Preparation of Monodisperse Silica Spheres Based on Improved Stöber Method and Their Mechanism of Formation

2017-09-03,,,,

, , , ,

(1. School of Renewable Energy, Shenyang Institute of Engineering, Shenyang 110136, China; 2. College of Biology Engineering, Beijing University of Chemical Technology, Beijing 100029, China)

材料科学

Preparation of Monodisperse Silica Spheres Based on Improved Stöber Method and Their Mechanism of Formation

DINGYanbo1,WANGCunxu1,BIXiaoguo1,ZHANGDong1,

LIYucai1,SONGShiwei1,WANGJian1,WANGGang1,WANGHan1,LIULiying1,XUZhao1,ZHAOZiqing2

(1. School of Renewable Energy, Shenyang Institute of Engineering, Shenyang 110136, China; 2. College of Biology Engineering, Beijing University of Chemical Technology, Beijing 100029, China)

In this paper, monodispersed spherical silica particles were prepared by sol-gel hydrolysis of tetraethoxy silane (TEOS) in alcohol-water mixed solvent using ammonia as catalyst by improved Stöber method. Effect of the concentration of TEOS, the type of solvents, the concentration of ammonia, the particle diameter and morphology of silica were investigated. Scanning electron microscopy to characterize the structure and morphology of the silica microspheres, the result shows that the hydrolysis of TEOS is control step in SiO2preparation and the diameter of SiO2increased as the concentration of ammonia increased.

monodisperse; Silica; formation mechanism

0 Introduction

Silica microspheres with high mechanical strength, good liquidity are widely used in chromatographic column packing, structure of ceramic materials, coatings, cosmetics, printing ink additives, etc.[1-2]. Beside, the silica has a non-toxic, high biological activity. The surface of the silicon hydroxyl group is very suitable as a modified bridge which suitable for variety of functionalization[3]due to their great potential application value in the fields of composite materials, catalysis, sensors, biomedical etc. In addition, after E. Yablonovitch's concept of photonic crystal, the dielectric function in space can change the mode of photon state in materials[4], which received wide attention of scientists interested of photonic crystals. The existence of photonic band gap in photonic crystals has produced a lot of new physical properties and phenomena, thus showing a very broad development and application prospects. The photonic crystal has become the hot research focus of physics and materials science, and developing rapidly at present.

1In the preparation of many photonic crystals, the process of preparing the photonic crystal by the colloidal crystal template method is considered as the most simple and effective, and also has the most development and application prospect[5]. However, one of the most challenging problems in the preparation of photonic crystals by this process is the large area preparation of ordered thin film photonic crystals.

Monodispersed silica microspheres prepared by self-assembly have been extensively application in the field of photonic crystal, data storage, optoelectronics which attracting a wide range of scientists interested[6]. There are many preparation methods of silica microspheres, such as micro emulsion method, plasma, chemical vapor deposition, etc. However, micro emulsion method needs large amounts of organic matter during the preparation process[7]. The recycling is much more troublesome, high cost and may cause pollution to the environment, the plasma method and chemical vapor deposition methods require specific device, high energy consumption[8]. On the basis of Stöber method using alcohol as solvent to make silicon alkoxide under ammonia catalytic hydrolytic condensation, then preparing silica microspheres through a post-processing, which not only simple in process, but also low cost, and can get good monodispersity products[9]. In this paper, based on the Stöber method for preparing silica microspheres, broadening the range of particle size of particles, the different alcohol solvent for the effect of silica particle size and dispersion under ammonia catalyst and its mechanism are discussed systematically.

1 Experimental section

Reagents used were anhydrous ethanol C2H5OH(A.R.), isopropyl alcohol CH3CH(OH)CH3(A.R.),butanol CH3CH2CH2CH2OH(A.R.), ammonia NH3·H2O(A.R.), tetraethyl orthosilicate (C2H5O)4Si (TEOS) (A.R.).Water used in all experiments was purified with a resistivity greater than 18ΩM/cm.

The improved Stöber method was used in this experiment. At first adding water into the reactor, then adding ethanol and ammonia solution into water, stirring for about 5 min.Finally, adding drops of TEOS slowly into reactor, constant temperature react about 5 hours to make the TEOS complete hydrolysis. The silica colloidal particles can easily obtain after TEOS sufficiently hydrolyzed. The improved Stöber method can avoid the larger initial concentration of TEOS which would make a good reproducibility of sample preparation. The particle size and morphology of silica microspheres can also be more precise control.

At the end of reaction, the product was spin-evaporated at 70 ℃ and 60 r/min, cleaned with ethanol until the pH was 7, dried in an oven to obtain SiO2samples Monodispersed silica microspheres was ultrasonic for 20 min in ethanol, take a certain amount of dispersed droplets on the aluminum film after drying, The silica microspheres was measured by scanning electron microscope (SEM) of Philips S-4800 type field-scanning microscope.

2 Results and discussion

2.1 Effect of Ethylorthosilicate and Formation Mechanism of Silica Microsphere

This experiment studied the adding amounts of ethylorthosilicate on silica microspheres. Fig.1 shows morphologies of silica microspheres with the concentrations of TEOS varying. The SEM micrographs of SiO2microspheres with the addition of 10% TEOS shown on Fig.1a. The SiO2particle size is 326 nm with smooth surface, high sphericity, uniform particle size and good monodispersity. Fig.1b shows the SEM micrographs of SiO2microspheres with the addition of 12% TEOS. The particle size of SiO2is 297 nm, the SiO2particle size is uniform, the monodispersity is good and the sphericity is high. Fig.1c shows the SEM micrographs of SiO2microspheres with 14% TEOS addition. It can be seen that SiO2is also spherical with smooth surface, but the particle size is not uniform and a double-size distribution occurs, obviously. The hydrolysis of ethylorthosilicate is the controlling step of the whole reaction. Once the supply of ethylorthosilicate exceeds its hydrolytic capacity, the monodisperse balance of the system will be destroyed, which will could not accord with the requirement of colloidal crystals self-assembly. TEOS addition should be controlled within 14% during the preparation of SiO2microspheres. Monodispersed SiO2synthesis of the main components of the alkyl silicates, short-chain alcohol, a certain concentration of ammonia and ultra-pure water, orthosilicate alkyl ester hydrolysis and polycondensation reaction principles usually described by the following reactions[10].

(1)

(2)

(3)

R in Equation is alkyl groups CxH2x+1, in (1) hydrolysis reaction, alcohol-based functional groups (RO-) are replaced by (OH-) functional groups, and then with (2) and (3) the polycondensation reaction, generate Si-O-Si, at the same time water and alcohol generate. Water and alcohol generating, Simultaneously. All these reactions are reversible. The reverse reactions of these reactions are hydrolysis and alcoholysis, respectively. The polycondensation can take place in both acidic and basic conditions. The adverse reactions of these are hydrolyzed and alcoholysis reactions, and the condensation reaction can react in both acidic or alkaline cases.

(a) TEOS 10%; (b) TEOS 12%; (c) TEOS 14%.

The polycondensation reaction begins with H+or OH-reacting rapidly with the hydrolyzate to form a charged intermediate followed by an electrically neutral silicon group which slowly attacks the charged intermediate. As with the hydrolysis reaction, the rate of polycondensation reaction also depends on the steric effect and the transition state of the charged state, in alkali catalyzed reaction, due to the formation and nucleation of orthosilicic acid, and then grow to form monodispersed spherical colloidal microspheres.

2.2 Effects of Solvent on Particle Size of Silica Microspheres

Fig.2a shows the SEM micrographs of SiO2microspheres prepared by using ethanol as solvent. It can be seen from the figure that the silica microspheres are spherical and have high sphericity, uniform particle size distribution and good monodispersity. Fig.2b shown the SiO2microspheres morphology prepared with isopropanol as solvent. SEM photographs can clearly see that the preparation of silica is spherical, particle size distribution is also very uniform, but the sphericity is not as high as with ethanol as solvent. SEM photographs shown in the Fig.2c demonstrate that the use of ethylene glycol as solvent to prepare SiO2microspheres due to no spherical silica particles and agglomeration seriously. This may be due to the alkyl chain of isopropanol is longer than the alkyl chain of ethanol, the faster reaction rate in the isopropanol solvent. When ethylene glycol used as solvent, the viscosity is larger. The polarity is small due to the large surface tension. Which leads to large steric hindrance during hydrolysis, so it is easy to agglomerate during hydrolysis.

(a) Ethanol; (b) Isopropanol; (c) Ethylene glycol.

While ethanol is a kind of solvent that dissolves in water and dissolves in TEOS, it can be mixed with water and ammonia in any proportion. The reactants and water can be evenly mixed and can participate in the reaction better during the reaction. The prepared silica has better dispersibility and smoother surface.

2.3 Ammonia concentration on the influence of silica microspheres

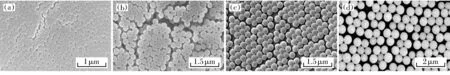

Fig.3 is a scanning electron micrograph of silica microspheres prepared at different ammonia concentrations. Fig.3a shows that the particle size of the prepared SiO2microspheres is 142 nm when the ammonia concentration is 6%. Fig.3b shows the particle diameter of the prepared SiO2microsphere is 310 nm when the ammonia concentration become 9%. Fig.3c shows the particle size of the prepared SiO2microspheres is 384 nm when the ammonia concentration enhance up to 12%. Fig.3d shows the particle size of the prepared SiO2microspheres is 423 nm when the ammonia concentration increase up to 15%. SiO2microspheres particle size increases gradually with the increasing of ammonia concentration. In addition, ammonia is not only the catalyst for the hydrolysis of ethyl orthosilicate, but also the morphology regulator of SiO2microspheres, which can’t form SiO2microspheres without ammonia. The mechanism of the preparation of monodisperse silica colloidal particles by TEOS hydrolysis under the catalysis of aqueous ammonia shown as following[11]:

Normally, a small amount of deionized water added into the TEOS and a reaction occurs, but the reaction rate is very slow and the gel is particularly prone to be formed. The addition of aqueous ammonia plays a catalytic role. there are has four-alkoxy -OR(-OC2H5) bonding around the silicon atom in the TEOS molecules has four-alkoxy -OR(-OC2H5) with it. In the presence of a basic catalyst (NH4OH), the OH-nucleophilic attack on the silicon nucleus causes the silicon nucleus to be negatively charged and causes the electron cloud to shift to the OR-group on the other side, so that the Si-O bond become weakened and broken, and hydrolysis occurs. Hydrolysis of monomer between Si-OH, the Si-OH group and the Si-R group undergo dehydration or dealcoholysis polymerization reaction. Forming Si-O-Si chain, Si-O-Si chain between the continuous cross-linking, synthesizing granular SiO2aggregates ultimately.

(a) ammonia 6% 142 nm; (b) ammonia 9% 310 nm; (c) ammonia 12% 384 nm; (d) ammonia 15% 423 nm.

In the presence of a basic catalyst (NH4OH), with the small radius, OH-ions attack negatively, which directly causes nucleon attack on the silicon nucleus and causes the silicon nucleus to be negatively charged and the electron cloud shifting to the other side of the OR-group, so that the Si-O bond of the group is weakened and cleaved out of the OR-to complete the hydrolysis reaction. Under the condition of alkali catalysis, TEOS hydrolysis belongs to the nucleophilic reaction mechanism of OH-ion attacking silicon nucleus directly, the intermediate process is little, and OH-ion radius is small, so the hydrolysis rate is faster. Silicon nucleus in the middle of the process obtains a negative charge, therefore if there are acceptor groups such as -OH or -OSi which are easy to attract electrons around the silicon nucleus, the induction can stabilize the negative charge and facilitate the hydrolysis of TEOS. In the alkaline catalysis system, the hydrolysis rate is higher than the polymerization rate, and the hydrolysis of TEOS is relatively complete. Therefore, it is considered that the polymerization is carried out in the multidimensional direction under the condition of complete hydrolysis, which forms a short chain cross linking structure. The internal polymerization of the intercalated structure strengthens the cross linking between short chains and forms unstable microcrystalline nuclei. The microcrystal nucleus has small volume and large diffusion coefficient, and the surface has many negative charges and is susceptible to background solution ionization species so that continue growing.Silicon nuclei in the middle process to obtain a negative charge, therefore, there exist acceptor groups such as-OH or-O-Si are easy to attract electrons around the silicon nucleus which is beneficial to the hydrolysis of TEOS due to its induction can stabilize the negative charge and is conducive.

3 Conclusion

In the process of silicon dioxide growth, TEOS concentration, the type of solvent, the concentration of ammonia have very important influence in the property of silica, such as particle size, morphology. Silica particle size will become larger with the increases amount of TEOS in the system. However, the TEOS concentration is too high will lead to less monodispersibility or double particle size distribution. The amount of TEOS addition should be controlled within 14%. The particle size distribution of silica microspheres was broadened with the more carbon chain alcohols. The morphology and particle size of SiO2prepared by using ethanol as solvent were superior. The particle size of the silica microspheres is larger as the ammonia concentration increasing. The diameter of silica microspheres will distribution under excessive ammonia, and the best pH value is about 9.

[ 1 ]VEVEL O D,JEDE T A,LOBO R F,et al. Porous silica via colloidal crystallization[J]. Nature, 1997,389:447-448.

[ 2 ]STEIN A. Sphere templating methods for periodic porous colloids[J]. Microporous and Mesoporous Mater, 2001,44:227.

[ 3 ]NIELSEN K H,ORZOL D K,KOYNOV S, et al. Large area,low cost anti-reflective coating for solar glasses[J]. Sol Energy Mater Sol Cells, 2014,128:283-288.

[ 4 ]YBLONOVITCH E. Inhibited Spontaneous Emission in Solid-State Physics and Electronics[J]. Phys Rev Lett, 1987,58:2059-2062.

[ 5 ]LIU Y,SHEN J,LI X G,et al. Effect of hydrophobicity on the vacuum-contamination resistance and laser damage threshold of sol-gel silica coating[J]. Chin J Inorg Chem, 2013,29:1339-1344.

[ 6 ]MORI T,HASEGAWA K,HATANO T,et al. Surface-relief gratings with high spatial frequency fabricated using direct glass imprinting process[J]. Opt Lett, 2008,33:428-430.

[ 7 ]HU Q F,LI G,WANG J H. The sediment method prepares the high strength white carbon black[J]. Non-metallic Mineral, 2000,23(6):23-24.

[ 8 ]GAN L M,ZHANG K,CHEW C H. Preparation of silica nanoparticles from sodium orthosilicate in inverse microemulsions[J]. Colloids Surf A:Physicochemical and Engineering Aspects. 1996,110:199-200.

[ 9 ]STBER W,FINK A. Controlled growth of monodisperse silica spheres in the micron size range[J]. Colloid & Interface Sci, 1968,26:626.

[10]MATSOUKAS T,GULARI E. A growth model for silica particles from alkoxides[J]. Colloid lnterface Sci, 1989,132:13.

[11]ASSINK R A,BRUEE D, KAY J. LDRD final report on gas separation by fullerene membranes[J]. Non-Crystal Solids, 1996(9):359-371.

1673-5862(2017)03-0281-05

基于改进的Stöber法制备单分散二氧化硅微球及其形成机理探讨

丁艳波1, 王存旭1, 毕孝国1, 张 东1, 李昱材1, 宋世巍1, 王 健1, 王 刚1, 王 晗1, 刘丽莹1, 徐 昭1, 赵子青2

(1. 沈阳工程学院 新能源学院, 沈阳 110136; 2. 北京化工大学 生物工程学院, 北京 100029)

使用改进的Stöber法,在醇水混合物中,以氨水作催化剂,正硅酸乙酯(TEOS)作为硅源,通过溶胶-凝胶水解工艺制备单分散的二氧化硅微球。研究了正硅酸乙酯的浓度、溶剂类型、氨水浓度、二氧化硅微球粒径和形貌的影响。采用扫描电子显微镜对所制备的二氧化硅微球进行结构和形貌的表征,结果表明正硅酸乙酯的浓度越大,二氧化硅微球的粒径越大。氨水的浓度增加,二氧化硅微球的粒径增大,单分散性较好。

单分散性; 二氧化硅; 形成机理

date: 2017-01-20.

TQ016 Document code: A

10.3969/ j.issn.1673-5862.2017.03.004

Supported: Fund of Liaoning Provincial Education Department under Grant (L2014516,L2015377,L2015370, L201610) .

Biography: DING Yanbo(1981-),female, was born in Wuhan of Hubei Province, lecturer of Shenyang Institute of Engineering,Doctor.