B1) are qual-run free, which means no qual-run is needed between two batches, while batches in Block 2 (B2) require qual-runs.

Definition 1 provides a fundamental theoretic basis of the scheduling. Thus, if the solution obtained goes against the concept of Definition 1, it will not be regarded as feasible in the following sections. It is also notable thatB1is certainly scheduled beforeB2. Since ifB2is executed beforeB1, it is impossible that all jobs of families inB1can be spared from qual-runs. SinceB1must be processed first, the number of each type of block is set to 0 or 1, which is good enough for operating easily and comprehending clearly.

In view of families in blocks, the following properties are obtained.

Property1Only when families inB1andB2are not overlapped is the solution near optimal.

ProofFor jobs of a family, there are only threesets of assignment ways. Set 1: BothB1andB2have jobs of familyf. Set 2: OnlyB2has jobs of familyf. Set 3: OnlyB1has jobs of familyf. For Set 1, familyfinB1is out of qual-runs, while the one inB2requires qual-runs, so the total setup and qual-run time (t1) islf·sf+qf. For Set 2, the total setup and qual-run time (t2) issf+qf, less thant1. For Set 3, if the total setup and qual-run time (t3) is more thant1, Set 2 is better. Ift3≤t1, Set 2 or 3 is better. All in all, either Set 2 or 3 invariably performs better than Set 1. Therefore, only when families inB1andB2are not overlapped is the solution near optimal.

An excellent scheduling of the problem features that as few setups as possible are performed and as many qual-runs as possible are averted. As shown in Definition 1, all families inB2are supposed to execute qual-runs, so it’s better to continuously process all jobs of the same family inB2to avoid extra setups. So, the difficulty and key point of the study focus onB1, instead ofB2. Thanks to the help of Property 1, the scheduling difficulty is reduced. The scheduling is simplified to two main tasks, one is to determine the member ofB1,B2and another is to consider the appropriate batch size of families inB1to avoid qual-runs.

Definition2Periodic scheduling scheme: a pattern of the batch size of each family inB1. For instance, period 1 includes all families assigned toB1. With the scheduling process moving on, jobs of a certain family may be exhausted, then the next period is prepared and batch sizes of the rest of families are recalculated.

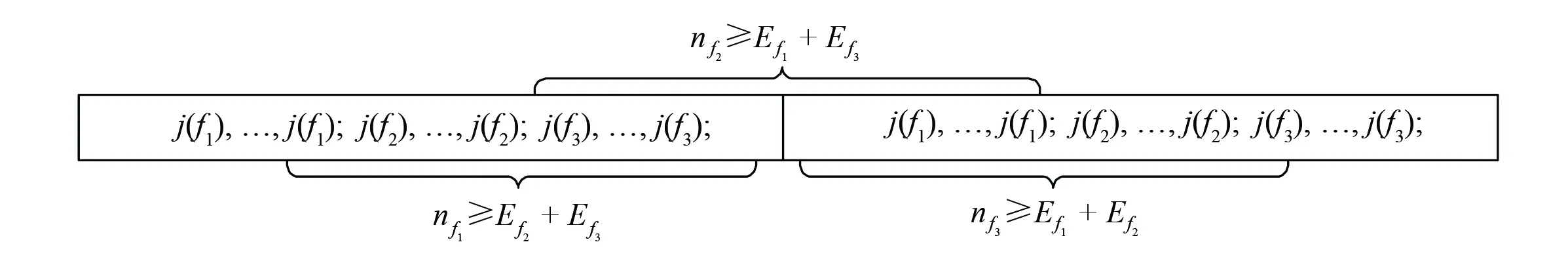

Property2A feasible solution is possible to obtain when families inB1satisfy the following relation.

(8)

Fig.2 An illustrative example of batch sizes in B1

Theorem1The batch sizes of families inB1are required to satisfy the following formula, which develops a feasible solution forB1to avoid the qual-run.

(9)

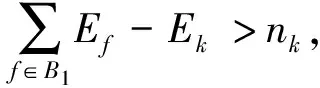

Theorem2The number of families inB1(NB1) which meets Formula (10) can generate a feasible solution forB1.

NB1≤minnj∈B1+1,0≤NB1≤N

(10)

ProofGiven that the number of the families inB1reaches the maximum, the batch sizes of all families inB1are supposed to be 1, which makesB1have the maximal capacity. The number of jobs between the last job to the next job of this family is limited to minnj∈B1, meanwhile, batch sizes of all families inB1are 1, soNB1(max)=minnj∈B1+1. Batch sizes of all families inB1may not all equal 1, soNB1≤minnj∈B1+1.

Theorem3The maximum of the sum of the batch sizes (vmax) in a pattern satisfies Formula (11).

(11)

3 Algorithm Design

Since the multi-family scheduling problem with qual-run and setup constraints in a single machine case is an NP-hard problem[10], the exactly accurate solution on a large scale is hard to figure out. On the basis of the non-linear programming model, a modified adaptive catastrophic differential evolution algorithm with depth neighborhood search (MACDE) is put forward. The algorithm adopts a multi-tier encoding mechanism elaborating the scheduling scheme. With the help of the catastrophe theory and adaptive process, the disadvantage of differential evolution that the population is prone to be premature can be avoided and the speed of convergence can be accelerated[17-20].Moreover, armed with the depth neighborhood search, the algorithm conducts the deep-going search. The proposed hybrid differential evolution algorithm balances the exploration and exploitation, showing a strong optimization capability with a larger and deeper search scope and range. The details of the algorithm are listed as follows.

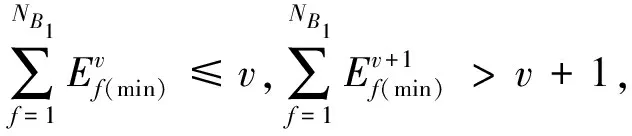

3.1 Encoding

Multi-tier encoding is employed in the algorithm, as shown in Fig.3. For better understanding, the first level is named as the main level, and the remaining levels are called the subsidiary level.

Fig.3 The schematic diagram of encoding representation

In the main level, the first position of the code is a positive integer, expressing the family number inB1, the rest are real numbers in an increasing order. Each real number which represents a family is randomly assigned.

In the subsidiary levels, the first position represents the first periodic scheduling scheme, the rest show the batch size of each family. When jobs of a certain family are exhausted, the next level is prepared to be set up.

3.2 Initialization

First, generate a target vector by randomly producing real numbers assigned for families between 0 and 1 and ranking the numbers in an increasing order, denoted by {Xr1,Xr2,Xr3,…,XrN}.

Second, adopting the concept of Theorem 2, it is easy to figure out at most how many families belong toB1.

Third, the initialization for batch sizes of families is performed, which requires to satisfy Theorems 1 and 3. Ensuring thatv=Vmaxis a better approach to diminish the searching range and speed up the exploration.

3.3 Fitness Evaluation

Based on the objective of the paper, the fitness function can be obtained as below:

(12)

The fitness value of each individual can be calculated by Formulas (4), (5) and (12).

3.4 Adaptive Mutation Operator

Choose a target vector of an individual of current population as a disturbance vectorXp1,rf, pick up two diverse individuals and treatXp2,rf,Xp3,rfas two differential vectors. The mutation operation is carried out according to Formula (13).

Yp1,rf(G+1)=Xp1,rf(G)+δF·(Xp2,rf(G)-

Xp3,rf(G))

(13)

wherep1,p2,p3∈{1,…Pop},p1≠p2≠p3,rf∈{1,2,…,N},Xp1,rf(G) represents the vector of familyfof individualp1in theGth generation,δFis the adaptive mutation probability and calculated as Formula (14).

(14)

whereλcsignifies the countdown of catastrophe,λis the catastrophe operator, andδis the initial mutation probability.

3.5 Crossover Operator

A trial vectorZp1,rf(G+1) is produced according to Formula (15) that shows a recombination of the arget vectorXp1,rf(G) and the mutation vectorYp1,rf(G+1), andZp1(G+1) is rearranged in an increasing order.

Zp1,rf(G+1)=

(15)

whereμcrepresents the crossover probability,Rrf(0,1) is a uniformly distributed random number for therfth dimension,rf(rand)is a randomly selected integer between [1,N].

3.6 Depth Neighborhood Search

On the basis of Theorems 1 and 3, the depth neighborhood search is carried out to redefine the batch sizes of families inB1.

Step1Let the periodic scheduling scheme (l) be 1. Let the count value (ccount) be 0.

Step2Let the sequence number of the family inB1(k) be 1, and the number of the families inB1is denoted byNB1.

Step4Leta=g/1, ifa=0, go to Step 5; otherwise, chooseaof families fromB1{f}, add one job to the batch size.

Step5Iffequals current number of families inB1(Nf1), go to Step 7. Iff≠Nf1, thenf=f+1 and return to Step 3.

Step6Count the remainder jobs of each family, if jobs of a certain family are exhausted, thenccount=ccount+1.

Step7Ifccount=Nf1, thenl=l+1 and go to Step 2; otherwise, go to Step 8.

Step8The number of the families inB1(N'B1) equals toN'B1-1, ifN'B1=Nf1, then finish the neighborhood search; otherwise, return to Step 1.

3.7 Selecting Operator

Compare the target population and the trial population that are produced by a series of operations, and consequently choose the one with better fitness. The selecting operation can be described as follows:

Op1,rf(G+1)=

(16)

3.8 Catastrophe Operator

The catastrophe countdownλcis updated based on judging whether there emerges a new optimal solution, if yes, resetλc=λ, if not,λc=λc-1. Whenλc<10, the mutation probability is adjusted, by which some characteristics of the previous evolutions can be maintained. Whenλc=0, the best individual can be retained, and then go back to reinitialize the population.

4 Experiments and Analysis

Performance ratio (R) and computation time (T) constitute two criteria, evaluating the performance of the proposed algorithm effectively[21].

R=

whereV(H,T,Y) represents the result of problem instanceYsolved by algorithmHin theTth iteration,qf(max)is the maximal value of qual-run time among all families. The smaller the value is, the better the performance of the approach is. The computation time is determined by the complexity of the algorithm. The smaller the computation time is, the more efficient the algorithm is.

Programming language C++ is adopted on the basis of Visual Studio 2012 for the proposed algorithm. A computer with Intel Core i3 2.10 GHZ processor and 4 GB of main memory is adopted to conduct the following experiments.

4.1 Parameters Analysis

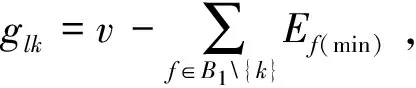

Under the situation where the number of families is 15, 30, instances are generated randomly, where the numbers of families are uniformly distributed between [3, 8], setup time is uniformly distributed between [1, 16], processing time is uniformly distributed between [50, 80], and qual-run time is equivalent with the value of the processing time. The proposed algorithm and the basic differential evolution algorithm (DE) are carried out to solve the problem instances and the corresponding results are shown in Figs.4 and 5.

Fig.4 shows that MACDE outperforms DE on the convergence performance. When the number of iterations is from 90 to 120, the solutions of the two algorithms are both tend to be stable. Fig.5 displays that when the number of iterations grows to 200, the computation time increases precipitously. With a comprehensive of performance and computation time, it is reasonable to set the number of iterations be 100.

Fig.4 Number of iterations versus performance ratio for two algorithms

Fig.5 Number of iterations versus computation time for two algorithms

The other parameters are analyzed in the same manner with an extensive range of experiments that make use of varied values. The results demonstrate that the proper initial population size, the mutation probability, the crossover probability, the catastrophe frequency are 30, 0.3, 0.5, 10, respectively.

4.2 The Impact of Qual-run Constraints on Scheduling Performance

Set the number of families respectively be 15, 20, 25 and maintain the values of other input parameters. Qual-run time is uniformly distributed between [30, 50], [50, 70], [70, 90], [90, 110], [110, 130]. The experimental results are shown in Fig.6.

It is not hard to find from Fig.6 that qual-run time is closely related to performance ratio. Generally, qual-run time lasts so long that a prominent scheduling approach that makes a trade-off between the qual-run and setup times is more important, which is best explained by Fig.6.

Fig.6 Relationship between qual-run time and performance ratio

4.3 Comparisons Between Other Algorithms

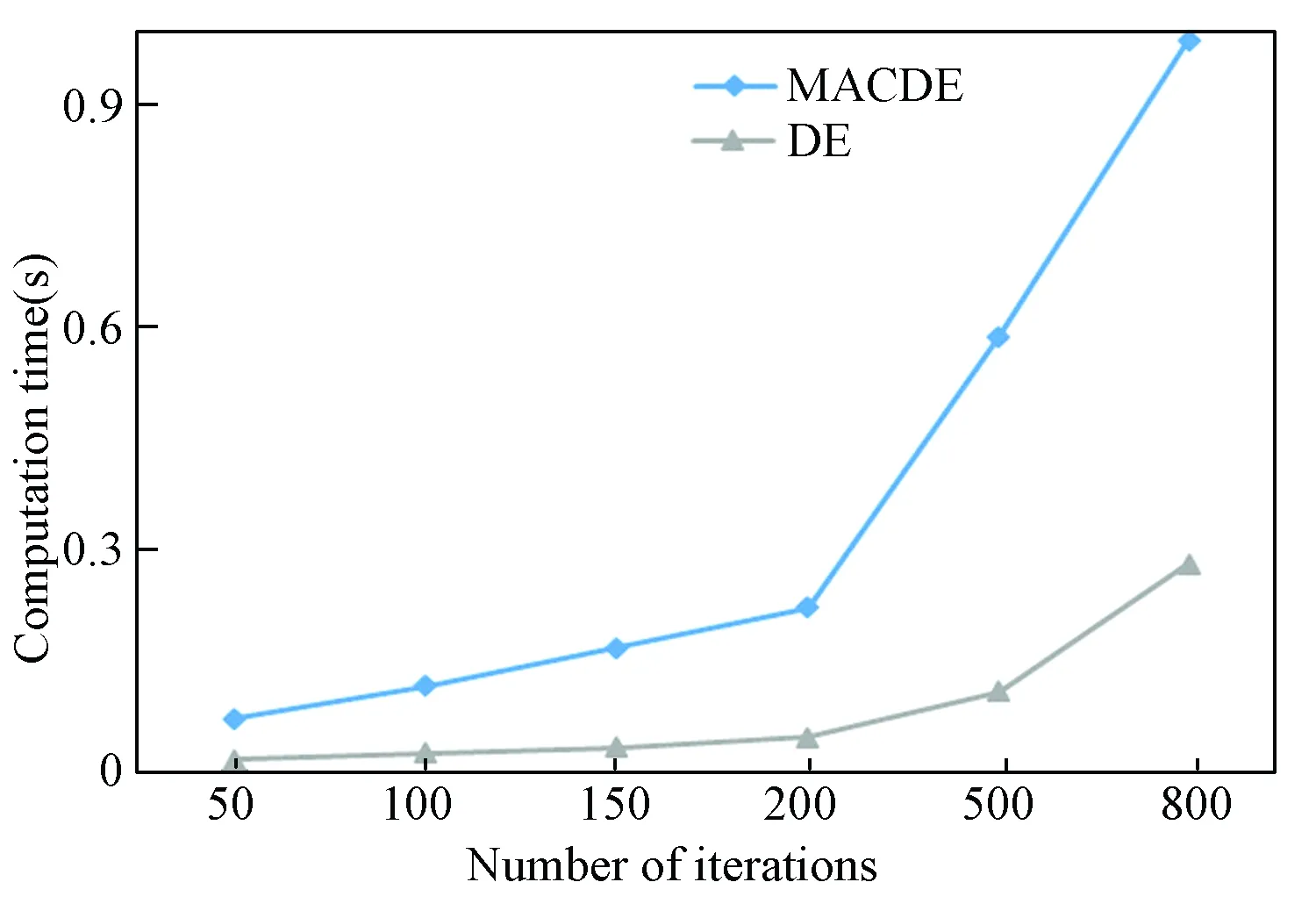

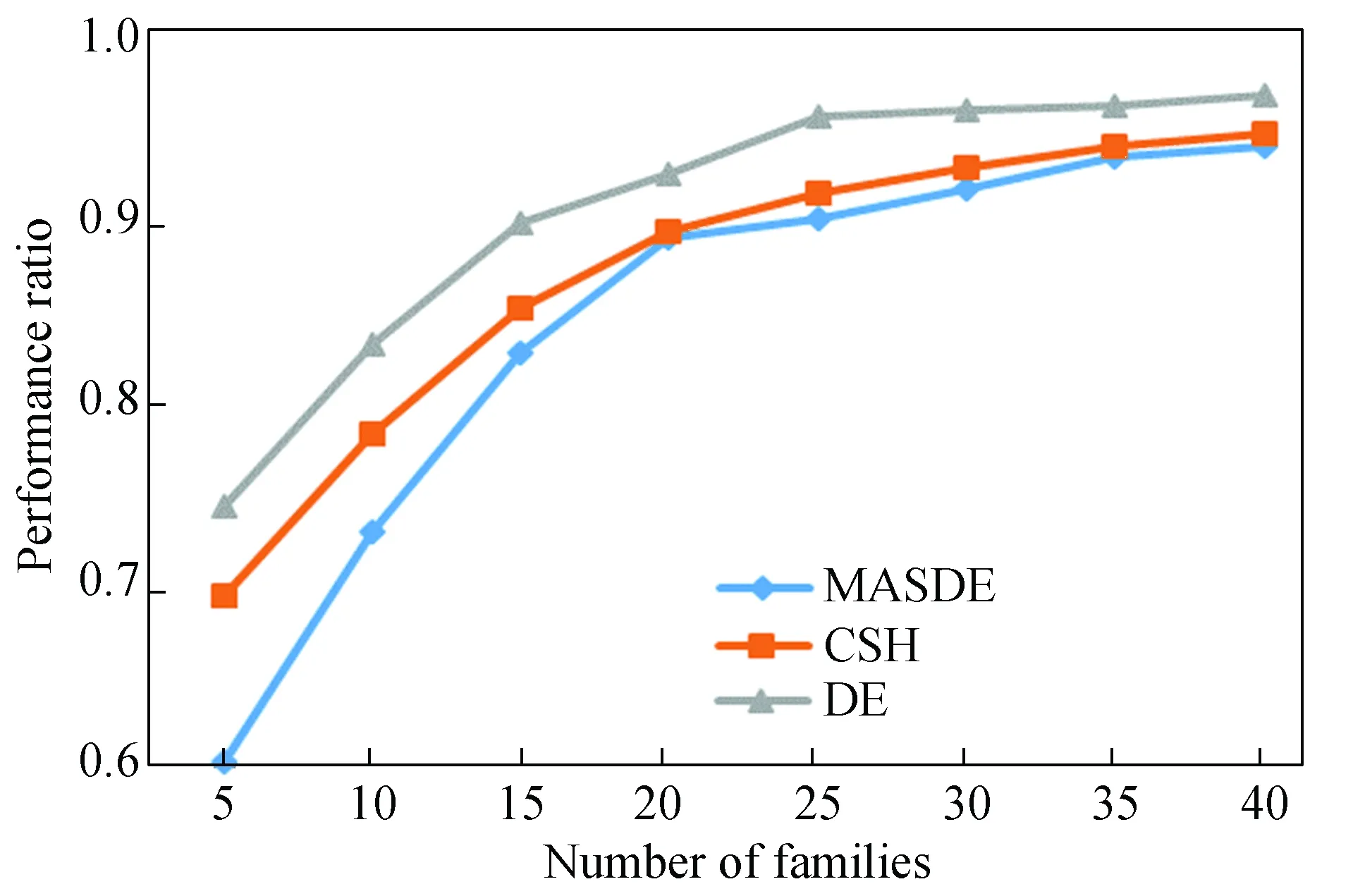

Due to the limitation of few studies considering qual-runs as well as setups, the structural heuristic algorithm (CSH) proposed by Cai et al.[10]is employed to serve as the benchmark for our problem under the same input parameters,and the comparative results are shown in Figs.7 and 8.

Fig.7 Comparisons on performance ratio between DE, MASDE and CSH

Fig.8 Comparisons on computation time between MACDE and Benchmark

Fig.7 displays that when the number of families is 15, MASDE has a distinct advantage over DE and CSH on the scheduling solution. With the number of families increasing, although the superiority is slipping, the competitive edge is still there. Similarly, as shown in Fig.8, when the number of families is less than 20, the mutation time of MASDE is much less than that of CSH. When the number of families grows to 40, the computation time is roughly equal, however, with the number of families increasing, the computation time remains to be less than 0.5 s within a reasonable range. With a comprehensive consideration of performance ratio and computation time, a conclusion can be drawn that MASDE undoubtedly outperforms others. The reason can be firstly explained by that CSH is complemented based on each property on its own, however the four presented properties are supposed to be dependent and interactive. Secondly, due to its incomplete back search, CSH fails to obtain the optimal solution. All these shortcomings are overcome in MASDE and its novel search method is manifested to be effective both theoretically and practically.

5 Conclusions

This paper studies a multi-family scheduling modeling of single machine at the backdrop of the semiconductor manufacturing system, considering qual-run constraints which are common in practical production and make a profound impact on machine utilization and production efficiency. An adaptive differential evolution based on catastrophe algorithm with depth neighborhood search is developed not only to resolve the problem but also to enrich the theoretical methods of the similar scheduling problem. Furthermore, the satisfying experimental results verify the validity and feasibility of the proposed algorithm. As future works, it is planned to develop the algorithm for optimizing problems in hybrid flow shops with more additional constraints, such as time constraints.

[1]Akcalt E, Nemoto K, Uzsoy R. Cycle-time improvements for photolithography process in semiconductor manufacturing. IEEE Transactions on Semiconductor Manufacturing, 2001, 14(1): 48-56. DOI: 10.1109/66.909654.

[2]Zhou Binghai, Pan Qingzhi, Wang Shijing, et al. Modeling of photolithography process in semiconductor wafer fabrication systems using extended hybrid Petri nets. Journal of Central South University of Technology, 2007, 14(3): 393-398. DOI: 10.1007/s11771-007-0077-1.

[3]Sun Xiaoqing, Noble J S. An approach to job shop scheduling with sequence-dependent setups. Journal of Manufacturing Systems, 1999, 18(6): 416-430. DOI: 10.1016/S0278-6125(00)87643-8.

[4]Allahverdi A, Ng C T, Cheng T C E, et al. A survey of scheduling problems with setup times or costs. European Journal of Operational Research, 2008, 187(3): 985-1032. DOI: 10.1016/j.ejor.2006.06.060.

[5]Chern C C, Liu Y L. Family-based scheduling rules of a sequence-dependent wafer fabrication system.IEEE Transactions on Semiconductor Manufacturing, 2003, 16(1): 15-25. DOI: 10.1109/TSM.2002.807742.

[6]Zheng R, Li H, Zhang X. Scheduling an unbounded batching machine with family jobs and setups times. The Journal of the Operational Research Society, 2012, 63(2): 160-167. DOI: 10.1057/jors.2010.187.

[7]Yugma C, Dauzère-Pérès S, Artigues C, et al. A batching and scheduling algorithm for the diffusion area in semiconductor manufacturing. International Journal of Production Research, 2012, 50 (8): 2118-2132. DOI: 10.1080/00207543.2011.575090.

[8]Rowshannahad M, Dauzere-Peres S, Cassini B. Capacitated qualification management in semiconductor manufacturing. Omega, 2015, 54: 50-59. DOI: 10.1016/j.omega.2015.01.012.

[9]Yugma C, Blue J, Dauzère-Pérès S, et al. Integration of scheduling and advanced process control in semiconductor manufacturing: review and outlook. Journal of Scheduling, 2015, 18(2): 195-205. DOI: 10.1007/s10951-014-0381-1.

[10]Cai Yiwei, Kutanoglu E, Hasenbein J, et al. Single-machine scheduling with advanced process control constraints. Journal of Scheduling, 2012, 15(2): 165-179. DOI: 10.1007/s10951-010-0215-8.

[11]Li Li, Qiao Fei. The impact of the qual-run requirement of APC on the scheduling performance in semiconductor manufacturing. Proceedings of the 2008 International Conference on Automation Science and Engineering. Piscataway: IEEE, 2008. 242-246. DOI: 10.1109/COASE.2008.4626542.

[12]Patel N S. Lot allocation and process control in semiconductor manufacturing-A dynamic game approach. Proceedings of the 43rd IEEE Conference on Decision and Control. Piscataway: IEEE, 2004. 4234-4248. DOI: 10.1109/CDC.2004.1429418.

[13]Peng Wuliang, Huang Min. A critical chain project scheduling method based on a differential evolution algorithm. International Journal of Production Research, 2014, 52(13): 3940-3949. DOI: 10.1080/00207543.2013.865091.

[14]Feng Xiaoqiang, He Tiejun. Fast matching pursuit for traffic images using differential evolution. Journal of Harbin Institute of Technology (New Series), 2010, 17(2): 193-198.

[15]Zhou Binghai, Hu Liman, Zhong Zhenyi. A hybrid differential evolution algorithm with estimation of distribution algorithm for reentrant hybrid flow shop scheduling problem. Neural Computing and Applications, 2016. 1-17.(Published online) DOI: 10.1007/s00521-016-2692-y.

[16]Onwubolu G, Davendra D. Scheduling flow shops using differential evolution algorithm. European Journal of Operational Research, 2006, 171(2): 674-692. DOI: 10.1016/j.ejor.2004.08.043.

[17]Wang Meng, Li Bixin, Wang Zhengshan, et al. An optimization strategy for evolution testing based on cataclysm. Proceedings of the 2010 IEEE 34th Annual Computer Software and Applications Conference Workshops. Piscataway: IEEE, 2010. 359-364. DOI: 10.1109/COMPSACW.2010.69.

[18]Dong Chaojun, Liu Zhiyong, Qiu Zulian. Catastrophe-particle swarm optimization algorithm and its application to traffic control. Computer Engineering and Applications, 2005, 41(29): 19-23. (in Chinese)

[19]Li Xiangtao, Yin Minghao. Modified differential evolution with self-adaptive parameters method. Journal of Combinatorial Optimization, 2016, 31(2): 546-576. DOI: 10.1007/s10878-014-9773-6.

[20]Elsayed S M, Sarker R A, Essam D L. An improved self-adaptive differential evolution algorithm for optimization problems. IEEE Transactions on Industrial Informatics, 2013, 9(1): 89-99. DOI: 10.1109/TII.2012.2198658.

[21]Zhou Binghai, Wang Teng. Scheduling multiple orders per job with various constraints for hybrid flow shop. Control and Decision, 2016, 31(5): 776-782. (in Chinese). DOI: 10.13195/j.kzyjc.2015.0399.

杂志排行

Journal of Harbin Institute of Technology(New Series)的其它文章

- Review:Application of the CALPHAD Approach and First-Principles Calculations to Electrode Materials in Li Ion Batteries

- Improved Ship Target Detection Accuracy in SAR Image Based on Modified CFAR Algorithm

- Modeling of Geometric Variations Within Three-Dimensional Tolerance Zones

- Comprehensive Assessment of Pilot Mental Workload in Various Levels

- Design and Testing of a Novel Passive Isolator for a Space Optical Payload

- Dynamic Analysis of Fractional-Order Memristive Chaotic System