北京现代全球旗舰工厂在重庆落成打造全球汽车旗舰“绿色工厂”,“智能、绿色、品质、高效”是其最大特点

2017-08-22熊怡

□ 文/本刊记者 熊怡

北京现代全球旗舰工厂在重庆落成打造全球汽车旗舰“绿色工厂”,“智能、绿色、品质、高效”是其最大特点

□ 文/本刊记者 熊怡

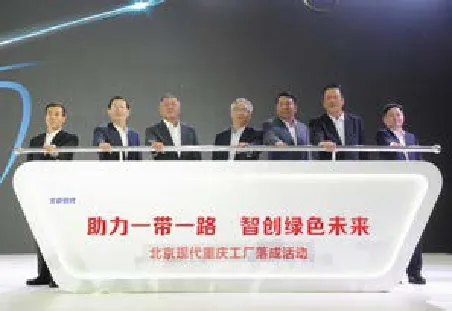

重庆市委副书记、市长张国清(中),市委常委、副市长、两江新区党工委书记、管委会主任陈绿平(左二),北汽集团党委书记、董事长、北京现代董事长徐和谊,现代汽车集团副会长郑义宣等嘉宾出席北京现代重庆工厂落成仪式。

7月19日,整车年生产能力达30万辆、发动机年生产能力达30万台的北京现代重庆工厂顺利落成。预计年内,重庆工厂将推出全新瑞纳等多款经济型及新能源车型。由此,重庆汽车产业再添一整车汽车生产企业,为国内最大汽车产业基地进一步增加强劲动力。

北京现代重庆工厂位于重庆两江新区鱼复工业开发区,占地面积187万平方米,总投资77.5亿元。北京现代重庆工厂是其在国内布局的第五座工厂,也是现代化程度最高的“全新旗舰工厂”。智能、绿色、品质、高效,成为该工厂的最大特点。

重庆市委副书记、市长张国清,市委常委、副市长、两江新区党工委书记、管委会主任陈绿平,北汽集团党委书记、董事长、北京现代董事长徐和谊,现代汽车集团副会长郑义宣等嘉宾出席落成仪式。

打造全球汽车旗舰“绿色工厂”

“北京现代重庆工厂是优化产业布局、拓展市场空间的重要战略基地。”徐和谊介绍,依托西南地区汽车产业桥头堡—重庆的优势,北京现代将加速本地化布局,“致力于打造全球领先的高品质、智能化、环境友好型工厂。”

重庆是西部唯一的直辖市,也是国家中心城市,北京现代重庆工厂的落成,将推动重庆现代制造业规模化、基地化布局,推动重庆汽车产业提档升级,也将助力重庆两江新区更好地打造全国重要的汽车生产基地。

据悉,2016年,两江新区汽车产量达到214万台,形成370万辆整车、100万台变速器、450万台发动机、200余家零部件企业、4700亿元产值布局,建立了完整的汽车零部件产业链。

2015年6月,北京现代重庆工厂动工建设。该工厂采用国际先进的汽车制造设备和生产工艺,以冲压、车身、涂装、总装四大工艺和发动机工厂组成全自动化生产线,在金属板件生产自动化率、焊接自动化率、喷涂自动化率、车型互换交叉生产、机加工艺自动化率等方面实现“5个100%”的智能生产理念。

在建设之初,北京现代重庆工厂就立足环保、低碳的环境友好型建设、生产理念,采用多种环保技术,实现低排放、低能耗和绿色物流。据了解,重庆工厂热能来源于先进的RTO蓄热式氧化炉,该设备可以将废气中的有机物(VOCs)通过物理和化学反应,转变为的二氧化碳和水,可把对废气进行净化回收利用。重庆工厂采用的高密度保温复合板及TPO防水材料,以确保车间的保温性和气密性,并采用LED照明和自然光照明结合的方式,最大限度的节约能源。

同时,重庆工厂还构筑了数字化的能源管理系统,对锅炉及压缩空气供应进行全自动监控,量需供给,实现能源的智能管理。在绿色物流领域,重庆工厂的大型部件将采用桥式自动运输,减少生产运输过程的能源消耗与尾气排放,从而实现“绿色物流”。

此外,重庆工厂还将通过综合运用质量完结系统、生产指示系统、全球保全管理系统、节能监控系统等多种现代化管理体系,实现对品质的全程把控,保证车辆的良好品质。

本土化布局辐射整个西南地区

依托西南地区汽车产业桥头堡—重庆的优势,北京现代将加速本地化布局,致力于打造全球领先的高品质、智能化、环境友好型工厂。

作为中国中西部地区重镇,重庆辐射半径500公里范围内聚集了两亿多城市人口,市场消费需求与增长潜力巨大。北京现代重庆工厂的落成,既是北京现代为响应国家“一带一路”倡议和长江经济带发展规划所做的重要布局,也是落实供给侧结构性改革,加速转型升级步伐的重要举措。

北京现代相关负责人表示,重庆工厂将以当地客户需求为中心进行产品研发、生产、销售并提供超前的售后服务,通过深耕西南市场的“本土化”。

重庆地处“一带一路”和长江经济带的联接点上,拥有承东启西、连接南北的交通优势。另外,作为中国重要的汽车生产基地,重庆拥有上千家核心配套企业,已形成含研发、制造、配套、物流及人才储备在内的完整产业链,具备得天独厚的产业优势。

而两江新区汽车产业采用“整机+配套”模式,通过上中下游产业链集聚,整机企业+零部件企业集聚,打造一批具备区域影响力和竞争力的产业集群。目前,汽车千亿级产业基地基本成型,聚集了长安、长安福特、上汽通用五菱、北京现代等知名品牌商,引进了发动机、变速器、制动系统、转向系统、钢板、轮胎等一大批关键零部件配套企业,本地配套率达七成以上。

这些优势都为北京现代重庆工厂的建设、落成和后期生产提供了雄厚的基础条件和广阔的市场空间。北京现代重庆工厂落成,将更好地完善两江新区在汽车产业的基地化、集群化布局,进一步优化两江新区汽车产业结构,推动汽车产业提档升级。

(图片由两江新区宣传部提供)

July 19 witnessed the completion of Beijing Hyundai’s Chongqing branch which aims to make 300,000 cars and 300,000 engines in a year. It is estimated that this Chongqing branch will launch a variety of economic and new energy models including new VERNA series in this year. From this, Chongqing automobile industry has added a whole auto manufacturer, which injects more power into the largest automobile industry base.

Beijing Hyundai’s Chongqing Branch located on the Yufu Industrial Development Zone, Liangjiang New Area, which covers 1.87 million square meters with the total investment of RMB 7.75 billion. As the fi fth plant of Beijing Hyundai in China, it represents a “ it represents a ts with the highest degree of modernization, as well as with the advantages including intelligent, environmental protection, quality and ef fi cient.

Of fi cial leaders like Zhang Guoqing, Vice Secretary and Mayor of Chongiqng, Chen Luping, standing committee and Vice Mayor of Chongqing, secretary of the Party working committee and director of Administrative Committee, Xu Heyi, secretary of the party committee and chairman in Beijing Automotive Group, Chairman of Beijing Hyundai, Zheng Yixuan, Vice President of Hyundai Automotive Group attended the ceremony.

Create a “green plant” to lead global automobile manufacturing

Introduced by Xu Heyi, “Beijing Hyundai Chongqing Branch is an important strategic base for optimizing industrial layout and expanding market space.” Supported by Chongqing’s advantage— a bridgehead of automobile industry in Southwest China, Beijing Hyundai will speed up to its layout in domestic. “We are committed to build the world’s leading eco-friendly factories with high-quality and intellectualization.”

As the only municipality directly under the Central Government in the west, Chongqing also honored as one of the national central cities. The completion of Beijing Hyundai Chongqing Branch will promote the large-scale and base of modern manufacturing industry in Chongqing as well as the upgrading of the automobile industry in Chongqing and give power to Liangjiang New Area to better build major auto production base in China.

It is reported that, 2.14 million cars were manufactured in Liangjiang New Area in 2016. It has formed a complete industry chain for auto parts with 3.7 million cars, 1 million transmissions, 4.5 million engines, over 200 auto parts enterprises and 470 billion value of output.

Beijing Hyundai Chongqing Branch started its construction in June, 2015. Applied with international advanced automotive manufacturing equipment and processes, this factory has formed its entire automatic production line with four processes: stamping, car body, painting, assembly and engine plant. The intelligent production concept of “Five 100 Percent” has been realized in areas like rate of production automation in sheet metal, rate of automation of welding, rate of automation of spraying, rate of crossover production, and rate of machining.

At the beginning of construction, based on environmental protection, low carbon and environment-friendly conceptions for construction and production, Chongqing Branch of Beijing Hyundai adopted a variety of environmental protection technology, realized low emission, low energy consumption and green logistics. It is understood that the factory’s heat energy comes from the advanced RTO regenerative oxidation furnace. The device can convert the organic substance (VOCs) in the exhaust gas into carbon dioxide and water through physical and chemical reactions, and can purify, recycle the waste gas. A high-density insulation composite board and TPO waterproof material were used in Chongqing Branch to ensure the insulation and air-tightness of the workshop. LED lighting and natural lighting were combined to save energy in maximum.

At the same time, the Chongqing factory also built a digital energy management system. The boiler and the compressed air supply are monitored automatically, and the quantity is supplied to realize the intelligent management of the energy. In the fi eld of green logistics, the large parts will adopt automatic bridge transportation to reduce the energy consumption and exhaust emissions in the process of production and transportation, so as to achieve “green logistics”.

In addition, the Chongqing plant will also be comprehensively equipped with quality system, production management system, global security management system, energy-saving monitoring system and other modern management systems, to achieve full quality control of products and ensure the good quality of the vehicle.

The whole southwest region is bene fi ted from localization layout

As a major city in the central and western regions of China, there are more than 200 million people living in city with a radius of 500 km. The market demand and growth potential are enormous. The completion of Beijing Hyundai Chongqing Branch is not only an important layout of this enterprise to cater for the “Belt and Road”Initiative and Yangtze River Economic Zone but also an important measure to implement supply side structural reform and accelerate the pace of transformation and upgrading.

Related principals of Beijing Hyundai said that the Chongqing factory will give priority to the demand of local customer for product development, production, marketing, and provide advanced aftersales service to realize the deep localization in southwest market. Chongqing is located at the connection point of “The Belt and Road” and the Yangtze River Economic Belt, connecting the east and west, south and north. In addition, as an important automobile production base, it boasts thousands of core supporting enterprises and has formed a complete industrial chain including research and development, manufacturing, supporting facilities, logistics and personnel reserve with unique industrial advantages.

Supported by the model of “cars + supporting facilities” and the agglomeration across the upstream, midstream and downstream industrial chains and the industrial cluster like “automobile enterprises + parts enterprises”, Liangjiang New Area created a number of industrial clusters with regional influence and competitiveness. At present, automotive industry base of hundreds of billions RMB is basically shaped. It has attracted famous brands like Changan, Changan Ford, SAIC-GM-Wuling Automobile, Beijing Hyundai and introduced a large number of key components supporting enterprises which manufacture engines, transmissions, braking system, steering system, steel plates and tyres, with a local matching rate of more than 70 percent.

These advantages provide a strong foundation and broad market space for the construction, completion and post production of the Beijing Hyundai Chongqing Branch. The completion of Beijing Hyundai Chongqing Branch will better improve the Liangjiang New Area in the layout of base and cluster of automotive industry, and further optimize automobile industrial structure in Liangjiang New Area and the upgrading of automobile industry.

(Pictures were provided by propaganda department of Liangjiang New Area)

A Global Flagship Plant of Beijing Hyundai Has Been Completed in Chongqing As a fl agship in global automobile manufacturing, this “Green Plant” is equipped with advantages: intelligent, environmental protection, quality and ef fi cient

Article/ Journalist Xiong Yi