盘吸式水稻排种器吸种动力学过程模拟及参数优化

2018-04-11田春杰吴亚芳黄贺东

赵 湛,田春杰,吴亚芳,黄贺东

盘吸式水稻排种器吸种动力学过程模拟及参数优化

赵 湛,田春杰,吴亚芳,黄贺东

(江苏大学农业工程研究院,镇江 212013)

准确控制盘吸式排种器的吸种位置是提高水稻育秧播种精度的关键因素,吸盘的吸种位置能够根据种盘内籽粒数量的变化进行自适应调节则是稳定排种器连续作业性能的重要保证。该文通过多球拟合建立了2种椭球体水稻籽粒模型,采用标准–湍流模型和Euler气固两相流模型进行计算流体动力学和离散元(CFD-DEM)耦合,完成了排种器的吸种动力学过程仿真。根据籽粒的空间分布特点,采用均匀分布模型和矩估计法计算了籽粒的空间分布范围和离散系数,获取了垂直往复振动激励下的籽粒离散运动状态和稳定特性,确定了理想的种层厚度范围。以能够有效吸附籽粒为条件,仿真获取了不同种层厚度下的临界吸种位置,分析了吸种距离的变化规律、籽粒形状对吸种性能的影响以及造成漏吸和重吸的原因。受到籽粒相互碰撞挤压等因素影响,CFD-DEM仿真获取的吸种距离小于静止状态下的籽粒吸附临界距离,考虑到实际振动种盘内种群运动的随机性更强,提出在仿真获取的临界吸种位置基础上,适当降低调节距离以提高吸盘的整体吸种性能。结合振动种盘内种层厚度的实时监测技术,以PLC为控制器设计了排种器吸种位置的自动控制装置,并在排种器性能试验台上以压差、吸种位置调节距离、种盘振动频率、种层厚度为因素进行正交试验,通过对吸种合格率的数学回归建模和优化得到:当吸孔直径为2.5 mm、种盘振幅为4.0 mm时,理想的压差为4.4 kPa、种盘振动频率为10.6 Hz、吸种位置调节距离为2.7 mm。根据优化结果进行吸种性能试验,当种层厚度在15~25 mm范围变化时,排种器的吸种合格率达到94.5%。研究结果可以为提高盘吸式排种器的自动化水平和连续作业性能提供借鉴。

机械化;优化;模型;育秧排种器;盘吸式;EDEM-CFD耦合;吸种位置;控制方法

0 引 言

育秧是水稻生产的重要环节,育秧质量的优劣直接影响着苗期品质、移栽后的生长和产量。随着水稻品种的改良、高产水稻种植的迅速推广,提出了每穴1~2粒精密育秧的农艺要求[1-2],现有的槽轮式、窝眼轮式、型孔式等排种器的播种精度和均匀性无法保证、伤种现象严重[3-5]。近年来,许多学者开展了气吸式排种器的研究工作[6-11],其主要优点是播种精度高、伤种率低和适应性强。盘吸式排种器是水稻育秧播种的重要装备,它主要由振动种盘和正负压吸盘组成[12-13],种盘通过振动使种群产生向上的抛掷运动而相互分离,以减少内摩擦力,根据育秧盘结构,在吸盘面板上加工多组吸孔,通过负压吸力将籽粒吸附在吸孔上,然后将吸盘移至育苗盘上方,进行正负压转换,籽粒在重力和正压气流场作用下落入育苗盘中。

目前,盘吸式排种器的研究包括结构优化设计、气流场分布规律、籽粒受力分析以及吸种性能试验等方面[12-17],结果表明:准确控制吸盘与离散种群的相对距离是提高吸种精度的重要因素,相对距离过大,籽粒不能进入吸种气流场中,漏吸率增加;相对距离过小又会造成重吸率的增加,种群还容易与吸盘发生急剧碰撞,造成籽粒损伤和吸孔堵塞。排种器作业时,振动种盘内的籽粒数量始终处于动态变化过程,即随着吸排种作业的进行,籽粒的数量连续减少,向种盘内添加种子后,籽粒的数量又迅速增加,这就需要对吸盘的吸种位置进行自动调节。因此,本文将振动种盘激励下的种群与负压气流场进行耦合仿真吸种动力学过程,分析水稻籽粒的离散运动特性、空间分布规律及排种器的吸种性能,提出吸种位置的控制方法,根据建立的吸种位置与种层厚度变化关系,在排种器试验台上进行了吸种性能试验和工作参数优化。

1 CFD-DEM耦合方法

CFD-DEM耦合是在每个时间步长中首先通过CFD对流场进行计算,获得颗粒所在网格单元内的流体条件,采用曳力模型计算出每个颗粒所受流体作用力,然后根据DEM计算出颗粒的运动过程,并以动量汇的形式更新CFD中的颗粒位置、速度等信息,进行下一步迭代计算,这一方法在农业物料的混合、筛分清选等研究领域运用较多[18-23],针对气吸式排种器吸种运动的研究报道较少。气固耦合方法是CFD-DEM计算的核心,它主要包括Lagrangian和Euler 2种模型[24-25],其中Lagrangian模型适用于分析单相或稀相固体颗粒的运动,考虑到吸种过程中,籽粒密集分散在吸种口附近,会与气流场会产场复杂的交互作用,故本文选用Euler耦合模型。

根据颗粒对流场的影响,Euler模型中引入了体积分数项,由于籽粒不会做高加速度或高速旋转运动,气流对颗粒的影响主要体现为曳力,可以通过计算曳力的动量汇进行气固两相的耦合,除了能够计算流体相和固相之间的动量交换,还能够分析固体颗粒对流体相的影响。由于吸孔附近气流雷诺数>>4 000,处于高雷诺数的紊流状态,因此采用Navier-Stokes方程和标准-湍流方程构成的封闭方程组计算气流场,颗粒阻力系数取值为0.44,壁面使用无滑移条件,通过壁面函数修正法计算距离壁面位置的气流速度、湍动能和耗散率。

吸种过程中,籽粒在振动种盘中处于离散状态,采用EDEM软件仿真籽粒的运动特性,籽粒与籽粒、籽粒与种盘之间通过Hertz-Mindlin无滑动模型计算碰撞接触力,该模型在水稻籽粒的筛分、输送等方面有成功的应用[26-30]。

2 吸种过程仿真

2.1 籽粒模型

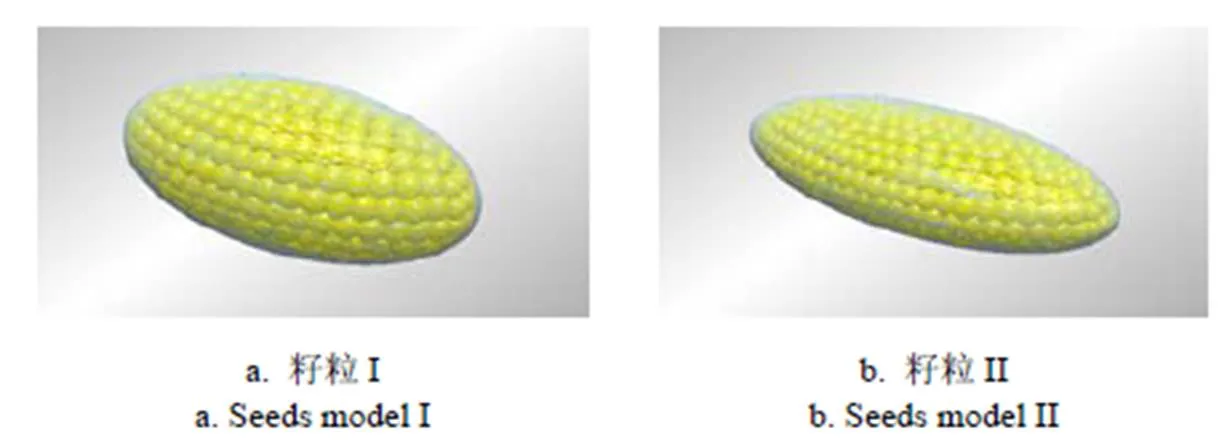

水稻籽粒通常为椭球体颗粒,不同品种的形状存在一定差异,为了分析籽粒形状对吸种过程的影响,本文采用多球拟合法建立了2种水稻籽粒模型,如图1所示,籽粒I和II的三轴尺寸分别为2.85 mm × 1.55 mm × 1.35 mm和3.75 mm × 1.60 mm × 1.05 mm,设定力学参数[31-33]:密度为1 150 kg/m3、剪切模量为23 MPa、泊松比为0.25、恢复系数为0.42、静摩擦系数为0.56、滚动摩擦系数为0.05、千粒质量分别为26.5和28.2 g;排种器的种盘和吸盘材料均选用7075铝合金,密度为2 800 kg/m3、剪切模量为72 000 MPa、泊松比为0.33;籽粒与铝合金的碰撞恢复系数为0.48、静摩擦系数为0.35、滚动摩擦系数为0.02。

图1 水稻籽粒模型

2.2 吸种过程

实际使用的吸盘面板为矩形结构,长宽尺寸为610 mm × 280 mm,为了与448穴钵体毯状育秧盘相匹配,在吸盘面板上加工了32×14正方形排列的圆形吸孔,吸孔直径2.5 mm,中心距为19 mm。由于种盘和吸盘均为平板结构,籽粒在垂直往复振动激励下具有相似的离散运动特性,因此,为了提高计算效率,仿真建立了缩小的矩形吸盘模型,长宽尺寸为140 mm × 80 mm,设计了7×4的圆形吸孔。

CFD-DEM仿真过程中,首先建立吸种气流场的三维流道模型,然后进行非结构网格划分,由于吸孔尺寸远小于吸盘尺寸,且在吸孔附近的气流速、压强等变化显著,因而在此区域进行了局部网格加密,提高计算精度。以吸盘顶面为气流出口面,以吸盘面板向外延伸50 mm作为气流入口面,设定入口面为标准大气压力1,出口面为恒定压力2,压差为Δ=1–2。采用Fluent软件中的Simple压力速度耦合方法进行气流场计算。在EDEM中建立种盘模型,尺寸为170 mm × 100 mm,种盘作垂直往复振动,根据前期性能试验结果[12],设定振动频率为11 Hz、振幅为4 mm,通过控制生成籽粒数量使种盘内的种层厚度在10~35 mm范围内变化,计算时间步长为4×10–6s,约为Rayleigh时间的20%。

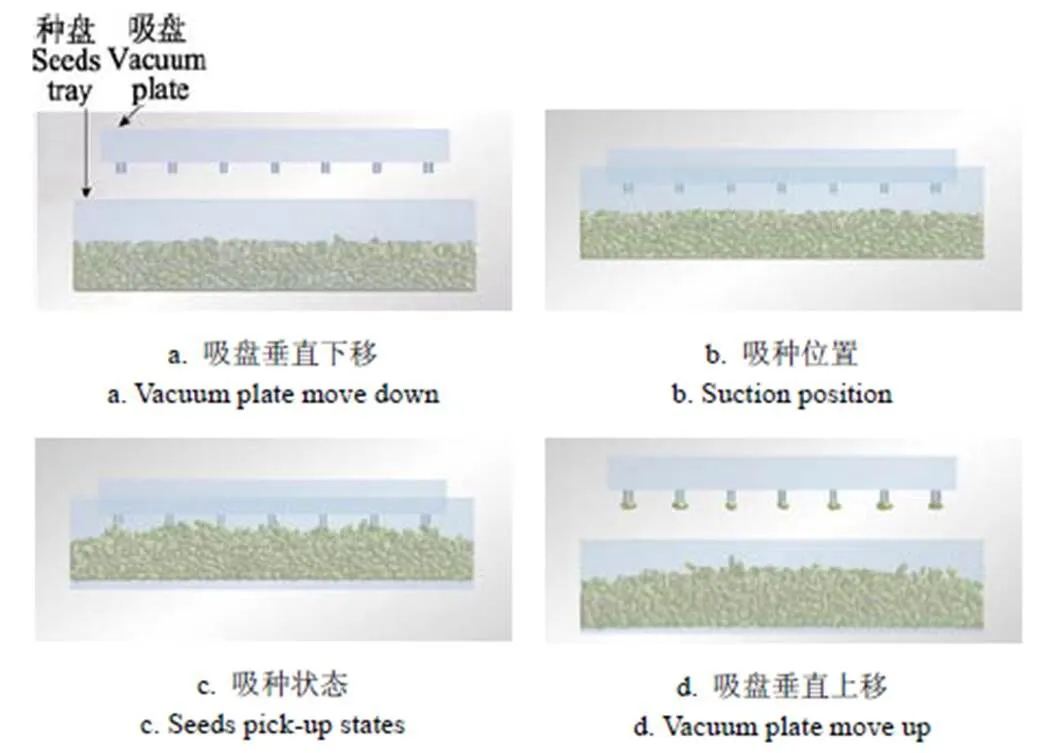

当吸孔直径为2.5 mm、压差Δ为5 kPa、种层厚度为20 mm时的吸种仿真过程如图2所示:首先,给吸盘施加压差,迭代运算收敛后建立吸种气流场,同时在振动种盘内生成籽粒(时间为0.5 s),种盘振动5 s后种群达到近似周期运动状态,如图2a所示;此时,吸盘以0.04 m/s的垂直速度向种盘运动,到达设定位置后保持静止一定时间进行吸种,如图2b所示;在振动激励下,种群与吸孔的距离会随着种盘位移作周期变化,受到的气流场吸力也随之变化,当吸力大于重力时,籽粒被吸附于吸孔,如图2c所示;然后吸盘以0.04 m/s的垂直速度上移,完成整个吸种过程,如图2d所示。

图2 CFD-DEM吸种仿真过程

定义吸盘保持静止吸种状态的时间为吸种时间,吸盘面板与种盘振动中心的垂直位移为吸种位置。

3 仿真结果与分析

籽粒能够进入有效负压气流场中是实现吸种的根本条件,根据仿真过程可知,吸种总是在种群被抛掷到高点的瞬间完成,且被吸附的是处于种群上层的籽粒,因此,籽粒在振动种盘内的离散运动特性和空间分布规律是决定吸盘吸种位置和性能的重要参数。

3.1 籽粒离散运动特性

为了描述籽粒的离散运动特性,定义种层厚度、质心垂直位移0和离散系数v分别为

式中为籽粒数量;z为第个籽粒的垂直位移,m;V为第个籽粒的体积,m3;p为种盘底面积,m2;为籽粒容积率,测量获得2种籽粒模型在自然堆积下的取值范围为0.6 ~0.65;()为时刻籽粒的空间分布范围,它是随种盘振动的时间变量。

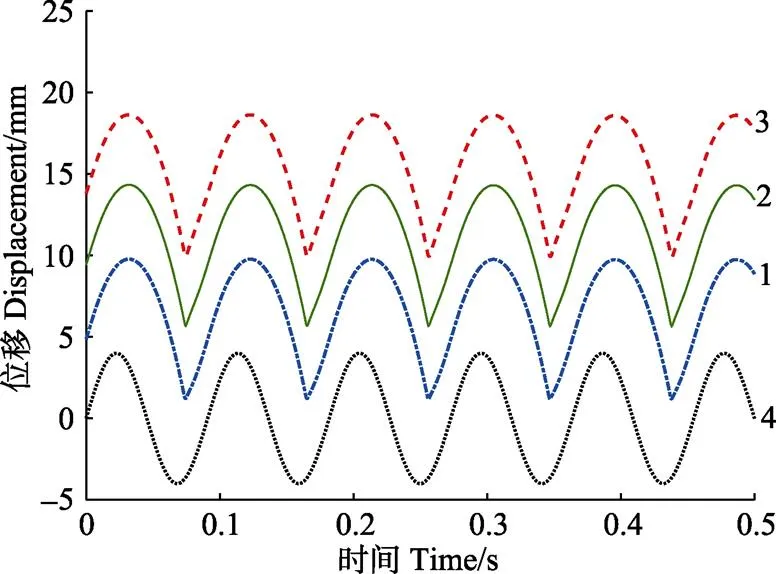

当种层厚度分别为10、20、30 mm时,质心垂直位移0的变化如图3所示。由于种盘的振动强度v=∙2/g大于1,种群会被抛离种盘底板,并发生周期碰撞,0呈现与种盘同频率的近似周期运动,幅值约为5 mm,略大于种盘振幅。

1. 种层厚度为10 mm 2. 种层厚度为20 mm 3. 种层厚度为30 mm 4. 种盘位移

1. Seeds thickness is 10 mm 2. Seeds thickness is 20 mm 3. Seeds thickness is 30 mm 4. Seeds tray displacement

注:振动频率为11 Hz;振幅为4 mm。

Note: Vibrational frequency is 11 Hz, and amplitude is 4 mm.

图3 种群质心垂直位移与种盘位移变化规律

Fig.3 Variation of vertical displacement of seeds mass center and tray displacement

分析不同时刻籽粒的空间分布特点发现,它呈现以0为中心的[–,]均匀分布规律。本文首先采用矩估计法计算时刻的参数,然后计算籽粒的空间分布范围= 2和离散系数v,并取10个稳定振动周期的v,计算出其均值v和标准差E。v越大表明籽粒离散程度约高,E越小表明离散状态的稳定性越好,v和E的变化如图4所示。

种层厚度在10~30mm范围内,v随的增加而迅速降低,当大于30 mm时,v缓慢下降至约1.5,籽粒接近于密集堆积状态,说明随着种层厚度的增加,通过振动使籽粒相互离散越来越困难,籽粒间的挤压、碰撞、摩擦作用力加剧,这会增加吸种难度;在10~15 mm范围内,E随增加而迅速降低,说明种层厚度较小时,籽粒空间分布不均匀,离散状态的稳定性差。适当的离散程度和稳定的离散状态有利于提高吸种性能[12,34],因此,15~25 mm应该是理想的种层厚度范围。根据质心垂直位移0和离散系数均值v,可以得到种群在抛掷高点时的上层籽粒平面坐标p为

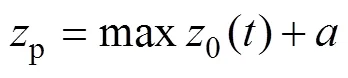

3.2 吸种位置

确定吸盘的吸种位置就是合理控制吸孔与上层籽粒平面p的距离,即吸种距离,=–p。仿真过程中,以0.5 mm为步长逐步降低吸盘位置,以所有吸孔都能够精确吸附籽粒为判断条件,得到临界吸种位置0。当吸孔直径为2.5 mm、压差Δ为5 kPa、吸种时间为2 s,临界吸种位置0随种层厚度的变化曲线如图5所示。

注:吸孔直径为25 mm,压差为5 kPa,吸种时间为2 s。

由图5可知,随着种层厚度的增加,上层籽粒平面坐标p随之增大,相应的临界吸种位置0也随之增大。由于籽粒离散系数v随的增加而减小,使得0的增速逐步减缓;根据2.1节建立的2种籽粒模型的0存在微小差异,这主要受到千粒质量、几何形状等物理特性的影响。由于籽粒在水平姿态下的迎风面积和所受气流吸力最大[35],籽粒被吸附后以水平姿态为主;增加吸孔直径和压差Δ均能够增大籽粒受到的气流场吸力,但由于籽粒受力与吸种距离的平方呈反比例关系,导致在2~2.5 mm、Δ在3~5 kPa范围,0的变化小于1 mm。

当吸种位置大于0时,籽粒不能进入有效的吸种气流场,当为2.5 mm、Δ为4 kPa、比0增加1 mm时,仿真结果发现,籽粒的漏吸率显著增加;当吸种位置小于0时,则会造成重吸率的增加,即1个吸孔吸附多个籽粒,种群还会与吸盘面板发生碰撞,容易造成籽粒损伤和吸孔堵塞。泄漏气流场是造成重吸的重要因素,籽粒的椭圆率越小,形状越接近于球体,被吸附后与吸孔的间隙越小,可以降低泄漏的气流场影响,有利于提高单粒吸种率,反之,随着籽粒椭球率的增大,重吸率也随之增加。当比0减小2 mm时,籽粒I可以实现单粒精确吸种,而籽粒II则出现了重吸情况。

计算图5获取的临界吸种位置0和上层籽粒平面坐标Z仿真结果,可以看出随着种层厚度的变化,吸种距离也存在一定差异:当为10 mm时,约为2.5 mm,这是由于种层厚度较小,籽粒空间分布密度低、运动随机性强,需要减小,以增加籽粒进入负压气流场的机率;当为15~25 mm时,籽粒运动稳定、离散均匀,有利于精确吸附,也随之增加到约3.5~4.0 mm;当大于30 mm时,籽粒离散困难,相互作用力增加,吸种所需要的吸力随之增大,造成又降低到约2.0~3.0 mm。但总体而言,通过CFD-DEM耦合仿真获取的吸种距离均小于文献[35]给出的静止状态下的籽粒吸附临界距离,这主要时由籽粒的运动特性所决定。籽粒振动运动过程中,上层籽粒不可能处于相同的姿态和水平位置,受到气流场的吸力存在差异,籽粒之间还存在相互的碰撞挤压,这些因素增加了吸种的不确定性和难度。要使每个吸孔都能够有效吸附籽粒,需要适当减小吸种距离,以提高整体吸种性能。

仿真过程中也发现,精确吸种、漏吸和重吸所对应的吸种位置会在一个小范围内波动,并且考虑到实际种盘要大于仿真种盘模型,种群运动受到的干扰和随机性也会随着种盘尺寸的增大而增加,因此,实际排种器的吸种位置应小于仿真获取的临界吸种位置0,定义两者的距离为吸种位置调节距离H,H的取值需要通过试验进行优化。

综上分析可知,准确控制吸种位置是提高盘吸式排种器吸种精度的关键因素,需要根据种盘内籽粒数量的变化进行调节,从而稳定排种器的连续作业性能。

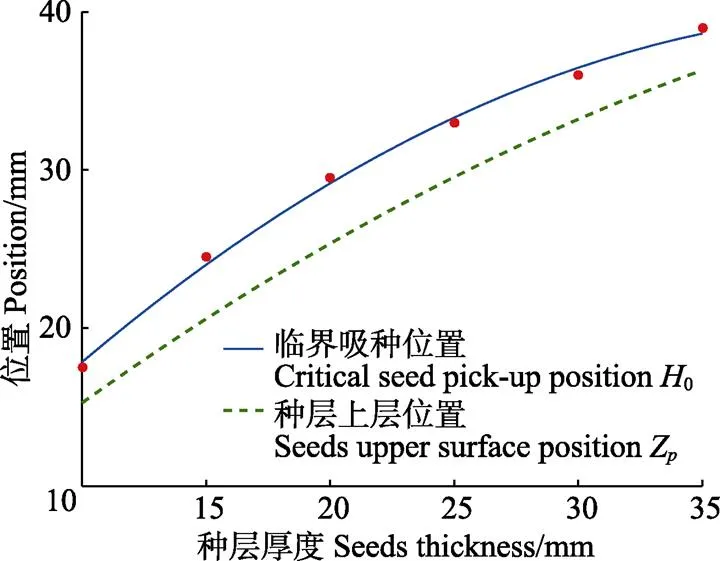

4 吸种性能试验优化

为了验证仿真临界吸种位置的合理性、分析实际工作环境对吸种位置的影响、进一步优化作业参数,在自行研制的盘吸式水稻育秧排种器试验台上进行吸种性能试验,试验台由种盘、吸盘、风机、压力表、电磁换向阀组、控制系统和机架等组成,如图6所示。它由风机提供气压源,由PLC控制电磁换向阀的通断组合实现吸盘内腔正负气流场的转换,通过变频器调节风机转速以改变风压大小,压差通过压力表测量。电机通过曲轴连杆机构驱动种盘沿垂直方向作直线往复运动,矩形吸盘安装于“十”字交叉滑台模组,可以实现水平和垂直运动。吸种时,吸盘以0.04 m/s的匀速从种盘上方20 cm位置垂直向下运动,通过PLC调节吸盘运动时间,实现吸种位置的控制,时间控制精度为0.01 s,的控制误差小于0.6 mm。课题组采用悬臂梁称质量传感器测量种盘内种群的冲击力,已经实现了振动状态下种群质量(种层厚度)的实时监测,测量结果通过PLC采集,误差小于4.0%[33,36]。

1. 风机 2. PLC 3. 种盘 4. “十”字滑台 5. 压力表 6. 吸盘

1. Fan 2. PLC 3. Tray 4. Cross sliding table 5. Pressure gauge

6. Suction plate

图6 盘吸式水稻排种器试验台

Fig.6 Precision seeder test-rig using vacuum rectangular plate for rice seedling

采用“常优”超级稻进行吸种性能试验,将籽粒近似拟合为椭球体,测量获得其三轴尺寸的统计值为3.45 mm × 1.58 mm × 1.15 mm,千粒质量为27 g,吸孔直径为2.5 mm、种盘振幅为4 mm。根据水稻排种器作业参数范围,设定压差和种盘振动频率分别为3~4 kPa和10~12 Hz。随着吸排种作业的进行,振动种盘内的籽粒数量总是处于动态变化过程,根据籽粒离散运动特性分析结果,选择种层厚度的范围为15~25 mm。在PLC中建立图5所示的临界吸种位置0随种层厚度的变化模型,计算不同种层厚度下的吸盘的临界吸种位置0,考虑到实际吸种作业的干扰性和随机性,吸盘的实际吸种位置在临界吸种位置0的基础上,向种盘方向微调一定距离H,即=0–H。

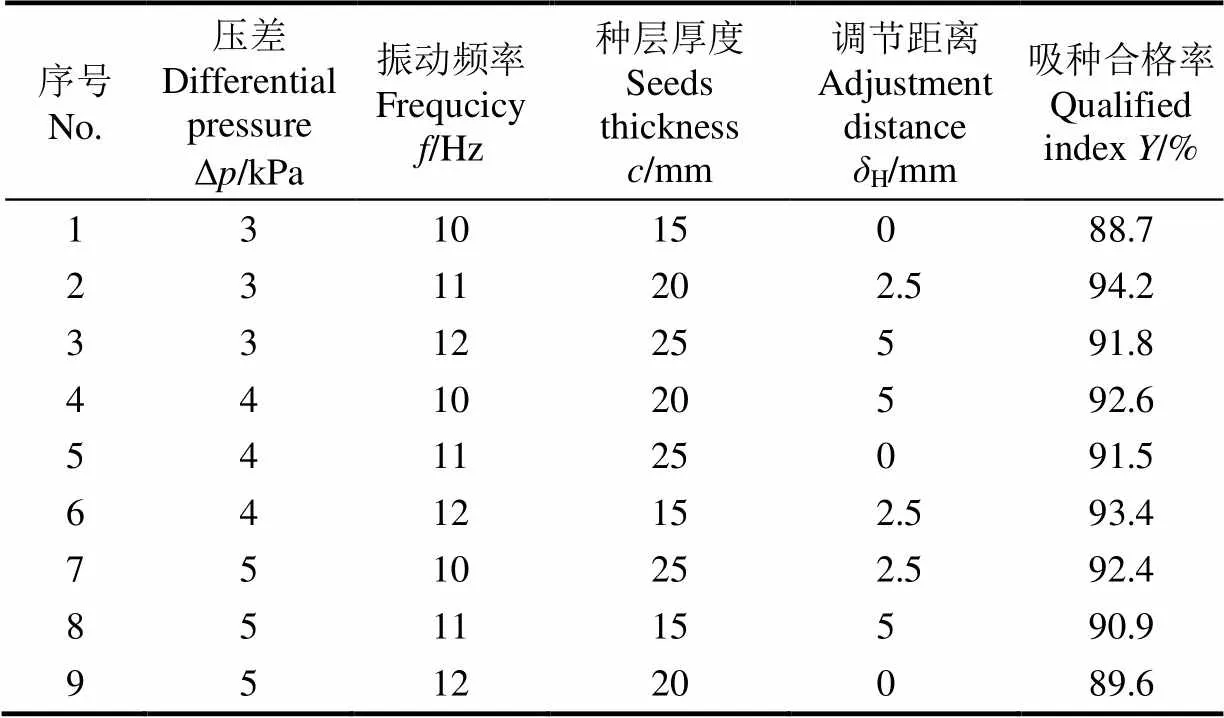

为了避免吸盘在吸种位置时,籽粒与吸盘面板发生急剧碰撞而造成籽粒损伤,调节距离H的范围设定为0~5 mm。排种器可以实现在PLC的控制下,根据实时监测的种层厚度自动调节吸种位置。因此,选择压差Δ、种盘振动频率、种层厚度和吸种位置调节距离H为因素,根据高产水稻每穴1~2粒精密育秧的农艺要求,以每个吸孔吸附1~2个粒子为合格,进行四因素三水平正交试验,吸种时间为5 s,试验结果如表1所示。吸种合格率=/´100%,其中和分别为实验过程中总的吸孔数量和吸附2~3个籽粒时的吸孔数量。

表1 正交试验设计与结果

根据试验结果,采用DPS建立吸种合格率的二次多项式回归方程为

= 45.30+22.36Δ+6.727H−2.414Δ2−0.356 0H2

−0.071 7Δ+0.008 4−0.484 2H(5)

经检验,方程的值小于0.01、值大于6 400、决定系数2大于0.999 8,表明模型显著、拟合度高。根据建立的回归方程,DPS优化获得压差Δ为4.4 kPa、频率为10.6 Hz、吸种位置调节距离H为2.7 mm时吸种合格率最高。从回归方程可以看出,压差和吸种位置调节距离是影响吸种合格率的主要因素,由于排种器作业过程中,压差和种盘振动频率通常设定为优化的作业参数,不需要进行实时调整,吸盘的吸种位置主要取决于图5建立的临界吸种位置0模型和试验优化的吸种位置调节距离H。根据优化结果进行吸种性能试验,种层厚度在15~25 mm范围变化时,通过自动调节吸种位置,排种器的吸种合格率可以达到94.5%。

5 结 论

1)采用CFD-DEM耦合实现了盘吸式排种器水稻籽粒吸种过程仿真,得到种层厚度在15~25 mm范围时的籽粒离散运动状态稳定,籽粒分布空间随着种层厚度的增加而增大,吸盘的临界吸种位置也随之增大,但增速逐步减缓。

2)准确控制吸种位置是提高吸种精度的关键因素,当吸种位置大于临界吸种位置时,籽粒不能进入有效吸种气流场,会导致漏吸率增加,当吸种位置小于临界吸种位置时,则会造成重吸率的增加,且籽粒的椭球率越大,泄漏气流场造成籽粒重吸现象越显著。

3)受到籽粒离散运动的随机性、相互碰撞挤压等因素影响,CFD-DEM仿真获取的吸种距离小于静止状态下的籽粒吸附临界距离;实际排种器种盘内种群运动受到的干扰和随机性更强,可以通过适当降低吸盘的吸种位置,以提高整体吸种性能。

4)在排种器试验台进行吸种性能正交试验,通过吸种合格率的数学回归建模和优化得到:吸孔直径为2.5 mm、种盘振幅为4 mm时,理想的压差为4.4 kPa、种盘振动频率为10.6 Hz、吸种位置调节距离为2.7 mm。当种层厚度在15~25 mm范围时,排种器的吸种合格率达到94.5%。

[1] 孙涛,商文楠,曹海峰,等.同播种粒数对水稻生育及其产量的影响[J].中国农学通报,2005,21(7):134-137. Sun Tao, Shang Wennan, Cao Haifeng, et al. Effects of different seeding quantity on rice growing and yield[J]. Chinese Agricultural Science Bulletin, 2005, 21(7): 134-137. (in Chinese with English abstract)

[2] Jiang Xinlu, Li Xuyi, Chi Zhongzhi, et al. Research on potted-tray grown rice seedling transplanting by machine[J]. Agricultural Science & Technology, 2014, 15(11): 1923-1927.

[3] 俞亚新,赵匀,张斌.水稻精密播种器的研究现状与展望[J].农机化研究,2007(9):5-8. Yu Yaxin, Zhao Yun, Zhang Bin. Review for the research of the rice precision seeder[J]. Journal of Agricultural Mechanization Research, 2007(9): 5-8. (in Chinese with English abstract)

[4] 周海波,马旭,姚亚利.水稻秧盘育秧播种技术与装备的研究现状及发展趋势[J].农业工程学报,2008,24(4):301-306. Zhou Haibo, Ma Xu, Yao Yali. Research advances and prospects in the seeding technology and equipment for tray nursing seedlings of rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(4): 301-306. (in Chinese with English abstract)

[5] 许剑平,谢宇峰,徐涛.国内外播种机械的技术现状及发展趋势[J].农机化研究,2011,33(2):234-237. Xu Jianping, Xie Yufeng, Xu Tao. The present technic status and developing tendency of the domestic and abroad drill[J]. Journal of Agricultural Mechanization Research, 2011, 33 (2): 234-237. (in Chinese with English abstract)

[6] Karayel D. Performance of a modified precision vacuum seeder for no-till sowing of maize and soybean[J]. Soil & Tillage Research, 2009, 104(1): 121-125.

[7] Yazgi A, Degirmencioglu A. Optimisation of the seed spacing uniformity performance of a vacuum-type precision seeder using response surface methodology[J]. Biosystems Engineering, 2007, 97 (3): 347-356.

[8] 翟建波,夏俊芳,周勇.气力式杂交稻精量穴直播排种器设计与试验[J].农业机械学报,2016,47(1):75-82. Zhai Jianbo, Xia Junfang, Zhou Yong. Design and experiment of pneumatic precision hill-drop drilling seed metering device for hybrid rice[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(1): 75-82. (in Chinese with English abstract)

[9] Movahedi E, Rrzvani M, Hemmat A. Design, development and evaluation of a pneumatic seeder for automatic planting of seeds in cellular trays[J]. Journal of Agricultural Machinery,2014,4 (1): 65-72.

[10] Rathinakumari A C, Kumaran G S, Mandhar S C. Design and development of tray type vacuum seeder and tray type[J]. Applied Horticulture, 2005, 7 (1): 49-51.

[11] 张顺,夏俊芳,周勇,等.气力滚筒式水稻直播精量排种器排种性能分析与田间试验[J].农业工程学报,2017,33(3):14-23. Zhang Shun, Xia Junfang, Zhou Yong, et al.Field experiment and seeding performance analysis of pneumatic cylinder-type precision direct seed-metering device for rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(3): 14-23. (in Chinese with English abstract)

[12] 陈进,龚智强,李耀明,等.超级稻穴盘育苗精密播种装置研究[J].农业机械学报,2015,46(1):73-78. Chen Jin, Gong Zhiqiang, Li Yaoming, et al.Experimental study on nursing seedlings of super rice precision seeder device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(1): 73-78. (in Chinese with English abstract)

[13] 刘彩玲,宋建农,王继承,等.吸盘式精密播种装置气力吸种部件流场仿真分析[J].中国农业大学学报,2010,15(1):116-120. Liu Cailing,Song Jiannong, Wang Jicheng,et al. Analysis of flow field simulation on vacuum seed-metering components of precision metering device with sucker[J]. Journal of China Agricultural University, 2010, 15(1): 116-120. (in Chinese with English abstract)

[14] 张敏,吴崇友,张文毅.吸盘式水稻育秧播种器吸孔气流场仿真分析[J].农业工程学报,2011,27(7):162-167. Zhang Min, Wu Chongyou, Zhang Wenyi. Airflow field simulation on suction nozzle of cupule-type disseminator for rice seedling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 162-167. (in Chinese with English abstract)

[15] 王朝辉,马旭,贾瑞昌.工作参数对超级稻育秧播种部件吸种性能的影响[J].农业工程学报,2009,25(8):88-92. Wang Zhaohui, Ma Xu, Jia Ruichang. Effects of working parameters on seed suction performance of seeder device for super hybrid rice seeds[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(8): 88-92. (in Chinese with English abstract)

[16] Guarella P, Pellerano A, Psscuzzi S. Experimental and theoretical performance of a vacuum seeder nozzle for vegetable seeds[J]. Journal of Agricultural Engineering Research, 1996, 64(1): 29-36.

[17] Gaikwad B B, Sirohi N P S.Design of a low-cost pneumatic seeder for nursery plug trays[J]. Biosystems Engineering, 2008, 99(3): 322-329.

[18] 蒋恩臣,孙占峰,潘志洋,等.基于CFD-DEM的收获机分离室内谷物运动模拟与试验[J].农业机械学报,2014,45(5):73-78. Jiang Enchen, Sun Zhanfeng, Pan Zhiyang, et al. Numerical simulation based on CFD-DEM and experiment of grain moving laws in inertia separation chamber[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(5): 73-78. (in Chinese with English abstract)

[19] 刘立意,郝世杨,张萌,等.基于CFD-DEM的稻谷通风阻力数值模拟与试验[J].农业机械学报,2015,46(8):27-33. Liu Liyi, Hao Shiyang, Zhang Meng, et al. Numerical simulation and experiment on paddy ventilation resistance based on CFD-DEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(8): 27-33. (in Chinese with English abstract)

[20] Lei X L, Liao Y T, Liao Q X. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat[J].Computers and Electronics in Agriculture, 2016, 131: 29-39.

[21] Fries L, Antonyuk S, Heinrich S, et al. DEM-CFD modeling of a fluidized bed spray granulator [J]. Chemical Engineering Science, 2011, 66(11): 2340-2355.

[22] Xiana R F, Hermann N. Simulation of particles and sediment behaviour in centrifugal field by coupling CFD and DEM[J]. Chemical Engineering Science, 2013, 94(3): 7-19.

[23] 韩丹丹,张东兴,杨丽,等.内充气吹式玉米排种器工作性能EDEM-CFD模拟与试验[J]. 农业工程学报,2017,33(13):23-31. Han Dandan, Zhang Dongxing, Yang Li, et al.EDEM-CFD simulation and experiment of working performance of inside-filling air-blowing seed metering device in maize[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(13): 23-31. (in Chinese with English abstract)

[24] Kafui D K, Johnson S, Thornton C, et al. Parallelization of a Lagrangian–Eulerian DEM/CFD code for application to fluidized beds[J]. Powder Technology, 2011, 207(1–3): 270-278.

[25] 孙晨,陈凌珊,汤晨旭. 气固两相流模型在流场分析中的研究进展[J]. 上海工程技术大学学报,2011,25(1):49-53. Sun Chen, Chen Lingshan, Tang Chenxu. Study and development of gas-solid two-phase flow model in flow field analysis[J]. Journal of Shanghai University of Engineering Science, 2011, 25(1): 49-53. (in Chinese with English abstract)

[26] Li Hongchang, Li Yaoming, Gao Fang, et al. CFD-DEM simulation of material motion in air-and-screen cleaning device[J]. Computers and Electronics in Agriculture, 2012, 88: 111-119.

[27] Tijskens E, Ramon H, Baerdemaeker De J. Discrete element modelling for process simulation in agriculture[J].Journal of Sound and Vibration, 2003, 266: 493-514.

[28] 马征,李耀明,徐立章.农业工程领域颗粒运动研究综述[J].农业机械学报,2013,44(2):22-29. Ma Zheng, Li Yaoming, Xu Lizhang. Summarize of particle movements research in agricultural engineering realm[J].Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(2): 22-29. (in Chinese with English abstract)

[29] 刘月琴,赵满全,刘飞,等.基于离散元的气吸式排种器工作参数仿真优化[J].农业机械学报,2016,47(7):65-73. Liu Yueqin, Zhao Manquan, Liu Fei, et al. Simulation and optimization of working parameters of air suction metering device based on discrete element[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(7): 65-73. (in Chinese with English abstract)

[30] 贾富国,姚丽娜,韩燕龙,等.基于离散元法的糙米匀料盘仿真优化设计[J].农业工程学报,2016,32(4):235-241. Jia Fuguo, Yao Lina, Han Yanlong, et al. Simulation and optimal design of uniform plate of brown rice based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(4): 235-241. (in Chinese with English abstract)

[31] 徐立章,李耀明. 水稻谷粒冲击损伤临界速度分析[J].农业机械学报,2009,40(8):54-57. Xu Lizhang, Li Yaoming. Critical speed of impact damage on a rice kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(8): 54-57. (in Chinese with English abstract)

[32] Varnamkhasti M G, Mobli H, Jafari A, et al. Some physical properties of rough rice grain[J]. Journal of Cereal Science, 2008, 47(3): 496-501.

[33] Zhao Zhan, Wu Yafang, Yin Jianjun, et al. Monitoring method of rice seeds mass in vibrating tray for vacuum-panel precision seeder[J]. Computers and Electronics in Agriculture, 2015, 114: 25-31.

[34] 李耀明,赵湛,陈进,等.气吸振动式排种器种盘内种群运动的离散元分析[J].农业机械学报,2009,40(3):56-59. Li Yaoming, Zhao Zhan, Chen Jin, et al. Discrete element method simulation of seeds motion in vibrated bed of precision vacuum seeder [J].Transactions of the Chinese Society for Agricultural Machinery, 2009, 40(3): 56-59.(in Chinese with English abstract)

[35] 龚智强,陈进,李耀明,等.吸盘式精密排种装置吸种过程气流场中种子受力研究[J].农业机械学报,2014,45(6):92-97. Gong Zhiqiang, Chen Jin, Li Yaoming, et al. Seed force in airflow field of vacuum tray precision seeder device during suction process of seeds [J].Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(6): 92-97. (in Chinese with English abstract)

[36] 周洪如,吴亚芳,李洪昌,等.排种器振动种盘内种群质量实时监测方法[J].农机化研究,2017,39(12):20-25. Zhou Hongru, Wu Yafang, Li Hongchang, et al. Real-time monitoring method of seeds mass in reciprocating vibration rray [J].Journal of Agricultural Mechanization Research, 2017, 39(12): 20-25.(in Chinese with English abstract)

Dynamic simulation of seed pick-up process and parameter optimization on vacuum plate seeder for rice

Zhao Zhan, Tian Chunjie, Wu Yafang, Huang Hedong

(212013,)

The key factor to improve seeds pick-up accuracy of vacuum plate seeder is to control the suction position accurately. During the working progress, the number of seeds in vibrating tray is always changing. So, it is an important guarantee for improving the continuous working performance of seeder that the suction position of vacuum plate can be adjusted automatically according to the variation of seeds in vibrating tray. In the paper, 2 different ellipsoid paddy seeds models were established using multi-sphere fitting method, and the contact forces were calculated using Hertz-Mindlin model. Then, the kinetics simulations of seeds pick-up process were completed using CFD-DEM (computational fluid dynamics- discrete element method) coupling method which includes the standard-turbulence model and Euler gas-solid two-phase model. According to the spatial distribution variation law of seeds in vibrating tray at different time, their distribution region and discrete coefficients were calculated using the uniform distribution model and the moment estimate algorithm. Discrete motion states and stability characteristics of seeds under excitation of vertical reciprocating vibration were obtained, and the reasonable range of seeds layer thickness was determined. Seeds pick-up processes were finished when the seeds were thrown up to the high point by vibrating tray, and the absorbed seeds were generally in the upper layer. Under the conditions that seeds could be picked up accurately, the critical suction position in different seeds layer thickness was determined, and then the variation of pick-up distance, the influence of seeds shape on the pick-up performance, and the reasons leading to seeds single pick-up, missing pick-up and repeated pick-up were analyzed. It was obtained that the repeated pick-up ratio will increase with the increasing of seeds ellipticity which leads to the strong leakage flow field. Under the influence of collision and extrusion between seeds, the pick-up distance received by simulations is less than the value at static condition. Considering the influence of uncertain motion state of seeds in actual vibrating tray is much stronger, a modification method of suction position was proposed to improve the overall seeds pick-up performance of vacuum plate. That is to properly reduce the regulated distance based on the critical suction position received by simulation. Combined with the real-time monitoring method of seeds mass, an adaptive control device of suction position of vacuum plate was designed using PLC (programmable logic controller) as the controller. Using the established suction position control model, and taking differential pressure, regulated distance of suction position, vibration frequency of tray and seeds layer thickness as factors, each nozzle picking-up 1-2 seeds as evaluating indicator, the orthogonal tests were carried out on precision seeder test-rig with the diameter of suction nozzle of 2.5 mm and vibration amplitude of tray of 4 mm. The mathematical regression equation of seeds pick-up qualified index was established based on orthogonal tests results, and it was shown that the differential pressure and regulated distance of suction position were the 2 major factors that affected operating performance. By optimizing the established mathematical regression equation, the ideal working parameters were received including differential pressure of 4.4 kPa, vibration frequency of 10.6 Hz, and regulated distance of suction position of 2.7 mm. Under the above optimization parameters, further seeds pick-up tests were carried out with the seeds layer thickness varying in the range of 15-25 mm, and the results indicated that the seeds pick- up qualified index could reach about 94.5%. The proposed control method of suction position according to the variation of seeds layer thickness in vibrating tray can provide references for improving automation level and operating performance of vacuum plate precision seeder.

mechanization; optimization; models; precision seeder; vacuum plate; EDEM-CFD coupling; suction position; control method

赵 湛,田春杰,吴亚芳,黄贺东. 盘吸式水稻排种器吸种动力学过程模拟及参数优化[J]. 农业工程学报,2018,34(7):38-44. doi:10.11975/j.issn.1002-6819.2018.07.005 http://www.tcsae.org

Zhao Zhan, Tian Chunjie, Wu Yafang, Huang Hedong. Dynamic simulation of seed pick-up process and parameter optimization on vacuum plate seeder for rice[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 38-44. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.07.005 http://www.tcsae.org

2017-10-20

2018-02-05

国家自然科学基金资助项目(51775246、51305169);江苏高校优势学科建设工程资助项目(PADP)

赵 湛,副研究员,主要从事农业机械系统监测与控制技术研究。Email:zhaozhan@ujs.edu.cn

10.11975/j.issn.1002-6819.2018.07.005

S223.2

A

1002-6819(2018)-07-0038-07