Consideration on Issues about Structural Durability of Shield Tunnels

2017-12-11HEChuanFENGKunSUNQiWANGShimin

HE Chuan, FENG Kun, SUN Qi, WANG Shimin

(1. Key Laboratory of Transportation Tunnel Engineering, Ministry of Education, Southwest Jiaotong University, Chengdu 610031, Sichuan, China; 2. China-Japan RSC Structure Research Center, Southwest Jiaotong University, Chengdu 610031, Sichuan, China)

ConsiderationonIssuesaboutStructuralDurabilityofShieldTunnels

HE Chuan1,*, FENG Kun1, 2, SUN Qi1, WANG Shimin1

(1.KeyLaboratoryofTransportationTunnelEngineering,MinistryofEducation,SouthwestJiaotongUniversity,Chengdu610031,Sichuan,China; 2.China-JapanRSCStructureResearchCenter,SouthwestJiaotongUniversity,Chengdu610031,Sichuan,China)

Structural durability of shield tunnel lining is a trans-scale problem from mesoscopic material to macroscopic structure. With increasing amount of shield tunnel construction in China, the issues related to structural durability become more prominent. In this paper, the typical applications of shield tunnel lining in China and other countries are introduced. The service conditions and diseases of shield tunnel lining structure are then analyzed. The factors affecting the structural durability of shield tunnel lining, such as material, design, environment, construction, management and maintenance, are summarized. The research results and progress related to structural durability of shield tunnel lining are then reviewed in terms of tunnel durability, durability evaluation and prediction, durability ensuring techniques. Finally, the existing problems and future research directions in structural durability of shield tunnel lining are discussed in terms of durability ensuring techniques, impact of diseases and accidents, tunnel evaluation and rehabilitation, arrangement of secondary lining and establishment of dynamic evaluation system for structural durability.

shield tunnel; segmental lining; structure durability; tunnel disease; research progress; prospect

0 Introduction

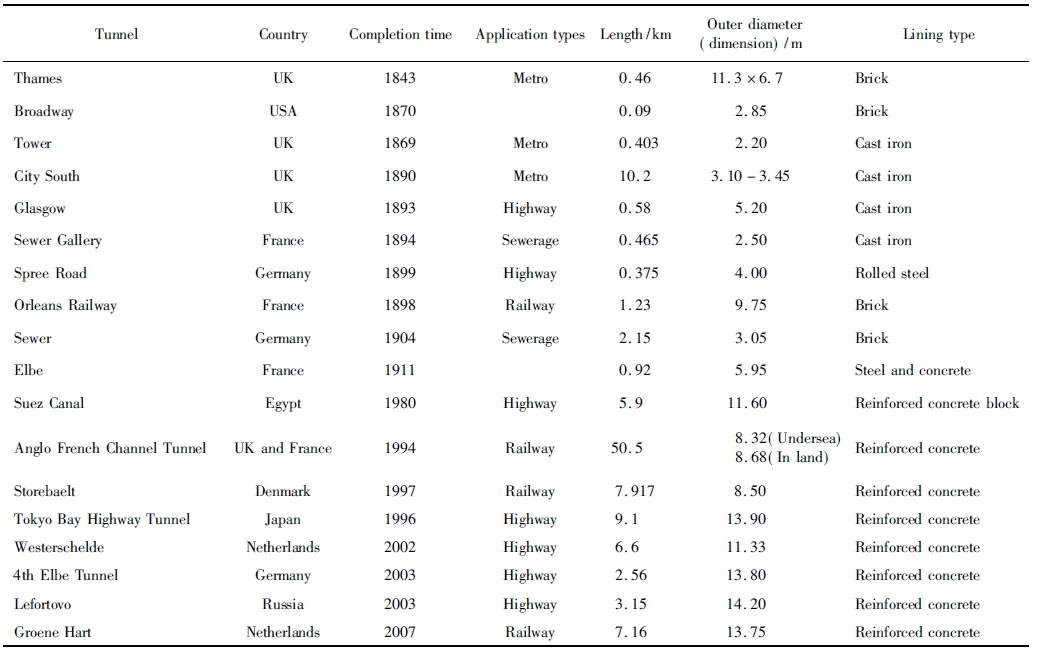

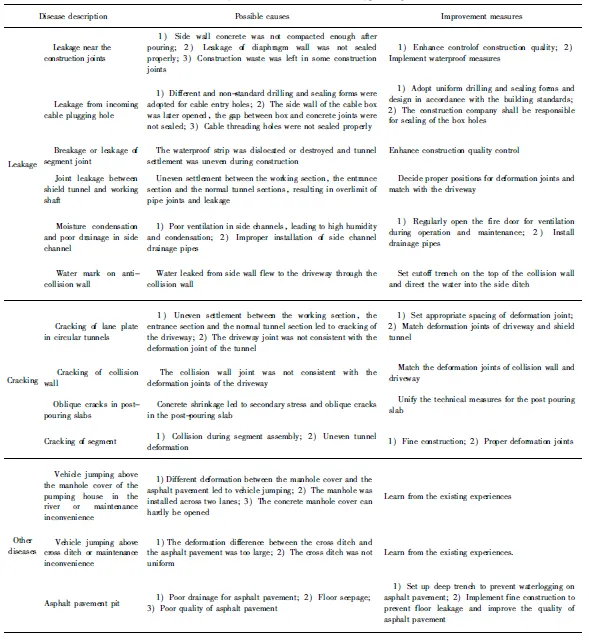

Shield tunneling method was first proposed by British engineer Sir Marc Isambard Brunel in the early 19th Century, and was put into practice during construction of a road tunnel under the Thames River in England from 1825 to 1843. The linings were made by rubble from a tile factory originally. However, due to water leakage, cast iron was adopted later for tunnel lining. Subsequently, the shield tunneling method had been developed rapidly in Japan and Germany. The lining materials were also changed from rubble, brick, cast iron and steel to reinforced concrete (RC). In 1936, the Kanmon Tunnel, with an outer diameter of 7 m, was completed in Japan. The cast iron segmental lining was adopted, which was later replaced by RC segmental lining. Application of RC segments was successful and promoted. It has gradually become the most popular form of shield tunnel lining[1-2]. The typical applications of shield tunnel lining around the world are listed in Table 1.

Table 1 Typical applications of shield tunnel lining abroad

Compared to cast iron or steel segments, the precast RC segment has higher durability and stiffness. The manufacturing process can be programmed, resulting in relatively lower manufacturing cost. This is an important prerequisite for feasible implementation of shield tunneling. Over the last half century, the shield tunneling method has been widely applied around the world. A large number of large-scale and complex shield tunnels have been completed one after another, such as the Storebaelt Tunnel (7.917 km) in Denmark, the 4th Elbe Tunnel (with outer diameter of 14.2 m) in Hamburg, Germany, and the well-known Channel Tunnel (50.5 km) etc., which have been the outstanding achievements in the history of shield tunnel construction.

In China, the RC segmental lining was applied successfully in Shanghai Tangqiao Test Tunnel and Dapu Road Tunnel in 1962. After development and practices over half a century, the RC segmental lining has become the first choice of shield tunnel structure system, and been successfully applied in a number of underwater shield tunnels, such as the Yangtze River Tunnels in Wuhan, Shanghai and Nanjing, the Shiziyang Tunnel of Guangzhou-Shenzhen-Hong Kong High Speed Railway, etc. Some of these tunnels have broken records in China and even in the world. Nowadays, the RC segmental lining is widely used in tunnel engineering for urban rail transit, railway, highway, public utility, water supply, gas supply, flood control, hydropower and other fields[3-5]. Some typical applications of shield tunnel lining in China can be found in Table 2.

However, in spite of wide application of RC segmental lining, inadequate durability of concrete leads to deterioration of tunnel lining structure during its service life. Concrete durability may be affected by various factors during the whole life cycle of segment manufacturing, transportation, construction and operation, such as erosive environment, complex loading condition and construction damage etc. For example, the defects in corner and edge during manufacturing, cracking and damage due to jacking during segment erection, cracking and dislocation in the service stage, bursting in case of fire, and the premature failure in corrosive environment, etc. It has become a major concern for scholars all over the world. The importance of lining structure durability in its service life has been recognized by tunnel engineers owing to the huge cost of maintenance and strengthening in the later stage. Structural durability of shield tunnel lining has become an important research topic in shield tunnel technology.

Table 2 Typical applications of shield tunnel lining in China

Owing to huge investment for tunnel construction, and difficulties in maintenance and reconstruction, it is of crucial importance to ensure the service life and durability of segmental lining structure, and establish a sustainable design theory and technology system for the life cycle from design, construction, service, maintenance, repair, reinforcement, demolition to reutilization[6]. Therefore, starting from the service state of shield tunnel segmental structure, this paper first analyses the disease characteristics and the main influencing factors of shield tunnel structure. The latest research achievements and findings are summarized from the aspects of corrosion-induced deterioration of shield tunnel structure, evaluation and prediction of tunnel structural durability and its ensuring techniques. The existing problems and related research trends are also discussed.

1 Analysis of service state of shield tunnel segmental structure

It is not uncommon that tunnels built long time ago are still in use today. However, it is undeniable that tunnels supported by RC linings have many disturbing problems related to durability, and these tunnels are facing challenges in long-term durability and safety.

Due to the particularity of concrete material properties and the shield tunneling methods, shield tunnels with cracked segments are allowed to operate in design codes of many countries. Micro-cracks or even visible cracks can hardly be avoided in concrete segments. Many factors may cause segment cracking, such as segments assembly, shield jacking, vehicle collision, fire, and cyclic frost and heave force, etc., even the change of external environment or loading.

Taking the metro shield tunnel as an example, Burgess et al.[7]investigated the extensive sulfate erosion and cracking of the shield tunnels of North London Line in 1950s and 1960s. According to the monitoring data by London Underground Limited (LUL), the effective treatment measures were discussed and the corresponding solutions were proposed, including replacement of cast iron segments by special acid-resistant large-diameter stainless steel segments. The replacement work was carried out by a specially-made shield machine at night, in order to guarantee normal operation during the daytime. Together with the 4 years for research and design, the renovation work took 6 years and eventually cost 15 million pounds. Another example is the Hong Kong Metro tunnels built in 1970s. Most steel bars inside the tunnel were corroded severely after 20-year operation, leading to concrete spalling. Hong Kong MTR had to spend plenty of time and cost to repair the tunnel without affecting normal operation. The inner steel bars were removed by using ultra high pressure water jet, and replaced by steel fiber concrete, or steel bars covered with polymer concrete[8]. Water pipes in Beijing Metro tunnels were corroded and perforated after operation for a few years. It was also found that the steel bars in tunnel linings of Guangzhou Metro Line No.1 were corroded after 10-year operation. The carbonization depth was generally greater than the thickness of the concrete layer. Both arc damage and stray current corrosion were revealed[9].

In terms of highway and railway tunnels, severe leakage and corrosion occurred in Seikan Tunnel after 30-year operation. Significant deformation occurred at some sections with adverse geological conditions, resulting in floor heaving and decrease of inner cross-sectional area. Extensive repair work will be carried out recently, according to the survey and test results. Severe leakage was found in the Kanmon Tunnel built in 1942. As a result, the steel bars in concrete lining were subjected to sulfate corrosion. The maintenance cost was up to 100 million yen per year. Many defects occurred in the subsea tunnel across Kaohsiung Harbor in Taiwan after 20-year operation, such as lining cracking, water leakage at the floor, deterioration of the beam protection layer, and corrosion of the steel rings[10]. Shanghai Dapu Road Tunnel was built in early 1970s. The tunnel structure was subjected to severe aging problems. Deterioration of concrete lining, aging of joint sealing material, corrosion of steel bars and bolts, severe water leakage and large deformation difference in the vertical and horizontal directions have threatened safe operation of the tunnel[11]. The steel bars and the primary support of Xiamen Subsea Tunnel were corroded even during tunnel construction[12].

A comprehensive investigation and diagnosis for water conveyance tunnels was conducted in Japan in 2013. The main disease was cracking in the arch and vault, which was always accompanied by ground surface collapse. These tunnels were often full of water. Tunnel cracking occurred first, followed by seepage at linings, ground softening, and eventually ground surface collapse. In the tunnels under study, a maximum shear deformation of 2 cm occurred below a collapse zone with a depth of 20 cm. For pressurized water conveyance tunnels, instability of tunnel lining may occur under the combined action of internal and external water pressures and earth pressure. For example, in 1999, the steel water pipes of the 6.3 km long Mito Tunnel in Ibaraki, Japan, yielded under pressure; in 2006, the 10.6 m long lining of a water conveyance tunnel in Hiroshima, Japan, fell from the tunnel crown after 41 years in service. The service status of water conveyance tunnels in China was seldom reported. However, similar problems existed in many tunnels. For instance, due to long-term operation without maintenance, water leakage and seepage occurred in many locations in the drainage tunnel of Toutunhe Reservoir in Xinjiang. Field investigation indicated that 17 annular cracks with a total length of 355.2 m occurred in lining, and the concrete surface was abraded extensively by water flow, presenting risks to tunnel operation[13]. Pan et al.[14]and Zhai & Luo[15]summarized the diseases commonly found in water conveyance tunnel linings, mainly including cracks, frost heave, grinding, cavitation, alkali aggregate reaction, carbonization, dissolution, and erosion, among which the most prominent one is cracking.

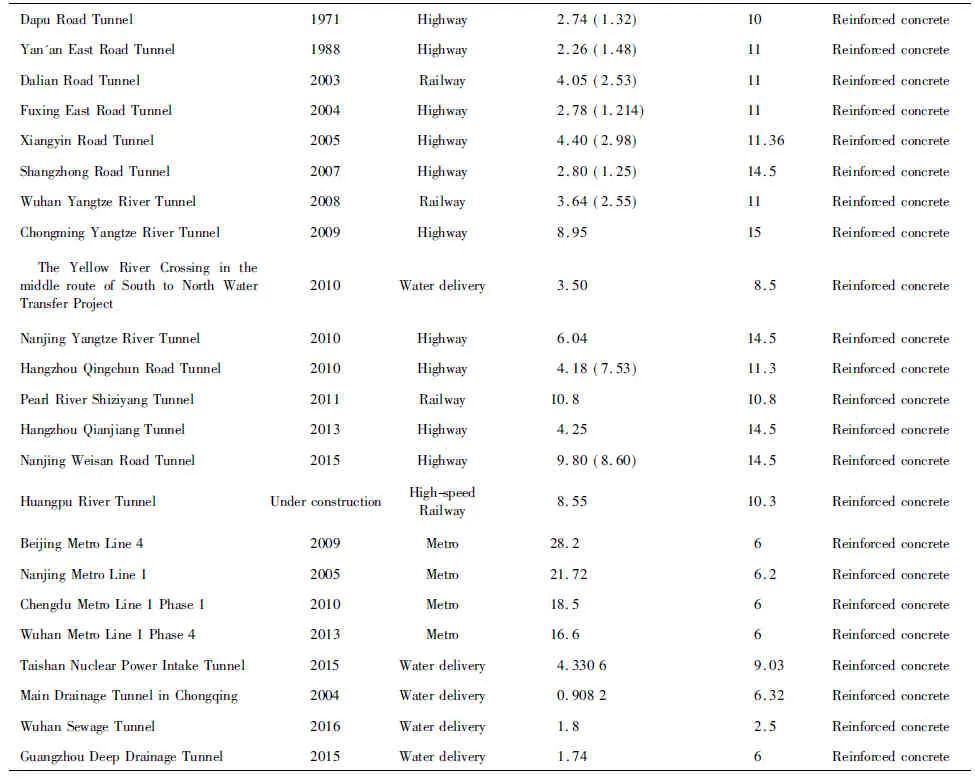

Importance has been attached to tunnel maintenance in view of the large number of tunnel lining diseases and related accidents. Investigation and monitoring of tunnel lining structures is put on the agenda. Investigation of railway tunnels was conducted in Japan in 1979 and 1986, respectively. The results showed that the main tunnel diseases were lining cracking, lining dislocation, water damage (including both icing and leaking) and lining surface spalling. According to the statistical results from a survey in 1990 in Japan, leakage and lining cracking occurred in about 60% of the 6 705 highway tunnels with a total length of 1 970 km, and material deterioration was found in nearly 24% of the tunnels. Similarly, many tunnels in Europe and the United States are degraded due to concrete aging, frost and heave damage, corrosive media and other reasons after long-term service. By investigating 13 representative tunnels in six cities in Zhejiang, China, Li[16]found that aging phenomenon was prevalent in many concrete tunnels in service. The main tunnel disease is leakage, which occurred in 77% of the tunnels, and more than 90% of the diseases took place in the lining. However, compared with the large number of shield tunnels, the existing investigation and diagnosis data were not enough. Therefore, in this study, investigation was carried out on the current service status of the lining structures of shield tunnels in typical regions in China. The results showed that various degrees of diseases existed in these tunnels due to geological conditions, hydrological conditions and changes in the surrounding environment of the tunnel, and it was also limited by the technology at the time of construction, as listed in Table 3. For example, severe leakage (Fig.1(a)), segment dislocation, steel corrosion (Fig.1(b)) and concrete spalling (Fig.1(c)) occurred in some metro tunnels and river-crossing tunnels. In addition, poor ventilation, emission of a large amount of exhaust gas and harmful gases were also found in many tunnels. As a result, the brightness and illumination of the tunnels cannot meet the requirements of relevant codes, and easily lead to traffic accidents, etc. All of these problems have brought great risks to normal service of tunnel lining. Ignoring or improper treatment of these problems may cause further deterioration or damage of tunnel lining, and would lead to the decrease of its bearing capacity and threaten tunnel safety.

In general, due to the particularity of the shield tunnel structure (mainly single-layer segmental lining) and shield tunnel construction in China (mostly in central and eastern China, with short operation period), the main diseases of existing shield tunnel linings are leakage, concrete cracking and steel corrosion etc. Standardized disease investigation, diagnosis and systematic remediation measures are still absent for the existing shield tunnels. A large number and various types of diseases may occur, which are difficult to repair in the long run. It is critical to conduct regular inspection and timely remediation according to their causes.

2 Factors affecting shield tunnel durability

The single-layer RC segmental lining is widely applied in most shield tunnels and the double-layer lining with both primary and secondary linings is adopted in some cases. Many factors may affect the durability of tunnel structure, including material, design, environment, construction, management and maintenance.

2.1Material

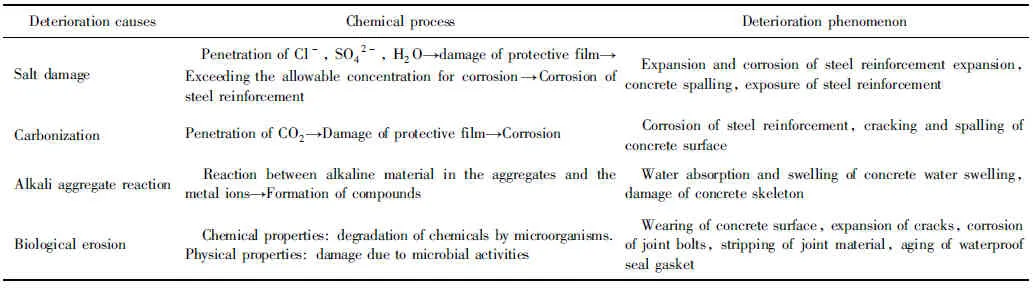

Concrete has been used as a building material for very long time. Approximately 5 000 years ago, the floor of the Dadiwan Relics in Tai An County, Gansu Province of China was constructed with concrete. More than 2 000 years ago, the sewers, shrines and arenas in Rome were also made of concrete. Since cement was invented in 1824, modern concrete has a history of 200 years. However, since the mid 1980s, the durability of concrete materials has not been fundamentally solved. For segmental lining in shield tunnels, deterioration of concrete durability is mainly caused by salt damage, carbonization, alkali aggregate reaction and biological erosion, as shown in Table 4.

At present, high requirements in strength and permeability are in place for concrete used for manufacturing of shield tunnel segments in China. However, no regulatory mechanism is available for controlling raw materials for concrete segments. Different standards are implemented in different regions or even tenders. In fact, the quality of concrete raw materials is very important to the durability of the segmental structure, which should be strictly controlled.

The effect of steel reinforcement on the segment durability mainly exhibits in the form of corrosion, which is determined by the resistance of steel material to corrosion, and also affected by the steel fatigue capacity. The use of epoxy coated steel bars with high fatigue capacity can effectively improve the segment durability. However, as the epoxy coating results in lower bonding force between the steel bars and concrete and higher cost, it is seldom used.

Table 3 Statistical analysis of shield tunnel diseases in typical regions of China

(a) Segment joint leakage

(b) Segment dislocation and reinforcement corrosion

(c) Concrete spalling near joint

Table 4 Main causes for deterioration of lining concrete

In addition, synchronous grouting is also an important means to ensure the durability of shield tunnel lining structure. However, in groundwater-rich strata, synchronous grouting cannot fill up the gap behind the segmental lining in time because a long time is required for consolidation. The cement-sodium silicate grouting can consolidate rapidly. However, its reaction products are unstable and easily decomposed. As a result, the mechanical performance of grouting ring declines and the durability of shield tunnel cannot be guaranteed.

2.2Design

In terms of design theory and method for segmental lining, the allowable stress design method is usually employed. This method can satisfy the requirements of bearing capacity and stiffness. It is assumed that concrete durability is related to its strength and it is based on the structure state after completion. Degradation and durability of the structure is not fully considered, resulting in some problems associated with durability. It has been recognized by many design engineers that the working conditions after completion, the ability to withstand random external loading in various stages after use and aging, the construction cost, the maintenance, reinforcement, renovation and some other costs have to be considered. The current design method shall develop toward the limit state design method and the life cycle design method.

In addition, proper mixing ratio is the key to ensure the durability of segment concrete. High-performance concrete is widely used in shield tunnel segments, which has the advantages of high strength, good compactness, low permeability, high wear, corrosion and frost resistances. However, great efforts have to be devoted to further develop concrete with high durability, so that the segment structure can withstand various loads and environmental chemical corrosion in its service life. It can be seen from the aforementioned diseases that the proper thickness of concrete protection layer for a segment shall be determined based on whether the concrete layer is able to prevent harmful substances from entering into the steel bars and ensure the bonding between the steel bars and concrete. In addition, in spite of increasing application of fiber-reinforced concrete around the world, its durability needs to be further studied. The design method for segmental lining with fiber-reinforced concrete has yet to be established.

2.3Environment

The long-term effect of environment on tunnel lining leads to corrosion of steel bars and corrosion and damage of concrete. As a result, the bearing capacity of the lining structure declines, leading to premature failure, shorter service life and lower durability of the lining structure.

First of all, seepage occurs in the segment concrete under the action of groundwater, resulting in not only the loss and damage of the segment, but also more cracks in the concrete. At the same time, some corrosive ions are brought into the cracks, leading to accelerated concrete deterioration. For instance, free diffusion of carbon dioxide and free water into concrete and reaction with the carbonatable substances lead to carbonization of the concrete segment. Erosion by chloride ion and sulfate ion is also caused by penetration of water and corrosive ions into concrete. Corrosion of steel bars also starts with penetration of water and erosive ions through the passivation film of steel bars.

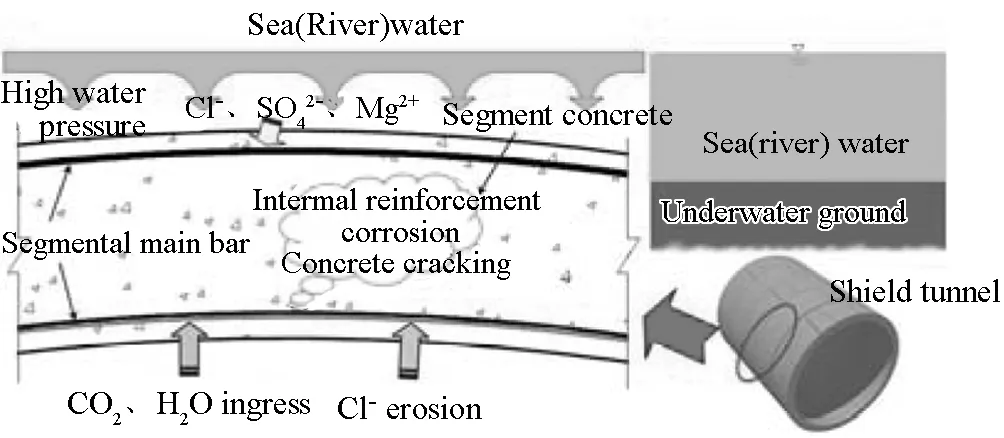

For shield tunnels in operation, the segmental linings are affected by geological and hydrological environment in the surrounding strata and subjected to external loading and environmental erosion. On one hand, the segment is externally in contact with soil and rock strata. The segment structure is subjected to erosion by Cl-, SO42-, Mg2+and other ions, which penetrate into the concrete layer, spread to the steel bar surface and break down the passivation film. On the other hand, it is usually humid and poorly ventilated in the tunnel. Under normal train operation and ventilation conditions, the CO2concentration in the tunnel is 3-5 times higher than that in the atmosphere. In a space with such high acid gas concentration and humidity, the rate of concrete carbonation is much higher than that above the ground. High concrete carbonization rate leads to premature corrosion of steel bars and joint bolts, accelerated deterioration of lining structure and loss of bearing capacity. In particular, for the underwater shield tunnels built in the eastern coastal region, under the combined action of high groundwater load and surrounding erosive environment, the shield tunnel segments are exposed to chloride ions in the groundwater from the outside, and air from the inside, which is a typical alternating dry and wet environment, as shown in Fig. 2.

Fig. 2 Typical working environment of underwater shield tunnel in marine environment

With longer tunnel service time, the inner reinforcement bars are corroded by corrosive ions in the surrounding environment. At the same time, the segment structure always needs to withstand the stresses from surrounding rock mass or soil and groundwater. It is subjected to high-pressure permeation. Seawater and corrosive groundwater may cause more severe corrosion through crisscrossing joints. Furthermore, high water pressure leads to further propagation of microcracks and macrocracks in the segment concrete, formation of new macrocracks or extension of the existing macrocracks. Finally, a damage zone is formed, resulting in degradation of structural performance or even failure of the segment structure. For metro tunnels, the reinforcement bars are corroded and expanded due to diffusion current in the tunnel, leading to degraded performance of the reinforced concrete.

The following phenomena usually occur under complex stress conditions: underground structure built in soft soil is prone to uneven settlement. The large uneven settlement not only leads to changes in the loading condition of the original support structure, but also damage and cracking of the joint parts. The cracks provide a seepage channel, resulting in more aggressive penetration of corrosive media into the segment. This is obviously detrimental to the stability and durability of the segment structure.

In addition, tunnels are located underground. Hence, they are subjected to biological erosion. On one hand, the chemical substances produced by microorganisms leads to concrete degradation. On the other hand, concrete is damaged by the microbial activities, such as wear and crack propagation, thus affecting the durability of segment structure. In particular, for large-scale urban sewage tunnels, in addition to the external ultra-high water pressure, soil load and internal super-high water pressure, erosion by organic matters, mold, corrosive acids and other corrosive ions has to be considered. These factors may lead to deterioration of the concrete structure, corrosion of the joint bolts, and spalling of joint sealing materials and aging of the waterproof sealing gasket.

2.4Construction

The influence of construction on the durability of shield tunnel structure mainly exhibits by the effect of construction disturbance and change in the internal force of the structure. For shield tunnels, the segments are prefabricated. Cracks formed during segment manufacturing process and intrinsic concrete defects lead to lower durability of the segment. In the process of segment transportation and assembly, collision and squeezing of segments can lead to corner damage. Meanwhile, the lining needs to provide the thrust force for shield advancing and turning. When the jacking force intersects the segment at a certain angle instead of in line with the segment, additional bending moment is generated, leading to unfavorable stresses on the segment or even cracking of the segment. In addition, the extrusion force from the shield tail may also cause dislocation or even cracking of the segment.

The lining damage during construction seems small, but it may cause significant problems after long-term deterioration. For instance, falling of concrete segmental lining occurred three times in railway tunnels in Japan. The accidents were triggered because the concrete supply was interrupted during segment manufacturing, resulting in formation of joints in concrete. In addition, vibrations and demolding agent were not sufficient. Cracks were formed in a large area in the inner side. Later in the operation stage, under the repeated impacts from long-term leakage, temperature changes, air pressure wave produced by running trains and train vibrations, the cracks on joint surface propagated, and ultimately led to accidents such as train damage and derailment. Therefore, attention has to be paid on the construction-induced damage on shield tunnel lining structure.

2.5Disasterandaccidents

It is generally recognized by the engineering field that, due to constraints provided by the surrounding strata, the vibration amplitude of underground shield tunnel structures is smaller than that of surface structures. In addition, owing to the existence of joints, the shield tunnel is a flexible structure with strong seismic resistance. However, under intensive earthquakes, seismic hazards are still prominent. For instance, a series of strong earthquakes, including the 1923 Kanto Earthquake and the 1995 Osaka-Kobe Earthquake in Japan and the 1999 Chi-Chi Earthquake in Taiwan, China, resulted in severe damage of subway stations and shield tunnel structures[17-18](Fig. 3). A total number of 110 tunnels were damaged by the "5.12" Wenchuan Earthquake in Sichuan, China in 2008. Some minor seismic damage occurred in the shield tunnel sections and stations of Chengdu Metro. The seismic damage of the shield tunnel was mainly featured by cracking, spalling, dislocation and leakage of segmental lining. Although the above-mentioned seismic damage did not result in failure of the main tunnel structure and the construction clearance, it would still have great impact on the long-term durability of the tunnel.

Furthermore, during tunnel operation, accidents such as fire, train collision, truck collision and explosion may occur sometimes, due to human, management and other factors. In addition, due to the lack of health monitoring and structural maintenance, the tunnel usually operates with diseases, leading to reduced service life. For high-speed railway tunnels, once train derailment occurs under high speed, the tunnel structure is subjected to violent impact, which may lead to fire or explosion. In addition, leakage of chemical substances in the tunnel will cause not only poisoning, but also corrosion of the lining concrete structure, thus affecting the durability of tunnel lining structure.

Fig. 3 Seismic damage of shield tunnel[17]

3 Recent research progress

At present, a large number of underwater shield tunnels have been built. The structural durability of shield tunnels has been studied by many researchers. The results are summarized as follows.

3.1Studyofdurabilityofshieldtunnel

Currently, the studies on the durability of shield tunnel mainly focus on the material performance of tunnel lining concrete and the effect of soil and water load and corrosive environment.

In order to investigate the performance of tunnel lining concrete, Ji[19]studied the mixing ratio of segment concrete, taking Qianjiang Tunnel in Hangzhou as the engineering background. By tests on the permeability and diffusion coefficients, the optimum mixing ratio of raw materials was obtained. Jin et al.[20]and Liu et al.[21]carried out durability tests on the reinforced concrete segments with different admixtures and water-cement ratios, and the law of concrete deterioration in erosive environment was obtained.The durability and corrosion resistance was investigated for the shield tunnel of Tokyo Bay Expressway in Japan. The seawater resistance was improved by addition of blast furnace slag to the segment concrete[22]. With laboratory tests, corrosion of fiber-reinforced concrete segments and ordinary concrete segments were carried out in Canada. The variation of ion content in concrete with the concentration and time of erosive solution was studied[23].

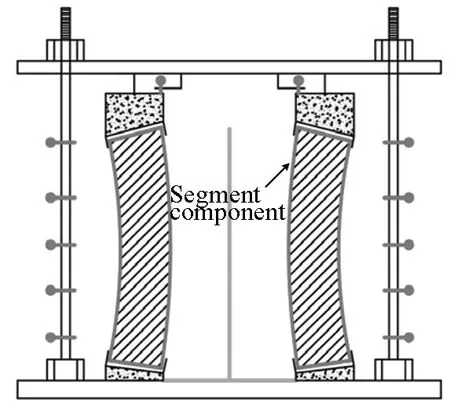

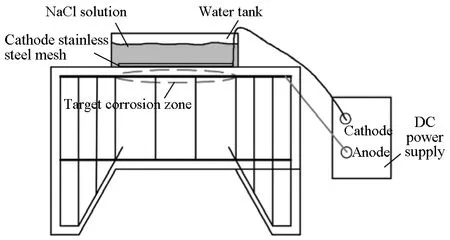

In the aspect of soil and water load and corrosive environment, Lei et al.[24]carried out unilateral one-dimensional erosion test of shield segment structure under the coupled effect of chloride salt erosion and structural load (Fig. 4), and discussed the effects of chloride ion concentration, erosion time and load level on chloride ion infiltration and its concentration distribution. With accelerated corrosion-induced deterioration, Li et al.[25]investigated the bearing capacity, deformation and failure characteristics of the corroded members and obtained the degradation law of tunnel lining structure with chloride ion erosion.Liu et al.[26]investigated accelerated corrosion-induced deterioration of mini segments (Fig. 5) under bending and compression. The evolution of corrosion-induced deterioration of the shield tunnel segment under different working conditions was analyzed. The results showed that the fracture pattern of non-corroded segments was dominated by transverse tensile cracks. Cracks only appeared along the steel bars in corroded segments without loading, and the crack width increased first and then tended to be stable. In addition, spalling and shearing of concrete occurred locally in the corroded area under the combined effect of corrosion-induced cracks and tensile cracks in the loading stage. The law of performance degradation for tunnel lining structures subjected to chloride ion erosion was obtained.

Fig. 4 Semi-soaking test device in artificial environment

(a) Sketch of accelerated corrosion by the cofferdam method

(b) Segment under loading and accelerated corrosion

Fig. 5 Accelerated corrosion of segments under bending and compression

However, the current studies on shield tunnel durability are based on the tunnels under zero water pressure, i.e., without considering the influence of water pressure. Underwater shield tunnels are different from mountain tunnels. The segmental lining is subjected to long-term high water pressure. The current studies cannot truly reflect the tunnel service environment. Therefore, it is more realistic to study shield tunnel durability with consideration of water pressure.

3.2Evaluationandpredictionofshieldtunneldurability

Many studies have been carried out on evaluation and prediction of shield tunnel durability.

In terms of durability assessment for shield tunnels, a national road network has been established in Sweden to predict the tunnel service state by analyzing the collected data. The network can effectively diagnose tunnel pathologies and ensure tunnel reliability and safety[27]. The US ACI364 Committee and Federal Highway Administration specified the evaluation schemes for tunnels with different structural forms[28-31]. Lee[32]established a real-time health monitoring system of high-speed railway tunnels in Korea, which can monitor the deformation of tunnel lining, the stresses on shotcrete, the groundwater level and other parameters in real time or periodically. The tunnel safety can be evaluated according to the monitoring data. Huang and Yang[33]calculated the durability risk of the segmental lining by the Monte Carlo method. Based on the Analytical Hierarchy Process (AHP) for various risk factors, the durability risk grade of the tunnel structure was determined, and the corresponding treatment measures and countermeasures were put forward. With the confidence index method and the AHP, Gu et al.[34]conducted risk assessment for subsea tunnels during operation, with reference to the risk acceptance criteria and risk rating standards of tunnels and underground projects. Based on the fuzzy characteristics, Wu et al.[35]made a fuzzy comprehensive evaluation on the influence of the segment surface cracks on the durability of the segment structure by the principle of maximum membership degree.

For prediction of durability life of shield tunnel, a trial monitoring system was installed on concrete lining in Green Hart Tunnel in Holland, according to the principle of the PRSLD framework, the system can be used for early warning and assessment of service life. It can also be used to predict the Macrocell corrosion in steel bars[36]. A tunnel safety performance prediction model with structural performance and life cycle cost as indicators was proposed by Wang et al.[37]A reasonable choice of maintenance programs can be selected by evaluating the strength of the structure and predicting the remaining service time. With Xiamen Xiang′an Susea Tunnel as the engineering background and based on the service life theory of lining structure, Sun[38]predicted the service life of lining structure by laboratory tests. Taking Shanghai Chongming Yangtze River Tunnel as an example, Sun[39]carried out systematic study of the durability design of shield lining structure, and discussed the corrosion mechanism of the lining structure and the durability of the joint bolts and the waterproof materials. The service life of Shanghai Chongming Yangtze River Tunnel was then predicted from the viewpoint of durability design. Based on the change in porosity of the concrete under loading and the Fick′s second law, Lei et al.[40]proposed a prediction model for concrete durability of shield tunnel segment under the coupling effect of chloride salt and structural load.

At present, durability assessment of shield tunnels is still qualitative judgment based on field detection and comprehensive evaluation. Quantitative evaluation of the health status of tunnels in operation has not been realized yet. Meanwhile, few studies have been conducted on the evolution of structural performance for shield tunnels. In particular, quantitative assessment of the structural performance and health status of shield tunnels under the multi-factor coupling effect.

3.3Durabilityensuringtechniquesforshieldtunnel

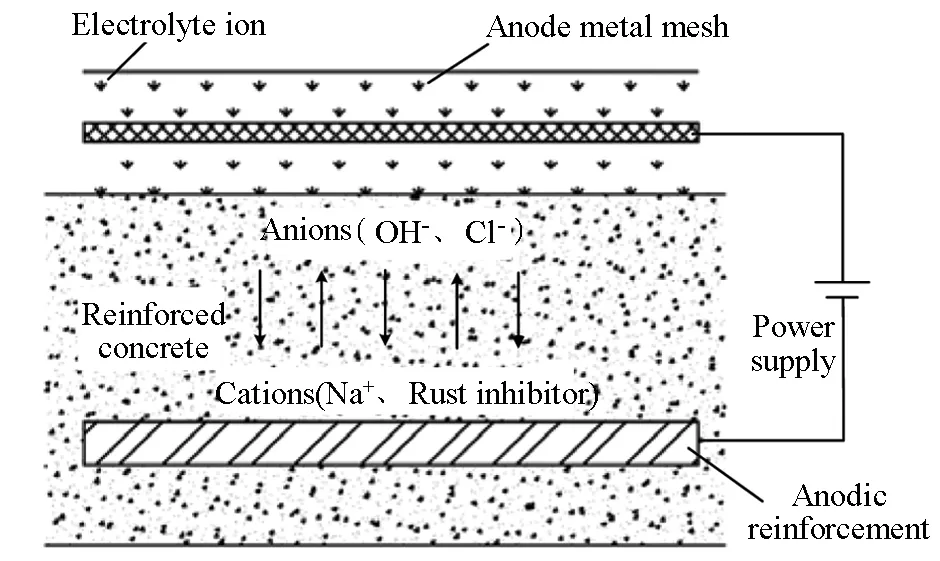

Qian et al.[41]studied the effect of crack width and depth on the repair effect by using microbial self-healing concrete with the aid of the relevant test equipment. With the bidirectional electroosmotic repair technology for reinforced concrete, Jin et al.[42]studied the influence of current density (Fig. 6), power-on time, water-cement ratio and concentration of chloride salt on the bidirectional electro osmotic efficiency. With self-healing of underground concrete microcapsules, Zhou et al.[43]put forward a two-dimensional self-healing mesoscopic mechanical model for underground structures subjected to tension and established an damage evolution equation based on the Taylor′s elastic damage model. The formula for flexibility after healing was proposed.

Fig. 6 Bidirectional electroosmosis technology

In terms of shield tunnel reinforcement, Liu et al.[44-45]and Bi et al.[46]studied the shield lining structure, designed the static loading test on shield tunnel reinforced by steel rings, and investigated the effect of steel rings on the bearing capacity of shield tunnel. By numerical simulation, Liu and Zhang[47]discussed the reinforcement mechanism and effect of AFRP on the tunnel transverse deformation. Parametric studies were conducted to analyze the influence of the affixing time and layers of AFRP on the reinforcement effect.

In view of insufficient durability of single-layer segmental lining under erosive environment, extreme condition, disaster and collision, higher structural safety factor is required by adopting double-layer segmental lining in China. Qiu et al.[48]studied the fire resistance of double-layer lining structure of railway shield tunnels. It was found that the temperature and stress in segmental lining after installation of secondary lining were less affected by the fire source, and the fire prevention effect was better, compared to single-layer lining. Deng et al.[49]analyzed the forces in double-layer lining of shield tunnels under the ground fissure active environment. It was concluded that the monolithic reinforced concrete lining can effectively reduce the internal force and deformation of the tunnel lining under ground fissure movement. Therefore, increasing tunnel diameter is a good way to reserve space for secondary lining. However, the installation time of the secondary lining is the key issue. If handled improperly, it is counterproductive. The interaction between the segmental lining and the secondary lining installed at different time needs to be further studied.

In terms of utilization of recycled aggregates, Ying et al.[50]quantitatively analyzed the primary and secondary relationship between the chloride ion permeability, frost resistance, wear resistance and carbonation resistance of recycled concrete by the gray correlation method. The influence of recycled aggregate replacement ratio on durability of recycled aggregate concrete was presented. Geng et al.[51]studied the influence of temperature, water-cement ratio, coarse aggregate replacement rate and cement dosage on the depth of carbonization of recycled aggregate concrete by the orthogonal test .

In the aspect of tunnel disease detection, the automatic monorail automatic train (Fig.7) equipped with overhaul and maintenance devices is adopted in the LHC Tunnel in Europe. The train is equipped with a variety of sensors, which can monitor the tunnel structure, temperature and even the change of oxygen level in the tunnel in real time. The staff can take this specially-made train for field inspection and maintenance.

Fig. 7 Automatic monorail train for tunnel maintenance

In recent years, a number of achievements in the new tunnel detection technology have been made in China. The research team led by Professor Zan Yuewen from Southwest Jiaotong University has developed a new type of tunnel detection equipment (Fig.8), which can detect the state of the tunnel lining structure efficiently and rapidly and realize detection of the whole tunnel without disturbing normal operation. Both the labor cost and the detection cost are reduced. The rapid detection vehicle (Fig.9) developed in China can greatly improve the detection efficiency. A number of precision instruments and equipment are mounted on the vehicle. A circle of flash lamps and industrial cameras are set up in the middle of the vehicle. The camera can take photos at an interval of 1/8 000 second, and the images from 16 cameras are spliced together to accurately capture the deformation and cracks in the tunnel surface.

In general, a lot of efforts have devoted on the durability ensuring techniques for shield tunnel. It is the key issue and challenge to explore how to improve the ensuring techniques and put forward the scientific and economic ensuring techniques for shield tunnel durability.

Fig. 8 Vehicle mounted ground penetrating radar detection system

Fig. 9 Rapid monitoring vehicle for tunnel

4 Prospects

4.1Durabilityensuringtechniquesforsegmentstructureincomplexenvironment

At present, the single-layer segmental lining is the main structure type of shield tunnel. Under the influence of erosive environment, extreme condition, disaster, collision and so on, the long-term safety of single-layer segmental lining is yet to be verified. Cracking and damage of lining structure often occurs during tunnel construction. Simple repair after tunnel construction cannot guarantee the strength of the lining structure, leading to higher safety risk. Therefore, the new-type segmental lining for shield tunnel has attracted more attention. One of the research directions is to development of high-performance and high-durability segmental lining. Meanwhile, it is imperative to establish the whole life design theory for shield tunnel lining structure.

In addition, effective detection and maintenance is necessary during tunnel operation. Development of new detection means has also become an important direction. For instance, the EU ROBINSPE project team developed a detection robot for tunnels (Fig.10), and a pipeline robot for water and sewerage pipelines (Fig.11), which can be used to detect small cracks and deformation that can hardly be recognized by naked eyes in the tunnel structure and identify cracks, rust, corrosion, and exposure of steel bars under extremely difficult conditions.

Fig. 10 Tunnel detection robot

Fig. 11 Pipeline robot

4.2Influence,evaluationandrehabilitationofdisastersandaccidents

The disasters and accidents in shield tunnels in operation include fire, explosion, collision and so on. A large number of examples show that the high temperature due to fire and explosion leads to cracking and deterioration of concrete cracking, in addition to tremendous harm to personnel in the tunnel. Subsequently, varying degrees of damage to the lining structure occurs. Especially for the damaged lining under high water pressure, the bearing capacity and safety of the structure are greatly reduced, and it is very difficult to replace or repair, and in some cases it cannot be repaired. At the same time, sudden temperature increase leads to changes in the mechanical properties of the surrounding strata and accelerated evaporation of pore water, resulting in increasing load on the tunnel.

Since early 21st century, increasing number of and all kinds of terrorist activities have taken place around the world. As an urban transportation means, underground urban rail transit lines are more vulnerable to sudden explosions or terrorist attacks, which also pose new challenges to the anti-explosion capacity of the tunnel structure, especially the river-crossing tunnels. Particularly, the study on the impact of internal explosion on shield tunnel structure is of great significance.

4.3Installationofsecondarylining

Whether to install secondary lining and its installation time and method has always been a debate between engineering and academic fields for shield tunnels. The connection measures between the segmental lining and secondary lining are different for shield tunnels for different purposes. At present, it is still questionable to divide them into superposed and composite connections. The mechanism and modeling treatment of segmental lining and secondary lining should be further studied.

4.4Establishmentofdynamicevaluationsystemforliningstructuredurability

A large number of random, fuzzy and incomplete information is encountered during tunnel construction and operation. Therefore, it is necessary to set up an effective detection and monitoring system for lining structure durability and to establish the relationship between the detection and monitoring data and the lining structure durability. It is very important to develop a dynamic evaluation system for tunnel structure durability. The stochastic theory can be adopted to perform evaluation based on the detection and monitoring data and prediction of lifetime performance for the lining structure.

5 Concluding remarks

With continuous exploration of underground space in the future, more high-density traffic projects at depth will be constructed. Requirements on the stability and safety of shield tunnel lining structure in its service life have been raised, which brings up a series of challenges to the supporting technology for structural durability of shield tunnels. With continuous exploration of engineering materials, construction and management technology, and supporting system for tunnel structural safety, the shield tunnel lining structure will become more ecologically, economically, socially and culturally sustainable.

Acknowledgements

The study was supported by the National Key Research and Development Program of China (2016YFC0802202), and the National Natural Science Foundation of China (51578462, 51578461,U1361210).

[1] WANG Jianhong, TANAKA H, KOIZUMI A. Tunnel technology for developing sustainable infrastructure: Part 1: Maintenance and management[C]// The Eighth China-Japan Conference on Shield Tunneling. [S.l.]: [s.n.], 2015.

[2] HE Chuan, FENG Kun. Review and prospect of structure research of underwater shield tunnel with large cross-section[J]. Journal of Southwest Jiaotong University, 2011, 46(1): 1.

[3] HE Chuan, FENG Kun, FANG Yong. Review and prospect on constructing technologies of metro tunnels using shield tunnelling method[J]. Journal of Southwest Jiaotong University, 2015, 50(1): 97.

[4] HE Chuan, WANG Bo. Research progress and development trends of highway tunnels in China[J]. Journal of Modern Transportation, 2013, 21(4): 209.

[5] LI Tian, LIU Xila. Analysis and design on the durability of concrete structures[M]. Beijing: Science Press, 1999.

[6] JIN Weiliang, YUAN Yingshu, WEI Jun, et al. Theory and design method of durability of concrete structures in chloride environment [M]. Beijing: Science Press, 2011.

[7] BURGRESS N, FAGENTS J, PATERSON J. Northern line tunnel reconstruction at Old Street[J].Proceedings of the ICE-Transport, 2002, 153(1): 1.

[8] YANG Xinan,HUANG Hongwei. Tunnel disaster prevention and treatment [M]. Shanghai: Tongji University Press, 2003.

[9] TIAN Meicun. Durability investigation and analysis of

underground reinforced concrete structure in Guangzhou area[J]. Guangdong Architecture Civil Engineering, 2014(3): 13.

[10] ZHANG Yi. Mechanism of chloride ions transportation in concrete[D]. Hangzhou: Zhejiang University, 2008.

[11] YUAN Yong, LIU Tao, LIU Xian. Investigation and evaluation of present state and serviceability of existing river-crossing tunnel[J]. Journal of Southeast University (Natural Science Edition), 2006, 36(S2): 83.

[12] ZHAO Tiejun, JIANG Fuxiang. Durability of subsea tunnels[M]. Beijing: China Communications Press, 2010.

[13] ZHANG Ping. Treatment of hydraulic concrete of drainage tunnel in the reinforcement project of Xinjiang Reservoir[J]. Water Conservancy Construction and Management, 2011(4): 50.

[14] PAN Jinlu, PAN Kun, CUI Tongzhu. Analyses and control of seepage and building liner structure disease hydro-channel[J]. Exploration Engineering(Rock & Soil Drilling and Tunneling), 2005(S): 327.

[15] ZHAI Yaowu, LUO Peng.Common defects of hydraulic tunnel concrete and prevention[J]. Sichuan Water Power, 2010, 29(4): 64.

[16] LI Qiang. Investigation on durability of concrete tunnels in southeast coastal areas[J]. Concrete, 2009 (9): 33.

[17] JSCE. The 1995 Hyogoken-Nanbu Earthquake[J]. Japan Society of Civil Engineers, 1996, 81(3): 38.

[18] SHIN T C, TENG Taliang. An overview of the 1999 Chi-Chi, Taiwan Earthquake[J]. Bulletin of the Seismological Society of America, 2001, 91(5): 895.

[19] JI Bin. Application of high durable concrete for large-diameter segments of Qianjiang Tunnel [J]. Tunnel Construction, 2012, 32(1): 41.

[20] JIN Nanguo, XU Yibin, FU Chuanqing, et al. Influence of carbonation, chloride attack and loading on concrete deterioration[J]. Journal of the Chinese Ceramic Society, 2015, 43(10): 1483.

[21] LIU Jiguo, SONG Kanglin, GUO Xiaohong,et al. Experi-mental study of segment durability in the Nanjing Weisan Road River-Crossing Tunnel[J]. Modern Tunnelling Technology, 2015(4): 80.

[22] GUO Shutang. Study of durability and corrosion resistance: A case study of Tokyo Bay-crossing highway shield tunnel[J]. Collection of Translation on Tunnels, 1994(10): 20.

[23] ABBAS S, SOLIMAN A M, NEHDI M L. Chloride ion penetration in reinforced concrete and steel fiber-reinforced concrete precast tunnel lining segments[J]. ACI Materials Journal, 2014(2): 613.

[24] LEI Mingfeng, PENG Limin, XIE Youjun, et al. Experimental study of the diffusion law of the chloride ion in a shield segment under coupled erosion and load[J]. Modern Tunnelling Technology, 2014(3): 98.

[25] LI Zhong, CHEN Haiming, SUN Fuxue,et al. Test on structure behavior′s degradation of shield tunnel lining in chloride erosion [J]. Chinese Journal of Underground Space and Engineering, 2009, 5(6): 1092.

[26] LIU Sijin, HE Chuan, FENG Kun, et al. Research on the influence of segment reinforcement corrosion on the mechanical behaviors of shield tunnel lining structures[J]. Modern Tunnelling Technology, 2015(4): 86.

[27] SANDRONE F, LABIOUSE V. Identification and analysis of Swiss National Road tunnels pathologies[J]. Tunnelling and Underground Space Technology, 2011, 26(2): 374.

[28] ACI Committee 364. Guide for revaluation of concrete structures prior to rehabilitation [J]. ACI Material Journal, 1993, 90(5): 479.

[29] Federal Transit Administration. Inspection policy and procedures for rail transit tunnels and underground structures[R]. Washington: Federal Transit Administration, 1997.

[30] Federal Highway Administration and Federal Transit Administration. Highway and rail transit tunnel maintenance and rehabilitation manual[R]. Washington: Federal Transit Administration, 2003.

[31] Federal Highway Administration and Federal Transit Administration. Highway and rail transit tunnel inspection manual[R]. Washington: Federal Transit Administration, 2003.

[32] LEE J S. Installtion of real-time monitoring system for high-speed railroad tunnel[J]. Korean Tunnel Association, 2001(3): 63.

[33] HUANG Kang, YANG Linde. A study of the risk assessment of shield lining durability of Chongming Yangtze River-crossing Project [J]. Modern Tunnelling Technology, 2004, 41(2): 8.

[34] GU Leiyu, HUANG Hongwei, HU Qunfang. Risk assessment on one sub-sea tunnel in its operational period[J]. Chinese Journal of Underground Space and Engineering, 2007, 3(7): 1236.

[35] WU Zhenzhi, YANG Linde, SHI Beiling,et al. Study of the influence of crack on the durability of tunnel segments using fuzzy evaluation[J]. Chinese Journal of Underground Space and Engineering, 2007, 3(2): 224.

[36] BIGAJ A, KOOIMAN A. Monitoring durability aspects of the Green Heart Tunnel lining[J]. IABSE Symposium Report, 2003, 87(2): 51.

[37] WANG Jianhong, KOIZUMI Atsushi, TANAKA Hiroshi. Framework for maintenance management of shield tunnel using structural performance and life cycle cost as indicators[J]. Structure and Infrastructure Engineering, 2016, 13(1): 44.

[38] SUN Fuxue, RONG Yao. Study of tunnel lining service-life prediction[J]. Chinese Journal of Underground Space and Engineering, 2006, 2(3): 358.

[39] SUN Jun. Durability design of segment lining structure in Chongming Yangtze River Shield Tunnel [J]. Journal of Architecture and Civil Engineering, 2008, 25(1): 1.

[40] LEI Mingfeng, PENG Limin, SHI Chenghua. Durability evaluation and life prediction of shield segment under coupling effect of chloride salt environment and load [J]. Journal of Central South University (Science and Technology), 2015, 46(8): 3092.

[41] QIAN Chunxiang,LI Ruiyang,PAN Qingfeng,et al. Microbial self-healing effects of concrete cracks [J]. Journal of Southeast University (Nature Science Edition), 2013, 43(2): 360.

[42] JIN Weiliang, HUANG Nan, XU Chen,et al. Experimental research on effect of bidirectional electromigration rehabilitation on reinforced concrete: Concentration changes of inhibitor, chloride ions and total alkalinity[J]. Journal of Zhejiang University (Engineering Science), 2014, 48(9): 1586.

[43] ZHOU Shuai, ZHU Hehua, YAN Zhiguo,et al. Self-healing micromechanical model of microcapsule-enabled self-healing concrete in underground structures[J]. Journal of Tongji University (Natural Science), 2014, 42(10): 1467.

[44] LIU Xian, TANG Min, LU Liang,et al. Experimental study of ultimate bearing capacity of shield tunnel reinforced by full-ring steel plate [J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(11): 2300.

[45] LIU Xian, ZHANG Haoli, TANG Min, et al. Experimental study of the ultimate bearing capacity of a shield tunnel reinforced by a semi-ring steel plate[J]. Modern Tunnelling Technology, 2014, 51(3): 131.

[46] BI Xiangli, LIU Xian, WANG Xiuzhi, et al. Experimental study of the ultimate load-bearing capacity of deformed segmental tunnel linings strengthened by steel plates[J]. China Civil Engineering Journal, 2014, 47(11): 128.

[47] LIU Zisheng, ZHANG Dongmei. The mechanism and effects of AFRP reinforcement for a shield tunnel in soft soil[J]. Modern Tunnelling Technology, 2014, 51(5): 155.

[48] QIU Yue, FENG Kun, ZHANG Yuchun, et al. Numerical simulation analysis on the fireproof performance of double-layered lining structure in railway shield tunnel [J]. China Railway Science, 2015, 36(1): 83.

[49] DENG Yahong, PENG Jianbing, FAN Wen, et al. Analysis of double-layered liner behaviors of shield tunnel under active moving ground-fissures[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(S2): 3860.

[50] YING Jingwei, XIAO Jianzhuang. Influence of recycled aggregate replacement ratio on durability of recycled aggregate concrete[J]. Journal of Architecture and Civil Engineering, 2012, 29(1): 56.

[51] GENG Ou, ZHANG Xin, ZAHNG Chengkai. Prediction models of the carbonization depth of recycled concrete[J]. Journal of China University of Mining and Technology, 2015, 44(1): 54.

U 451+.4

A

2096-4498(2017)11-1351-15

盾构隧道结构耐久性问题思考

何 川1,*, 封 坤1, 2, 孙 齐1, 王士民1

(1. 西南交通大学交通隧道工程教育部重点实验室, 四川 成都 610031;2. 西南交通大学中日RSC结构研究中心, 四川 成都 610031)

盾构隧道衬砌结构耐久性问题是一个从细观材料到宏观结构的跨尺度问题,随着盾构隧道建设数量的日益增长,其结构耐久性问题愈发凸显。阐述国内外代表性盾构隧道衬砌应用情况; 分析盾构隧道管片结构服役状态及病害型式; 总结影响盾构隧道结构耐久性的因素,主要包括材料因素、设计因素、环境因素、施工因素及管理和维护因素。从盾构隧道耐久性能、耐久性评估与预测以及耐久性保障措施等方面综述国内外在盾构隧道耐久性研究上取得的成果及进展。最后从复杂环境管片结构的耐久保障技术,灾害、事故的影响、评估与修复,二次衬砌的设置,衬砌结构耐久性动态评估体系的构建等方面讨论盾构隧道结构耐久性研究尚存在的问题及进一步研究的方向。

盾构隧道; 管片衬砌; 耐久性; 隧道病害; 研究进展; 展望

*Corresponding author. E-mail: chuanhe21@163.com.

10.3973/j.issn.2096-4498.2017.11.001