Laser-induced periodic surface structures with ultrashort laser pulse

2018-03-03LIChenSTOIANRazvanCHENGGuanghua

LI Chen, STOIAN Razvan, CHENG Guang-hua,2*

(1.Laboratoire Hubert Curien,UMR 5516 CNRS,Université de Lyon,Université Jean Monnet,42000 Saint Etienne,France;2.State Key Laboratory of Transient Optics and Photonics,Xi′an Institute ofOptics and Precision Mechanics,CAS,Xi′an 710119,China;3.College of Mechanical and Electrical Engineering,ShaanxiUniversity of Science and Technology,Xi′an 710012,China)

1 Introduction of LIPSS

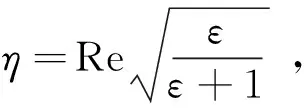

In 1965, Birnbaum firstly observed the phenomenon of ripples induced by a ruby laser on semiconductor surfaces, which is consisted of regular patterns of cracks and a system of parallel grooves(spacing of about 0.000 1 cm)[1]. This was the beginning of a prolific research field with respect to formation mechanisms and applications fields. In the following years, LIPSS were created and observed on many kinds of solid materials for a range of laser pulse durations. This suggests that LIPSS is a universal phenomenon induced by light. More recently, ultrashort pulsed radiation has received a specific attention for its potential in determining rippled surfaces, following the idea that nonlinear excitation on electronic non-equilibrium can induce novel interaction features. In particular, femtosecond(fs) laser-induced ripples show a range of orientation and periodicities that go on scales, much smaller than laser wavelength[2]. Under the ultrafast laser ablation in the range from femtosecond to picosecond laser, we observe several types of regular ripple patterns: low-spatial-frequency LIPSS(LSFL), high-spatial-frequency LIPSS(HSFL), with the different orientation parallel(⊥E) or perpendicular(║E) to the laser polarization. For example in Fig.1, LSFL(⊥E) exist widely on metal tungsten, semiconductor single crystal silicon, bulk metal glass(BMG), crystal alloy(CA) from BMG and the superalloy CMSX-4; LSFL(║E) exist on the dielectric fused silica; HSFL(⊥E) exist on the superalloy CMSX-4; HSFL(║E) exist on the CA. In addition, coarse macro-ripples(also called groove) are observed with the spatial periods of several microns much bigger than laser-wavelength, for example, grooves are observed on the silicon in Fig.1(b)[3].

Fig.1 SEM images of LIPSS on different materials irradiated by linearly-polarized fs laser pulses: (a)Metal tungsten; (b)semiconductor single crystal silicon; (c)fused silica; (d)bulk metal glass(BMG); (e)crystal alloy(CA) from BMG; (f)CMSX-4. The laser polarization (E)direction is indicated in (a) with a double-head arrow. Note that different scales in each image

In general, LIPSS formation is affected by irradiation conditions, ambience and material state. The irradiation conditions include laser fluence, number of laser pulses, polarization state, incident angle, scanning speed,etc. Typical ambient conditions includes air, oxygen, vacuum, water, high refractive index liquid and other factors that can modify the properties around the interface. These factors exercise a complex influence as they affect light coupling and scattering, the dynamic aspect of nascent topologies and feedback issues. In this work, we investigated LIPPS formation in air environments. Material condition includes complex optical characteristicsi.e. refractive index, surface roughness and thermal properties, such as thermal coefficients and transition points(melting point, vaporizing temperature,etc).

As a typical product of laser ablation or structuring, LIPSS formation involves some physical processes of the laser-material interaction, for example, laser excitation, energy deposition, material movement and the development of surface topologies. It equally involves a multi-scale dynamics fixed by the optical and thermal material response. Brief presentations of excitation and transformation processes are introduced in the following part and we will focus on characteristic features leading to ordered structured patterns.

2 Mechanisms of LIPSS

We have seen in the introductory part that LIPSS is a universal phenomenon on almost all the solids, including metals[3-4], semiconductors[5-6], dielectrics[7-8], ceramics[9]and polymers[10]. The continuous wave laser[11]and pulse lasers with long pulse duration can generate the classical ripples with periods of about the laser wavelength, which is often termed as low-spatial-frequency LIPSS(LSFL)[2]. Under the ultrafast laser ablation in the range from femtosecond to picosecond laser, except LSFL, fine nano-ripples are generated with the spatial periods much smaller than the half of applied laser wavelength, which is often termed as high-spatial-frequency LIPSS(HSFL)[2]. Furthermore, coarse macro-ripples with the spatial periods in a several microns range, as well as the arrays of conical features are generated in ultrafast laser ablation[6]. Generally, LIPSS completely form after a certain number of pulses at the fluence near the single-pulse ablation threshold. The feedback process between incident laser and surface nanostructures plays an important role in the ripple formation[12]. The LIPSS orientation is controlled by the polarization of the laser electric field. However, surface defects also play an important role in LIPSS orientation[12].

Several LIPSS experiments on a wide range of materials under different laser wavelengths have been carried out and analyzed with intensive theoretical studies, however, LIPSS formation mechanisms are not yet fully understood and still under debate until now. Several mechanisms were suggested to explain the formation of LIPSS, including probably to most comprehensive approach such as the generalized scattering and interference(Sipe) model[13-14], plasma mediated LIPSS formation[2,15-16], surface plasmon polariton(SPP) mediated LIPSS formation[17-20], and self-organization of unstable matter[21]. Part of LIPSS reported on different solids upon near-infrared fs-laser pulse irradiation and proposed formation mechanisms are summarized in Tab.1. The main LIPSS formation mechanisms are discussed in the following.

Tab.1 Literature summary of LIPSS reported on different solids(metals, semiconductors and dielectrics) upon near-infrared fs-laser pulse irradiation(λ=740-800 nm, τ=25-160 fs, ν<5 kHz) and nearly normal incidence in air or vacuum, and proposed formation mechanisms. (Lattice structure:c-single-crystalline, a-amorphous; LIPSS orientation: ⊥: ripples aligned perpendicular to polarization, ║:ripples aligned parallel to fpolarization; LIPSS ormation mechanism: Sipe:Sipe theory[14], SPP:surface plasmon polariton, roughnesseffect, heat effect, surface plasma, interference mechanism, Drude:Drude model for transient optical properties,exCE:Coulomb plosion. Material classes:metal-red color, semiconductor-green color, dielectric-blue color)

2.1 The Sipe diffraction theory

For the classical LSFL ripples, Sipe theory has been widely accepted to describe the formation, based on the interference between the incident laser and surface-scattered electromagnetic wave[13-14]. J.E.Sipeetal. developed the theory of LIPSS formation by associating the Fourier component of LIPSS with the corresponding Fourier component of inhomogeneous energy deposition beneath the surface[14]. Sipe theory describes the electric field intensity distribution created by a plane wave incident on a thin and rough surface selvedge region, whose height is much less than wavelength. The roughness of the surface selvedge region is characterized by shape factorsand filling factorF. Shape factorsis the ratio of the correlation distance on the surface to the thickness of the selvedge, corresponding to the shape of nanoparticles which make up the rough surface. Filling factorFrepresents the fraction of the surface filled up with the nanoparticles.

Fig.2 Drawing of laser beam incidence on rough surface in Sipe theory

A sketch of the geometry of the laser beam incidence on a rough surface in Sipe theory is shown in Fig.2. The regionz>0 is air and the regionz<0 represents the bulk material. The surface roughness is confined in a region of thicknessIs. The incident laser withsorppolarization carrying the wave vectorKLis incident on the rough surface at an angle of incidenceθ, which has a componentKiin the horizontal plane. The LIPSS wave vector isK=2π/λ. Sipe theory provides an expression for the inhomogeneous energy deposition on the surface, which is proportional toη(K,Ki)×|b(K)|, where the efficacy factorη(K,Ki) describes the efficacy with which the roughness leads to an inhomogeneous energy absorption atK; |b(K)| represents a measure of amplitude of the surface roughness atK. It is assumed that ripples grow where the absorbed energy is the largest. Because |b(K)| varies slowly for a surface with homogeneously distributed roughness, the efficacy factorη(K,Ki) exhibits sharp peaks at certainK, which determines the spatial ripple periodicity[14].

Sipe model based on a modulated energy deposition was in good agreement with many experimental results, such as LIPPS on metals[13-14], semiconductors[13-14,38]and dielectrics[42].

However, along with its strong predictive character on processing features, Sipe model itself has some limitations. Firstly, Sipe model is an approximate solution, in which the longitudinal component of the electromagnetic field is treated by a variational principle and the transverse component of the electromagnetic field is treated by a perturbation series. The accuracy of Sipe model is limited. Secondly, the physical nature of the electromagnetic field structures “radiation remnants” in Sipe model is still a question, which takes the place of the surface-scattered wave concept in the semiconductor. Finally, for metal, the excitation of surface plasmons may take the place of radiation remnants in Sipe model. The relationship between radiation remnants and surface plasmons is not clear[14].

To overcome these problems in Sipe theory, other mechanisms are proposed, such as second harmonic generation(SHG) on surfaces[5], transient changes of the optical properties in the excited material during the laser pulse[41], as well as self-organization based on the instability of excited materials[21]. However, none of the above mentioned mechanisms can explain all characteristics of LIPSS.

2.2 Surface plasmon polariton(SPP) mediated LIPSS formation

In the Sipe theory, alternatively or in addition to surface-scattered electromagnetic waves on metal surface, surface plasmon polaritons(SPPs) may play an important role. Sipeetal.[14]indicated that the formation of LSFL ripples on metals can, in particular conditions, be seen as deriving from the interference between the incident laser and SPPs where the former may be seen as a type of surface scattered wave.

When a linearly polarized laser pulse is irradiated at the air-metal interface at the incident angle ofθ, the periodΛof LIPSS formed due to the interference between the incident laser and the excited SPP is given by Refs.[47-49,18]:

(1)

(2)

Fig.3 Plasmon wavelength calculated as a function of electron density for the glassy carbon(GC)/diamond like carbon(DLC) interface(lower curve) and for the air/GC(upper curve)[47]

Hereλis the incident laser wavelength,ηis the real part of the effective refractive index of the air-metal interface for surface plasmons,εis the dielectric constant of the metal. Under the intense ultrafast irradiation, the effective refractive index may change and affect the scattered wave or surface plasmons. For example, G.Miyajietal. explained the LIPSS formed on diamond-like carbon film by the excitation of SPP, shown in Fig.3.

C.Guoetal. investigated fs-LIPSS on metal Pt and Au and found that both the calculated periods of Pt and Au are overestimated by about 30% in SPP theory, which was explained by the increase in the real part of the refractive index duo to the effects of surface nano- and micro-roughness, as well as a heating effect[18].

M.Huangetal. proposed the mechanisms of initial direct surface plasmon(SP)-laser interference and the subsequent grating-assisted SP-laser coupling to explain the LIPPS formation on all the solids including metals, semiconductors and dielectrics, which involve the grating-coupling mechanism leading to the decrease of spatial periods with the increase of groove depth[30].

The theory of SPP-mediated LIPSS formation can explain some experiment results on metals[50], for example, LSFL on metal Ni[24], Al and brass[13]. However, J.Z.P.Skolskietal.′ s investigation by FDTD simulations showed that the propagation of SPPs is not a necessary condition for LSFL formation, moreover, the grating-assisted SP-laser coupling mechanism proposed by M.Huang[30]seems inapplicable because the spatial periods of surface structures are same as the periods of energy modulation. This indicates that it needs further experiments to clarify and to evidence the behavior of non-plasmonic metals, semiconductor and dielectric surfaces and the potential that they may support SPP during the irradiation by short-pulse laser around the damage-threshold fluence.

2.3 FDTD-electromagnetic(EM) approach

The finite-difference time-domain(FDTD) method can simulate light propagation, scattering and diffraction phenomena by solving Maxwell′s equations numerically. The method was introduced by Yee in 1966[51]and since then has been a powerful engineering tool for integrated and diffractive optics device simulations. J.Z.P.Skolskietal. proposed the numerical method based on the finite-difference time-domain(FDTD) method to investigate qualitatively LIPSS formation on rough surface and the effect of inter-pulse feedback mechanisms[37-38,52], which is simplified as FDTD-EM approach. Not including incubation effects and the thermodynamics of molten or ablated materials,ablation model(HAM) is used as rough surface model in this approach. The FDTD method can provide electric field distributions in the vicinity of the surface, identifying thus electromagnetic effect in the definition of anisotropic energy absorption patterns. Present approaches takes into account the role of scattering from surface roughness and the creation of stationary field patterns with evanescent components. It will be shown in this work that the FDTD approach can take into account the effect of polarization and topographic surface features, being thus a powerful instrument in LIPSS analysis[50].

Fig.4 (a)holographic ablation model used in FDTD simulations. (b)Inter-pulse feedback mechanisms in FDTD simulations[52]

A recent advance in FDTD methods applied to LIPSS consists of the attempt of accounting for feedback effects. After the first laser pulse, the absorbed electromagnetic energy in the surface layer causes the modification of rough surface by material removal. After next laser pulse, the new surface morphology is used for subsequent FDTD simulation, leading to a new absorbed energy profile and a further modification of the rough surface. Hence, the feedback cycle can be iterated many times until expected LIPSS form. The sketch map of inter-pulse feedback mechanisms in FDTD simulations is shown in Fig.4.

Some of the main conclusions derived from employing FDTD methods are emphasized here[52]:

(a)For LSFL formation, surface plasmon polaritons(SPPs) are not a necessary condition. The grating-assisted mechanism proposed in Ref.[30] can′t explain the periodicity decreasing of LSFLs with increasing pulses because the spatial periods of surface structures are same as the periods of laser-induced energy modulation.

(b)HSFL orthogonal to the polarization looks like double frequency of LSFL in spatial frequency domain, which is a striking result of the FDTD-feedback simulations.

(c)Except HSFL on semiconductors and dielectrics, HSFLs parallel to the polarization can be expected on metals, which are in agreement with experimental results.

(d)Groove(micro-ripples) parallel to the polarization can be predicted by the approach. Grooves without LSFLs are not found.

However, the deficiencies of FDTD-feedback simulations are also listed in the following:

(a)HSFLs parallel to the polarization form only when Re()>Im(), which is not in agreement with the experiment results on alloyed steel and titanium[52]. The reason may be from the algorithm chosen for the FDTD calculations depended on the optical properties of the medium. In cases where Re() (b)The FDTD-EM approach provides a rather embedded result of EM numerical calculations, that does not uncover the underlying physics of LIPSS formation, for example, HSFL orthogonal to the polarization with double frequency of LSFL in spatial frequency domain, grooves only with LSFL. Giving global field solutions, the access to sources and electronic currents is problematic. (c)The FDTD-EM remains simplistic without the inclusion the complex processes, such as nonlinear absorption, transient excitation, incubation effect, SHG[40]and self-organization based on material movement. Inspired by the similarity of the laser-generated patterns with the patterns induced by energetic ions, self-organization model upon femtosecond laser ablation[55-56]is proposed according to the existing formation theory of ion-beam induced ripples[57]with a dependence on laser polarization related to an asymmetry in the ionized kinetic energy distribution[56], which supposes an active contribution of the irradiated unstable material. The absorbed laser energy causes an unstable surface region by the perturbation and softening of the crystal bonding, where self-organization is driven by competition between surface roughening due to erosion and smoothing, leading to LIPSS formation in the laser-modified area[58-59]. Spatial and temporal evolution of the perturbed surface can be represented by nonlinear equations of the Kuramoto-Sivashinsky type[60-61]. Marangoni effect may also play a role in LIPSS formation. Marangoni effect cause the liquid flowing from the hotter to the cooler regions in the molten material because surface tension decreases with increasing temperature for most liquids[62], which is also called thermo-capillary convection[63]. Until now, self-organization model has estimated LIPSS formation, interaction times/number of incident pulses, as well as the relative influence of input energy on the ripple period[59]. However, self-organization model is just a possible scenario and was not yet verified by experiments. It nevertheless positions itself as an alternative process to the coherent interference model involving surface waves. Femtosecond laser ablation towards regular patterns may equally include some nonlinear effects generated at the surface, as among them second harmonic generation(SHG). SHG is related to the surface-generated symmetry breaking. It is still in debate if SHG might be involved in the formation of the HSFL, however its involvement was justified by the appearance of structures of higher periodicities. For example, J. Bonse′s investigation revealed the SHG is generated in the regime of HSFL formation on ZnO by spectroscopic experiments[40]. However, other experiments on TiO2and Al2O3surfaces confirmed that SHG does not affect ripple periodicity[64]. The inconsistencies of these results still promote a debate if SHG contributes to LIPSS formation. In order to explain the LIPSS spatial periods of subwavelength range in ultrafast laser ablation of various semiconductors, J.Bonseetal. proposed an approach, which combines the Sipe theory with the transient excitation and the intra-pulse transient changes of the optical properties in the irradiated materials[36]. Thus, with Drude-like free-electron contributions in the optical response, the real part of the dielectric function will go down, potentially allowing plasmonic excitation if the synchronism conditions permit. This approach is proposed to explain the LSFL formation on silicon originating in a spatially modulated energy deposition at the surface, and the modulation is due to the interference between the incident laser beam and the excitation of surface plasmon polaritons on the dense free-electron-plasma in the excited material during the pulse. This approach and the role of the feedback upon the multi-pulse irradiation are shown in Fig.5. Fig.5 Scheme of physical processes involved in the formation of LSFL on silicon surface upon femtosecond laser pulse irradiation[65] However, LIPSS formation on Ge can be explained by Sipe theory without transient optical properties[13]. In addition, it is an important question if transient changes of the optical properties in the irradiated semiconductors could support SPPs in the pulse duration. And it needs strong experimental evidences that the intra-pulse transient changes of the optical properties in the irradiated materials contribute to the LSFL formation. Due to the importance of the time-varying optical coupling during irradiation, the issue of optical transients will be detailed in the next chapter, in a general context of ultrafast laser-material interaction. Recently, J. Bonse et al reported the experiments, in which LIPSS formations on fused silica, silicon and titanium were studied with linear, parallel or cross-polarized, two-color double-fs-pulse sequences(50 fs, 400 nm and 800 nm) under sub-threshold conditions in the temporal pulse delay(-10 ps All these observations show the multitude of hypotheses and scenarios in ripple formation, requiring thus novel physical insights to foster further understanding. Material response to laser irradiation usually results in permanent changes to the chemistry, composition, crystal structure and morphology of material surface. For multi-component materials, the species in the surface layer may be depleted at different speeds in laser ablation in fluence regimes connected with inhomogeneous heating, leading to the changed chemical composition of the remaining material[66]. In ultra-fast laser irradiation, the large temperature gradients induced by rapid heating generate thermal stresses and thermo-elastic acoustic waves, resulting in the mechanical response of the material, for example, hardening and warping[67]. When the material is heated above melting point, hydrodynamic motion can reshape the molten material. For example, convective and thermo-capillary forces can cause the retribution of molten material which frozen during solidification. Laser ablation is always accompanied by a dense vapor plume including atomic and molecular species, and solid and liquid clusters of material ejected from the irradiated surface. Recoil from the plume also generates shockwaves, resulting in plastic deformation and hardening of the material. The recoil can also expulse the remaining molten material. Residual heat left in the remaining material can cause further melting or other thermally activated processes. After rapid heating, the condensation of plume material leads to the formation of clusters and nanoparticles at the surrounding areas of the ablated region. Rapid self-quenching of the material can freeze in defects, supersaturated solutes and metastable phases. Slower re-solidification can induce the recrystalization of the material. Energy relaxation depends on the strength of electron-phonon coupling[68]. This shows an influence of the strength of the electron-phonon coupling on ripple formation. Material responses and final properties are dependent on the laser parameters. For the desired application, final material properties after irradiation can be precisely controlled by choosing the appropriate laser parameters. There are several conventional techniques for surface processing, for example, mechanical surface processing, sand blasting with Al2O3particles or acid etching that roughen surface randomly but may contaminate the material[69]. These are complex procedures and cannot process non-planar surfaces in the micro/nano-scale. Ion beam and electron beam milling which can fabricate nanostructures precisely but cost expensively and need the vacuum condition[70]. Unlike conventional techniques, lasers provide a fast, non-contact, precise and clean alternative for surface processing in ambient conditions. As one of the major advantages, laser has the ability to precisely control deposited energy in desired regions and energy rates by many methods, for example, beam steering by galvanometric scanning mirrors, beam shaping with amplitude masks, refractive elements[71]and diffractive optical elements[72]as well as spatial light modulators[73]. Duo to the advantages, laser has been applied widely in the surface processing. Beyond the idea of accurate remote processing, the possibility of achieving multiscale structuring in periodic patterns is of interest. Thus, LIPSS provides a fast, precise and low-cost tool for surface micro/nano-structuring and the possibility to design hierarchical surfaces and models for structured contact interfaces in optics and mechanics. Some specific applications of LIPSS are discussed in the following. Fig.6 (a)Water drops on a lotus leaf. (b)SEM image of the micro-structures on the surface of a lotus leaf(scale bar 10 μm) and inset: nano-structures(scale bar 5 μm)[74]. (c)SEM images of femtosecond laser textured Si surface showing micro-structures(scale bar 5 μm) and inset: nano-structures(scale bar 1 μm) . (d)A water droplet on a laser-structured Si surface[76] Inspired by the remarkable nature example of the lotus leaf, super-hydrophobic surfaces induced by hierarchical micro/nano-structures were demonstrated, as shown in Fig.6(a,b)[74-75]. Except the hierarchical topography surface chemistry also contributes to the wettability, such as pH, H adsorption, oxidation,etc. LIPSS including hierarchical micro/nano-structures can thus precisely control the surface wetting characteristics with super-hydrophobic[76]or super-hydrophilic properties[77]by the choice of laser parameters. An example of laser-induced hydrophobicity is shown in Fig.6(c,d)[76]. Laser surface processing has been widely in the applications for surface wetting, for example, self-cleaning surfaces[76], micro fluidics[78], water proof and de-icing coatings for aviation[79]. For years, laser surface texturing(LST) has been used to enhance the tribological properties of material surface[80]. For instance, the structuring of cylinder walls in combustion engines serving as reservoirs for oil can prevent the breakdown of oil-film, resulting in significantly reduced particle emission[81]. In this case, ultrashort laser pulses can produce high quality shallow structures, such as LIPSS without recast layers and burr[82]. An remarkable example shows that LIPSS formed on the titanium alloy by femtosecond laser pulses can lead to a significant reduction of the friction coefficient, indicating the potential benefit of laser surface structuring for tribological applications[83]. Via surface structuring on the nano-, micro-, and submillimeter-length scales, the creation of color metals with femtosecond laser surface structuring has been demonstrated by several researchers[84-85]. Femtosecond laser provides a controllable modification of optical properties of metals from UV to terahertz wavelengths. The size of the optically modified metal surface area can be as small as a tightly focused laser spot,i.e., down to about 10 μm, or as large as needed when a scanning laser beam is used. Giving the additional advantages of laser processing such as low contamination and capability to process complicated shapes, the color metals created have a tremendous potential in various technological applications. For example, Fig.7 shows the gray and black aluminum produced by femtosecond laser pulses[84]. Fig.7 Gray and black aluminum produced by femtosecond laser pulses[84] Color marking is made by the use of ordered nano-ripples with designed orientation and spatial periods on desired regions, which are controlled by laser parameters[31]. Two-dimensional data codes can be written, consisting in an array of controlled nanostructures by femtosecond laser pulses which are useful for traceability[83]. The process can be rendered parallel by laser beam shaping technologies employing spatial light modulators. An example is the colorful marking and two-dimensional code created on stainless steel by femtosecond laser pulses from French Qiova company. Light trapping is useful for photodiodes, sensors and solar harvesting cells. Multiple length scales of surface features reduce the reflections based on three mechanisms dependent on the size of surface features:(a)For feature size much longer than the incident wavelength, light trapping due to multiple reflections from protruding structures enhances coupling into the material, moreover, refraction at oblique angles increases the effective optical path length; (b)For feature size close to incident wavelength, light trapping due to scatter increases the effective optical path length and enhances absorption; (c)For feature size much smaller than incident wavelength, light trapping due to moth-eye effect reduces reflection[85]. LIPSS, similar to a surface grating, induces the dispersion, but LIPSS usually doesn't enhance the absorption significantly due to their shallow height[85]. However, laser-induced arrays of high-aspect-ratio cones or columns features can trap light efficiently[86]. For example, the micro-structured silicon with micro-cones by femtosecond laser in the atmosphere of SF6shows the broadband reduction in reflectivity[87]. LIPSS can enhance the efficiency in light emitting devices, useful for solid state illumination. Increased emission by LIPSS is due to the surface increase and sharp surface nanostructures reducing the work function of material[88]. LIPSS can also change the emission spectrum. For example, the efficiency of lamp was increased and the emission spectrum can be controlled by making LIPSS on the tungsten filament in lamp by fs laser[89-90]. Fig.8 Black silicon made without special gas ambient[92] In 1999, black silicon was produced by irradiating silicon with femtosecond laser pulses[91]. After irradiation in the presence of a gas containing sulfur hexafluoride and other dopants, the surface of silicon develops a self-organized microscopic structure of micrometer-sized cones. The resulting material has many remarkable properties, such as absorption that extends to the infrared range, below the band gap of silicon, including wavelengths for which ordinary silicon is transparent. Sulfur atoms are forced to the silicon surface, creating a structure with a lower band gap and therefore the ability to absorb longer wavelengths. Similar surface modification can be achieved in vacuum using the same type of laser and laser processing conditions. In this case, the individual silicon cones lack sharp tips, shown in Fig.8. The reflectivity of such a micro-structured surface is very low, 3%-14% in the spectral range 350-1 150 nm[92]. Such reduction in reflectivity is contributed by the cone geometry, which increases the light internal reflections between them. Hence, the possibility of light absorption is increased. The gain in absorption achieved by fs laser texturization was superior to that achieved by using an alkaline chemical etch method, which is a standard industrial approach for surface texturing of mono-crystalline silicon wafers in solar cell manufacturing. LIPSS has been widely used in biological and medical applications. LIPSS on biological implants encourages cell growth and improves osseo-integration[93-94]. For example, LIPSS form on a scaffold-usable biodegradable polymer by femtosecond laser, which enables to control cell behaviors[95]. Another example is the black Si with LIPSS created by fs laser, which has the bactericidal function[96]. For a remarkable example, LIPSS on noble metals can be used as high-efficiency substrates for surface-enhanced Raman spectroscopy(SERS)[97]. LIPSS formation involves a range of complex processes related to optics, photophysics, photochemistry, thermodynamics, hydrodynamics, condensed matter physics, plasma and so on. Only considering optical features, the scenarios of LIPSS formation put forward features of linear and nonlinear optics, such as scattering, interference, excitation of surface plasmon polaritons(SPPs), excitation of plasma, second harmonic generation(SHG) and transient changes of the optical properties in the irradiated materials. For ultrafast laser ablation, it is a challenge to investigate the complex LIPSS formation in fs-ns time domain, in which limited instruments can be applied. Until now, LIPSS formation mechanisms are not yet fully understood and still under debate. Sipe theory has been widely accepted to explain the LSFL formation based on scattering and interference, but Sipe theory still faces some challenges especially in the limited accuracy. However, potential self-organization model only works in ultra-short pulse, not proper for the laser with long pulse duration related to the weaker laser peak fluence. FDTD-EM approach offers a precise numerical tool to investigate LIPSS formation in the electromagnetic domain, which showed that the propagation of SPPs is not a necessary condition for LSFL formation, and the grating-assisted SP-laser coupling mechanism seems inapplicable because the spatial periods of surface structures are same as the periods of laser-induced energy modulation. In that concern LIPSS formation theories respectively mediated with SPP, SHG and intra-pulse transient optical properties, they still need strong experimental evidences. LIPSS is a universal phenomenon on almost all the solids induced by the lasers ranging from long pulse to ultra-short pulse. Their appearance on the different materials such as metals, semiconductors and dielectrics, the parts of LIPSS mainly related to LSFL are very similar, which reveals a common LIPSS formation mechanism existing in all solids in the electromagnetic domain. However, now the LIPSS formation theories are different on metals, semiconductors and dielectrics. For example, the interference with SPPs in Sipe theory for metals, the interference with surface-scattered electromagnetic wave in Sipe theory for semiconductors, plasma-mediated formation resulting in regular patterns of self-trapped excitons(STE) and color centers-mediated structural transitions for dielectrics need to converge towards more unified frames. This implies further consideration and we have identified opportunities to find common LIPSS formation mechanisms on metals, semiconductors and dielectrics in the electromagnetic domain by FDTD-EM approach. Except LSFL and HSFL, other laser-induced micro/nano-features such as bubbles, cones, columns and abnormal ripples as well as macro-structures, and in general surface topographies should be taken into LIPSS formation theory. In order to explain the complex LIPSS formation in ultrafast laser ablation, more experiments need to be designed and carried out. For example, fs laser-induced transient optical properties can be measured to check the LIPSS formation theory in connection to transient optical properties. In addition, for some complex materials, such as bulk metal glass, there are some distinctive types of LIPSS, which also need more investigations. In this paper, we introduce the general aspects of laser-induced periodic surface structures(LIPSS). Several LIPSS forms and periodicities reported on different solids upon near-infrared fs-laser pulse irradiation are reviewed. However, LIPSS formation mechanisms are not yet fully understood and still under debate until now. Several LIPSS formation theories with merits and limitations are introduced, including Sipe theory, FDTD-EM approach, self-organization model of unstable matter and LIPSS formation respectively mediated with surface plasmon polariton(SPP), second harmonic generation(SHG) as well as with the evolution of optical properties during irradiation. We introduce material transformations under LIPSS, related to the permanent changes of the material in the chemistry, composition, crystal structure and surface morphology. At last, we show the applications of LIPSS in material surface processing, including surface wetting, tribology, modification of optical properties, marking and coding, light trapping and emitting, as well as bio-medical application. [1] BIRNBAU M. Semiconductor surface damage produced by ruby lasers[J].JournalofAppliedPhysics,1965,36(11):3688-3689. [2] ZHANG W,CHENG G H,FENG Q,etal.. Abrupt transition from wavelength structure to subwavelength structure in a single-crystal superalloy induced by femtosecond laser[J].AppliedSurfaceScience,2011,257(9):4321-4324. [3] DERRIENA TJ-Y,TORRES R,SARNET T,etal.. Formation of femtosecond laser induced surface structures on silicon: Insights from numerical modeling and single pulse experiments[J].AppliedSurfaceScience,2012,258:9487-9490. [4] GOLOSOV E V,IONIN A A,KOLOBOV Y R,etal.. Formation of periodic nanostructures on aluminum surface by femtosecond laser pulses[J].NanotechnologiesinRussia,2011,6:237-243. [5] BOROWIEC A,HAUGEN H K. Subwavelength ripple formation on the surfaces of compound semiconductors irradiated with femtosecond laser pulses[J].AppliedPhysicsLetters,2003,82(25):4462-4464. [6] BONSE J,BAUDACH S,KRUGER J,etal.. Femtosecond laser ablation of silicon-modification thresholds and morphology[J].AppliedPhysicsA,2002,74(1):19-25. [7] COSTACHE F,ARGUIROVA S K,REIF J. Sub-damage-threshold femtosecond laser ablation from crystalline Si:surface nanostructures and phase transformation[J].AppliedPhysicsA,2004,79(4):1429-1432. [8] HSU E M,CRAWFORD T H R,TIEDJE H F,etal.. Periodic surface structures on gallium phosphide after irradiation with 150 fs-7 ns laser pulses at 800 nm[J].AppliedPhysicsLetters,2007,91:111102. [9] DUMITRU G,ROMANO V,WEBER H P,SENTIS M,etal.. Ablation of carbide materials with femtosecond pulses[J].AppliedSurfaceScience,2003,205:80-85. [10] BAUDACH S,BONSE J,KAUTEK W. Ablation experiments on polyimide with femtosecond laser pulses[J].AppliedPhysicsA,1999,69(Suppl.):S395-S398. [11] KANEKO S,ITO T,AKIYAMA K,etal.. Nano-strip grating lines self-organized by high speed scanning CW laser[J].Nanotechnology,2011,22:175307. [12] LI C,CHENG G H,COLOMBIER J P,etal.. Impact of evolving surface nanoscale topologies in femtosecond laser structuring of Ni-based superalloy CMSX-4[J].JournalofOptics,2016,18(1):015402. [13] YOUNG J F,PRESTON J S,DRIEL H M,etal.. Sipe. Laser-induced periodic surface structure.II.experiments on Ge, Si, Al, and brass[J].PhysicalReviewB,1983,27(2):1155-1172. [14] SIPE J E,YOUNG . F,PRESTON J S,etal.. van Driel. Laser-induced periodic surface structure.I[J].Theory.PhysicalReviewB,1983,27:1141-1154. [15] SAKABE S,HASHIDA M,TOKITA S,etal.. Mechanism for self-formation of periodic grating structures on a metal surface by a femtosecond laser pulse[J].PhysicalReviewB,2009,79(3):033409. [16] OKAMURO M,HASHIDA M,MIYASAKA Y,etal.. Laser fluence dependence of periodic grating structures formed on metal surfaces under femtosecond laser pulse irradiation[J].PhysicalReviewB,2010,82(16):165417. [17] HWANG T Y,GUO C. Angular effects of nanostructure-covered femtosecond laser induced periodic surface structures on metals[J].JournalofAppliedPhysics,2010,108(7):073523. [18] VOROBYEV A Y,MAKIN V S,GUO C. Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals[J].JournalofAppliedPhysics,2007,101(3):034903. [19] VOROBYEV A Y,GUO C. Femtosecond laser-induced periodic surface structure formation on tungsten[J].JournalofAppliedPhysics,2008,104(6):063523. [20] COLOMBIER J P,GARRELIE F,BRUNET P,etal.. Plasmonic and hydrodynamic effects in ultrafast laser-induced periodic surface structures on metals[J].JournalofLaserMicro/Nanoengineering,2012,7(3):362-368. [21] VARLAMOVA O,REIF J,VARLAMOV S,etal..ProgressinNonlinearNano-optics(Ed. by Sakabe Shuji, Lienau Christoph, Grunwald and R diger)[M]. Springer,2015:4. [22] WANG J,GUO C. Ultrafast dynamics of femtosecond laser-induced periodic surface pattern formation on metals[J].AppliedPhysicsLetters,2005,87(25):251914. [23] WANG J,GUO C. Numerical study of ultrafast dynamics of femtosecond laser-induced periodic surface structure formation on noble metals[J].JournalofAppliedPhysics,2007,102(5):053522. [24] GARRELIE F,COLOMBIE J P,PIGEON F,etal. Parriaux. Evidence of surface plasmon resonance in ultrafast laser-induced ripples[J].OpticsExpress,2011,19(10): 9035-9043. [25] TSUKAMOTO M,ASUKA K,NSKSNO H,etal.. Periodic microstructures produced by femtosecond laser irradiationon titanium plate[J].Vacuum,2006,80(11):1346-1350. [26] BONSE J,KRUGER J,HOHMS,etal.. Femtosecond laser-induced periodic surface structures[J].JournalofLaserApplications,2012,24(4):042005. [27] GOLOSOV E V,EMELYANOV V I,IONIN A A,etal.. Femtosecond laser writing of subwave one-dimensional quasiperiodic nanostructures on a titanium surface[J].JETPLetters,2009,90(2):107-110. [28] VOROBYEY A Y,GUO C. Femtosecond laser structuring of titanium implants[J].AppliedSurfaceScience,2007,253:7272-7280. [29] ZHAO Q Z,MALZER S,WANG L J. Formation of subwavelength periodic structures on tungsten induced by ultrashort laser pulses[J].OpticsLetters,2007,32(13):1932-1934. [30] HUANG M,ZHAO F,CHENG Y,etal.. Origin of laser-induced near-subwavelength ripples:interference between surface plasmons and incident laser[J].ACSNano,2009,3:4062-4070. [31] DUSSER B,SAGAN Z,SODER H,etal.. Controlled nanostructures formation by ultra fast laser pulses for color marking[J].OpticsExpress,2010,18(3):2913-2924. [32] BYSKOV-NIELSEN J,SAVOLAINEN J M,CHRISTENSEN M S,etal.. Ultra-short pulse laser ablation of metals: threshold fluence, incubation coefficient and ablation rates[J].AppliedPhysicsA,2010,101(1):97-101. [33] BONSE J,ROSENFELD A,KRUGER J. On the role of surface plasmon polaritons in the formation of laser-induced periodic surface structuresupon irradiation of silicon by femtosecond-laser pulses[J].JournalofAppliedPhysics,2009,106(10):104910. [34] DERRIEN T J Y,ITINA T E,TORRE R,etal.. Possible surface plasmon polariton excitation under femtosecond laser irradiation of silicon[J].JournalofAppliedPhysics,2013,114:083104. [35] BONSE J,KRUGER J. Pulse number dependence of laser-induced periodic surface structures for femtosecond laser irradiation of silicon[J].JournalofAppliedPhysics,2010,108(3):034903. [36] BINSE J,ROSENFELD A,KRUGER J. Implications of transient changes of optical and surface properties of solids during femtosecond laser pulse irradiation to the formation of laser-induced periodic surface structures[J].AppliedSurfaceScience,2011,257:5420-5423. [37] SKOLSKI J Z P,ROMER G R B E,OBONA J V,etal.. Laser-induced periodic surface structures:fingerprints of light localization[J].PhysicalReviewB,2012,85(7):075320. [38] SKOLSKI J Z P,ROMER G R B E,OBONA J V,etal.. Inhomogeneous absorption of laser radiation:trigger of LIPSS formation[J].JournalofLaserMicro/Nanoengineering,2013,8(1):1-5. [39] BONSE J,MUNZ M,STURM H. Structure formation on the surface of indium phosphide irradiated by femtosecond laser pulses[J].JournalofAppliedPhysics,2005,97(1):013538. [40] DUFFT D,ROSENFELD A,DAS S K,etal.. Femtosecond laser-induced periodic surface structures revisited:a comparative study on ZnO[J].JournalofAppliedPhysics,2009,105(3):034908. [41] WU Q,MA Y,FANG R,etal.. Femtosecond laser-induced periodic surface structure on diamond film[J].AppliedPhysicsLetters,2003,82(11):1703-1705. [42] HOHM S,ROSENFELD A,KRUGER J,etal.. Femtosecond laser-induced periodic surface structures on silica[J].JournalofAppliedPhysics,2012,112:014901. [43] ROHLOFF M,DAS S K,HOHM S,etal.. Formation of laser-induced periodic surface structures on fused silica upon multiple cross-polarized double-femtosecond-laserpulse irradiation sequences[J].JournalofAppliedPhysics,2011,110(1):014910,. [44] SUN Q,LIANG F,VALLEE R,etal.. Nanograting formation on the surface of silica glass by scanning focused femtosecond laser pulses[J].OpticsLetters,2008,33(22):2713-2715. [45] ROSENFELD A,ROHLOF F M. Formation of laser-induced periodic surface structures on fused silica upon multiple parallel polarized double-femtosecond-laser-pulse[J].AppliedSurfaceScience,2012,258:9233-9236. [46] YAMAGUCHI M,UENO S,KUMA R. Raman spectroscopic study of femtosecond laser-induced phase transformation associated with ripple formation on single-crystal SiC[J].AppliedPhysicsA,2010,99(1):23-27. [47] MIYAJI G,MIYAZAKI K. Origin of periodicity in nanostructuring on thin film surfaces ablated with femtosecond laser pulses[J].OpticsExpress,2008,16(20):16265-16271. [48] ZHOU G S,FAUCHET P M,SIEGMAN A E. Growth of periodic surface structures on solids during laser illumination[J].PhysicalReviewB,1982,26(10):5366. [49] SIEGMAN A E,FAUCHET P M. Stimulated wood′s anomalies on laser-illuminated surfaces[J].IEEEJournalofQuantumElectronics,1986,22:1384-1403. [50] ZHANG H,COLOMBIER J P,LI C,etal.. Coherence in ultrafast laser-induced periodic surface structures[J].PhysicalReviewB,2015,92(17):174109. [51] YEE K S. Numerical solution of initial boundary value problem involving Maxwell′s equations in isotropic media[J].IEEETransactionsonAntennasandPropagation,1966,14(3):302-307. [52] SKOLSKI J Z P,R MER G R B E,VINCENC OBONA J,etal.. Huis in′t Veld. Modeling laser-induced periodic surface structures:finite-difference time-domain feedback simulations[J].JournalofAppliedPhysics,2014,115(10):103102. [53] KOKHANOVSKY A A. Light scattering and remote sensing of atmosphere and surface[J].LightScatteringReviews,2012,6,Springer. [54] TAFLOVE A,HAGNESS S C. Computational electrodynamics:the finite-difference time-domain method[R]. 3rd ed,Artech House,Norwood,2005. [55] REIF J,COSTACHE F,HENYK M,etal.. Ripples revisited: non-classical morphology at the bottom of femtosecond laser ablation craters in transparent dielectrics[J].AppliedSurfaceScience,2002,197:891-895. [56] REIF J,VARLAMOVA O,VARLAMOV S,etal.. The role of asymmetric excitation in self-organized nanostructure formation upon femtosecond laser ablation[J].AppliedPhysicsA,2011,104(3):969-973. [57] BRADLEY R M,HARPER J M E. Theory of ripple topography induced by ion bombardment[J].JournalofVacuumScience&TechnologyA,1988,6:2390. [58] REIF J,COSTACHE F,BESTEHORN M.Chapter9inRecentAdvanceinLaserProcessingofMaterials[M]//Ed. by J. Periere,E. Millon,E. Fogarassy. Amsterdam,Elsevier,2006:275. [59] VARLAMOVA O,RATZKE M,REIF J. Feedback effect on the self-organized nanostructures formation on silicon upon femtosecond laser ablation[J].SolidStatePhenomena,2010,156:535-540. [60] KURAMOTO Y,TSUZUKI T. Persistent propagation of concentration waves in dissipative media far from thermal equilibrium[J].ProgressofTheoreticalPhysics,1976,55(2):356-369. [61] SIVASHINSKY G I. On self-turbulization of a laminar flame[J].ActaAstronautica,1979,6(5):569-591. [62] BENNETT T D,KRAJNOVICH D J,GRIGOROPOULOS C P,etal.. Marangoni mechanism in pulsed laser texturing of magnetic disk substrates[J].J.HeatTransfer,1997,119(3):589-596. [63] GETLING A V. Rayleigh-B nard convection: structures and dynamics[J].WorldScientific,Singapore,1998. [64] BUIVIDAS R,ROSA L, LIUPAS R,etal.. Mechanism of fine ripple formation on surfaces of (semi)transparent materials via a half-wavelength cavity feedback[J].Nanotechnology,2011,22(5):055304. [65] HOHM S,HERZLIEB M,ROSENFELD A,etal.. Dynamics of the formation of laser-induced periodic surface structures(LIPSS) upon femtosecond two-color double-pulse irradiation of metals, semiconductors, and dielectrics[J].AppliedSurfaceScience,In Press,2015,doi:10.1016/j.apsusc.2015.12.129. [66] MAO X L,CIOCAN A C,RUSSO R E. Preferential vaporization during laser ablation inductively coupled plasma atomic emission spectroscopy[J].AppliedSpectroscopy,1998,52(7):913-918. [67] CLAUER A H,FAIRRAND B P,WILCOX B A. Laser shock hardening of weld zones in aluminum alloys[J].MetallurgicalandMaterialsTransactionsA,1977,8(12):1871-1876. [68] COLOMBIER J P,GARRELIE F,FAURE N,etal.. Effects of electron-phonon coupling and electron diffusion on ripples growth on ultrafast-laser-irradiated metals[J].JournalofAppliedPhysics,2012,111(2):024902. [69] BECKFORD S,LANGSTON N,ZOU M,etal.. Fabrication of durable hydrophobic surfaces through surface texturing[J].AppliedSurfaceScience,2011,257:5688-5693. [70] SCHULZE A,MAITZ M F,ZIMMERMANN R,etal.. Permanent surface modification by electron-beam-induced grafting of hydrophilic polymers to PVDF membranes[J].RSCAdvances,2013,3:22518-22526. [71] ROMERO L A,DICKEY F. Lossless laser beam shaping[J].JournaloftheOpticalSocietyofAmericaA,1996,13(4):751-760. [72] MOMMA C,NOLTE S,KAMLAGE G,etal.. Beam delivery of femtosecond laser radiation by diffractive optical elements[J].AppliedPhysicsA,1998,67(5):517-520. [73] SANNER N,HUOT N,AUDOUARD E,etal.. Programmable focal spot shaping of amplified femtosecond laser pulses[J].OpticsLetters,2005,30(12):1479-1481. [74] BLOSSEY R. Self-cleaning surfaces-virtual realities[J].NatureMaterial,2003,2(5):301-306. [75] ZORBA V,STRATAKIS E,BARBEROGLOU M,etal.. Tailoring the wetting response of silicon surfaces via fs laser structuring[J].AppliedPhysicsA,2008,93(4):819. [76] BARBEROGLOU M,ZORBA V,STRATAKIS E,etal.. Bio-inspired water repellent surfaces produced by ultrafast laser structuring of silicon[J].AppliedSurfaceScience,2009,255(10):5425-5429. [77] VOROBYEV A Y,GUO C. Laser turns silicon superwicking[J].OpticsExpress,2010,18(7):6455-6460. [78] GAMALY E,VAILIONIS A,MIZEIKIS V,etal.. Warm dense matter at the bench-top:fs-laser-induced confined micro-explosion[J].HighEnergyDensityPhysics,2012,8(1):13-17. [79] CHARPENTIER T V J,NEVILLE A,MILNER P,etal.. Development of anti-icing materials by chemical tailoring of hydrophobic textured metallic surfaces[J].JournalofColloidandInterfaceScience,2013,394:539-544. [80] DUNN A,WLODARCZYK K L,CARSTENSEN J V,etal.. Laser surface texturing for high friction contacts[J].AppliedSurfaceScience,2015,357:2313-2319. [81] ABELN T,KLINK U. Laser strukturieren zur Verbesserung der tribologischen Eigenschaften von Oberfl chen[R]. Proc. of Stuttgarter Lasertage,2001. [82] WEIKERT M,DAUSINGER F. Surface structuring, in femtosecond technology for technical and medical applications[R]//Ed. by Dausinger F,Lichtner F,Lubatschowski H. Berlin,Springer-Verlag,2004:117-129. [83] BONSE J,KOTER R,HARTELT M,etal.. Femtosecond laser-induced periodic surface structures on steel and titanium alloy for tribological applications[J].AppliedPhysicsA,2014,117(1):103-110. [84] VOROBYEV A Y,GUO C. Colorizing metals with femtosecond laser pulses[J].AppliedPhysicsLetters,2008,92(4):041914. [85] SUGIOKA K,MEUNIER M,PIQUE A.Laserprecisionmicrofabrication[M]. Springer Series in Materials Science,2010,135,Chapter 4. [86] VOROBYEV A Y,GUO C. Spectral and polarization responses of femtosecond laser-induced periodic surface structures on metals[J].JournalofAppliedPhysics,2008,103(4):043513. [87] SANCHEZ F,MORENZA J L,AGUIAR R,etal.. Whiskerlike structure growth on silicon exposed to ArF excimer laser irradiation[J].AppliedPhysicsLetters,1996,69(5):620. [88] SHEEHY M A,WINSTON L,CAREY J E,etal.. Role of the background gas in the morphology and optical properties of laser-microstructured silicon[J].ChemistryofMaterials,2005,17:3582-3586. [89] VOROBYEV A Y,MAKIN V,GUO C. Brighter light sources from black metal: significant increase in emission efficiency of incandescent light sources[J].PhysicalReviewLetters,2009,102(23):234301. [90] WAN J. Tunable thermal emission at infrared frequencies via tungsten gratings[J].OpticsCommunications,2009,282(8):1671-1675. [91] WU C,CROUCH C H,ZHAO L,etal.. Near-unity below-band gap absorption by microstructured silicon[J].AppliedPhysicsLetters,2001,78(13):1850-1852. [92] TORRES R,VERVISCH V,HALBWAX M,etal.. Femtosecond laser texturization for improvement of photovoltaic cells:black silicon[J].JournalofOptoelectronicsandAdvancedMaterials,2010,12(3):621-625. [93] KHAKBAZNEJAD A,CHEHROUDI B,BRUNETTE D M,etal.. Effects of titanium-coated micromachined grooved substrata on orienting layers of osteoblast-like cells and collagen fibers in culture[J].JournalofBiomedicalMaterialsResearchPartA,2004,70(2):206-218. [94] COCHRAN D L,BUSER D,BRUGGENKATE C M,etal.. The use of reduced healing times on ITI implants with a sandblasted and acid-etched(SLA) surface:early results from clinical trials on ITI SLA implants[J].ClinicalOralImplantsResearch,2002,13(2):144-153. [95] YADA S,TERALAWA M. Femtosecond laser induced periodic surface structure on poly-L-lactic acid[J].OpticsExpress,23(5):5694-5703. [96] IVANOVA E P,HASAN J,WEBB H K,etal.. Bactericidal activity of black silicon[J].NatureCommunications,2013,4:2838. [97] MESSAOUDI H,DAS S K,LANGE J,etal.. Femtosecond-laser induced nanostructuring for surface enhanced Raman spectroscopy[J].Proc.SPIE,2014,8972:89720L.2.4 Self-organization model based on material instability

2.5 Second harmonic generation(SHG)

2.6 Transient optical coupling for LIPSS

3 Materials transformations under LIPSS

4 Applications of LIPSS in material surface processing

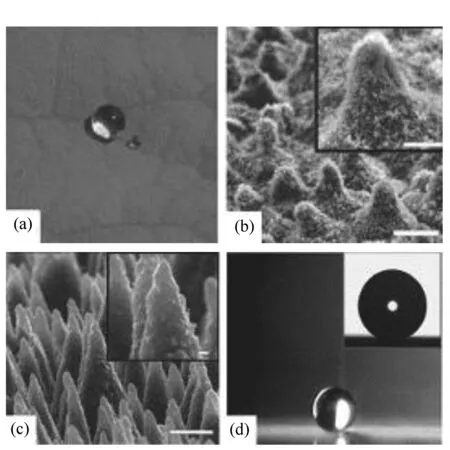

4.1 Hydrophobicity and hydrophilicity

4.2 Tribology

4.3 Metal colorization

4.4 Light trapping and emitting

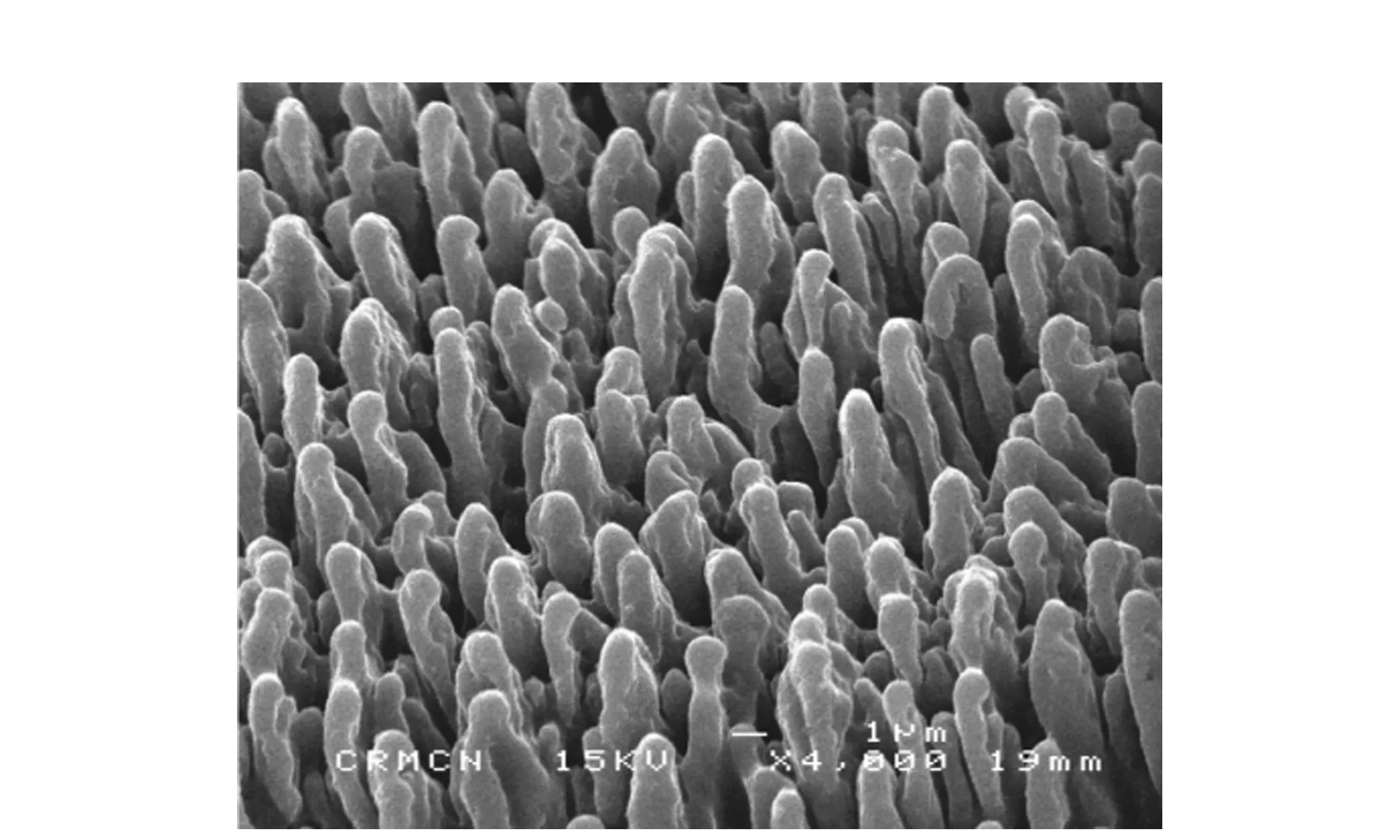

4.5 Bio-medical application

5 Challenges and opportunities

6 Conclusion

杂志排行

中国光学的其它文章

- 新型二维材料在固体激光器中的应用研究进展

- 纳米尺度下的局域场增强研究进展

- Influence of the geometric parameters of the electrical ring resonator metasurface on the performance of metamaterial absorbers for terahertz applications

- Grating diffractive behavior of surface plasmon wave on meta-surface

- 基于近红外量子点的荧光共振能量转移生物探针构建及应用

- 基于光谱指数的蜜橘成熟度评价模型研究