锰氧化物材料的制备及应用进展

2017-06-05张晓东李红欣侯扶林杨阳董寒崔立峰

张晓东,李红欣,侯扶林,杨阳,董寒,崔立峰

锰氧化物材料的制备及应用进展

张晓东,李红欣,侯扶林,杨阳,董寒,崔立峰

(上海理工大学环境与建筑学院,上海200093)

锰作为一种常见的变价金属,其在催化反应中能够起到很好的催化作用。而且锰的氧化物作为最常用的过渡金属氧化物之一,因其较易调控出较大的比表面积、较强的吸附性能、较好的氧化还原能力以及较好的低温催化活性,已经成为了环境治理以及能源领域中的研究热点。介绍了MnO催化剂材料的合成、性质,以及在CO催化氧化、挥发性有机污染物的催化氧化、气体的吸附与分离以及电池的电极材料等应用方面一些最新的研究进展。

纳米结构;催化;吸附;锰氧化物;合成;应用

引 言

锰作为一种过渡变价金属,通常有多种容易转化的不稳定化合价态,其中+2、+3、+4、+6和+7是较稳定的氧化态。MnO作为最具有应用前景的过渡金属氧化物,因其较易具有高比表面积、较强的吸附性能、较好的氧化还原能力、低成本、电化学性能良好等优点而被广泛关注。MnO通常包括MnO、Mn3O4、Mn2O3、MnO2等。不同价态的MnO具有不同的形态结构,而相同价态的MnO也会因为合成方法、制备条件、原材料的差异而呈现不同的形态结构。例如MnO2,现已知的形貌就有纳米线、中空形状、棒状以及兰花状[1-4]。此外MnO2又有a-MnO2、δ-MnO2、ε-MnO2等晶相,其中,a-MnO2晶体由于骨架上含钾等异原子,和其他二氧化锰相比,严格意义上不能构成同质异相关系。研究显示,不同晶体结构的MnO具有不同的孔结构、比表面积以及形貌等,都会影响到MnO的性能。由于锰元素多价态的存在,导致锰氧化物的原子排布形式多种多样,引起了学术界的关注[5]。越来越多的研究者们致力于研究出简单易行的合成方法,不断提升MnO的物理、化学性能进而在相应的应用领域取得较好的性能。研究显示,纳米MnO在吸附分离和催化去除气态污染物等方面表现出较好的性能[6-8]。目前,MnO的综述主要集中在电池方面[9-15],其中较多的是MnO2在超级电容、电极材料中的应用,而对于气体吸附分离及催化氧化方面的综述则较少。因此,本文综述了MnO的常见的合成方法,以及其现阶段在气体吸附与分离、催化氧化以及电极材料等方面应用的最新进展。

1 合成方法

近几年来,越来越多的学者开始研究MnO的合成与制备,也衍生了越来越多的合成方法。本文将对现有的合成方法进行归纳。

1.1 水热合成法

水热合成法是合成MnO材料最常用的方法。即在密封的压力容器中,以水溶液为溶剂,温度100~400℃,使那些在常压下不溶或难溶的物质溶解,或反应生成该物质的溶解产物[16-20]。Zhu等[16]采用低温水热法将高锰酸钾和碳酰胺一起,通过调控反应温度,在90℃密封条件下反应24 h得到了δ-MnO2,而这种δ-MnO2具有层状结构以及高达230 m2·g-1的比表面积。Dai等[17]通过水热合成法,改变合成原材料,除了硝酸锰、高锰酸钾及P123等传统材料之外,又加入了碳纳米管,制备出了一种中空的锥体Mn2O3,有别于之前大部分球状中空的Mn2O3。这种材料表现出高达900 mA·h·g-1的比电容以及较好的倍率性能和循环稳定性。Guo等[18]以醋酸锰和高锰酸钾为锰源,通过固定反应温度,改变反应时间来调控α-MnO2的形态,制备了不同形貌的MnO2和石墨烯复合物。结果显示当时间从0.1 h到5 h时,制备的复合物形貌是片状的,且随着时间的增加逐渐增厚,当时间超过5 h时,则呈现出棒状形貌,且复合物的比电容可达到332 F·g-1。Zhao等[19]用水热合成法,通过控制反应温度制备出了不同形貌的MnO2,当合成温度在100~300℃时,合成了无定形MnO2,而当温度超过400℃时,则制备了δ-MnO2、α-MnO2纳米棒,并且具有较好的几何性能和稳定性。

1.2 沉淀法

沉淀法通常是在溶液状态下将不同化学成分的物质混合,在混合液中加入适当的沉淀剂制备前体沉淀物,再将沉淀物进行干燥或煅烧,从而制得相应的粉体颗粒。Nathsarma等[21]从矿石浸出液中提取不同含量的锰,然后加入硫酸铵和铵,控制反应的pH为8.1~9.2并用空气和氩气吹扫,制备了MnO2,其浸出率可达57.2%~99.9%。Moradkhani等[22]通过甲烷还原锰矿石,再通过热沉淀法,加入过硫酸铵和硫酸,调控沉淀反应温度25~90℃,合成了纳米MnO2,结果表明该方法制备的α-MnO2平均粒径在50 nm左右,比表面积高达174 m2·g-1。Hlaing等[23]以MnSO4和KMnO4为原材料,通过控制反应温度和时间制备锰氧化物,结果显示在90℃,2 h的热沉淀法条件下制备了一维α-MnO2纳米棒,其粒子直径在30~50 nm,并具有较好的晶型以及形态结构。

1.3 固相法

固相法作为一种比较传统的方法,是指通过对固体物料进行加工,经过研磨后再进行煅烧,发生固相反应后直接得到或经过再研磨得到超细粉体的方法。通常包括热分解法、固相反应法、溶出法以及球磨法等。Donne等[24]通过热分解高锰酸盐,控制溶液的pH,制备了不同形貌的α-MnO2和β-MnO2,结果表明,pH从强碱到强酸的变化会导致产物形貌发生很大的变化,虽然产物有结晶性且孔隙率低,但其具有明显的介孔特性和优越的电化学特性。Fang等[25]用固相法,将醋酸锰和草酸进行热分解,调控反应温度,在250℃、10 h的条件下制备了一种粒径为200 nm的球形MnO2(包括α-MnO2和γ-MnO2),其电容值可达到337 F·g-1,具有较好的循环稳定性。Hao等[26]以高锰酸钾和水杨酸在700℃下通过控制反应时间制备了MnO纳米球,封装在碳上,再将其转化为α-MnO2纳米棒。用这种方法合成的MnO/C复合物的电容量达到了585.9 mA·h·g-1,MnO2的电容量高达1269 mA·h·g-1,具有较好的应用前景。

1.4 熔盐法

熔盐法是指通常采用1种或数种低熔点盐类作为反应介质,反应物在熔盐中有一定的溶解度,使得反应在原子级进行。反应结束后,采用合适的溶剂将盐类溶解,经过滤、洗涤后即可得到合成产物。在熔盐法中,盐的熔体起到了熔剂和反应介质的作用。常见的低熔点盐有硫酸盐、硝酸盐等,如硝酸锰、硝酸钾、硝酸钠、硝酸铈、硫酸锰、硫酸钾。Cao等[27]以Zn-Mn电池中的γ-MnO2为锰源,用熔盐法调控反应温度制备了LiMn2O4,结果显示在770℃、4 h的条件下制备的材料具有较好的电化学性能。Peng等[28]通过熔盐法,在380℃下反应3 h制备了α-MnO2纳米线,负载金属离子后较大地提高了电化学性能以及电子导电率。

1.5 溶胶-凝胶法

溶胶-凝胶法是目前应用最多的制备纳米材料的方法。该方法是将硅氧烷或金属盐等在溶液中水解、缩合成溶胶液,然后加热除去溶剂而转化成凝胶,最终制得固体氧化物或其他固体化合物的方法。Picasso等[29]通过溶胶-凝胶法,调控反应温度和时间,制备了层状纳米结构的MnO催化剂,将其应用到正己烷的消除当中。

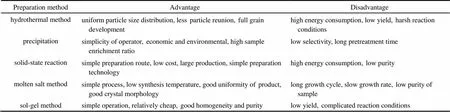

表1为几种合成方法的比较。通过归纳以上不同的合成方法,可以看出,MnO的合成方法多种多样,MnO的形貌、比表面积、孔结构、性能等很容易受实验条件,如温度、pH、反应时间、金属源、溶剂等的影响而改变。这就要求在制备中优化实验方法,以得到期望的结构。

2 锰氧化物的应用

2.1 MnO的催化性能

MnO由于具有出色的氧化还原能力、多种多样的晶型等性能常被应用到VOCs(挥发性有机污染物)处理、CO催化氧化、氧催化还原反应等领域中。Kim等[30]研究发现催化氧化甲苯的性能主要由锰氧化物的氧化态所决定,几种常见的MnO对于甲苯的氧化活性呈递减趋势:Mn3O4>Mn2O3> MnO2,这主要是与3种MnO比表面积大小、氧移动性高低及缺陷氧多少有关。Shi等[31]制备了棒状α-MnO2、花状ε-MnO2及哑铃状β-MnO2并发现MnO2的晶相及形态对催化氧化甲苯具有较大影响,3种MnO2对于甲苯的催化氧化顺序通常为ε-MnO2>α-MnO2> β-MnO2。Zhang等[32]以MnSO4·H2O、KMnO4和(NH4)2S2O8为前体,合成了α, β, γ和δ-MnO2,并应用于催化氧化甲醛。结果δ-MnO2的催化性能最好,大约80℃将甲醛完全转化。Li等[33]通过水热法合成了层状中空β-MnO2纳米球、双层中空β/α-MnO2纳米球及层状中空α-MnO2并用于催化氧化苯,结果这3种催化剂对苯的催化氧化活性按照α-MnO2> β/α-MnO2>β-MnO2顺序递减,揭示了催化剂的活性是和结构相关的。Jin等[34]研究发现,γ-MnO2八面体分子筛对甲苯催化氧化具有出色的催化效果及良好的选择性。除此之外,Li等[35]报道了α-MnO2对乙醛的效果要好于β-MnO2和γ-MnO2。Liu等[36]考察了由纯MnO从NH3中还原NO,结果表明NO的转化率按照MnO2> Mn5O8> Mn2O3> Mn3O4的顺序递减。

CO作为1种空气污染物,且常被用作模型反应研究催化剂的结构。近年来,有许多负载型的催化剂被应用于去除CO,如Ag[37-40]、Pt[41-43]、Pd[44-45]和Au[46-48]等。但是由于这些贵金属比较昂贵及热稳定性较差,所以应用也较局限。MnO对于CO的催化氧化机理一般被认为是氧化-还原机理[49-50]:即金属/载体首先经过1个单独被氧化的过程,吸附并被活化的CO分子与催化剂表面直接参与反应的晶格氧发生反应,气相中的分子氧吸附于催化剂表面并成为晶格氧,补充反应造成的晶格氧缺位,如此循环便实现CO的氧化,而产生的CO2则从催化剂表面脱附,见图1。MnO中尤其是MnO2,由于其与还原剂和氧化剂之间的氧化还原周期循环较容易,展现出了良好的氧储存和释放的能力。Xu等[51]合成了不同晶相的MnO2,结果显示α-MnO2和β-MnO2都表现出较好的催化氧化CO性能。由于α-MnO2具有更好的低温还原性,故对CO的催化效果更好。表2中列举了一些常见MnO对CO的催化氧化情况。从表2中可以看到不同MnO对于CO的催化氧化效果不同,相同MnO由于反应质量、预处理条件等不同,对CO的催化氧化效果也不同。一般情况下,Mn2O3对CO的催化氧化效果要好于Mn3O4和MnO2,这一结果与Wang等[57]和Ramesh等[8]的一致。

表1 几种无机材料合成方法对比

表2 MnOx对CO的催化氧化

① Temperature for 100% CO conversion.

MnO在氧还原催化领域中应用也较多。在阴极发生的电化学反应通常被叫作氧还原反应。在聚合物电解质燃料电池和质子交换膜燃料电池中氧还原反应发挥着关键的作用,而MnO由于具有低成本、较高的催化活性等特点而被用作氧还原催化剂。Wei等[66]在涂锌空气电池中采用以碳棒为载体负载了MnO2作为氧还原催化剂制备了一种空气电极,通过研究发现,MnO2最佳的负载量为6.7%(质量),且在270~450℃范围内加热发现在340℃加热1 h所得到的催化剂对氧还原展现了最好的催化活性。Wei等[67]同时又在涂锌空气电池的电极上以碳棒为载体负载了Mn3O4并将其诱导形成更有效的MnO2,结果表明,当Mn3O4的负载量在15%(质量)以内时,通过Mn3O4的诱导可以形成两种更有效的MnO2晶型,提高了氧还原效果。Li等[68]通过煅烧硝酸锰制备MnO2并通过对其电子结构及表面氧空位的数量和范围进行计算,结果发现适当浓度的氧空位可以减少带隙,增加MnOOH的水平并拉长了吸附氧的O—O键,这些变化均利于增加MnO2的导电性以及氧还原活性,最终发现具有适当浓度氧空位的β-MnO2具有最高的导电性及氧还原催化活性。Cheng等[69]也以MnO2为例,对其进行热处理增加氧空位来提高氧还原催化反应能力,结果发现在热处理后β-MnO2表现出更低的过电位、更大的电流,半波范围内比最初MnO2的电流高了50 mV, 通过计算也展现了更多的氧空位,进而增加了氧还原催化反应能力。Wang等[70]以CaMnO3作为氧还原催化剂的载体,探查了Pt/CaMnO3催化剂对氧还原催化反应活性和稳定性的影响。通过和Pt5/石墨烯对比,当Pt负载到CaMnO3时,Pt5和CaMnO3的作用力远远大于Pt5和石墨烯的作用力,具有更多的氧空位、更小的禁带宽度及更低的电子转移阻力,进而提高了电导率以及Pt催化剂的活性和稳定性。

研究发现,与传统催化剂相比,MnO对CO、甲苯等的催化氧化效果较佳主要是其能提供更多的活性金属阳离子位和还原分子氧的活性位数量以及更多锰氧化物的混合氧化态。此外,MnO中锰氧化态的变化、不稳定晶格氧和表面氧化产物的滞留也是影响其催化氧化效果的因素[71-72]。

2.2 电极材料

超级电容器由于具有高功率、长期循环稳定性、节能环保、独特的吸引力等特点而作为最具有吸引力的电化学存储系统之一。研究显示电解质和电极在超级电容器运行过程中发挥了关键作用,因而目前对超级电容器的研究重点也主要集中在这两个方向,尤其是电极材料。锰氧化物由于其高的比电容、低成本、天然丰富和环境友好型而受到越来越多的关注[73]。MnO之所以在电极材料领域引起了各国研究者的广泛兴趣,主要是其发生在电极/溶液界面的可逆Faraday反应,可产生远大于碳材料双电层电容的Faraday赝电容,即在电极活性材料的表面或体相的二维或准二维空间中,活性物质发生欠电位沉积,进行高度可逆的化学氧化/还原反应,从而产生与电极充电电位相关的电容[74-75]。纳米级的MnO2包含高孔隙度和良好的电导性容易形成混合或复合纳米结构进而使它们电化学性能最优化。据理论计算,MnO2的比电容可以高达1100 F·g-1,具有较好的电化学性质[76]。

中空状的Mn2O3核壳材料因成本低、环保和高理论容量(1018 mA·h·g-1)而成为了一种新兴的阳极电极材料。此外,具有大比表面积的中空Mn2O3核壳结构可以缓冲电极的体积变化并提供更多的锂离子插入或者提取的反应位点,这有助于增强锂离子电池的性能。表3中列举了一些常见MnO在电极材料中的应用情况。

表3 MnOx在电极材料中的应用情况

通过以上研究表明,采用不同方法、条件制备的MnO具有不同的晶体结构,而不同晶体结构的MnO又会导致比表面积、孔洞、尺寸以及形貌的差异,这些都会影响到MnO的比电容、导电率以及使用寿命等电化学性能及稳定性,一些特殊形貌的MnO往往具有更高的电导率和比电容。此外,Ghodbane等[84]通过研究得出了MnO的维度也对其比电容的大小有影响,与一维隧道结构相比,二维的层状以及三维的网状结构更加开阔,从而能够更好地使离子嵌入和脱出,因此离子传导率和比电容性能更好。与此同时,由于表面吸附-脱附和本体脱出-嵌入两种电荷存储原理在MnO电极充放电的过程中同时存在,所以推测,MnO的比电容大小可能会和其表面的表面氧和晶格氧的分布情况以及Mn3+/Mn4+的摩尔比有关联。但是如何让MnO更抗溶解、比表面积更大、电子电导率和离子导电性更好仍是一个亟需解决的难题。

2.3 吸附

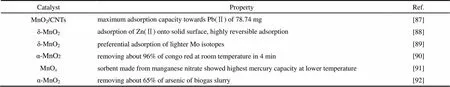

MnO作为一种多孔性的过渡金属氧化物,因其具有较大的比表面积、表面含有丰富的羟基,结构内部存在较多晶体缺陷,容易产生大量电子空穴,且与金属离子有很强的结合力。对某些有机物和重金属具有强烈的吸收和富集能力,而被作为一种较好的吸附剂,被广泛应用到大气污染物、水处理中重金属的去除等领域,对污染物进行吸附[85]。Zhao等[86]研究了锰的价态和锰等离子释放量与Pb2+吸附能力的关系,结果显示Pb2+的吸附量与锰的价态呈正相关趋势,同时,由于锰氧化物表面存在羟自由基,羟自由基基团与金属离子结合的过程中会释放氢离子,氢离子等的释放量也和Pb2+吸附能力呈正相关关系。表4中列举了一些MnO在吸附领域中的常见应用。

表4 MnOx在吸附领域中的应用

3 结论与展望

锰氧化物由于其特有的比表面积大、氧化还原能力强、低温催化氧化效果好等优势,现已成为过渡金属氧化物的研究热点。关于锰氧化物以及掺杂负载其他金属的锰氧化物的合成以及应用等方面的研究也越来越多,但是现在常用的主要的合成方法仍然是水热合成法。研究设计更简单易行、成本低廉、重现性好的合成方法仍然是个挑战。此外,MnO比较容易中毒且不抗湿,较容易吸水,关于如何提高锰氧化物催化剂材料的稳定性也是亟需解决的难题。寻找经济高效的其他非贵金属并负载到锰氧化物当中,进一步提高其催化活性,需要更多的尝试与创新。

References

[1] CHEN Y, ZHANG M L, JING X Y. Preparation and characterization of rod-shaped MnO2crystal[J]. Solid State Communications, 2005, 133: 121-123.

[2] LI X L, LI W J, CHEN X Y,Hydrothermal synthesis and characterization of orchid-like MnO2nanostructures[J]. Journal of Crystal Growth, 2006, 297: 387-389.

[3] YUAN Z Y, ZHANG Z L, DU D H,A simple method to synthesise single-crystalline manganese oxide nanowires[J]. Chem. Phys. Lett., 2003, 378: 349-353.

[4] XIA H, FENG J K, WANG H L,MnO2nanotube and nanowire arrays by electrochemical deposition for supercapacitors[J]. Journal of Power Sources, 2010, 195: 4410-4413.

[5] CHEN Z W, JIAO Z, PAN D Y,Recent advances in manganese oxide nanocrystals: fabrication, characterization, and microstructure[J]. Chem. Rev., 2012, 112: 3833-3855.

[6] QI G S, YANG R T, CHANG R. MnO-CeO2mixed oxides prepared by co-precipitation for selective catalytic reduction of NO with NH3at low temperatures[J]. Applied Catalysis B: Environmental, 2004, 51: 93-106.

[7] TANG X F, LI J H, SUN L,Origination of N2O from NO reduction by NH3over β-MnO2and α-Mn2O3[J]. Applied Catalysis B: Environmental, 2010, 99: 156-162.

[8] RAMESH K, CHEN L W, CHEN F X,Re-investigating the CO oxidation mechanism over unsupported MnO, Mn2O3and MnO2catalysts[J]. Catalysis Today, 2008, 131: 477-482.

[9] WANG X Y, LIU L, WANG X Y,Mn2O3/carbon aerogel microbead composites synthesized bycoating method for supercapacitors[J]. Materials Science and Engineering B, 2011, 176: 1232-1238.

[10] HUANG M, LI F, DONG F,MnO2-based nanostructures for high-performance supercapacitors[J]. Journal of Materials Chemistry A, 2015, 3(43): 21380-21423.

[11] WANG J G, KANG F Y, WEI B Q. Engineering of MNO2-based nanocomposites for high-performance supercapacitors[J]. Progress in Materials Science, 2015, 74: 51-124.

[12] CAO J Y, LI X H, WANG Y M,Materials and fabrication of electrode scaffolds for deposition of MnO2and their true performance in supercapacitors[J]. Journal of Power Sources, 2015, 293: 657-674.

[13] ZHAO J C, WANG J, XU J L. Synthesis and electrochemical characterization of mesoporous MnO2[J]. Journal of Chemistry, 2015, 2015: 768023-768028.

[14] ATHOUEL L, MOSER F, DUGAS R,Variation of the MnO2birnessite structure upon charge/discharge in an electrochemical supercapacitor electrode in aqueous Na2SO4electrolyte[J]. J. Phys. Chem. C, 2008, 112: 7270-7277.

[15] SCHMACHTEL S, TOIMINEN M, KONTTURI K,New oxygen evolution anodes for metal electrowinning: MnO2composite electrodes[J]. J. Appl. Electrochem., 2009, 39: 1835-1848.

[16] ZHU G, LI H J, DENG L J,Low-temperature synthesis of δ-MnO2with large surface area and its capacitance[J]. Materials Letters, 2010, 64: 1763-1765.

[17] DAI Y H, JIANG H, HU Y J,Hydrothermal synthesis of hollow Mn2O3nanocones as anode material for Li-ion batteries[J]. RSC Adv., 2013, 3: 19778-19781.

[18] GUO M X, BIAN S W, SHAO F,Hydrothermal synthesis and electrochemical performance of MnO2/graphene/polyester composite electrode materials for flexible supercapacitors[J]. Electrochimica Acta, 2016, 209: 486-497.

[19] ZHAO Y C, MISCH J, WANG C A. Facile synthesis and characterization of MnO2nanomaterials as supercapacitor electrode materials[J]. Mater. Electron., 2016, 27: 5533-5542.

[20] LU X L, ZHENG Y Y, ZHANG Y B,Low-temperature selective catalytic reduction of NO over carbon nanotubes supported MnO2fabricated by co-precipitation method[J]. Micro & Nano Letters, 2015, 10(11): 666-669.

[21] NATHSARMA K C, ROUT P C, SARANGI K. Manganese precipitation kinetics and cobalt adsorption on MnO2from the ammoniacal ammonium sulfate leach liquor of Indian Ocean manganese nodule[J]. Hydrometallurgy, 2013, 133: 133-138.

[22] MORADKHANI D, MALEKZADEH M, AHMADI E. Nanostructured MnO2synthesizedmethane gas reduction of manganese ore and hydrothermal precipitation methods[J]. Trans. Nonferrous Met. Soc. China, 2013, 23: 134-139.

[23] HLAING A A, PHYUWIN P. The synthesis of α-MnO2nanorods using hydrothermal homogeneous precipitation[J]. Adv. Nat. Sci.: Nanosci. Nanotechnol., 2012, 3: 25001-25003.

[24] DONNE S W, HOLLENKAMP A, JONESA B C. Structure, morphology and electrochemical behavior of manganese oxides prepared by controlled decomposition of permanganate[J]. Journal of Power Sources, 2010, 195: 367-373.

[25] FANG D L, WU B C, MAO A Q,Super capacitive properties of ultra-fine MnO2prepared by a solid-state coordination reaction[J]. Journal of Alloys and Compounds, 2010, 507: 526-530.

[26] HAO Q, XU L Q, LI G D,Synthesis of MnO/C composites through a solid state reaction and their transformation into MnO2nanorods[J]. Journal of Alloys and Compounds, 2011, 509: 6217-6221.

[27] CAO X, GUO G H, LIU F F,The properties of LiMn2O4synthesized by molten salt method using MnO2as manganese source recycled from spent Zn-Mn batteries[J]. International Journal of Electrochemical Science, 2015, 10(5): 3841-3847.

[28] PENG R C, WU N, ZHENG Y,Large-scale synthesis of metal-ion-doped manganese dioxide for enhanced electrochemical performance[J]. ACS Applied Materials & Interfaces, 2016, 8(13): 8474-8480.

[29] PICASSO G, SUN KOU M D R, SALAZAR I,Synthesis of nanostructured catalysts based on Mn oxide for-hexane elimination[J]. Rev. Soc. Quím. Perú, 2011, 77(1): 11-26.

[30] KIM S C, SHIM W G. Catalytic combustion of VOCs over a series of manganese oxide catalysts[J]. Appl. Catal. B, 2010, 98: 180-185.

[31] SHI F, WANG F, DAI H,Rod-, flower-, and dumbbell-like MnO2: highly active catalysts for the combustion of toluene[J]. Applied Catalysis A: General, 2012, 433/434: 206-213.

[32] ZHANG J, LI Y, WANG L,Catalytic oxidation of formaldehyde over manganese oxides with different crystal structures[J]. Catal. Sci. Technol., 2015, 5: 2305-2313.

[33] LI D, YANG J, TANG W,Controlled synthesis of hierarchical MnO2microspheres with hollow interiors for the removal of benzene[J]. RSC Adv., 2014, 4: 26796-26803.

[34] JIN L, CHEN C H, CRISOSTOMO V M B,γ-MnO2octahedral molecular sieve: preparation, characterization, and catalytic activity in the atmospheric oxidation of toluene[J]. Appl. Catal. A., 2009, 355: 169-175.

[35] LI Y Z, FAN Z Y, SHI J W,Post plasma-catalysis for VOCs degradation over different phase structure MnO2catalysts [J]. Chem. Eng. J., 2014, 241: 251-258.

[36] LIU C, SHI J W, GAO C,Manganese oxide-based catalysts for low-temperature selective catalytic reduction of NOwith NH3: a review[J]. Applied Catalysis A: General, 2016, 522: 54-69.

[37] ZHANG X D, DONG H, WANG Y,Study of catalytic activity at the Ag/Al-SBA-15 catalysts for CO oxidation and selective CO oxidation[J]. Chemical Engineering Journal, 2016, 283: 1097-1107.

[38] ZHANG X D, DONG H, ZHAO D,Effect of support calcination temperature on Ag structure and catalytic activity for CO oxidation[J]. Chem. Res. Chin. Univ., 2016, 32(3): 455-460.

[39] QU Z P, ZHANG X D, YU F L,Role of the Al chemical environment in the formation of silver species and its CO oxidation activity[J]. Journal of Catalysis, 2015, 321: 113-122.

[40] ZHANG X D, QU Z P, YU F L,Progress in carbon monoxide oxidation over nanosized Ag catalysts (review) [J]. Chinese Journal of Catalysis, 2013, 34(7): 1277-1290.

[41] LEI T, DENG Q, ZHANG S,Fast identification of CO by using single Pt-modified WO3sensing film based on optical modulation[J]. Sensors and Actuators B: Chemical, 2016, 232: 506-513.

[42] GAO H W. CO oxidation mechanism on the gamma-Al2O3supported single Pt atom: first principle study[J]. Applied Surface Science, 2016, 379: 347-357.

[43] KIM G J, KWON D W, HONG S C. Effect of Pt particle size and valence state on the performance of Pt/TiO2catalysts for CO oxidation at room temperature[J]. Journal of Physical Chemistry C, 2016, 120(32): 17996-18004.

[44] SHIPITCYNA A, KINNUNEN N M, HILLI Y,Characterization and activity of Pd-Ir catalysts in CO and C3H6oxidation under stoichiometric conditions[J]. Topics in Catalysis, 2016, 59(13/14): 1097-1103.

[45] BAI Y, WANG C L, ZHOU X Y,Atomic layer deposition on Pd nanocrystals for forming Pd-TiO2interface toward enhanced CO oxidation[J]. Progress in Natural Science: Materials International, 2016, 26: 289-294.

[46] DENG X Q, ZHU B, LI X S,Visible-light photocatalytic oxidation of CO over plasmonic Au/TiO2: unusual features of oxygen plasma activation[J]. Applied Catalysis B: Environmental, 2016, 188: 48-55.

[47] LIU Y X, ZHANG J L, SONG L X,Au-HKUST‑1 composite nanocapsules: synthesis with a coordination replication strategy and catalysis on CO oxidation[J]. ACS Applied Materials & Interfaces, 2016, 8(35): 22745-22750.

[48] LI H F, PAN C, ZHAO S J,Enhancing performance of PEM fuel cells: using the Au nanoplatelet/nafion interface to enable CO oxidation under ambient conditions[J]. Journal of Catalysis, 2016, 339: 31-37.

[49] MORGAN K, COLE K J, GOGUET A,TAP studies of CO oxidation over CuMnOand Au/CuMnOcatalysts [J]. J. Catal., 2010, 276(1): 38-48.

[50] LUO Y, DENG Y, MAO W,Probing the surface structure of α-Mn2O3Nanocrystals during CO oxidation by operando Raman spectroscopy[J]. The Journal of Physical Chemistry, 2012, 116 (39): 20975-20981

[51] XU R, WANG X, WANG D,Surface structure effects in nanocrystal MnO2and Ag/MnO2catalytic oxidation of CO[J]. J. Catal., 2006, 237(2): 426-430.

[52] LE M T, NGUYEN T T, PHAM P T M,Activated MnO2-Co3O4-CeO2catalysts for the treatment of CO at room temperature[J]. Applied Catalysis A: General, 2014, 480: 34-41.

[53] KUNLEKAR R K, SALKER A V. Activity of Pd doped and supported Mn2O3nanomaterials for CO oxidation[J]. Reac. Kinet. Mech. Cat., 2012, 106: 395-405.

[54] LIU Y X, DAI H X, DENG J G,. Controlled generation of uniform spherical LaMnO3, LaCoO3, Mn2O3, and Co3O4nanoparticles and their high catalytic performance for carbon monoxide and toluene oxidation[J]. Inorganic Chemistry, 2013, 52 (15): 8665-8676.

[55] CARABINEIRO S A C, BASTOS S S T, ÓRFAO J J M,Carbon monoxide oxidation catalysed by exotemplated manganese oxides[J]. Catal. Lett., 2010, 134(3): 21-227.

[56] NASKAR M K, ROY M, BASAK S. Bi-template assisted synthesis of mesoporous manganese oxide nanostructures: tuning properties for efficient CO oxidation[J]. Phys. Chem. Chem. Phys., 2016, 18: 5253-5263.

[57] WANG L C, HUANG S, LIU Q,Gold nanoparticles deposited on manganese (III) oxide as novel efficient catalyst for low temperature CO oxidation[J]. J. Catal., 2008, 259: 66-74.

[58] WANG L C, LIU Q, HUANG X S,Gold nanoparticles supported on manganese oxides for low-temperature CO oxidation[J]. Appl. Catal. B, 2009, 88: 204-212.

[59] LEE Y H, PARK J H, SHIN C H. Physicochemical properties of manganese dioxide synthesized using C2–C5 alcohols as reducing agents and their catalytic activities for CO oxidation[J]. Catalysis Today, 2016, 265: 7-13.

[60] PARK J H, KANG D C, PARK S J,CO oxidation over MnO2catalysts prepared by a simple redox method: influence of the Mn (II) precursors[J]. Journal of Industrial and Engineering Chemistry, 2015, 25: 250-257.

[61] ZHANG C, HAN L, LIU W,Facile synthesis of novel MnOnano-structures and their catalytic performance on CO oxidation[J]. CrystEngComm, 2013, 15: 5150-5155.

[62] 叶青, 霍飞飞, 闫立娜, 等.α-MnO2负载纳米Au催化剂低温催化氧化CO和苯的性能[J]. 物理化学学报, 2011, 27 (12): 2872-2880. YE Q, HUO F F, YAN L N,Highly active Au/α-MnO2catalysts for the low-temperature oxidation of carbon monoxide and benzene[J]. Acta Phys.-Chim. Sin., 2011, 27 (12): 2872-2880.

[63] LIANG S H, TENG F, BULGAN G,Effect of phase structure of MnO2nanorod catalyst on the activity for CO oxidation[J]. J. Phys. Chem. C, 2008, 112: 5307-5315.

[64] KUNKALEKAR R K, SALKER A V. Low temperature carbon monoxide oxidation over nanosized silver doped manganese dioxide catalysts[J]. Catalysis Communications, 2010, 12: 193-196.

[65] CHEN S Y, SONG W Q, LIN H J,Manganese oxide nano-array based monolithic catalysts: tunable morphology and high efficiency for CO oxidation[J]. ACS Appl. Mater. Interfaces, 2016, 8 (12): 7834-7842.

[66] WEI Z D, HUANG W Z, ZHANG S T,Carbon-based air electrodes carrying MnO2in zinc-air batteries[J]. Journal of Power Sources, 2000, 91: 83-85.

[67] WEI Z D, HUANG W Z, ZHANG S T,Induced effect of Mn3O4on formation of MnO2crystals favourable to catalysis of oxygen reduction[J]. Journal of Applied Electrochemistry, 2000, 30: 1133-1136.

[68] LI L, FENG X H, NIE Y,Insight into the effect of oxygen vacancy concentration on the catalytic performance of MnO2[J]. ACS Catalysis, 2015, 5: 4825-4832.

[69] CHENG F Y, ZHANG T R, ZHANG Y,Enhancing electrocatalytic oxygen reduction on MnO2with vacancies[J]. Angew. Chem. Int. Ed., 2013, 52: 2474-2477.

[70] WANG J, LIU D F, QI X Q,Insight into the effect of CaMnO3support on the catalytic performance of platinum catalysts[J]. Chemical Engineering Science, 2015, 135: 179-186.

[71] BAI B Y, LI J H, HAO J M. 1D-MnO2, 2D-MnO2and 3D-MnO2for low-temperature oxidation of ethanol[J]. Appl. Catal. B, 2015, 164: 241-250.

[72] LIUY X, DAI H, DENG J G,Controlled generation of uniform spherical LaMnO3, LaCoO3, Mn2O3and Co3O4nanoparticles and their high catalytic performance for carbon monoxide and toluene oxidation[J].Inorganic Chemistry, 2013, 52 (15): 8665-8676.

[73] SUN S M, WANG P Y, WU Q,Template-free synthesis of mesoporous MnO2under ultrasound irradiation for supercapacitor electrode[J]. Mater. Lett., 2014, 137: 206-209.

[74] AN C H, WANG Y J, HUANG Y N,Porous NiCo2O4nanostructures for high performance supercapacitorsa microemulsion technique[J]. Nano Energy, 2014, 10: 125-134.

[75] WANG C H, HSU H C, HU J H. High-energy asymmetric supercapacitor based on petal-shaped MnO2nanosheet and carbon nanotube-embedded polyacrylonitrile-based carbon nanofiber working at 2 V in aqueous neutral electrolyte[J]. J. Power Sources, 2014, 249: 1-8

[76] WANQ Q W, LI Z S, HUANG Y G,A novel hybrid supercapacitor based on spherical activated carbon and spherical MnO2in a non-aqueous electrolyte[J]. J. Mater. Chem., 2010, 20: 3883-3889.

[77] ZHANG C C, GUO C L, WEI Y H,A simple synthesis of hollow Mn2O3core-shell microspheres and its application in lithium ion batteries[J]. Phys. Chem. Chem. Phys., 2016, 18(6): 4739-4744.

[78] ZHAO J Z, TAO Z L, LIANG J,Facile synthesis of nanoporous γ-MnO2structures and their application in rechargeable Li-ion batteries[J]. Cryst. Growth Des., 2008, 8(8): 2799-2805.

[79] ZHONG K, ZHANG B, LUO S,Investigation on porous MnO microsphere anode for lithium ion batteries[J]. J. Power Sources, 2011, 196(16): 6802-6808.

[80] ZHU G, LI H J, DENG L J,Low-temperature synthesis of δ- MnO2with large surface area and its capacitance[J]. Materials Letters, 2010, 64: 1763-1765.

[81] CHEN Z D, GAO L, CAO J Y,Preparation and properties of γ-MnO2nanotubes as electrode materials of supercapacitor[J]. Acta Chimica Sinica., 2011, 69: 503-507.

[82] WANG Y T, LU A H, ZHANG H L,Synthesis of nanostructured mesoporous manganese oxides with three-dimensional frameworks and their application in supercapacitors[J]. J. Phys. Chem. C, 2011, 115(13): 5413-5421.

[83] LI W Y, SHAO J J, LIU Q,Facile synthesis of porous Mn2O3nanocubics for high-rate supercapacitors[J]. Electrochimica Acta, 2015, 157: 108-114.

[84] GHODBANE O, PASCAL J L, FAVIER F. Microstructural effects on charge-storage properties in MnO2-based electrochemical supercapacitors[J]. ACS Appl. Mater. Interfaces, 2009, 1(5): 1130-1139.

[85] HAN R P, LU Z, ZOU W H,Removal of copper (II) and lead (II) from aqueous solution by manganese oxide coated sand (II): Equilibrium study and competitive adsorption[J]. Journal of Hazardous Materials, 2006, B 137 (1): 480-488.

[86] ZHAO W, FENG X H, TAN W F,Relation of lead adsorption on birnessites with different average oxidation states of manganese and release of Mn2+/H+/K+[J]. Journal of Environmental Sciences, 2009, 21(4): 520-526.

[87] WANG S G, GONG W X, LIU X W,Removal of lead (II) from aqueous solution by adsorption onto manganese oxide-coated carbon nanotubes[J]. Separation and Purification Technology, 2007, 58(1): 17-23.

[88] LI X L, PAN G, QIN Y W,EXAFS studies on adsorption- desorption reversibility at manganese oxide-water interfaces(Ⅱ): Reversible adsorption of zinc on δ-MnO2[J]. Journal of Colloid and Interface Science, 2004, 271(1): 35-40.

[89] BARLING J, ANBAR A D. Molybdenum isotope fractionation during adsorption by manganese oxides[J]. Earth and Planetary Science Letters, 2004, 217(3): 315-329.

[90] WANG J, LIU J, ZHOU Y C,One-pot facile synthesis of hierarchical hollow microspheres constructed with MnO2nanotubes and their application in lithium storage and water treatment[J]. RSC Advances, 2013, 3(48): 25937-25943.

[91] 刘德宏, 谢江坤, 晏乃强. 锰氧化物的零价汞吸附性能初探[J]. 电力科技与环保, 2015, 31(3): 004-008. LIU D H, XIE J K, YAN N Q. Discussion on capacities for adsorbing elemental mercury of manganese oxides[J]. Electric Power Environmental Protection, 2015, 31(3): 004-008.

[92] 彭昌军, 姜秀丽, 计红芳,等. 铁锰复合氧化物对3As( Ⅲ)、As(Ⅴ)的吸附性能研究及其在沼液中的应用[J]. 化工学报, 2014, 65(5): 1848-1855. PENG C J, JIANG X L, JI H F,Adsorption behavior of Fe-Mn binary oxide towards As (Ⅲ) and As (Ⅴ) and its application in biogas slurry[J]. CIESC Journal, 2014, 65(5): 1848-1855.

Progress in preparation of MnOand its application

ZHANG Xiaodong, LI Hongxin, HOU Fulin, YANG Yang, DONG Han, CUI Lifeng

(School of Environment and Architecture, University of Shanghai for Science and Technology, Shanghai 200093, China)

It is know that Mn is a common variable valene metal, which plays a good catalytic role in catalytic reaction. Due to the large specific surface area, strong adsorption performance and the excellent catalytic activity, a common transition metal oxide MnOhas become a hot topic in the field of environmental pollution control and energy. In this paper, recent progress in the synthesis method of MnOand its application, such as CO catalytic oxidation, volatile organic pollutants catalytic oxidation, gas adsorption and separation and battery electrode materials, has been summarized.

nanostructure;catalysis; adsorption; manganese oxides; synthesis; application

10.11949/j.issn.0438-1157.20161329

O 614; O 643.3; X 131.1

A

0438—1157(2017)06—2249—09

张晓东(1986—),男,副教授。

国家自然科学基金项目(21507086, 51508327);上海市青年科技英才扬帆计划项目(14YF1409900, 16YF1408100)。

2016-09-21收到初稿,2017-03-05收到修改稿。

2016-09-21.

ZHANG Xiaodong, fatzhxd@126.com

supported by the National Natural Science Foundation of China (21507086, 51508327) and the Shanghai Sailing Program (14YF1409900, 16YF1408100).