双矢量定姿算法提高海参捕捞装置捷联惯导系统粗对准精度

2017-10-14包建华李道亮

包建华,乔 曦,李道亮

双矢量定姿算法提高海参捕捞装置捷联惯导系统粗对准精度

包建华1,2,3,乔 曦1,3,李道亮1,3※

(1. 中国农业大学信息与电气工程学院,北京 100083;2. 江苏师范大学电气工程及自动化学院,徐州 221116;3. 北京农业物联网工程技术研究中心,北京 100083)

针对传统解析粗对准算法中水平对准精度同时受陀螺仪和加速度计测量误差影响的问题,提出一种双矢量定姿粗对准算法,该算法在选定重力矢量为主参考矢量的前提下,预先对参与姿态解算的矢量作单位正交化处理。理论分析表明,所述算法使得水平对准精度只受加速度计水平测量误差影响,提高了捷联惯导系统粗对准精度;实测数据的试验结果表明,所述粗对准算法的水平误差角的大小不超过1°,方位误差角的大小不超过3°,在粗对准所要求的误差范围之内,为后续利用滤波方法进行精对准提供了有效的初始条件。

渔业;导航;算法;捷联惯导;粗对准;双矢量定姿;静基座;海参捕捞

0 引 言

用信息技术提升农业机械化水平是建设现代农业的战略选择,为加强农机装备的信息技术创新,需要突破智能农业装备数字化设计、自动导航协调控制等关键技术[1]。农业机械自动导航是精准农业的重要技术支撑,已广泛应用于现代农业生产各过程[2-5]。中国是海参生产和消费大国,目前,海参捕捞方式主要是拖网和人工捕捞,对潜水员的生命健康和海洋生态都有潜在危害[6]。为减轻潜水员的劳动强度,人们已开发了一些机械式捕捞装置来代替人工进行海参捕捞[7-9],但自动化程度低,作业效率不高。因此,在当前海参养殖规模不断扩大的背景下,开发一种自主式海参捕捞装置显得尤其迫切。自主式海参捕捞装置关键要解决海参柔性抓捕和载体的自主导航定位问题。捷联惯性导航系统(SINS,strapdown inertial navigation system)具有自主性和无源性的特点,已被广泛用于飞机、舰艇、船舶等的导航[10-12],随着低成本MEMS(micro-electro- mechanical system)惯性传感器技术的进步,捷联惯性导航系统被越来越多地应用于民用领域[13]。为解决海参捕捞装置的自主导航定位问题,课题组开展了以捷联惯导为主的组合导航研究。

初始对准是捷联惯导系统关键技术之一,其目的就是在执行导航任务之前,事先确定出载体坐标系相对导航坐标系的初始位置关系,即确定姿态矩阵的初始值,为后续捷联解算提供必要的初始条件[14-15],因此,初始对准的好坏将直接影响导航系统的性能。为了既快又准地实现对准,捷联惯导系统的初始对准过程通常分为粗对准和精对准两个阶段[16-17]。粗对准着重解决对准的快速性问题,尽快将姿态角误差缩小到一定的范围内,为下一步精对准提供有效的初始条件,因此,研究一种算法简单且具有较高精度的粗对准方案有其实际的应用价值[18-19]。传统解析粗对准是直接利用重力矢量和地球自转角速度矢量估算姿态矩阵[20],由于其水平对准精度同时受陀螺仪和加速度计测量误差的影响,使得粗对准效果不佳。为改善水平对准精度,本文提出一种双矢量定姿粗对准方案,并用MEMS惯性测量单元与三维电子罗盘的实测数据进行了试验验证。

1 材料与方法

1.1 坐标系规定

1)导航坐标系文中选地理坐标系为导航坐标系,其原点位于载体重心,轴指向东,轴指向北,轴指向天。

1.2 解析粗对准算法

1.2.1 传统解析粗对准

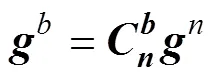

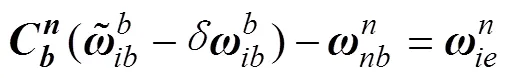

传统解析粗对准是借助空间两个“不共线”的地球自转角速度矢量和地球重力矢量,直接估算从载体坐标系到导航坐标系的初始姿态矩阵[21-22]。重力矢量、地球自转角速度矢量在导航坐标系和载体坐标系上的投影关系可分别表示为:

(2)

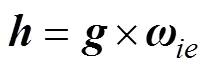

为了求解从系到系的变换矩阵,再利用和的叉乘运算构造一个新的矢量:

(4)

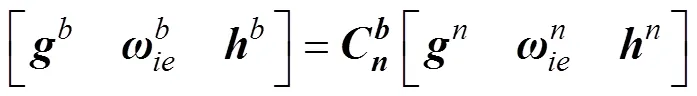

联立(1)、(2)、(4)式,写成矩阵形式:

(6)

(8)

受惯性传感器本身测量偏差和外界干扰的影响,使得按(6)式求解的姿态矩阵不能严格满足正交化要求[23],可以按下式进行正交化处理:

1.2.2 双矢量定姿粗对准

1)双矢量定姿原理

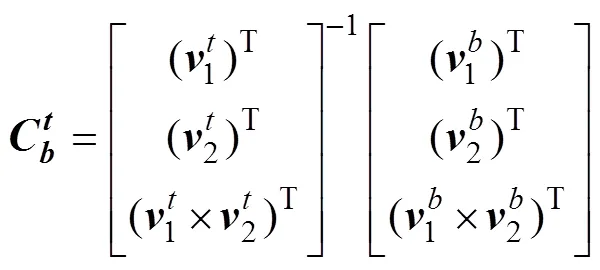

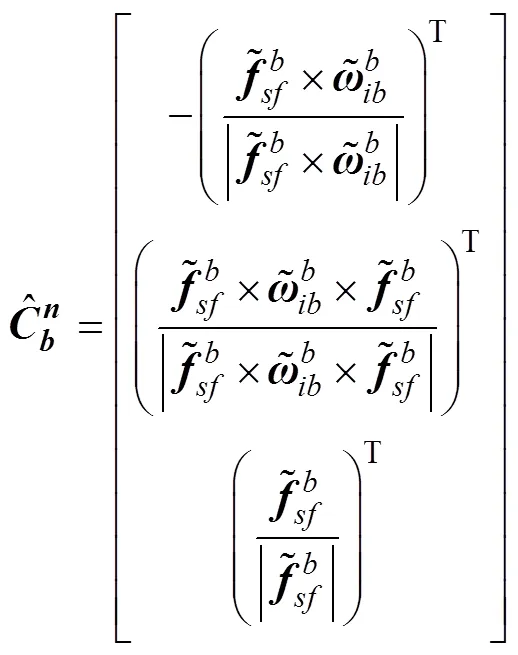

双矢量定姿是利用两个不共线的矢量在直角坐标系系和系下的投影坐标,从而确定两坐标系之间的方位关系[24-25]。不妨假设两个不共线的矢量为和,它们在系和系下的投影坐标依次记为、、、,则系和系间方位关系可用方向余弦矩阵(姿态矩阵)来描述,通过引入辅助矢量并利用矢量坐标变换关系,不难得到:

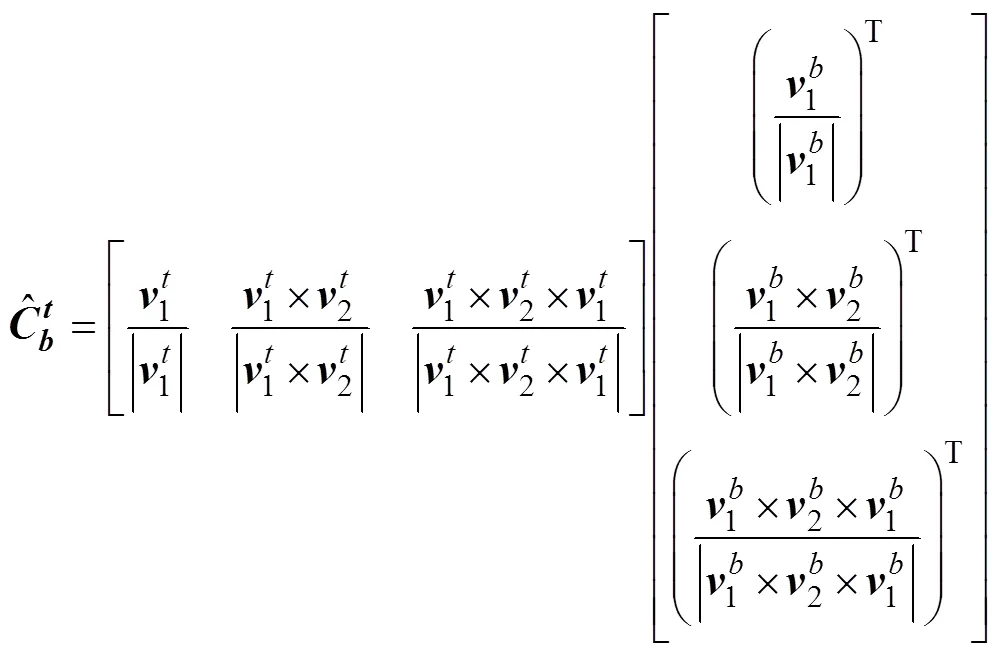

针对(10)式的一种改进思路是预先对参与解算的所有矢量作单位正交化处理。图1给出了由测量矢量和构造3个单位正交矢量、和的空间方位示意图。图1中,被选为主矢量,选择主矢量的一般原则是选择两个矢量中的测量误差较小者。

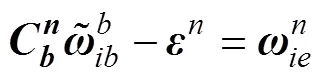

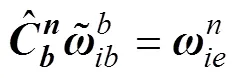

2)双矢量定姿粗对准

(13)

(15)

于是式(12)、(13)分别改写为:

(17)

进一步写成:

(19)

(21)

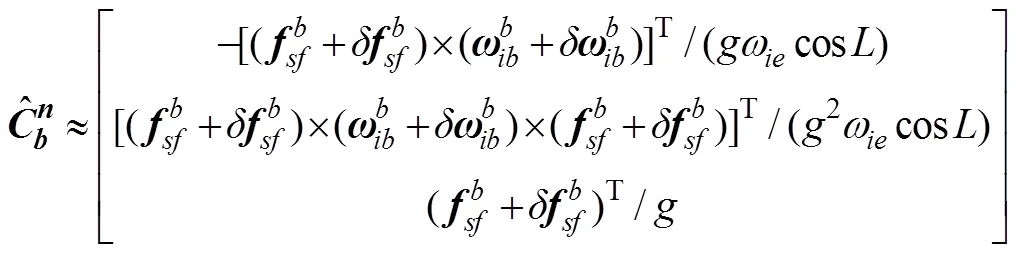

考虑到加速度计的测量误差一般小于陀螺仪的测量误差,文中选择作为主参考矢量,参照式(11)可得姿态矩阵估计算法表达式:

(22)

将式(7)、(8)代入式(22),经化简后得到:

实际对准过程中,为降低惯性传感器高频噪声的影响,可以采集一段时间内的传感器数据求平均,然后用该时间段内的平均角速度及平均加速度分别代替式(23)中的和,从而估算出初始姿态矩阵。

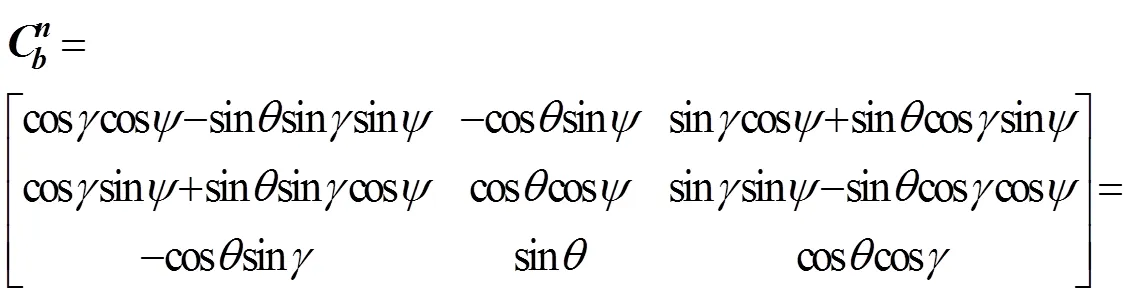

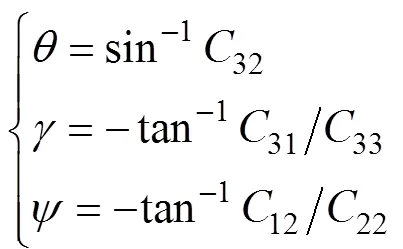

估算出姿态矩阵后,不难解算出载体的姿态角。假设海参捕捞装置的俯仰角、横滚角和航向角分别用(°)、(°)和(°)表示,则姿态矩阵可写成[26]:

(24)

由式(24),得:

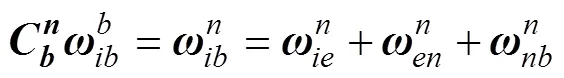

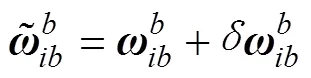

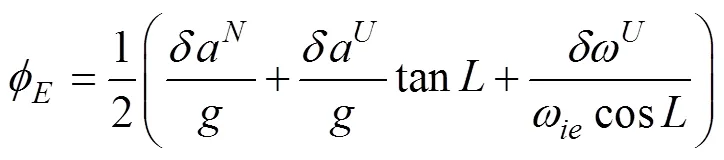

1.3 误差分析

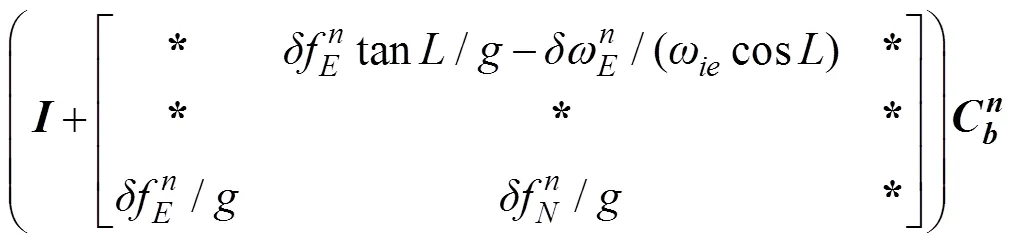

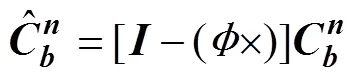

从理论上分析不同对准方法的误差特性,对于工程实践中选择更好的对准方案具有指导意义。传统解析粗对准中,正交化后的姿态矩阵估计值消除了刻度系数误差和歪斜误差,但仍然含有漂移误差,文献[27]导出的漂移误差失准角的估算式为:

(27)

(28)

将式(29)按向量叉乘运算规则展开,忽略二阶及以上小量,并记惯性传感器的测量误差和,得:

为简化书写,式(30)中与误差分析结果不相关的元素用“*”表示。

(32)

即有:

可见,双矢量定姿粗对准的水平失准角只受加速度计水平测量误差、的影响,而传统解析粗对准的水平失准角除跟加速度计测量误差有关外,还和天向陀螺漂移误差有关,一般情况下,由于陀螺测量误差远大于加速度计测量误差,因此,双矢量定姿粗对准算法提高了水平对准精度。对比式(28)、(33)可知,两者方位对准精度相当,且方位失准角主要取决于陀螺的东向漂移误差。

2 结果与分析

为验证上述2种粗对准算法的优劣,试验中使用瑞芬科技有限公司的AH106B型MEMS惯性测量单元和DCM260型三维电子罗盘的实测值进行对比试验,实物如图2所示。试验条件:当地纬度=40.004 9°;所用惯性测量单元的陀螺仪常值漂移20°/h,陀螺仪随机游走系数,加速度计零偏,陀螺仪和加速度计的最大数据输出频率300 Hz,试验中陀螺仪和加速度计的数据采集周期均设置为20 ms;三维电子罗盘的倾角分辨率0.1°,数据输出频率20 Hz。海参捕捞装置主要由导航模块、推进器模块、水下摄像机、捕捞机构等构成;其中,导航模块安装于海参捕捞装置载体中部的封闭式平台上。试验地点选择山东海阳某海参养殖场水域,与本试验相关场景图如图3所示。数据采集试验步骤如下:1)将惯性测量单元、三维电子罗盘固定于减振平台上,并保证两模块的向轴线分别平行,然后将减振平台静置于海参捕捞装置的载体上;2)同时采集并存储惯性测量单元中陀螺仪和加速度计输出的原始数据以及三维电子罗盘输出的姿态角数据;3)保持试验系统静止30 min后停止数据采集与记录。

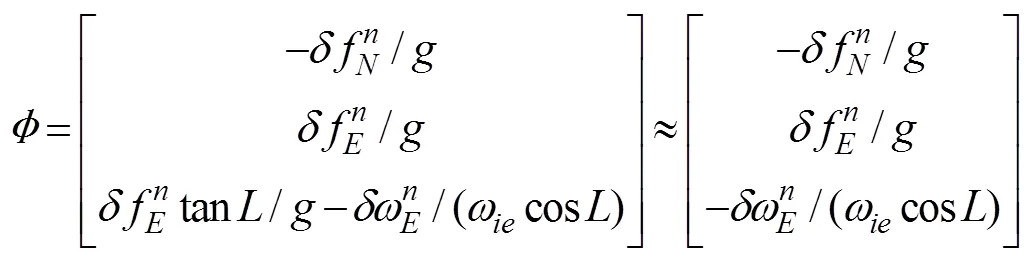

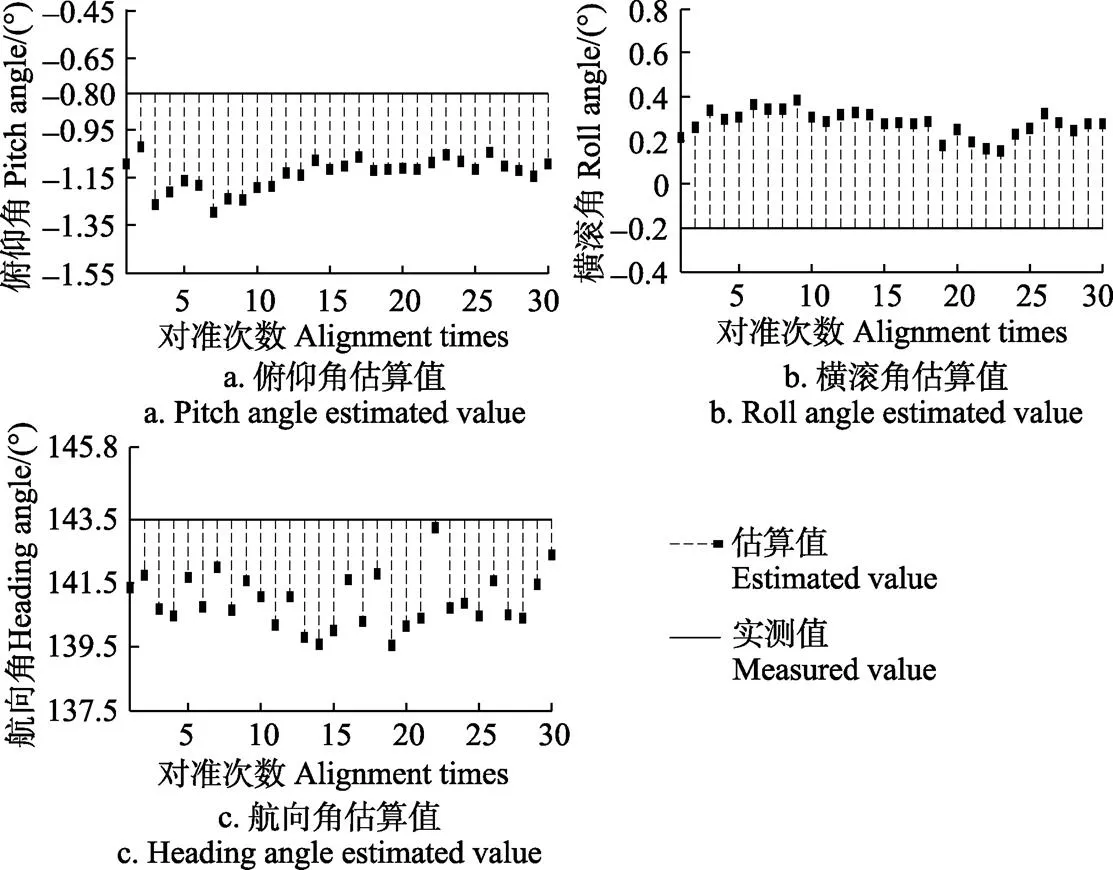

选取惯性测量单元采集的同一原始试验数据,在Matlab平台上,应用前述的两种粗对准算法分别进行粗对准解算,每次对准时间为1 min,共进行了30次对准试验。图4为传统解析粗对准算法得到的捷联惯导系统俯仰角、横滚角和航向角的估算值,而双矢量定姿粗对准算法得到的俯仰角、横滚角和航向角的估算值如图5所示。图4、5的俯仰角和横滚角代表载体的水平姿态,而航向角代表载体的方位姿态。图4的水平姿态角变化幅度大且呈现出明显的振荡特性,而图5的水平姿态角变化幅度小且变化平稳;图4和5的方位姿态角变化规律一致。

图4 传统解析粗对准算法估算的姿态角

图5 双矢量定姿粗对准算法估算的姿态角

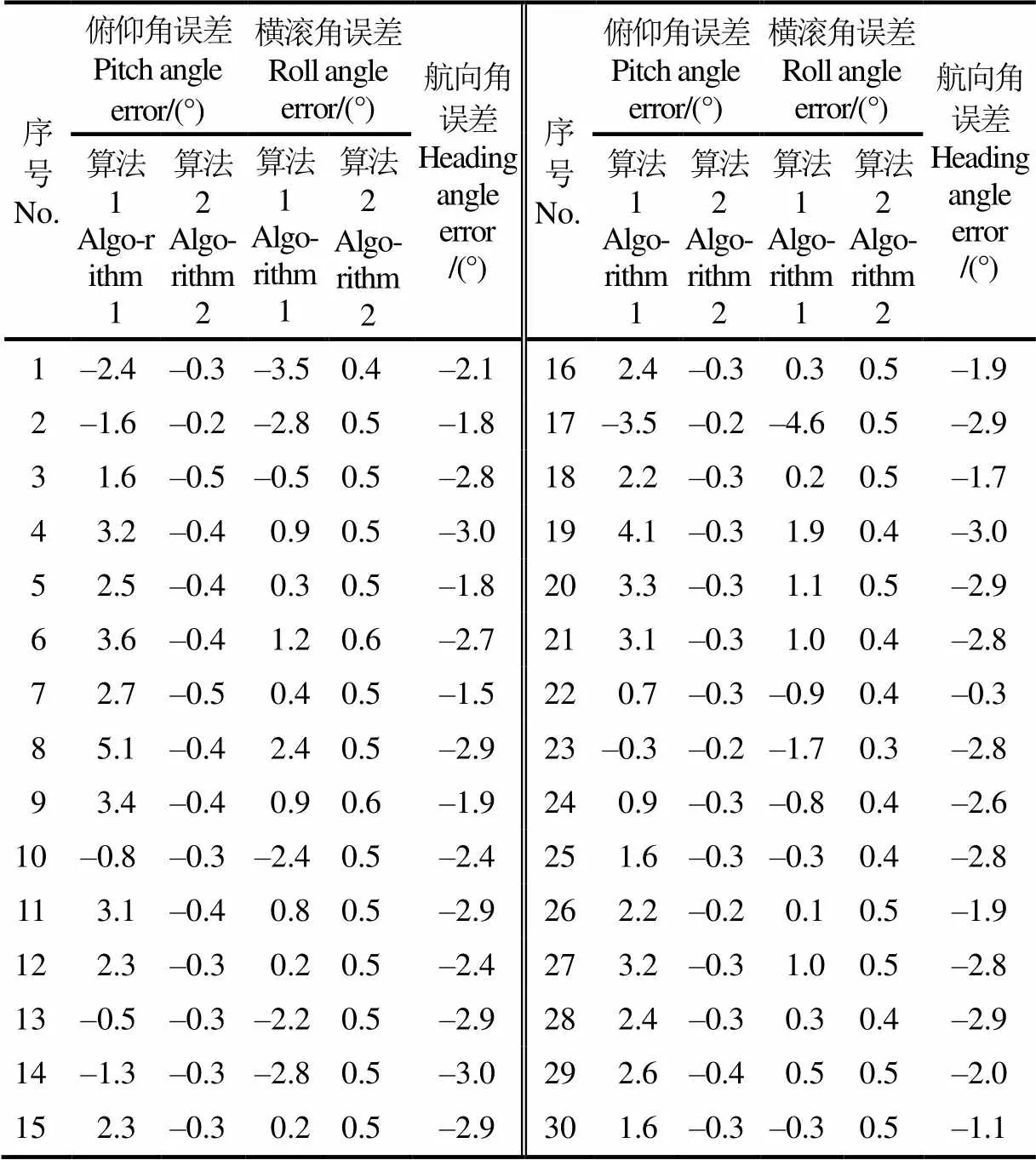

为进一步验证粗对准算法效果,文中使用三维电子罗盘实测值作为算法评估的参考基准,试验中所用三维电子罗盘的俯仰和横滚精度为0.1°、航向精度为0.5°。为使数据比较有意义,安装时,该电子罗盘的3个轴向与惯性测量单元模块的对应轴向平行且一致。在进行静态数据采集的30 min内,三维电子罗盘输出的俯仰角和横滚角的数值稳定,分别为–0.8°和–0.2°,而航向角做低频小幅度变化,取其平均值为143.5°,将这3个实测值在图4、5中标示成水平直线,以便与30次粗对准试验的估算值作对比。将粗对准算法所得的姿态估算值减去对应时刻三维电子罗盘实测的姿态值得到姿态误差。表1给出30次粗对准试验中2种粗对准算法对应姿态误差的试验结果,其中“算法1”代表传统解析粗对准算法,“算法2”代表双矢量定姿粗对准算法,由于2种算法的方位对准的精度相当,表1中合并列出了航向角误差。考虑到电子罗盘提供的参考基准精度仅为0.1°,表1中数值只保留一位有效数字。

表1 粗对准姿态估算值与电子罗盘姿态测量值间的误差

从表1所列粗对准结果可见,传统解析粗对准算法的俯仰角误差和横滚角误差偏大且变化比较剧烈,而双矢量定姿粗对准算法的水平误差角的大小不超过1°,方位误差角的大小不超过3°,方位误差大于水平误差,与前述误差特性的理论分析结果相吻合。

3 结 论

1)所提出的双矢量定姿粗对准算法预先对参与姿态解算的矢量作单位正交化处理,使得姿态矩阵估计值自然满足正交化条件,有效降低了惯性传感器测量误差和外界干扰对粗对准精度的影响。

2)理论分析和试验结果都表明,所述算法提高了海参捕捞装置捷联惯导系统的水平对准精度。以三维电子罗盘实测值作为基准,所述粗对准算法的水平误差角小于1°,方位误差角小于3°,在粗对准所要求的误差范围之内,为后续利用滤波方法进行精对准提供了有效的初始条件。

[1] 罗锡文,廖娟,邹湘军,等. 信息技术提升农业机械化水平[J]. 农业工程学报,2016,32(20):1-14. Luo Xiwen, Liao Juan, Zou Xiangjun, et al. Enhancing agricultural mechanization level through information technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 1-14. (in Chinese with English abstract)

[2] 胡静涛,高雷,白晓平,等. 农业机械自动导航技术研究进展[J]. 农业工程学报,2015,31(10):1-10. Hu Jingtao, Gao Lei, Bai Xiaoping, et al. Review of research on automatic guidance of agricultural vehicles[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(10): 1-10. (in Chinese with English abstract)

[3] 陈艳,张漫,马文强,等. 基于GPS和机器视觉的组合导航定位方法[J]. 农业工程学报,2011,27(3):126-130. Chen Yan, Zhang Man, Ma Wenqiang, et al. Positioning method of integrated navigation based on GPS and machine vision[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(3): 126-130. (in Chinese with English abstract)

[4] 赵德安,罗吉,孙月平,等. 河蟹养殖自动作业船导航控制系统设计与测试[J]. 农业工程学报,2016,32(11):181-188. Zhao Dean, Luo Ji, Sun Yueping, et al. Design and experiment of navigation control system of automatic operation boat in river crab culture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(11): 181-188. (in Chinese with English abstract)

[5] 洪剑青,赵德安,孙月平,等. 水产养殖自动导航无人明轮船航向的多模自适应控制[J]. 农业工程学报,2017,33(1):95-101. Hong Jianqing, Zhao Dean, Sun Yueping, et al. Multi model adaptive control of paddlewheel vehicle’s course in aquaculture[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 95-101. (in Chinese with English abstract)

[6] 杨卫中,徐银丽,乔曦,等. 基于对比度受限直方图均衡化的水下海参图像增强方法[J]. 农业工程学报,2016,32(6):197-203. Yang Weizhong, Xu Yinli, Qiao Xi, et al. Method for image intensification of underwater sea cucumber based on contrast-limited adaptive histogram equalization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 197-203. (in Chinese with English abstract)

[7] Guo Haizhi, Yu Fusheng, Zhao Yang, et al. Structure design of sea cucumber catching robot based on TRIZ theory[J]. Mechanical Engineering and Technology, 2016, 5(3): 227-237.

[8] 谢鑫建,王丽. 水上操控管吸式海参捕捞装置:2013106776810[P]. 2015-11-11. Xie Xinjian, Wang Li. Tube suction sea cucumber fishing device on water operation: 2013106776810[P]. 2015-11-11.

[9] 马秀芬. 吸入式海参捕捞器及捕捞方法:2014101574484[P]. 2015-10-28. Ma Xiufen. Suction sea cucumber fishing device and fishing method: 2014101574484[P]. 2015-10-28.

[10] 岳鹏,史震,王剑,等. 基于MEMS加速度计的无陀螺惯导系统[J]. 中国惯性技术学报,2011,19(2):152-156. Yue Peng, Shi Zhen, Wang Jian, et al. Gyro free inertial navigation system based on MEMS accelerometer[J]. Journal of Chinese Inertial Technology, 2011, 19(2): 152-156. (in Chinese with English abstract)

[11] Zhang Q Z, Meng X L, Zhang S B, et al. Singular value decomposition-based robust cubature Kalman filtering for an integrated GPS/SINS navigation system[J]. Journal of Navigation, 2015, 68(3): 549-562.

[12] 刘军,袁俊,蔡骏宇,等. 基于GPS/INS和线控转向的农业机械自动驾驶系统[J]. 农业工程学报,2016,32(1):46-53. Liu Jun, Yuan Jun, Cai Junyu, et al. Autopilot system of agricultural vehicles based on GPS/INS and steer-by-wire[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 46-53. (in Chinese with English abstract)

[13] 李博文,姚丹亚. 低成本车载MEMS惯导导航定位方法[J].中国惯性技术学报,2014,22(6):719-723. Li Bowen, Yao Danya. Low-cost MEMS IMU navigation positioning method for land vehicle[J]. Journal of Chinese Inertial Technology, 2014, 22(6): 719-723. (in Chinese with English abstract)

[14] 严恭敏,翁浚,白亮,等. 基于惯性参考系的动基座初始对准与定位导航[J]. 系统工程与电子技术,2011,33(3):618-621. Yan Gongmin, Weng Jun, Bai Liang, et al. Initial in-movement alignment and position determination based on inertial reference frame[J]. Systems Engineering and Electronics, 2011, 33(3): 618-621. (in Chinese with English abstract)

[15] Du Tao, Guo Lei, Yang Jian. A fast initial alignment for SINS based on disturbance observer and Kalman filter[J]. Transactions of the Institute of Measurement and Control, 2016, 38(10): 1261-1269.

[16] 赵长山,秦永元,白亮. 基于双矢量定姿的摇摆基座粗对准算法分析与实验[J]. 中国惯性技术学报,2009,17(4):436-440. Zhao Changshan, Qin Yongyuan, Bai Liang. Analysis and test of swaying-based analytic coarse alignment[J]. Journal of Chinese Inertial Technology, 2009, 17(4): 436-440. (in Chinese with English abstract)

[17] 王跃钢,蔚跃,雷堰龙,等. 捷联惯导一种优化的惯性系粗对准方法[J]. 科学技术与工程,2013,13(4):1102-1105. Wang Yuegang, Yu Yue, Lei Yanlong, et al. An improved method of inertial coordination coarse alignment in SINS[J]. Science Technology and Engineering, 2013, 13(4): 1102-1105. (in Chinese with English abstract)

[18] 陈令刚,刘建业,孙永荣,等. 微小型捷联惯导系统解析式对准方法研究[J]. 航天控制,2005,23(4):9-12. Chen Linggang, Liu Jianye, Sun Yongrong, et al. Study of analytic coarse alignment methods to micro SINS [J]. Aerospace Control, 2005, 23(4): 9-12. (in Chinese with English abstract)

[19] Weng J, Qin Y Y, Yan G M, et al. Analysis method on error distributions of in-flight alignment schemes [J]. Journal of Chinese Inertial Technology, 2015, 23(5): 570-574.

[20] 于飞,翟国富,高伟,等. 舰船捷联惯导系统粗对准方法研究[J]. 传感器与微系统,2009,28(5):15-18. Yu Fei, Zhai Guofu, Gao Wei, et al. Research on coarse alignment for vessel strapdown inertial navigation system[J]. Transducer and Microsystem Technologies, 2009, 28(5): 15-18. (in Chinese with English abstract)

[21] 徐博,孙枫,高伟. 舰船捷联航姿系统自主粗对准仿真与实验研究[J]. 兵工学报,2008,29(12):1467-1473. Xu Bo, Sun Feng, Gao Wei. The coarse alignment of strap-down inertial navigation system for ship[J]. Acta Armamentarii, 2008, 29(12): 1467-1473. (in Chinese with English abstract)

[22] Xiong J, Guo H, Yang Z H. A two-position SINS initial alignment method based on gyro information[J]. Advances in Space Research, 2014, 53(11): 1657-1663.

[23] Liu M, Gao Y B, Li G C, et al. An improved alignment method for the strapdown inertial navigation system (SINS) [J]. Sensors, 2016, 16(5): 12-17.

[24] 严恭敏,秦永元,卫育新,等. 一种适用于SINS动基座初始对准的新算法[J]. 系统工程与电子技术,2009,31(3):634-637. Yan Gongmin, Qin Yongyuan, Wei Yuxin, et al. New initial alignment algorithm for SINS on moving base[J]. Systems Engineering and Electronics, 2009, 31(3): 634-637. (in Chinese with English abstract)

[25] Tan Caiming, Zhu Xinhua, Su Yan, et al. A new analytic alignment method for a SINS[J]. Sensors, 2015, 15(11): 27930-27953.

[26] Chang L B, Li J S, Chen S Y. Initial alignment by attitude estimation for strapdown inertial navigation systems[J]. IEEE Transactions on Instrumentation and Measurement, 2015, 64(3): 784-794.

[27] Yeon Fuh Jiang. Error analysis of analytic coarse alignment methods[J]. IEEE Transactions on Aerospace and Electronic Systems, 1998, 34(1): 334-337.

[28] Li Q, Ben Y Y, Yang J L. Coarse alignment for fiber optic gyro SINS with external velocity aid[J]. OPTIK, 2014, 125(16): 4241-4245.

[29] Silva F O, Hemerly E M, Filho W C L. Error analysis of analytical coarse alignment formulations for stationary SINS [J]. IEEE Transactions on Aerospace and Electronic Systems, 2016, 52(4): 1777-1796.

[30] 薛海建,王解,郭晓松,等. SINS非线性自对准中的强跟踪UKF算法设计[J]. 上海交通大学学报,2015,49(9):1429-1434. Xue Haijian, Wang Jie, Guo Xiaosong, et al. Design of a strong tracing UKF for nonlinear self-alignment of SINS[J]. Journal of Shanghai Jiao Tong University, 2015, 49(9): 1429-1434. (in Chinese with English abstract)

Double-vector attitude determination algorithm improving coarse alignment accuracy of strapdown inertial navigation system for sea cucumber fishing device

Bao Jianhua1,2,3, Qiao Xi1,3, Li Daoliang1,3※

(1.100083,; 2.221116,; 3.100083,)

Autonomous navigation is one of the key technologies for an intelligent agricultural equipment, which has been widely used in modern agricultural production. Sea cucumber production and consumption are very large in China. At present, the sea cucumber harvest mainly relies on trawl or artificial fishing, which will cause a potential hazard to the health of divers and the marine ecology. Therefore, in order to overcome the shortcomings of traditional sea cucumber fishing methods, it is necessary to develop a sea cucumber fishing device with autonomous navigation and positioning functions. Strapdown inertial navigation system (SINS) is suitable for the navigation of the autonomous sea cucumber fishing device because of its autonomy, passivity and complete navigation parameters. For the SINS, initial alignment must be completed before starting a navigation mission. The purpose of the initial alignment is to determine the initial position of the carrier coordinate system relative to the navigation coordinate system, that is, to determine the initial value of the attitude matrix. Initial alignment is one of the key technologies of SINS, which is divided into coarse alignment and fine alignment, and the coarse alignment accuracy will directly determine the performance of the initial alignment. Therefore, it is of practical value to study a coarse alignment scheme with simple algorithm and high alignment precision. The traditional analytical coarse alignment algorithm directly utilizes the earth gravity vector and the earth rotation angular velocity vector to estimate the initial attitude matrix. In view of the problem that the horizontal alignment accuracy of SINS is affected by the measurement errors of gyroscope and accelerometer in the traditional analytical coarse alignment algorithm, a novel coarse alignment algorithm based on double-vector attitude determination is proposed. In general, the measurement error of the accelerometer is much smaller than that of the gyroscope, so the earth gravity vector in the proposed algorithm is chosen as the main reference vector. Then, 3 unit orthogonal vectors are constructed based on the earth gravity vector and the earth rotation angular velocity vector, and the resulting attitude matrix is a unit orthogonal matrix. The theoretical analysis shows that horizontal misalignment angles of SINS are only related to the accelerometer level measurement errors in the case of using the proposed algorithm, however, using the conventional algorithm, the horizontal misalignment angles are related to the accelerometer measurement errors and the gyroscope drift error. Therefore, the coarse alignment accuracy of SINS using the aforementioned algorithm is significantly improved.Based on the same measured data from an inertial measurement unit, the simulation experiment was carried out for 30 times using the conventional coarse alignment algorithm and the proposed algorithm, respectively. Simulation curves demonstrated that the variation of the horizontal attitude angles using the algorithm proposed was smoother. To further verify the effectiveness of the algorithm, the attitude angles calculated from the measured values of the inertial measurement unit were compared with the measured value of a high-precision three-dimensional electronic compass, and the experimental results showed that the horizontal error angles of the aforementioned coarse alignment algorithm did not exceed 1° and the azimuth error angle did not exceed 3°. The results can meet the accuracy requirement of coarse alignment and will provide an effective initial condition for the subsequent fine alignment using filtering methods.

fisheries; navigation; algorithms; strapdown inertial navigation; coarse alignment; double-vector attitude determination; stationary base; sea cucumber fishing

10.11975/j.issn.1002-6819.2017.12.037

TN966; TP391.9

A

1002-6819(2017)-12-0286-07

2016-12-29

2017-03-27

国家国际科技合作专项项目(2013DFA11320);中央高校基本科研业务费专项资金资助项目(2016XD001)

包建华,男,安徽肥东人,副教授,博士生,主要从事惯性导航及组合导航研究。北京 中国农业大学信息与电气工程学院,100083。 Email:baojhxz@cau.edu.cn

李道亮,男,山东垦利人,教授,博士生导师,主要从事农业信息先进感知与智能处理研究。北京 中国农业大学信息与电气工程学院,100083。Email:dliangl@cau.edu.cn

包建华,乔 曦,李道亮. 双矢量定姿算法提高海参捕捞装置捷联惯导系统粗对准精度[J]. 农业工程学报,2017,33(12):286-292. doi:10.11975/j.issn.1002-6819.2017.12.037 http://www.tcsae.org

Bao Jianhua,Qiao Xi,Li Daoliang. Double-vector attitude determination algorithm improving coarse alignment accuracy of strapdown inertial navigation system for sea cucumber fishing device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(12): 286-292. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.12.037 http://www.tcsae.org