羟基磷灰石-壳聚糖复合膜旋涂法制备及表征

2017-09-23袁秋华张自强徐安平巫剑波秦草坪陈泽汇林松鑫张培新

袁秋华,张自强,徐安平,巫剑波,秦草坪,陈泽汇,林松鑫,张培新

深圳大学化学与环境工程学院,广东深圳 518060

【化学与化工/ChemistryandChemicalEngineering】

羟基磷灰石-壳聚糖复合膜旋涂法制备及表征

袁秋华,张自强,徐安平,巫剑波,秦草坪,陈泽汇,林松鑫,张培新

深圳大学化学与环境工程学院,广东深圳 518060

为制备高效环保仿生材料,以Na2HPO4和Ca(NO3)2·4H2O为原料,采用化学沉淀法合成羟基磷灰石粉体,将粉体超声分散在壳聚糖醋酸溶液中,通过溶液共混和磁力搅拌的方法制备羟基磷灰石-壳聚糖(hydroxyapatite-chitosan, HA-CS)悬浮液.采用旋涂法在不锈钢304基材表面涂覆HA-CS悬浮液,分别在25 ℃和37 ℃条件下干燥12 h成膜.将两种HA膜样分别通过X射线衍射、傅立叶变换红外光谱、扫描电子显微镜、X射线能量色散仪和电子拉力机进行测试.结果表明,HA-CS复合材料的拉伸强度达(69.04±1.21)MPa;复合膜结晶度好,黏结致密,无分解,无杂质;旋涂法能更好的使HA均匀分散在CS中,减少HA微粒的团聚和游离;与25 ℃相比,37 ℃条件下干燥HA膜有助于HA与CS更多更好地结合,使制得的HA-CS复合膜具有优良性能.为HA-CS复合膜附着金属植入物在人体环境内成功生长提供理论参考.

生物材料学;羟基磷灰石;壳聚糖;复合膜;旋涂法;力学性能

通常骨缺损(bone defects)是由创伤、肿瘤、感染或先天性肌肉骨骼疾病引起的严重并发症[1],在临床上很常见,传统的治疗方法有自体骨移植、异体骨移植和使用金属替代材料[2].然而,这3种方法都有各自不足,达不到临床应用所需效果.近年来,组织工程技术的发展改善了骨缺损的传统治疗模式,开发出多种具有修复和改善组织或器官的仿生材料.其中,羟基磷灰石(hydroxyapatite, HA;Ca10(PO4)6(OH)2)因与生物硬骨组织有相似的组成和结构,且具有优良的生物相容性、生物活性以及可与骨组织发生很强的化学性结合而无排斥反应等特点,作为新型骨替代材料被广泛应用和研发[3].然而纯HA力学性能不足,自身强度低,韧性和力学性能的缺陷使其单独作为骨修复支架材料存在瑕疵.天然高分子聚合物壳聚糖(chitosan, CS)具有良好的力学性能、生物可降解性、生物相容性和活性,其自身无毒抑菌,可以促进伤口愈合[4].将HA与CS复合,有望弥补各自不足,优化材料的力学性能和黏结能力,从而满足植入人体的骨替代材料要求.在304不锈钢板表面涂覆HA-CS复合材料可作为很好的承重支架材料植入人体,附着于钢板一侧的复合膜可促进细胞黏附、增殖和新骨再生.因此,要保证HA-CS复合膜与宿主骨组织完美键合,提高金属植入物的骨结合性能,必须制备出理化性能优良的复合膜.传统制备薄膜方法有电泳沉积法[5-6]、溶胶-凝胶法[7]、电化学沉积法[8]、静电纺丝法[9]、流延溶剂挥发法[10-11]和离子胶法[12]等,新型涂膜技术旋涂法因具有设备简单、操作易控制、工艺条件温和等优点逐渐成为制备涂膜材料的首选法.

本实验采用化学沉淀法合成羟基磷灰石粉体,在304不锈钢基板表面用旋涂法制备HA-CS复合膜,并分析在室温(25℃)和接近人体温(37℃)两种干燥条件下对HA-CS复合膜组成和形貌的影响.

1 实 验

1.1试 剂

四水硝酸钙(Ca(NO3)2·4H2O)、磷酸氢二钠(Na2HPO4)和壳聚糖(脱乙酰度≥95%)均购自上海阿拉丁试剂有限公司;氢氧化钠购自天津百世化工有限公司;无水乙醇和丙酮购自广州市东红化工厂.以上试剂均为分析纯.

1.2基材预处理

基材选用10mm×10mm×1mm的304不锈钢小钢板,依次用800#、2000#和5000#的SiC水砂纸打磨钢板表面.将打磨平整光滑的钢板依次用丙酮、无水乙醇和去离子水超声清洗各15min.清洗后放入真空干燥箱中50℃恒温干燥2.5h.

1.3HA-CS复合膜的制备

采用化学沉淀法合成羟基磷灰石粉体[13]. 以Ca(NO3)2·4H2O和Na2HPO4为原料,按n(Ca)∶n(P)=1.67∶1.00分别配成0.5mol/L溶液,用恒流滴定泵以2mL/min滴定速度将Na2HPO4溶液滴加到Ca(NO3)2·4H2O溶液中,用1mol/LNaOH溶液控制pH值为10~11,40℃下磁力搅拌,搅拌速度为300r/min.待反应完全,恒温搅拌2h,静置沉化24h.将沉淀物真空抽滤、洗涤至pH值呈中性,得到的滤饼置于90℃烘箱中干燥12h.烘干的样品经研磨后置于700℃马弗炉中煅烧3h,得到羟基磷灰石粉体.合成HA的化学方程式为

Ca10(PO4)6(OH)2+14NaNO3+

6HNO3+40H2O

(1)

溶液混合法制备HA-CS悬浮液.取1.0g壳聚糖(脱乙酰度≥95%)溶于30mL质量分数为2%的醋酸溶液中,50℃条件下磁力搅拌2h.待CS完全溶解后,加入1.5g经200目筛子过筛后的HA粉末,超声分散0.5h,恒温搅拌6h,得到HA-CS悬浮液.

采用旋涂法制备HA-CS复合膜.将处理过的不锈钢板光滑面朝上吸附于SC-1B匀胶机旋转台上,用胶头滴管取配好的HA-CS悬浮液在钢板表面滴加1~2滴,以800r/min和2500r/min的启动速度和恒定速度分别转动10s和30s.如此重复涂膜3~5次,然后取出钢板,分别在25℃和37℃条件下干燥12h,最终得到成型的HA-CS复合膜.

1.4测试和表征

采用德国Bruker公司生产的AXS-D-8Advance型X射线衍射仪(X-raydiffraction,XRD)对试样进行物相鉴定和结构分析,测定条件为,铜靶Cu-Kα辐射(λ=1.5406×10-10m), 光阑狭缝为1mm,衍射角2θ为10°~60°,管电流为40mA,管电压为40kV, 扫描速度4°/min; 采用日本岛津IRAffinity-1傅立叶变换红外光谱分析仪(Fouriertransforminfraredspectroscopy,FTIR),对样品进行基团检测,用KBr作背景样,测试范围为400~4000cm-1;采用日本日立S-3400N(II)型扫描电子显微镜观测复合膜表面形貌,并结合EDX-能谱仪对HA-CS复合膜进行元素分析;采用深圳市新三思材料检测有限公司CMT4304(0.5级)型电子拉力机对HA-CS复合材料进行力学性能测试.

2 结果与讨论

2.1样品的XRD分析

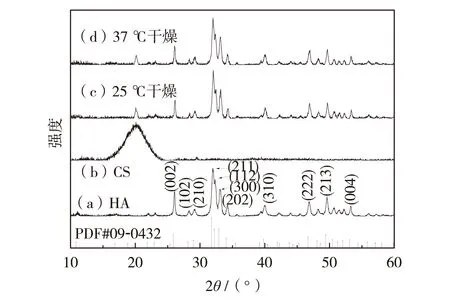

图1(a)是用沉淀法制备HA粉体的XRD谱图,与HA的PDF标准谱线(ICDD卡片编号09-0432)基本吻合.图中HA的晶面如(002)、(102)、(210)、(211)、(112)、(300)、(202)、(310)、(222)、(213)和(004)等均已出现特征衍射峰.其中,(002)、(211)、(112)和(300)4个晶面衍射最强,是其主要衍射峰,未出现其他杂质相衍射峰,证明HA结晶度高且晶型较完整[14].图1(b)是纯CS的XRD图,在2θ≈20°处有一宽泛的隆起峰,是CS的特征衍射峰.在25℃和37℃条件下,干燥得到HA-CS复合膜的XRD谱线分别如图1(c)和(d)所示,两条谱线HA晶面的衍射峰强度都有所减弱,在2θ≈20°处出现了CS的特征衍射峰,表明HA与CS复合会改变各自的结晶度.复合膜的XRD谱图中亦无杂质相衍射峰出现,说明在试验给定的条件下HA-CS复合膜并未降解,HA仍保持较高的纯度.

图1 HA(a)、CS(b)和不同干燥条件下HA-CS复合膜(c、d)的XRD图Fig.1 XRD patterns of HA(a), CS(b) and HA-CS composite coatings at drying temperatures of25 ℃(c) and 37 ℃(d)

2.2样品的FTIR分析

图2 CS(a)、HA(b)和不同干燥条件下HA-CS复合膜的FTIR图Fig.2 FTIR spectra of CS(a), HA powders(b) and HA-CS composite coatings at different drying temperatures

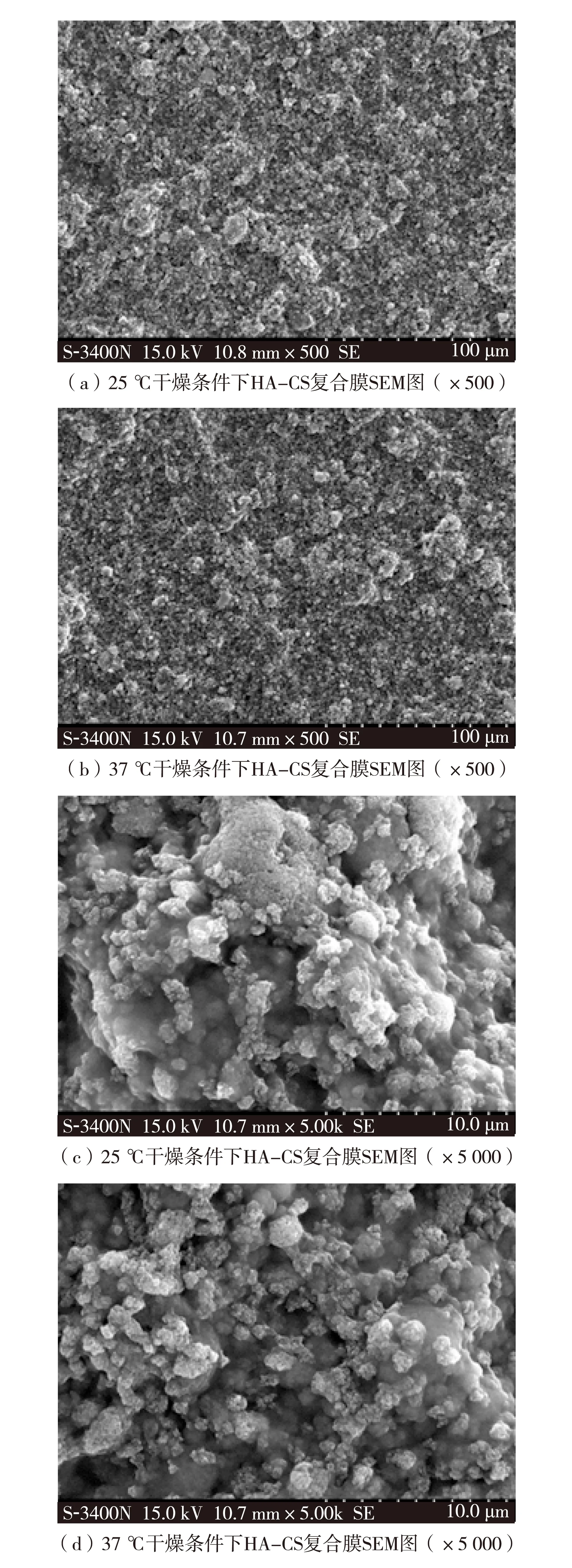

图3 不同干燥条件下HA-CS复合膜的SEM图Fig.3 SEM images of HA-CS composite coatings under different drying conditions

2.3样品的SEM-EDX分析

图3(a)和(c)为25℃干燥条件下制得HA-CS复合膜的不同放大倍率SEM照片;图3(b)和(d)则是37℃干燥条件下制得HA-CS复合膜的SEM图.图3(a)和(b)是放大500倍复合膜的表面形貌图,可以看出CS与HA黏结较好,结合致密,复合膜表面无裂纹,无机相均匀地分散在有机相中,且无明显界限.此外,图3(b)中复合膜表面较图3(a)更为平整、均匀,游离的HA颗粒相对较少.图3(c)和(d)是放大5000倍的复合膜表面微结构图,可清晰看到CS包覆HA颗粒形成的致密结构,HA颗粒团聚较少,且复合膜表面形成许多微孔结构,有利于引导成骨细胞黏附和生长,这也是骨替代材料的一个必要特性.与图3(c)相比,图3(d)中HA晶粒尺寸更小,在CS中分散更加均匀,并且复合膜表层的CS相对减少,更多融入内层,表明接近人体温度(37℃)的干燥条件更适宜理想的HA-CS复合膜成型.

通过EDX能谱仪测得37℃干燥条件下制得HA-CS复合膜的元素组成如图4.由图4可见,复合膜主要由C、O、P和Ca组成,其原子百分比分别为9.21%、58.11%、12.43%和20.25%,证实了FTIR中检测到官能团的存在.此外,HA-CS复合膜中n(Ca)∶n(P)=20.25∶12.43=1.63, 该值接近羟基磷灰石Ca和P的理论摩尔比1.67(n(Ca)∶n(P)=10∶6), 证明本方案合成的HA基本满足人体硬骨组织Ca和P摩尔比要求.

图4 37 ℃干燥条件下HA-CS复合膜的EDX图Fig.4 EDX image of HA-CS composite coatings drying at 37 ℃

2.4样品的力学性能测试

将制备的HA-CS悬浮液浇注在玻璃模具中,在37℃干燥条件下得到HA-CS复合材料,裁剪成10mm×40mm样品,用电子拉力机测试其力学性能,测试温度为25℃,测试距离为20mm,拉伸速度为20mm/min.样品连续测试10次,其力学性能如下:拉伸强度为(69.04±1.21)MPa,断裂伸长率为(4.05±0.26)%,弹性模量为(3447±17.52)MPa.HA-CS复合材料的平均拉伸强度达到(69.04±1.21)MPa,优于文献[17-18]报道的同等比例HA-CS复合材料的力学性能,且能满足骨替代材料所需的机械强度,可配合金属植入物研究作为支架材料[19-20]植入人体.

3.D 提示:根据2Al+6HCl==2AlCl3+3H2↑,2Al+2NaOH+2H2O==2NaAlO2+3H2↑可知,Al无论是与盐酸反应还是与NaOH溶液反应,相同质量的铝屑完全反应生成的H2的物质的量相同。若产生H2的体积比为1∶3,说明两份铝的质量比为1∶3。故选D项。

结 语

HA与CS之间的结合效果直接影响其复合材料的性能,本研究采用旋涂法在金属基材(304不锈钢板)表面成功涂覆HA-CS复合膜,改善了传统涂膜方法HA在CS中分散不均的缺憾,提高了复合膜的理化性能.通过XRD、FTIR、SEM、EDX和电子拉力机对样品进行分析测试,结果表明,HA-CS复合膜黏结较好,膜表面较平整、无裂痕,且形成利于引导组织细胞生长的微孔结构[21],复合材料力学性能也能满足骨修复材料所需的机械强度.此外,在接近人体温(37℃)干燥条件下复合膜性能更佳,也为HA-CS复合膜附着金属植入物在人体环境内能成功生长提供了理论依据.

/

:

[1] Li Ye, Chen Shukui, Li Long, et al. Bone defect animal models for testing efficacy of bone substitute biomaterials[J]. Journal of Orthopaedic Translation,2015,3(3):95-104.

[2] 徐小燕,刘涛涛,郑 军,等.壳聚糖/羟基磷灰石骨修复材料的研究进展[J].材料导报,2012,26(8):102-106. Xu Xiaoyan, Liu Taotao, Zheng Jun, et al. Progress of chitosan/hydroxyapatite bone repairing materials[J]. Materials Review,2012,26(8):102-106.(in Chinese)

[3] 袁秋华,张自强,巫剑波,等.羟基磷灰石-壳聚糖复合膜的制备及研究进展[J].广东化工,2016,43(14):75-78. Yuan Qiuhua, Zhang Ziqiang, Wu Jianbo, et al. Preparation and progress of hydroxyapatite-chitosan composite coatings[J]. Guangdong Chemical Industry,2016,43(14):75-78.(in Chinese)

[4] Dumont V C, Mansur A A P, Carvalho S M, et al. Chitosan and carboxymethyl-chitosan capping ligands: effects on the nucleation and growth of hydroxyapatite nanoparticles for producing biocomposite membranes[J]. Materials Science and Engineering C,2016,59:265-277.

[5] Zhong Zhenyu, Qin Jinli, Ma Jun. Electrophoretic deposition of biomimetic zinc substituted hydroxyapatite coatings with chitosan and carbon nanotubes on titanium[J]. Ceramics International,2015,41(7):8878-8884.

[6] Deen I, Pang X, Zhitomirsky I. Electrophoretic deposition of composite chitosan-halloysite nanotube-hydroxyapatite films[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2012,410(18):38-44.

[7] Stefan S, Gerald F, Ales D, et al. Chitosan-silane sol-gel hybrid thin films with controllable layer thickness and morphology[J]. Carbohydrate Polymers,2013,93(1):285-290.

[9] Majid A, Mohammad I, Jabir I, et al. Design and evaluation of chitosan/hydroxyapatite composite nanofiber membrane for the removal of heavy metal ions from aqueous solution[J]. Journal of the Taiwan Institute Chemical Engineers,2014,45(2):518-526.

[10] 李瑞欣,张西正,郝庆新,等.微米级煅烧羟基磷灰石/壳聚糖复合膜的制备及性能[J].复合材料学报,2013,30(1):103-111. Li Ruixin, Zhang Xizheng, Hao Qingxin, et al. Preparation and properties of micro-hydroxyapatite/chitosan composite membrane[J]. Acta Materiae Compositae Sinica,2013,30(1):103-111.(in Chinese)

[11] Cheng Xianmiao, Li Yubao, Zuo Yi, et al. Properties and in vitro biological evaluation of nano-hydroxyapatite/chitosan membranes for bone guided regeneration[J]. Materials Science and Engineering C,2009,29(1):29-35.

[12] Zhang Jian, Jia Jinpeng, Kim J P, et al. Ionic colloidal molding as a biomimetic scaffolding strategy for uniform bone tissue regeneration[J]. Advanced Materials,2017:1605546. doi:10.1002/adma.201605546

[13] 巫剑波,秦草坪,袁秋华,等.湿化学法合成羟基磷灰石晶体及其表征[J].深圳大学学报理工版,2015,32(5):465-472. Wu Jianbo, Qin Caoping, Yuan Qiuhua, et al. Synthesis and characterization of hydroxyapatite crystals using wet chemistry methods[J]. Journal of Shenzhen University Science and Engineering,2015,32(5):465-472.(in Chinese)

[14] 袁秋华,巫剑波,秦草坪,等.羟基磷灰石-聚乳酸复合膜的制备与表征[J].深圳大学学报理工版,2016,33(1):10-17. Yuan Qiuhua, Wu Jianbo, Qin Caoping, et al. Preparation and characterization of hydroxyapatite-polylactic acid HA-PLA composite film[J]. Journal of Shenzhen University Science and Engineering,2016,33(1):10-17.(in Chinese)

[15] Rogina A, Ivankovic'M, Ivankovic'H. Preparation and characterization of nano-hydroxyapatite within chitosan matrix[J]. Materials Science and Engineering C,2013,33(8):4539-4544.

[16] 李 健,韩志军,魏 延,等.纳米羟基磷灰石/壳聚糖复合微球的原位仿生制备及表征[J].无机材料学报,2014,29(12):1327-1332. Li Jian, Han Zhijun, Wei Yan, et al. In situ biomimetic fabrication and characterization of nano-hydroxyapatite/chitosan composite microspheres[J]. Journal of Inorganic Materials,2014,29(12):1327-1332.(in Chinese)

[17] 程先苗,李玉宝,张 利,等.纳米羟基磷灰石/壳聚糖复合膜的制备和表征[J].功能材料,2008,39(6):983-986. Cheng Xianmiao, Li Yubao, Zhang Li, et al. Preparation and characterization of nano-hydroxyapatie/chitosan composite membrane for guided bone regeneration[J]. Journal of Functional Materials,2008,39(6):983-986.(in Chinese)

[18] Li Xingyi, Nan Kaihui, Shi Shuai, et al. Preparation and characterization of nano-hydroxyapatite/chitosan cross-linking composite membrane intended for tissue engineering[J]. International Journal of Biological Macromolecules,2012,50(1):43-49.

[19] Wang Xiaojian, Xu Shanqing, Zhou Shiwei, et al. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review[J]. Biomaterials,2016,83:127-141.

[20] Carradò A, Perrin-Schmitt F, Le Q V, et al. Nanoporous hydroxyapatite/sodium titanate bilayer on titanium implants for improved osteointegration[J]. Dental Materials,2017,33(3):321-332.

[21] Salerno A, Fernández- Gutiérrez M, Román del Barrio J S, et al. Macroporous and nanometre scale fibrous PLA and PLA- HA composite scaffolds fabricated by a bio safe strategy[J]. The Royal Society of Chemistry,2014,4(16):61491-61502.

【中文责编:晨兮;英文责编:新谷】

Preparationandcharacterizationofhydroxyapatite-chitosancompositecoatingsusingaspin-coatingtechnique

YuanQiuhua,ZhangZiqiang,XuAnping,WuJianbo,QinCaoping,ChenZehui,LinSongxin,andZhangPeixin

CollegeofChemistryandEnvironmentalEngineering,ShenzhenUniversity,Shenzhen518060,GuangdongProvince,P.R.China

Based on a chemical precipitation method, the hydroxyapatite powders were prepared using Na2HPO4and Ca(NO3)2·4H2O as raw materials. The powders were dispersed into chitosan-acetic acid solution with the aid of continuous ultrasonic agitation to prepare hydroxyapatite-chitosan (HA-CS) suspension via solution blending and magnetic stirring. Hydroxyapatite-chitosan composite coatings were fabricated on304-type stainless steel substrates by a spin-coating technique, then dried at25℃ and37℃ for12h, respectively. The two synthesized samples were characterized and tested by X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX) and electronic tensile machine. The results indicate the tensile strength of HA-CS composites reaches up to (69.04±1.21) MPa, and the coatings display good crystallinity, good adhesion, high purity and little decomposition. In addition, by means of spin-coating technique, HA could be evenly dispersed in CS and there are no aggregated or free HA particles in the coatings. The HA-CS composite coatings show better performance when drying at37℃ than at25℃, which is more conducive to combine interaction between HA and CS.

biomaterials science; hydroxyapatite; chitosan; composite coatings; spin-coating technique; mechanical property

2016-11-01;Revised:2017-02-27;Accepted:2017-06-08

Associate professor Yuan Qiuhua. E-mail: yuanqiuh@szu.edu.cn

R 318.08

:Adoi:10.3724/SP.J.1249.2017.05451

Foundation:National Nature Science Foundation of China (21471102); Shenzhen Science and Technology Basic Research Foundation (JCYJ20150525092941007)

:Yuan Qiuhua, Zhang Ziqiang, Xu Anping, et al. Preparation and characterization of hydroxyapatite-chitosan composite coatings using a spin-coating technique[J]. Journal of Shenzhen University Science and Engineering, 2017, 34(5): 451-456.(in Chinese)

国家自然科学基金资助项目(21471102);深圳市科技基础研究计划资助项目(JCYJ20150525092941007)

袁秋华(1967—),男,深圳大学副教授、博士.研究方向:无机仿生材料.E-mail:yuanqiuh@szu.edu.cn

引文:袁秋华,张自强,徐安平,等.羟基磷灰石-壳聚糖复合膜旋涂法制备及表征[J]. 深圳大学学报理工版,2017,34(5):451-456.