The first offshore natural gas hydrate production test in South China Sea

2018-01-18JinLiJinlingYeXuwenQinHijunQiuNengyouWuHilongLuWenweiXieJingnLuFeiPengZhenqingXuChengLuZengguiKungJingongWeiQinyongLingHongengLuBeieiKou

Jin- Li , Jin-ling Ye, Xu-wen Qin, Hi-jun Qiu, Neng-you Wu, Hi-long Lu, Wen-wei Xie, e, Jingn Lu, Fei Peng, Zhen-qing Xu, Cheng Lu, g, Zeng-gui Kung, Jin-gong Wei, Qin-yong Ling, Hongeng Lu, Bei-ei Kou

a China Geological Survey, Beijing 100037, China

b Guangzhou Marine Geological Survey, China Geological Survey, Guangzhou 510075, China

c Qingdao Institute of Marine Geology, China Geological Survey, Qingdao 266071, China

d Peking University, Beijing 100871, China

e Institute of Exploration Techniques, China Academy of Geological Sciences, Langfang 065000, China

f CNPC Offshore Engineering Company Ltd., Beijing 100102, China

g Center of Oil &Natural Gas Resource Exploration, China Geological Survey, Beijing 100083, China

A B S T R A C T

Natural gas hydrates (NGH) is one of key future clean energy resources. Its industrialized development will help remit the huge demand of global natural gas, relieve the increasing pressure of the environment,and play a vital role in the green sustainable growth of human societies. Based on nearly two decades’studying on the reservoir characteristics in the South China Sea (SCS) and the knowledge of reservoir system, the China Geological Survey (CGS) conducted the first production test on an optimal target selected in Shenhu area SCS in 2017. Guided by the "three-phase control"exploitation theory which focused on formation stabilization, technologies such as formation fluid extraction, well drilling and completing,reservoir stimulating, sand controlling, environmental monitoring, monitoring and preventing of secondary formation of hydrates were applied. The test lasted for 60 days from May 10th when starting to pump,drop pressure and ignite to well killing on July 9th, with gas production of 3.09×105 m3 in total, which is a world record with the longest continuous duration of gas production and maximal gas yield. This successful test brings a significant breakthrough on safety control of NGH production.

Keywords:

Natural gas hydrate (NGH)

Production test

Shenhu area

South China Sea (SCS)

1. Introduction

NGH is a clathrate compound composed of natural gas and water under low-temperature and high-pressure conditions (Sloan ED, 1990). 1 m3NGH can be decomposed into about 0.8 m3water and 164 m3natural gas (dominantly methane, under standard atmospheric pressure). NGH mainly exists in the sediment beneath the seabed, permafrost area and some deep lake deposits. It is characterized by high energy density, extensive distribution, large resource reserve and shallow buried depth. NGH is also believed to be one of the new clean energy resources with the highest potentials of replacing coal, petroleum and conventional natural gas in the 21stcentury (Dallimore SR and Collett TS, 2005; Makogon et al., 2007).

In 1810, Humphrey Davy synthesized chlorine hydrate in the lab for the first time. In 1888, Villard verified the existence of hydrates of methane, ethane and propane. In the mid-1930s, Hammer Schmidt discovered the phenomenon that the NGH blocked gas transmission pipelines, which led to a wide interest on NGH research (Sloan ED and Koh CA, 2008). In the 1960s, when former Soviet reported there were convincing evidences that naturally formed gas hydrates occurring above the shallow gas reservoirs of Siberia, scientists believed that the temperature-pressure conditions favoring formation of gas hydrates were widely present in nature. Some of the expeditions being carried on the Deep Sea Drilling Program (DSDP), the Integrated Ocean Drilling Program (IODP)and the Oceanic Drilling Program (ODP) commencing from 1960s, as well as hydrate investigations by China, Japan,South Korea and India, demonstrated that NGH resource potentials were enormous. According to preliminary estimates,the total global NGH reserve is approximately 2.1×1016m3(Kvenvolden KA, 1999), nearly twice of the traditional fossil fuel reserves in the world, which is large enough to replace the increasingly depleted traditional oil and gas resources. The NGH is a worldwide strategic and prospecting commercial resource concerned by many countries in the 21stcentury.

The production test in SCS is the first trial on NGH bearing in silty clay formation in the world. The clayey-silt NGH reservoir is widely distributed across the world which bears more than 90% of the global NGH (Johnson H, 2011). It is more difficult to exploit this kind of NGH due to its low permeability characteristics. Several production tests having been carried on in Canada, USA and Japan were all in sandy reservoirs. Thus, the successful production test in the clayey-silt reservoirs in China has much more significant implications for the development and useage of NGH resources. This paper systematically describes the geological background of the production test area, the characteristics of the hydrate minerals, the key techniques and artifacts used in the test, the offshore engineering and the environmental impact assessments.

2. Characteristics of the gas hydrate systems in SCS

2.1. Geological background

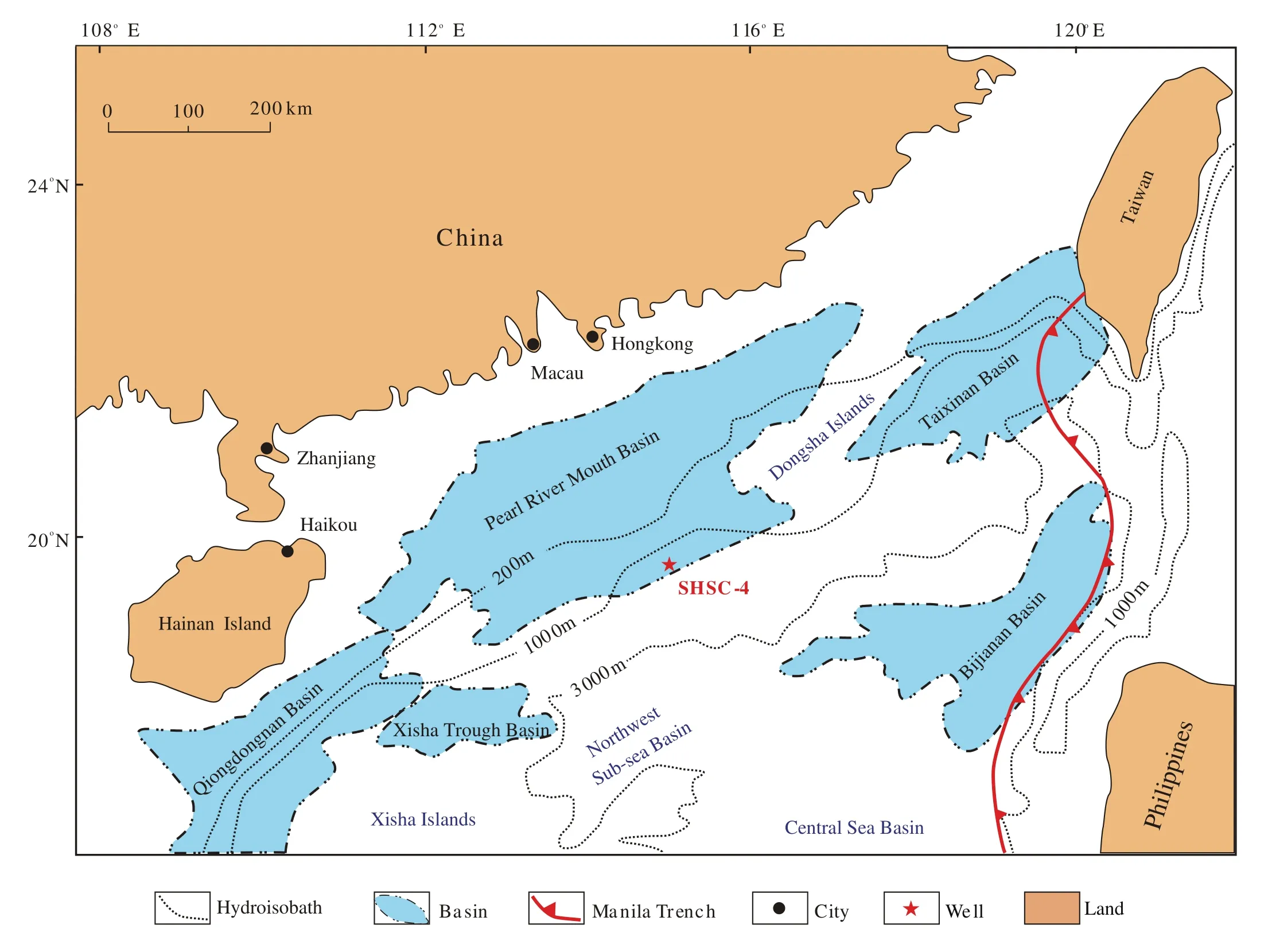

The production test field is structurally part of the Baiyun Sag of the Zhuer Depression in the Pearl River Mouth Basin(Fig. 1). The production test area is located in the middle of the continental slope of southeast Shenhu area, northern SCS between Xisha Trough and Dongsha Islands (Su PB et al.,2014; Fu SY and Lu JA, 2010). The topography of seafloor is complicated with high in the north and low in the south, the typical features including eroded channels, sea valley, sea mounts, steep slope, reverse slope, plateau, alluvial fan, slide fan and so on (Su PB et al., 2014; Wang JL et al., 2015; Liang J et al., 2013; Li W et al., 2013). Continental slope in the northern SCS, influenced by the interactions of Eurasian plate, Pacific plate and Indochina plate, is characterized by both passive continental and active continental features. Regional tectonic movements are very active during the Cenozoic, such as the Shenhu Movement, the Zhuqiong Movement,the SCS Movement and the Dongsha Movement (Liu CS et al., 2006; Fuh SC et al., 2009; Cui SS et al., 2009; Zhu WQ et al., 2014). Three groups of normal faults were developed in the directions of the NE, NW and NWW respectively. NW and NWW faults were formed earlier in the large scale with strong inherited activity cutting through the Miocene to Pliocene. NE normal fault was formed after the NW and NWW faults in a relative small scale, which is mainly composed of strata-bound faults with inherited features. Due to the plastic flow triggered by the tectonic movements, large-scale mud diapirs are formed and highly-angled fractures and vertical fissure systems are generated in the overlying formation,which are acted as conduits for the migration of fluid flow(Wang JL et al., 2015; Fu SY and Lu JA, 2010).

Fig. 1. Structural units in the northern SCS and the location of NGH production test area (modified from Yang SX et al., 2017).

Multi-tectonic movements changed the strata into rifted and depressed dual structures. Continental facies, transitional facies, marine facies were developed with transgression characteristics from the deep to the shallow (Su PB et al., 2014;Fu SY and Lu JA, 2010; Shi HS et al., 2014). The Cenozoic strata are including the Shenhu Formation, the Wenchang Formation, the Enping Formation, the Zhuhai Formation, the Zhujiang Formation and the Hanjiang Formation, the Yuehai Formation, the Wanshan Formation and the Quaternary. The deposition rate of the Cenozoic strata is fast. There is also enriched hydrocarbon preserved in the Cenozoic strata (He JX et al., 2008). The organics in the mud-rich marine-facies sediment of the Zhujiang Formation and above strata are mostly in immature or low-mature stages, producing massive quantities of biogenetic gas. Additionally, the Wenchang-Enping Formations might be the main source rocks for the hydrothermal gas (Su PB et al., 2014). Shenhu area have excellent conditions of gas hydrate accumulation, which is a target area for NGH exploration and development in the future.

2.2. Characteristics of the production test deposit

Since 2003, CGS has carried out investigation and assessment on NGH resources in Shenhu area, conducting geological, geophysical and drilling surveys, and obtained actual NGH samples in 2007 for the first time, a breakthrough for NGH exploration. In 2015 and 2016, CGS continued carrying out two expeditions for NGH drilling and eight NGH deposits were discovered. It is estimated more than a hundred billion cubic meters for controlled natural gas resource, suggesting a huge resource potential of NGH.

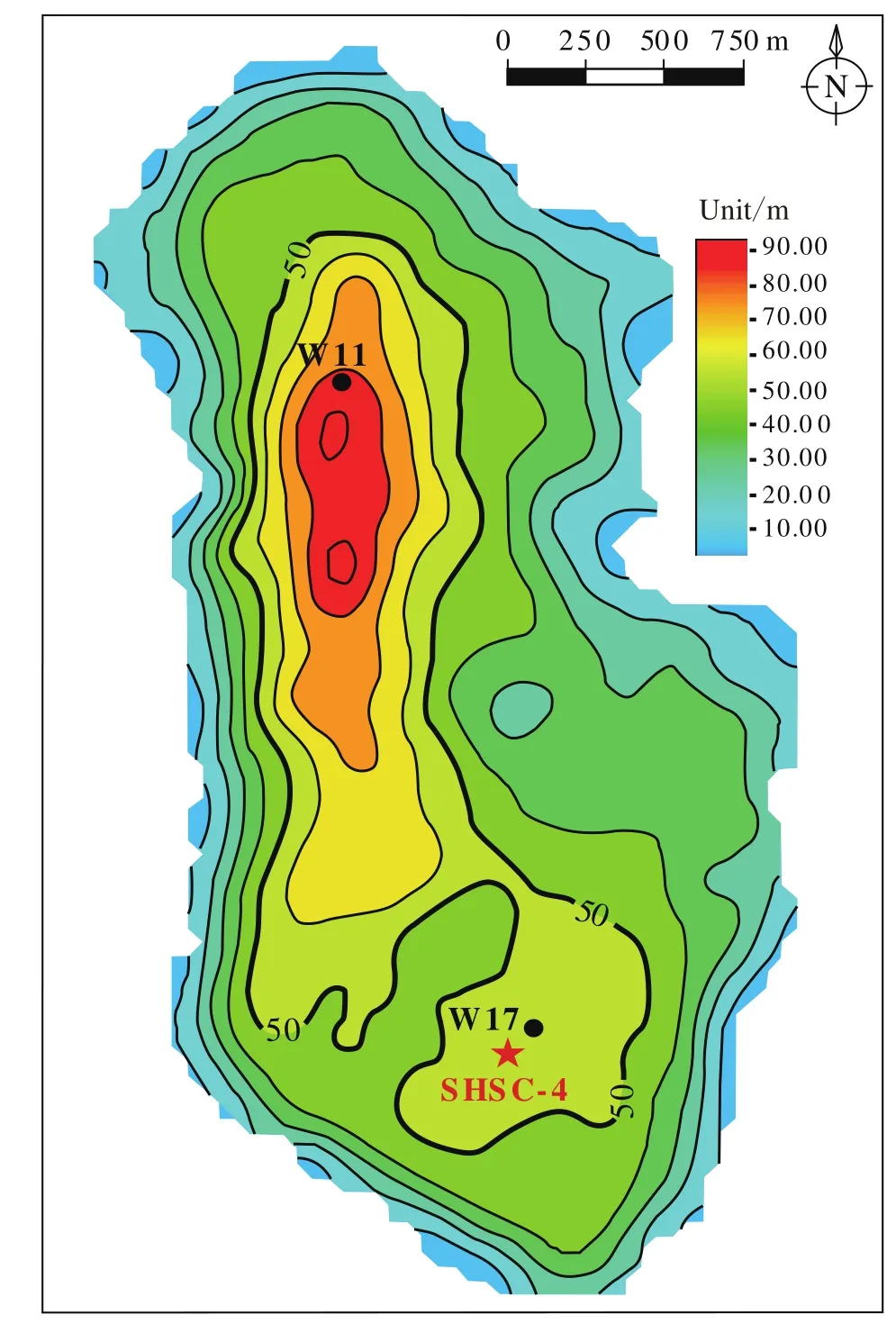

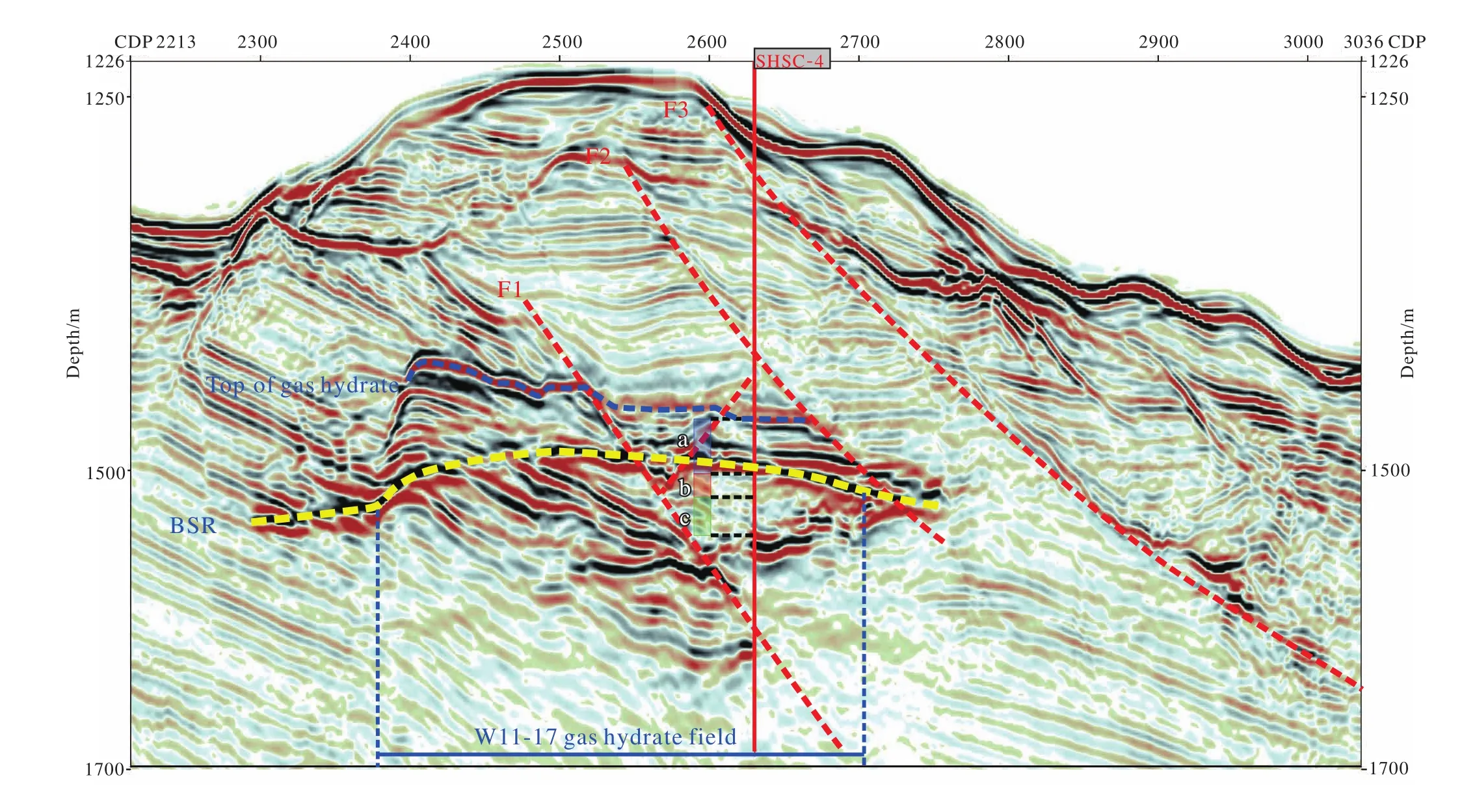

Among the eight NGH deposits, the W11-17 deposit (Fig. 2)was selected as the optimal target for the production test. The deposit, which is very thick and tends to be a north-south belt,is controlled by two wells, W11 and W17. The reservoir is 6.42 km2in area, the thickest place nearby well W11, where the maximal thickness was up to 95 m, and the mean available thickness is 57 m, featuring the thicker middle and the thinner margin. Seismic profile (Fig. 3) shows that, although the thickness of NGH in well W17 is not thicker than that of well W11, the deeper hydrate reservoir in well W17 affected by the fault F1 is better for project implementation, which is the most important factor to choose the W17 as the first target.

Fig. 2. Thicknesses of NGH of W11-17 deposit in Shenhu area.

2.3. Characteristics of gas hydrate systems

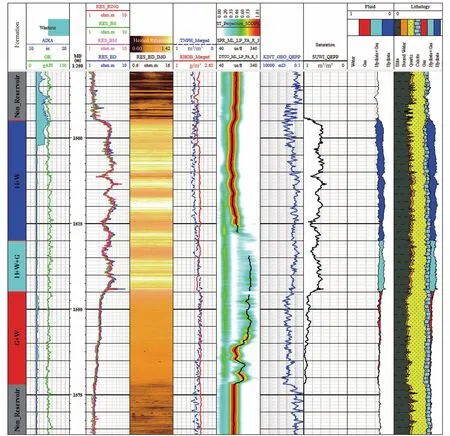

According to the logging interpretation and the results from the core analysis of SHSC-4 (Fig. 4), the overlying formation is from the sea bottom to 1495 m (201 mbsf; water depth 1266 m, rig floor 28 m). The NGH system in the test site consists of three intervals from top to bottom, which are:(a) 1495-1530 m (201-236 mbsf), with its pore space filled with solid NGH and liquid water; (b) 1530-1545 m (236-251 mbsf), with its pore space filled with three phases: solid NGH,free hydrocarbon gas and liquid water; (c) 1545-1572 m (251-278 mbsf), with the pore space filled with two phases: free hydrocarbon gas and liquid water. The reservoir lithology is clayey silt, whereas, the mean effective porosity within interval "a" is 35%, the mean hydrate saturation is 34%, and the mean permeability is 2.9 mD. The mean effective porosity of interval "b" is 33%, the mean hydrate saturation is 31%, and the mean permeability is 1.5 mD. The mean effective porosity of interval "c" is 32%, mean gas saturation is 7.8%, and the mean permeability 7.4 mD. This new kind of reservoir type, with different phases coexisting conditions, cannot be completely correspondent to any kind deposit type proposed by Moridis GJ et al., 2007, but a combination of IWand IG.

Fig. 3. Characteristics of seismic sections crossing the production test well SHSC-4 (a, b and c are described in details in section 2.3).

Based on the core analysis and well logging data (Fig. 4),the hydrate reservoir below 1530 m (236 mbsf), containing three phases (solid NGH, free hydrocarbon gas and liquid water), is regarded as the most active section. The temperature and pressure in this active section is closest to NGH phase equilibrium curve, and is suitable for gas hydrate production.

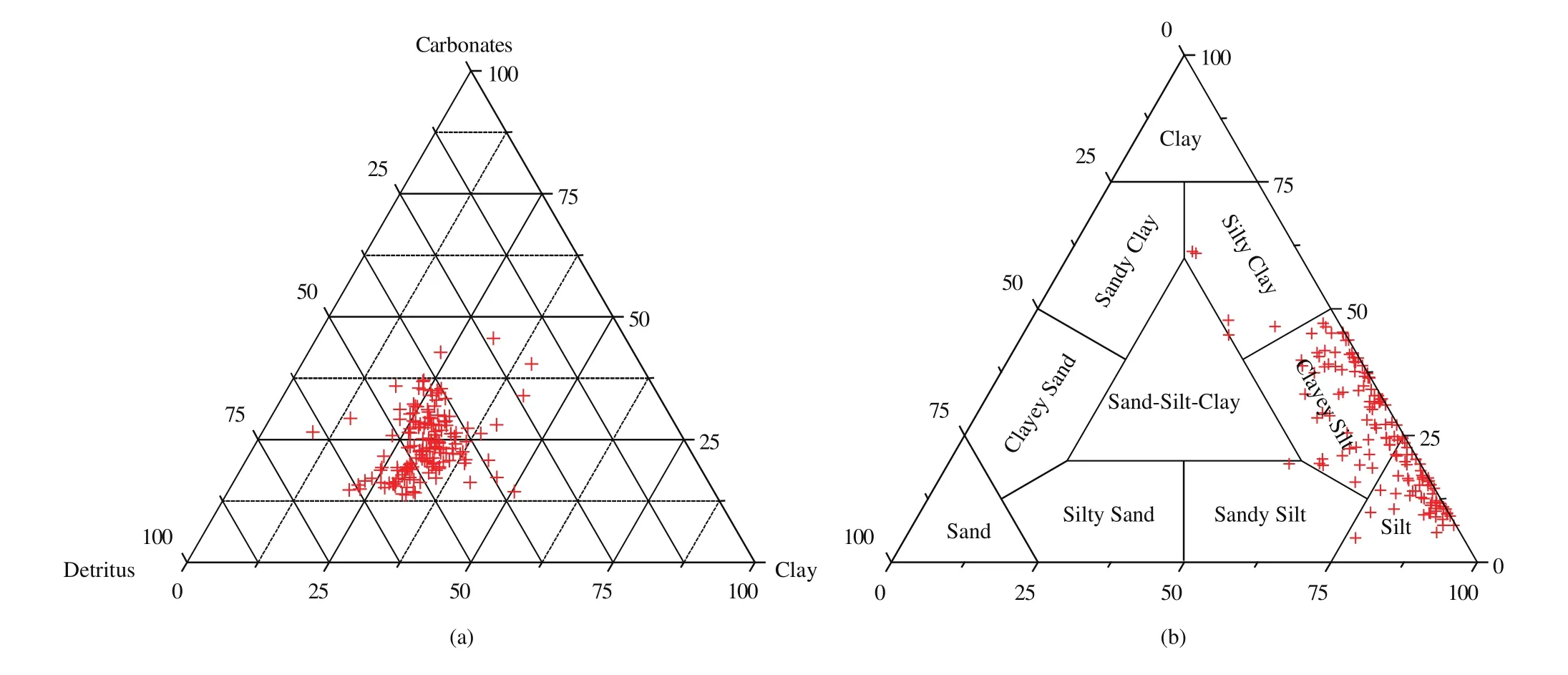

In the hydrate reservoir, the mean median grain size of the sediments is about 12 μm. The minerals are mainly quartzfeldspathic (53%), carbonates (16%) and clay minerals (26%-30%), which are mainly montmorillonite and illite (Fig. 5).The high content of clay minerals results in high bound water concentration more than 65%. The flow-speed sensitive experiment on the porous media of the reservoir formations indicates that the permeability of the porous media in the clayey-silt reservoir is strongly sensitive to flow speed. This non-linear relationship between the flow speed and the pressure gradient outstands the 'non-Darcy' vadose phenomenon.The very low permeability in the reservoir formation and the strong sensitivity to flow speed are the challenges to be overcome in order to improve the gas production during the gas hydrate production test.

Fig. 4. Logging curves of the production test well SHSC-4.

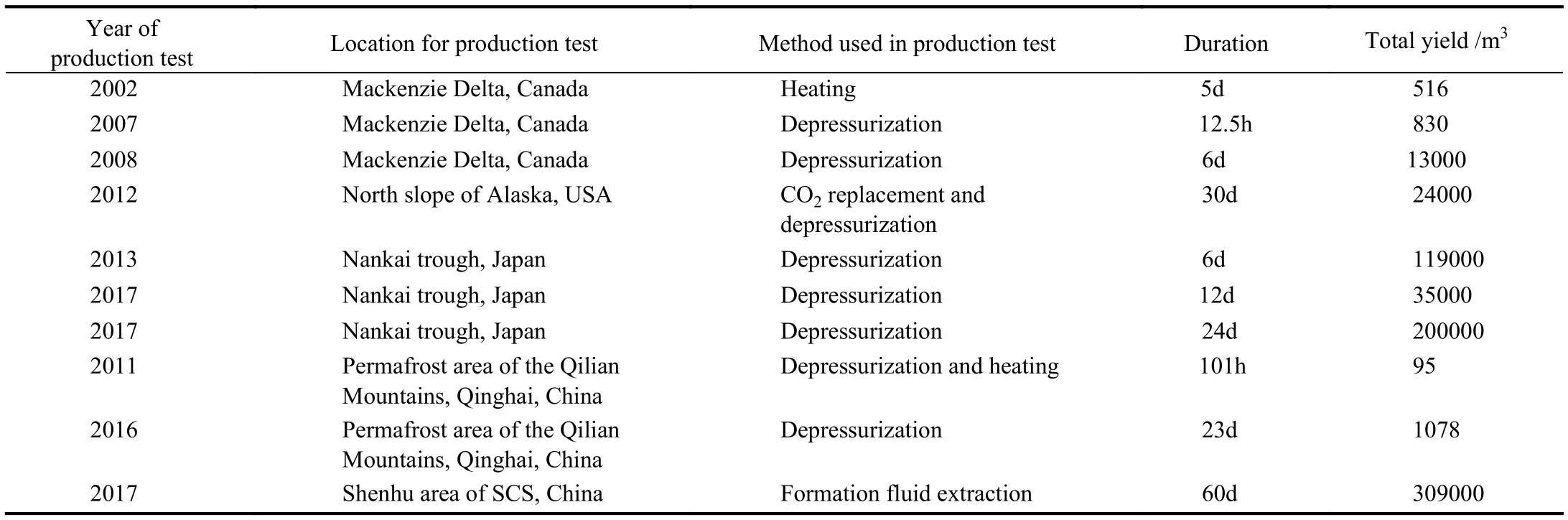

2.4. International comparison

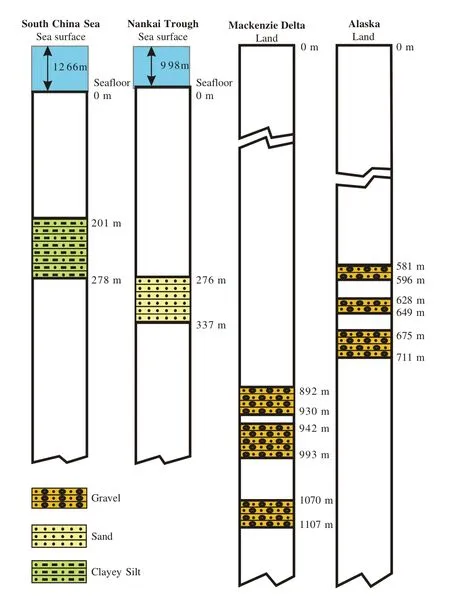

The Mallik production test project is a large international cooperation project involving the participation of more than 200 scientists from more than 50 research institutions in Japan, Canada and USA and so on. The production test conducted in 2002, 2007 and 2008. The drilling results of well Mallik 5L-38 (Collett TS et al., 2009; Dallimore SR and Collett TS, 2005; Zhang XH et al., 2014) show that NGH is distributed at a depth of 892-1107 m underground. The lithology is mainly composed of two facies: thick-layered sandstone interbedded with a conglomerate, and layered sandstone interbedded with conglomerate and siltstone. NGH is mostly produced in the form of pore filling with high saturation from 50% to 90%. The heat-injection layer was between 892 m and 930 m during the production test.

From February to April 2012, Conoco Phillips, DOE and JOGMEC, conducted a field production test, also known as the Ignik Sikumi gas hydrate Field trial, by jointly applying CO2-CH4replacement and depressurization in Alaska, USA.The lithology of the drilled samples is mainly thick-layered sandstone. The porosity of the sediments is 40%, the absolute permeability is 1000 mD and the hydrate saturation is about 70% (Anderson B et al., 2014; Schoderbek D and Boswell R,2011; Zhang XH et al., 2014).

Sponsored by the Ministry of Economy, Trade and Industry of Japan, the first NGH production test was conducted on the Daini-Atsumi Knoll in the eastern Nankai Trough in 2013. The planning, management and supervision was conducted by JOGMEC and the field operation was done by JAPEX. The second production test was performed in the same area in 2017 (Zhang W et al., 2017). The drilling results from the production test well and the monitoring well (Fujii T et al., 2015) showed that from 275.8 to 337.3 m is a highly-saturated hydrate layer and saturation is 60% to 80%. The lithology of upper section is mainly composed of thin silts interbedded with fine clay. The middle section is mainly mudrich sediments. The lower section is the most important hydrate layer reservoir, consisting of coarse sand interbedded with silts.

三、有着长达数千年“层累”优势的中国文化,其发育发展离不开中国乡村社会土壤,其思想内涵在村落生活中有丰富积存。因此,这种实验式村落民俗志书写还应在深描之中提炼理论话语,从国家推行、精英阐发与民众实践等维度对中国文化作交互式理解,特别是发掘与分析中国文化的民间表达形式与传承机制,以小见大地阐述中国社会的人文传统、基本国情与发展道路。

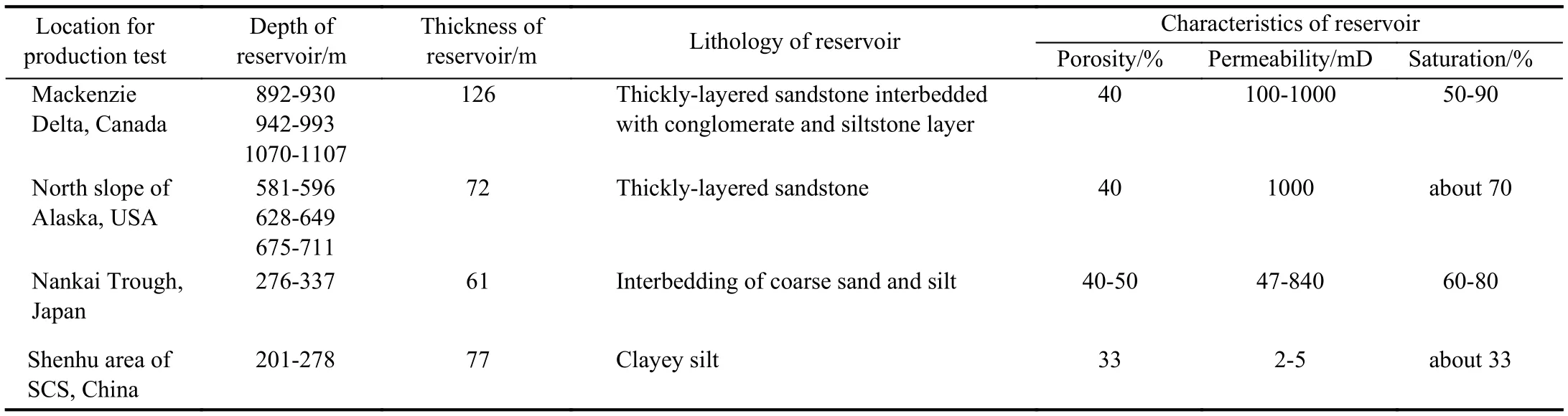

To summarize, the hydrate reservoir in the Shenhu area of China, is mainly composed of fine grained clay silt with low permeability, and very difficult for exploitation, which is very different from those discovered in USA, Canada (both are conglomerate) and Japan (generally coarse sand). Their basic characteristics are shown in Fig. 6 and Table 1.

Table 1. Characteristics of hydrate reservoirs and gas hydrate system for production test in the world.

Fig. 5. Mineralogy (a) and lithology (b) of the reservoir sediments.

Fig. 6. The cartoon of reservoir from global production test deposits.

3. Technologies used in production test

3.1. Theory for production test

A series of problems like shallow depth of reservoir, unconsolidated formation, fine grains in sediment, low permeability and sand production problem can occur during the production test. On the basis of the characteristics of NGH systems and formation stabilization, a "three-phase control" exploitation theory was proposed to solve the problems occurred during the test. The key idea is to establish the predominant fluid channels in the formation by extracting fluid to drop formation pressure, so as to effectively control the change of formation pressure, attaining the phase ex-transforming and induce the dissolving of NGH and keeping the formation stable.

Under the guidance of the "three-phase control" exploitation theory, "formation fluid extraction" was proposed. By extracting fluids from the formation to control the transforming of hydrate’s phase state and under the stabilization conditions of the reservoir and well wall, gas production from the NGH system was realized. Compared to traditional depressurization, the purpose of fluid extraction is not only depressurization, but also the control of the change of hydrate’s phase state and formation stabilization.

3.2. Production technologies

A number of important techniques were developed during the production test, thus technically guaranteeing successful production test. In this paper, descriptions are focused on the"sweet-spot" identification, formation stimulation, sand control, flow assurance technologies and environmental monitoring technologies. In addition, there are some other key technologies such as reservoir sensitivity-to-seepage-flow-speed analysis technology and depressurization control technology at the site of pilot production, which are in the patent application stage and will be discussed in the subsequent articles.

3.2.1. "Sweet-spot" identification

Technologies used in the oil and gas field were introduced in the NGH field to identify the sweet spot in NGH.The high-precision reservoir tomography, the HF full-wave inversion and well-constrained fine reservoir modeling are applied in combination with data from CESM, ocean bottom seismic and advanced well logging and so on to obtain the characteristics of NGH, so as to create a set of technological systems capable of identifying NGH efficiently.

3.2.2. Formation stimulation

3.2.3. Sand controlling

Sand controlling refers to adopt slow depressurization scheme under the preconditions of assuring well wall stability and scientifically design the sand controlling pipe to precisely prevent the sediments from entering the borehole. Sand yield can be monitored through ground testing.

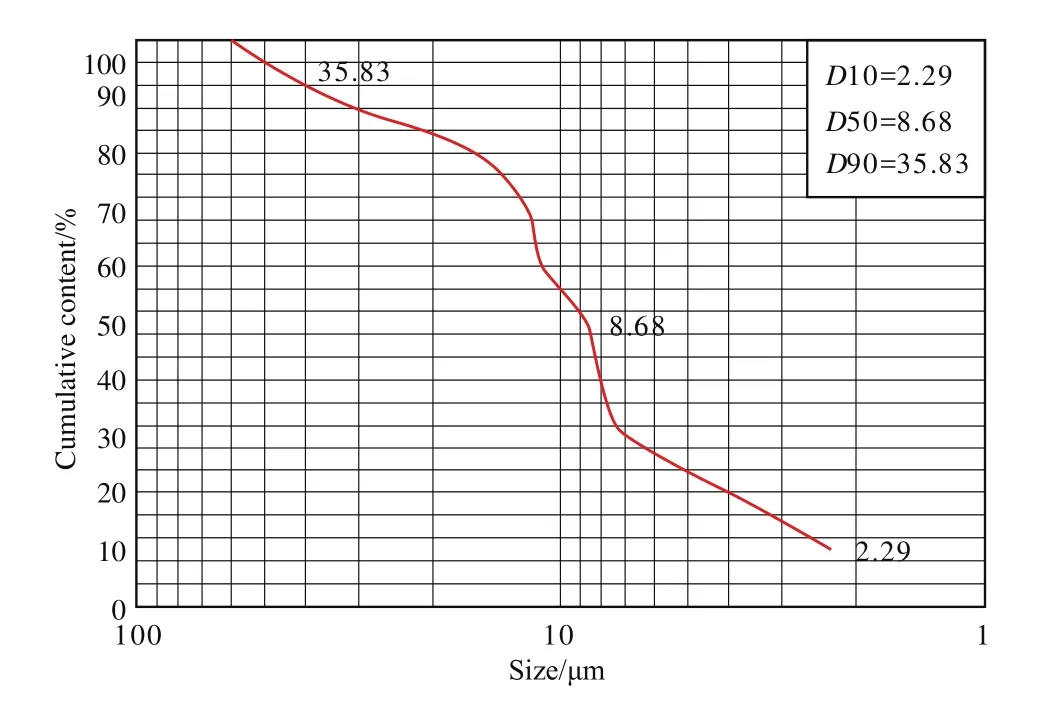

During the sand control testing experiments, prefilled sand controlling pipe was optimized to block the sand grains to 44 μm. Altogether 0.286 m3sediments was collected. To understand sand yield in the formation and the effect of the sandcontrol screen on sand prevention, the high-precision laser particle analyzer was used to analyze the grain size of the sediments in real time, and the results indicated that the median grain size of sediments was from 2.60 to 28.96 μm, and the average value is 8.49 μm, meaning it was a grade of silt (Fig. 7).The sand control technologies applied in the production test project worked successfully.

3.2.4. Flow assurance

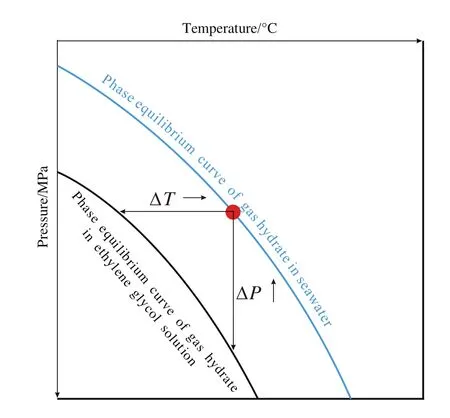

Gas in the borehole runs the risk of generating hydrate secondly, under conditions of certain temperature and pressure. During production test, the gas-water separation system and the depressant injection system are combined to effectively avoid secondary formation of hydrate. The gas-water separation system is designed to decrease the contact of gas and liquid, so as to prevent secondary formation of hydrate.During the test process, the concentric tubes and double-end oil tubes with inner and outer flow passages were used to separate gas from liquid in the gas-liquid mixture output from the reservoir, and deliver them separately to the platform via respective flow passages. The depressant injection is intended to raise the temperature and pressure (ΔT, ΔP) required for hydrate formation and then averts secondary formation of hydrate (Fig. 8). For the production test, two ethylene glycol (a depressant) injection points were designed. One injection point through the chemical injection valve located at the reservoir to mix with the fluid inside the well, and the other is the chemical injection valve in the marine test tree to mix with the fluid in the gas passage, effectively preventing secondary formation of hydrate.

Fig. 7. Grain size features of one sample from produced water.

Fig. 8. Diagram showing the process of inhibition of the secondary formation of hydrate with ethylene glycol.

It is similarly important to monitor and control the secondary formation of NGH in the borehole. As hydrate is mainly influenced by temperature and pressure for its stability, during the production test, not only were thermo barometers installed at a number of important downhole nodes, but distributed temperature sensors (DTS) were also installed at important sections. The DTS data 3D visualization and NGH secondary-formation determination program were innovatively used so that the risk of NGH secondary formation was monitored and controlled in real time.

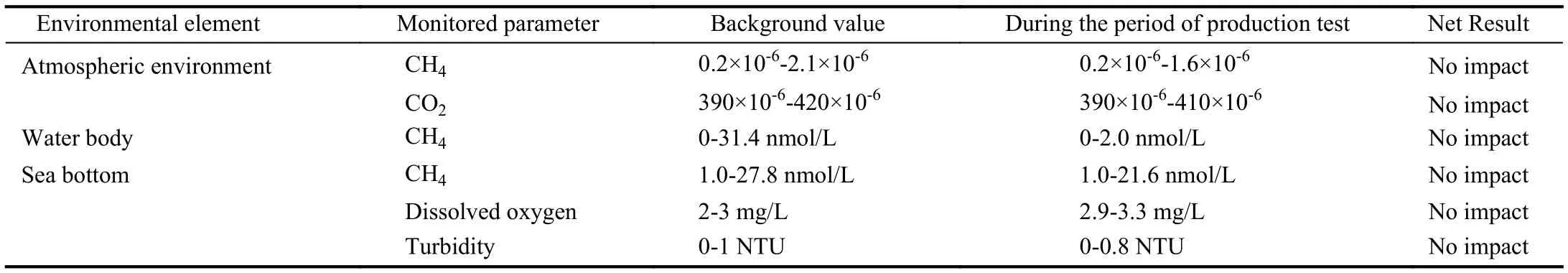

3.2.5. Environmental monitoring technologies

Regarding the NGH exploration area in the northern SCS,the NGH related environment problem was also concentrated on those areas by CGS. Since 2011, CGS has investigated the NGH environmental effect in the NGH drilling and exploration area, both the production test and the prospect areas.From June 2011 to March 2017, thirteen voyages for overall marine environmental investigation were conducted at the production test area to obtain background data of parameters regarding the marine environment, atmosphere, seawater and submarine methane and so on. Meanwhile, systematic researches were conducted on methane seepage, submarine landslide, subsidence, marine biological changes etc. potentially caused by marine NGH exploration and production test.

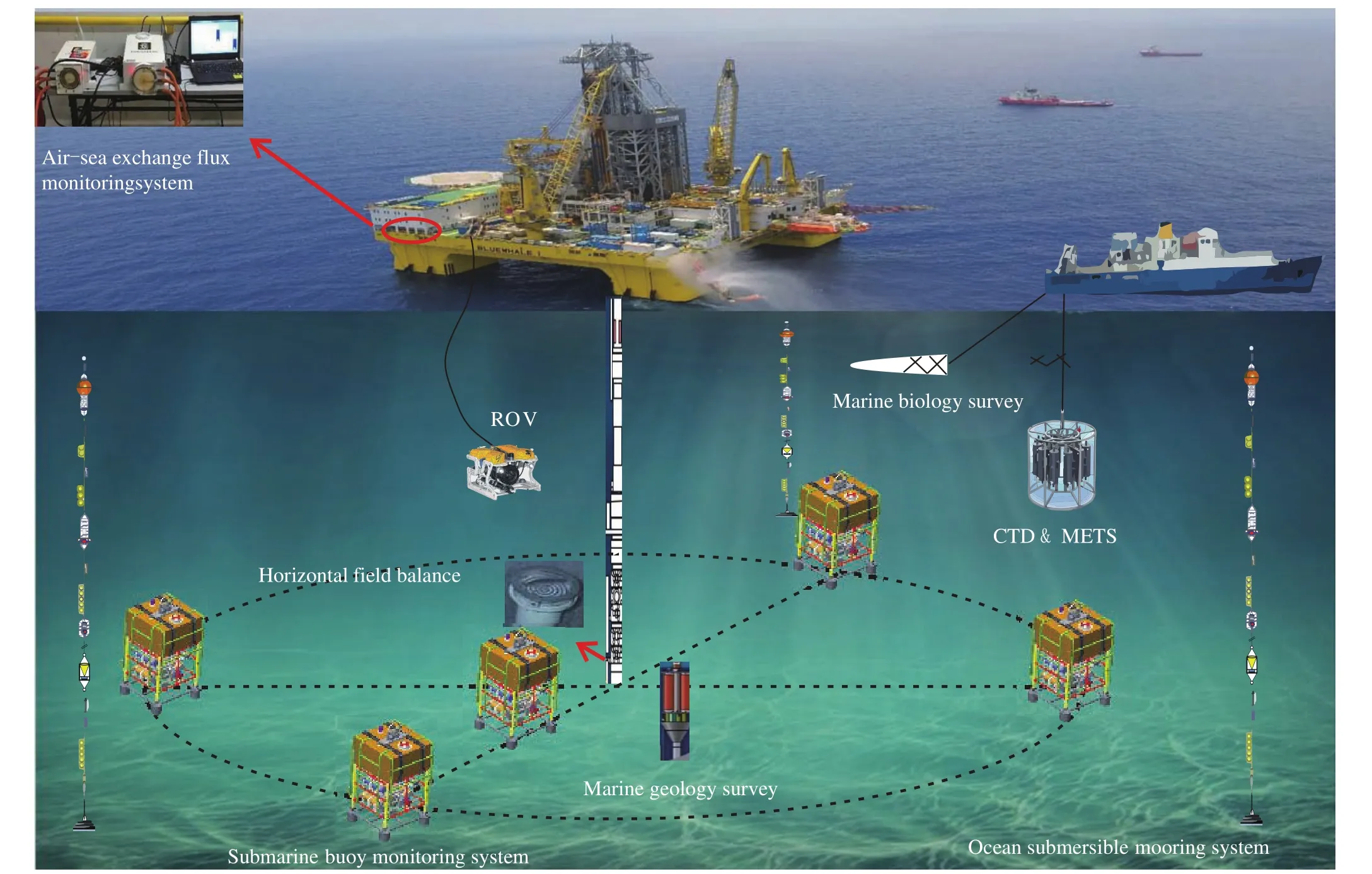

In 2016, at the Shenhu NGH production test area, a wellsite geophysical survey was conducted to get high-precision seabed topography and geomorphology, and the shallow stratigraphic structure. In order to achieve detail engineering geological characteristics of overlying sediment stratigraphy in the production test area, an engineering geological drilling voyage was down during hydrate drilling and exploration(GMGS4). These information were further used for analyzing the stability of the well-head, well wall, submarine slope and NGH reservoir, which providing decision for NGH production test. Moreover, during the production test, a 'four-in-one'monitoring system from near sea surface atmosphere, the seawater, the seafloor and borehole environments (Fig. 9) was set up to monitor the whole process of the production test. After the production test, an environmental survey was conducted to evaluate the environmental effect of the production test in September 2017.

Fig. 9. "Four-in-one" environmental monitoring system employed during the production test.

Based on the thirteen voyage surveys, the mean methane concentrations in the near sea surface atmosphere, seawater and seawater of near sea floor, in Shenhu area before NGH production test, were 1.5×10-6, 7.3 nmol/L and 3.1 nmol/L, respectively. During the process of production test, the values of methane concentration in the near sea surface atmosphere and seawater were 0.8×10-6and 0.7 nmol/L, respectively, both in the range of the background values of this area. During the production test, the concentration of dissolved methane in the bottom seawater nearly the production well site was mainly from 1.0 to 21.6 nmol/L. Only a relative higher concentration up to 193.0 nmol/L was detected when drilling to the NGH reservoir, which is much lower than that at natural methane seepage zones of other hydrate areas in the world (100-4000 nmol /L) (Charlou JL et al., 2004; Sauter EJ et al., 2006;Faure K et al., 2010; Krabbenhoeft A et al., 2010; Law CS et al., 2010; Jin YK et al., 2011). By the end of drilling and before fire test, the dissolved methane concentration in the bottom water had recovered to its base value. After the production test, the concentration of dissolved methane in the seawater was arranged from 1.0 to 4.4 nmol/L and the mean was 2.7 nmol/L, similar to the background value (Table 2). This indicates that after well cementation, the passage for methane leakage was closed and methane emission stopped, which further implies that the NGH production test is safely and controllable and will not cause methane to leak out. The comprehensive monitoring results showed that the methane concentration of near sea surface air, seawater, and the submarine environmental characteristics after production test, were consistent with the background values before the production test, suggesting that the NGH production test did not affect marine environment.

Table 2. Overall assessments on the environmental impact of the production test.

3.3. Production methods

NGH production tests of different time lengths were implemented in Mackenzie Delta, Canada, the permafrost area in the north of Alaska, USA, and in the trough of the South Japan Sea. At present, all of the most common production test methods are based on removing the conditions for the stable existence of hydrate, primarily utilizing depressurization,heating, depressant injection and CO2replacement. In 2002,the production test was conducted to recover hydrate in the permafrost area of Mackenzie Delta, Canada, by using the heating method for 5 days, yielding 516 m3(Sloan ED and Koh CA, 2008). Later on, in 2007 and 2008, the depressurization method was used for 12.5 hours and 6 days respectively,yielding 830 m3and 1.3×104m3, and then stopped because of sand production (Li XS et al., 2016). In 2012, CO2replacement and depressurization were used together at the north slope of Alaska for production test for 30 days, cumulatively yielding 2.4×104m3(Li XS et al., 2016). In 2013, depressurization was used in the production test to recover NGH from the sandy hydrate reservoir in the trough of the South Japan Sea for 6 days, cumulatively yielding 1.19×105m3gas, and the production had to be stopped due to seriously sand production. In 2017, two wells were put into production test by using depressurization in the trough of the South Japan Sea,of which one well was operated for 12 days yielding 3.5×104m3and ceased operation because of seriously sand production, while the other one operated for 24 days, yielding 2.0×105m3(Li XS et al., 2016).

The research on NGH production test in China, even though begun at later time, has made rapid progress. In 2011,CGS began to study on the work related to production test,and implemented two tests for production test in the permafrost area of the Qilian Mountains; in 2011, depressurization and heating were used for production test for 101 hours, cumulatively yielding 95 m3gas (Zhu YH, 2017); in 2016, it explored the '山'-shaped horizontally-butted well production test techniques, and applied depressurization to recover NGH for 23 days, yielding 1078.4 m3gas in total (Zhu YH, 2017). In 2015, China Geological Survey CGS formally initiated the offshore NGH production test project, and prepared for one year to accomplish the test site selection, the technical scheme making, optimization of drill rig and key equipment development etc. In 2017, in the Shenhu area of northern SCS, CGS using the drilling platform BLUEWHALE #1, conducted the first production test of offshore NGH by applying the 'formation fluid extraction' method for 60 days, yielding 3.09 × 105m3gas (Table 3).

Table 3. Exploitation characteristics of hydrates in the world.

4. Implementation of production test

The production test platform BLUEWHALE #1 set sailing on March 6th, 2017, and was positioned after arriving at the drill site. The water depth is 1266 m at the place where the well was to be drilled, and the KTB was 28 m. Drilling formally started on March 24thwith the 36″ conductor jet-drilling to 1397 m during the 1stspud, the 17-1/2″ borehole being drilled to 1470 m during the 2ndspud, before the 13-3/8″ casing was run down to 1467 m, and finally the underwater highpressure wellhead was installed and the well cemented. The blowout preventer and the marine riser were installed, and then the pressure was tested. The 3rdspud was implemented until it reached 1718 m and then the 9-5/8″ casing was run down to 1714 m. In the process of the 3rdspud in drilling, in-formation about the cuttings and hydrocarbons of the hydrate reservoir were obtained through mud-logging, and then combined with the physical parameters from LWD data to refine and divide the sections of hydrate reservoirs so that the accurate depth value being provided for formation stimulation.

Additionally, to monitor the temperature and pressure inside the hole for identifying the hydrate state, two thermo-barometers were installed at 1530 m and 1307 m, also the distributed optic-fiber temperature detection system along with the direct-reading thermo-barometer and the chemical injection tubing were deployed.

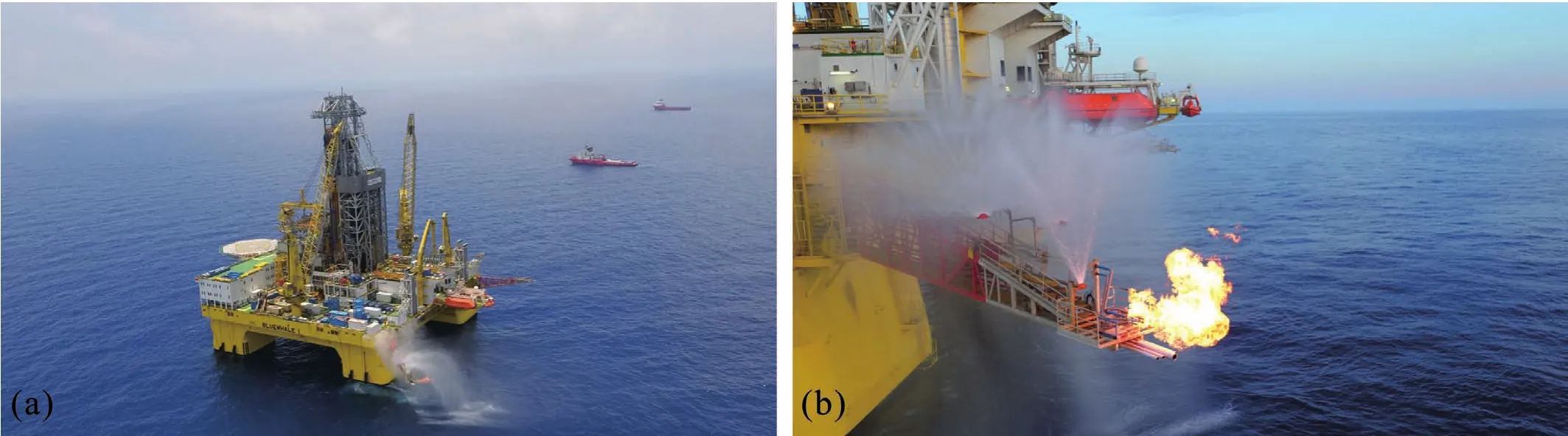

On May 10th, production started by dropping pressure in the hole. The chokes at the two passages respectively for liquid and gas and the rotary speed of the electric submersible pump were carefully regulated to stabilize the production pressure. At 09:20 a.m, the depressurization was started, with a successful ignition following at 14:52 (Fig. 10). From May 10thto the 18th, during the process of depressurization, it was observed that the temperature and the pressure differential responded synchronously. Throughout the production test, with the changing pulse of the pressure differential, the low-temperature abnormal pulse also occurred synchronously in the data of the distributed thermo-barometers, indicating that NGH was continually dissolving.

Fig. 10. Picture of first NGH production test in the SCS. The production test platform 'BLUEWHALE #1' (a) and the flame from the venting gas (b).

From June 12thto 15th, affected by a typhoon, the power cable of the electric submersible pump was damaged, and the artificial lift was stopped. However, because hydrate gas continually came out of the formation and water production was small, water continued to be discharged due to the gas self-lift effect, and the borehole pressure rose very slowly. Till June 16th, with nitrogen lifting, the borehole pressure was under manual control again, thus maintaining the pressure differential for continuous production. During the production test, the data of the thermobarometers inside the borehole indicated that, with changing production, the temperature constantly changed up and down, and the lowest temperature near the reservoir was 3.5°C. On July 9th, the well was artificially killed. The production lasted for 60 days in total, yielding 309046 m3of gas, at a mean daily yield of 5151 m3. The main gas composition is methane, accounting for more than 99.5%.After production, the production test string was recovered,and the well was abandoned.

Through analysis of LWD data acquired in the 4 monitoring holes surrounding the test well, variations were found to the logging curves in SHSC-4J1 which is 15 meters far away from SHSC-4. This variation supplies the key references for future study on the gas hydrate dissolving characters.

5. Conclusions

Comparing to other NGH production test sites, Shenhu production site is unique in the reservoir characters and is a complex system. The hydrate pay zone is marked by shallow depth, unconsolidated formation, fine particles of sediments,low permeability, rich of water absorption clay minerals, and is a clayey-silt type which is different from the medium to coarse sand reservoir in Japan, and the gravel reservoirs in USA and Canada.

The “three-phase control” exploitation theory, focusing on formation stabilization, was proposed for clayey-silt reservoir to guide the production scheme and was proven to be effective.

Formation fluid extraction, stimulation, sand control,'four-in-one' environmental monitoring technology, monitoring and control/prevention of secondary formation of hydrate etc. were developed to achieve outstanding results and guaranteed long-time production.

The results from environmental monitoring indicated that the test did not cause formation subsiding, methane leaking or any other geohazards, thus no adverse effects were made on the environment.

Acknowledgement

The test was funded by China National Project "Natural Gas Hydrate Exploration and Production Test". During the whole operation, China Geological Survey, China National Petroleum Company and Peking University paid greatest efforts for this trial. Sincere thanks would be given to them and also to those who had participated and supported the test.

猜你喜欢

杂志排行

China Geology的其它文章

- A super-large graphite deposit discovered in granite rocks at Huangyangshan,Xinjiang, China

- The oldest shale gas reservoirs in southern margin of Huangling uplift, Yichang,Hubei, China

- A discovery of Silurian tight shale gas in Jianshi, Hubei, China

- Three source rocks discovered in the Mid-Lower Jurassic, Dunhuang Basin in China

- Metamorphic petrology and geology in China: A review

- New prospecting progress using information and big data of coal and oil exploration holes on sandstone-type uranium deposit in North China