预处理对红枣分段间歇微波耦合热风干燥特性及品质的影响

2017-05-16罗东升朱玉丽胡小松吴继红

罗东升,朱玉丽,王 梅,胡小松,吴继红※

(1. 中国农业大学食品科学与营养工程学院,北京 100083;2. 国家果蔬加工工程技术研究中心,北京 100083;3. 农业部果蔬加工重点开放实验室,北京 100083;4. 哈密职业技术学院,哈密 100875)

预处理对红枣分段间歇微波耦合热风干燥特性及品质的影响

罗东升1,2,3,朱玉丽1,2,3,王 梅4,胡小松1,2,3,吴继红1,2,3※

(1. 中国农业大学食品科学与营养工程学院,北京 100083;2. 国家果蔬加工工程技术研究中心,北京 100083;3. 农业部果蔬加工重点开放实验室,北京 100083;4. 哈密职业技术学院,哈密 100875)

为探究分段间歇微波耦合热风干燥红枣最佳工艺,分析不同预处理对红枣品质的影响。该文采用响应面法,优化出最佳干燥工艺为:第一段间歇比为4、水分转换点为1g/g、第二段间歇比为6。此条件下,干燥时间为625.27 min,能耗为5 128 kJ,维生素C质量分数为419 mg/(100g),经验证,模型预测误差小于5%。基于最佳工艺,探究热烫、油酸乙酯结合预冻和高压二氧化碳3种预处理方式对红枣干燥速率、单位耗能及品质的影响。结果显示,油酸乙酯结合预冻处理组干燥时间最短(P<0.05)、能耗最低(P<0.05);高压二氧化碳处理组干燥后维生素C、总酮、总酚质量分数,抗氧化能力均最高(P<0.05);热烫预处理组褐变程度最低(P<0.05),组间色泽无明显差异(P>0.05)。试验证实,高压二氧化碳联合分段间歇微波耦合热风干燥是一种高效干燥技术,能保证红枣的营养品质,研究为该项技术的推广提供基础数据。

干燥;优化;品质控制;红枣;预处理;分段间歇微波耦合热风干燥

罗东升,朱玉丽,王 梅,胡小松,吴继红. 预处理对红枣分段间歇微波耦合热风干燥特性及品质的影响[J]. 农业工程学报,2017,33(7):261-267.doi:10.11975/j.issn.1002-6819.2017.07.034 http://www.tcsae.org

Luo Dongsheng, Zhu Yuli, Wang Mei, Hu Xiaosong, Wu Jihong. Effects of pretreatment on characteristics and qualities of Chinese jujube drying by segmented intermittent microwave coupled with hot air[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(7): 261-267. (in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2017.07.034 http://www.tcsae.org

0 引 言

红枣(Zizyphus jujubaMill.),俗名大枣、干枣等,是鼠李科,枣属的果实,具有极高的营养与医药价值[1]。中国是世界上唯一的红枣出口国,种植面积达100多万hm2,年产量为450万t,占世界总产量的99%,具有极大的商业价值[2]。由于鲜枣含水率高,采收后极易褐变、霉变而丧失食用价值,严重制约红枣产业的发展[3]。因此,提升红枣干燥技术对产业发展起着重要的推动作用。

微波干燥具有高效、卫生等优点,广泛应用于红枣干燥。但常规的连续或间歇微波干燥,会因功率密度过大引起“热点”或焦糊现象。因此,新型联合干燥技术已被开发[4-5],联合干燥过程中热风和低功率微波交替进行,可降低“热点”和焦糊概率,极大地提高干燥品质。但热风干燥效率低,使其推广受到一定限制。该文引入分段间歇微波耦合热风干燥(segmented intermittent microwave coupled with hot air drying ,IM&AD)技术,通过调整不同阶段微波间歇比,控制样品功率密度,避免焦糊。同时,微波场与热风场同时进行,样品在热风辅助下,增强物料内外的传质与传热能力,大幅度提高干燥效率。

另外,红枣表皮特殊的角质、蜡质等结构,阻碍水分蒸发,延长干燥时间,降低干燥品质[6]。干燥预处理可以改变红枣表皮结构,提高干燥效率与品质,常见的预处理技术包括热烫、冷冻、化学浸泡、高压等[7-8]。其中高压二氧化碳是一种兼具杀菌与钝酶特性的新型预处理技术,曾用于改善樱桃番茄的干燥品质[9]。该文将其应用于红枣干燥预处理,解决红枣特殊表皮结构引起的干燥难题。

该研究以分段间歇微波耦合热风干燥技术为主体,探究红枣干燥最佳的工艺条件及不同的预处理方式对干燥能效及红枣品质的影响,为工业上快速、优质干燥红枣提供参考。

1 材料与方法

1.1 原 料

金丝小枣,大小均一,无机械损伤、病虫害的优质全红果,种植于北京市门头沟区。

1.2 试验试剂

甲醇,氢氧化钠,偏磷酸,醋酸钠,没食子酸,氯化铁,福林酚,分析纯,北京化学试剂公司;乙腈,甲醇,色谱纯,美国MREDA公司;1,1-二苯基-2-三硝基苯肼,维生素C,水溶性维生素E(Trolox),标准品(纯度≥99.9%),美国Sigma-Aldrich公司。

1.3 仪器与设备

高压 CO2设备,CAU-HPCD-1(专利号:ZL200520132590.X),中国农业大学自主研发;间歇微波耦合热风干燥设备,最大微波功率700W,最高热风温度 60℃,最高风速 5 m/s,中国农业大学自主研发;CR21GIII型高速冷冻离心机,日本 HITACHI公司;LC-20A型高效液相色谱仪,日本 SHIMADUZU公司;DZF-6050型真空干制箱,法国Veolia Water Technologies公司;CM-3700d型分光测色仪,日本KONICA MINOLTA公司。

1.4 试验方法

1.4.1 分段间歇微波耦合热风干燥工艺优化

取200 g鲜枣(干基含水率为1.75 g/g),分散于微波炉转盘,避免“尖角效应”[10],红枣微波功率密度为2 W/g。当红枣含水率降至0.2 g/g时,停止干燥。含水率W(g/g)计算公式如下[11]

式中M鲜枣表示鲜枣质量,g;M干基表示干基质量,g。

参照 Fang等[12]方法,微波功率 60 W,热风温度45 ℃,风速2 m/s,以间歇比1、水分转换点(以含水率表示)及间歇比 2为影响因素,以干燥时间、能耗、维生素C质量分数为响应值设计优化试验。根据预试验结果,设计试验因素水平编码见表1。根据Estürk等[13]的报道,间歇比表达式:(ton+toff)/ton,ton为微波开启时间,s,toff为微波停止时间,s。

表1 响应面试验因素与水平Table1 Factors and levels of response surface

1.4.2 干燥预处理方法

高压二氧化碳处理(high pressure carbon dioxide,HPCD)参照郭蕴涵等[14]条件适当调整:将200 g鲜枣置于20 ℃、5 MPa的高压CO2反应釜中,保压20 min,卸压后,取出待用。

热烫处理参照Ade-Omowaye等[15]条件适当调整:取200 g鲜枣,在沸水中浸烫90 s,取出沥干,放至25 ℃,待用。

油酸乙酯结合预冻处理(alkaline ethyl oleate,AEEO+预冻)参照Zhu等[16]条件适当调整:取200 g鲜枣,在35℃的油酸乙酯中浸泡10 min。清洗表面油酯,在−18 ℃下冻藏12 h。25 ℃解冻,待用。

1.4.3 干燥特性测定

以红枣干燥速率变化反映干燥特性内容,包括不同预处理方式对干燥速率的影响及物料含水率对干燥速率的影响。干燥速率v(g/(g·s))的计算公式如下

式中t1,t2分别表示干燥的某个时刻,s;Q1与Q2分别表示t1与t2时刻的红枣干基含水率,g/g。

1.4.4 干燥能耗测定

总能耗表示200 g鲜枣干燥至含水率为0.2 g/g时消耗的电能,单位为kJ。

单位能耗表示蒸发单位质量水分所耗的电能[17],计算公式

式中N为单位能耗,kJ/g;E为总能耗,kJ;G为干燥过程中去除水分的质量,g。

1.4.5 干燥品质测定

褐变度:将枣样(干枣3 g,鲜枣5 g)与体积分数95%的乙醇混合匀浆,定容至50 mL。取10 mL离心后上清液与10 mL 95 %的乙醇混合,以420 nm处吸光值表示褐变度[18]。

颜色变化:将枣样(干枣9 g,鲜枣15 g)与蒸馏水冰浴下混合匀浆,定容至30 mL。参照Zhao等[19]方法分别测定浆液的L*(亮度),a*(红绿色度),b*(黄蓝色度)及总色差ΔE*值。

维生素C质量分数:将枣样(干枣3 g,鲜枣5 g)与质量分数 2.5%的偏磷酸冰浴下混合匀浆,定容至50 mL。参照Liu等[20]方法测定离心后上清液中维生素C质量分数,以 mg/(100g)计,维生素 C标准曲线为y=34 137x−101 345,R2=0.998 6。

总酮和总酚质量分数:将枣样(干枣3 g,鲜枣5 g)与体积分数80%的甲醇混合匀浆,定容至25 mL。在20 ℃下超声30 min,冷冻离心,取上清液。采用Folin-Ciocalteu比色法测定总酚质量分数[21],结果以没食子酸当量表示mg/g,其中没食子酸标准曲线为y=2.134x+0.0401,R2=0.997 8;采用NaNO2-Al(NO3)3-NaOH法测定总酮质量分数[22],结果以芦丁当量表示mg/g,其中芦丁标准曲线为y=0.004 3x−0.054 7,R2=0.993 8。

抗氧化能力:样液制备同总酮测定,采用铁氰化钾法(ferricyanide reducing power,FRAP)与自由基清除法(2,2-diphenyl-1-picrylhydrazyl,DPPH)表征红枣抗氧化能力[23];FRAP测定结果以维生素C质量分数表示mg/g,其中维生素C标准曲线为y=0.005 7x+0.032 3,R2=0.995 1;DPPH测定结果以Trolox质量分数表示mg/g,其中Trolox标准曲线为y=0.006 9x+0.023,R2=0.9963。

1.5 数据统计分析

以上试验均重复3次。响应面分析采用Design expert v8.0.6软件;差异性分析采用 SPSS v17.0软件,其中P>0.05时,表示差异不显著;P<0.05时,表示差异显著;采用Origin v8.5软件进行数据处理和绘图。

2 结果与分析

2.1 响应面优化结果与分析

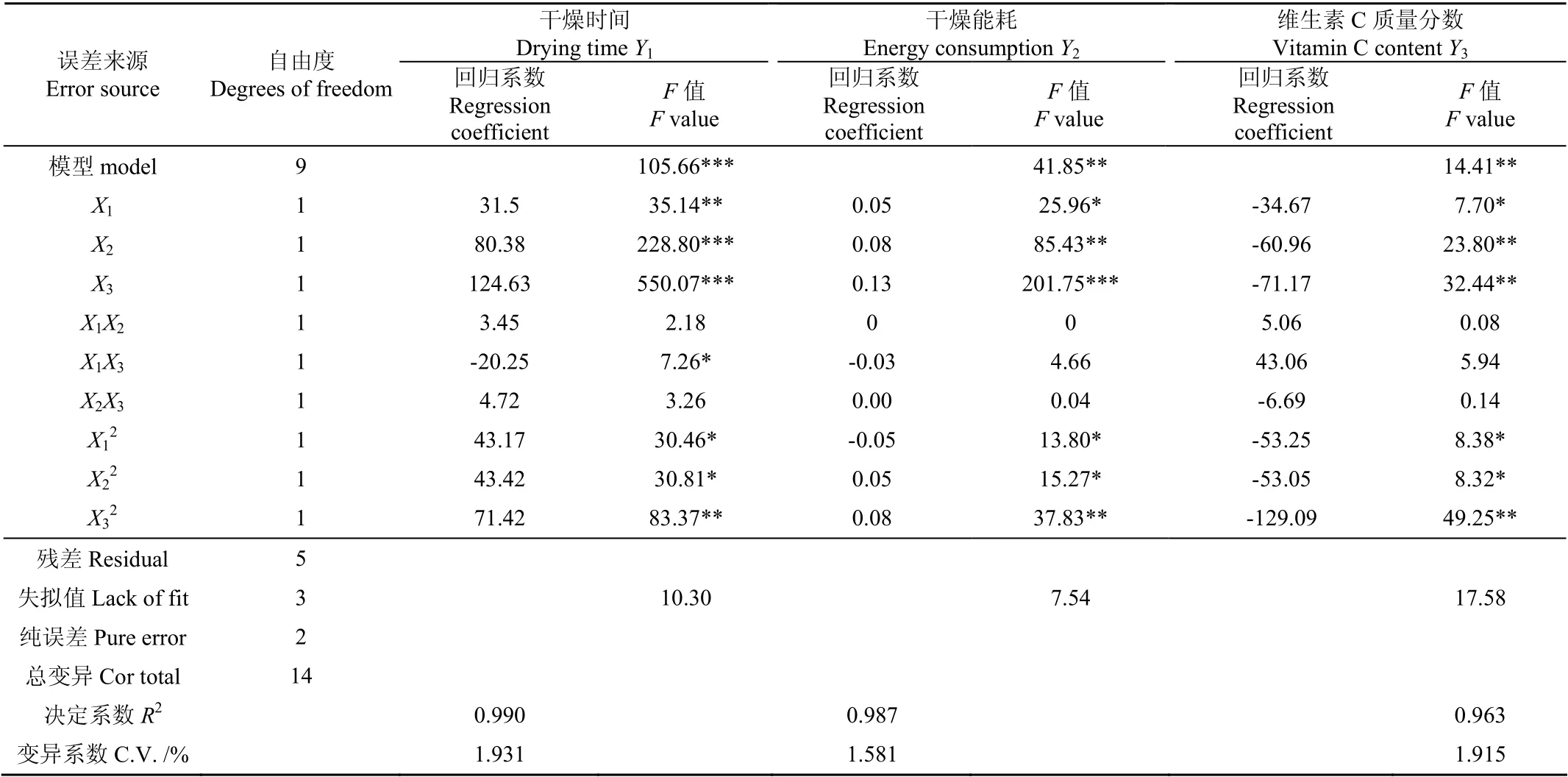

根据响应面软件中Box-Benhnken模型的中心组合原理设计试验,并对试验结果进行方差分析,结果如表2。

利用Design Expert 软件对数据进行多元回归拟合,去除非显著项,获得响应值干燥时间(Y1,min),干燥能耗(Y2,kJ)及维生素C质量分数(Y3,mg/(100 g))与影响因子间歇比1(X1),水分转换点(X2,g/g)及间歇比2(X3)间的简化二次多项式回归模型如下

表2 回归模型方差分析Table2 Variance analysis for the regression model

由表2方差分析可知,回归模型(4),(5)和(6)均显著(P<0.01),失拟项均不显著(P>0.05),决定系数均大于 0.96,表明模型可靠,误差小,实测值和预测值高度相关,3个模型能够准确地预测结果变化。由表2显著性分析可知,3个模型中一次项均显著(P<0.05),表明间歇比1(X1),水分转换点(X2),间歇比2(X3)对干燥时间(Y1),干燥能耗(Y2)及维生素C质量分数(Y3)影响显著,其影响强度顺序为X3>X2>X1。为保证Y1和Y2最小,同时Y3最大, 3个指标的权重认为同等重要,经响应面软件优化后,得出最佳工艺组合条件:X1为 4 (5 s/15 s),X2为1g/g,X3为6(5 s/25 s),此时Y1为623 min,Y2为5 148 kJ,Y3为425 mg/(100g)。经试验验证,所得Y1为 625.27 min,Y2为 5 128 kJ,Y3为419 mg/(100 g),与预测值误差均小于5%,说明响应面优化最佳工艺参数可靠,能够应用到预处理试验。

2.2 预处理方式对干燥特性的影响

由图1a可知,在干燥100 min内,无处理组和预处理组间的干燥速率差异不显著(P>0.05)。因为干燥初期,红枣内水分充足,利于吸收微波能促进蒸发,同时剧烈蒸发导致红枣内外形成的巨大压差与温差,也有助于水分散失。此时,表皮结构对水分散失的阻碍作用较小,各组干燥速率相近。在干燥100 min后,随着红枣内水分减少及间歇比增大,能效转化及供给效率降低,水分蒸发动力减小,红枣表皮结构阻碍能力相对增强,组间干燥速率差异显著(P<0.05)。预处理组的干燥速率均大于无处理组,且组间差异明显,表明预处理技术,能够改变红枣表皮特殊结构,提高干燥速率,但由于作用机理不同[24-27],对干燥后期速率的影响程度不同。图1b显示,干燥速率先上升后下降,中间接近恒速。干燥速率上升是因为样品内水分和热量在间歇期重新分配,有利于提升干燥速率[28]。恒速阶段是由于红枣内部水分充足,能够快速平衡红枣表面蒸发水分[29]。当红枣含水率降至1.0 g/g时,干燥速率下降,原因包括两方面:微波间歇比增大与含水率降低,水分蒸发所需能量减少;组织内多糖、蛋白质等含亲水性大分子物质以及细胞失水形成巨大的渗透压阻碍水分向表皮扩散[21]。

2.3 预处理方式对干燥能耗的影响

由图2可知,在含水率>1 g/g时,红枣单位能耗非常接近(P>0.05)。因为干燥初期各组红枣含水率均很高,能耗主要用于水分蒸发,此时组间差异并不显著(P>0.05)。在干燥后期,单位能耗迅速上升,组间差异逐渐明显。能耗上升的原因与上述干燥速率下降原因相似,主要由于能效转化与供给效率降低及亲水性大分子组分与细胞高渗透压的综合作用[21]。预处理组能耗均低于无处理组,以AEEO+预冻组单位能耗最低(P<0.05)。因为预处理能够破坏红枣表皮特殊结构,增强细胞通透性,减小传质阻力,利于水分扩散,同时AEEO+预冻处理可能对红枣表皮结构破坏最严重,这与干燥速率变化趋势相符。

图1 预处理方式对红枣含水率和干燥速率的影响Fig.1 Effect of different pretreatments on moisture content and drying rate of Chinese jujube

图2 红枣干燥单位能耗的变化Fig.2 Drying unit energy consumption of Chinese jujube

2.4 预处理方式对红枣品质的影响

2.4.1 预处理方式对褐变度的影响

红枣富含多酚、多糖、氨基酸、维生素C等成分,在酶与高温的作用下,易发生酶促及非酶褐变[30]。由表3可知,鲜枣出现褐变,表明发生了酶促褐变。干燥组褐变度显著高于鲜枣(P<0.05),表明除了酶促褐变,在干燥过程中仍会发生非酶褐变。预处理组褐变度均低于无处理组,且组间差异显著(P<0.05),因为预处理可以提高干燥速率,减少红枣热加工时间,降低酶促褐变程度,但不同预处理对红枣干燥速率提升能力不同,各组间褐变差异明显,表明褐变与干燥时间密切相关。热烫组干燥时间较HPCD和AEEO+预冻组长,褐变度却最低,可能由于热烫抑制了酶促褐变,而高压和冷冻破坏膜结构,引起酶与底物接触,加快酶促褐变[31]。

2.4.2 预处理方式对颜色的影响

由表3可知,干燥组亮度(L*值)低于鲜样组,预处理组亮度显著高于无处理组(P<0.05)。这表明干燥中的褐变反应能使红枣色泽变暗,且干燥时间越长色泽越暗。预处理组间亮度差异并不明显(P>0.05),表明亮度变化与上述褐变度相比,与干燥时间的关联性较低。干燥后,红色强度(a*值)显著高于鲜样(P<0.05),并且干燥组间差异明显(P<0.05)。这可能由于干燥过程中,黄酮类红色素发生热氧化,形成红色强度更高的聚合物[32],且氧化程度与干燥时间密切相关。干燥后红枣色泽(∆E值)均发生变化[33],预处理组与无处理组间差异明显(P<0.05),但预处理组间变化不明显(P>0.05),表明干燥时间,氧化及褐变反应对红枣色泽有一定的影响,但程度并不强烈。

2.4.3 预处理方式对维生素C质量分数的影响

由表3可知,与鲜枣相比,干燥处理后维生素C质量分数下降超过80%。其中,HPCD组维生素C质量分数最高,AEEO+预冻组最低。因为HPCD处理会使二氧化碳进入细胞,酸化细胞环境,增强维生素C的稳定性,减少氧化损失[34]。AEEO+预冻处理中碱性油脂和冻融都会破坏细胞壁膜结构,导致维生素C大量流失[35]。尽管热烫处理会导致部分细胞膜破坏,但与直接干燥及HPCD处理组相比,维生素C质量分数并无显著性差异(P>0.05)。这表明,它们维生素C质量分数下降的主要因素是氧化降解,流失较少。根据维生素C的流失程度,可以推测,在不同的预处理方式中,AEEO+预冻法对细胞结构破坏最严重,这与干燥动力学和能耗方面研究相呼应。

2.4.4 预处理方式对总酮和总酚质量分数的影响

根据表 3显示,干燥后,红枣中总酮和总酚的质量分数大幅下降。其中HPCD组内的总酮和总酚质量分数最高(P<0.05),因为热烫、油酸乙酯与冷冻在预处理过程中会破坏红枣膜结构,导致酮类和酚类氧化降解、或流失[36-37],而HPCD处理可以降低细胞内pH值,提高酮类和酚类热稳定性[38-39]。热烫及AEEO+预冻组和无处理相比,尽管有部分内容物流失,但酮类质量分数仍较高,酚类质量分数差异不明显(P>0.05)。这表明,热烫流失的酮类和酚类比氧化或高温降解量低很多,并且酚类在干燥完成前已经降到最低值。

2.4.5 预处理方式对抗氧化性的影响

如表3所示,红枣干燥处理后,HPCD组抗氧化能力最高,无处理组最低。这与干燥后各组中总酮、总酚质量分数的趋势非常接近,尤其是总酚质量分数。表明红枣的抗氧化能力与总酮,特别是总酚质量分数密切相关。另外红枣中含有丰富的维生素C、维生素E及色素等抗氧化成分[40],会在酮、酚的基础上增强红枣的抗氧化能力。经干燥处理后红枣的抗氧化能力(FRAP与DPPH自由基清除力)均下降,可能由于干燥过程中上述抗氧化成分的氧化、热降解及流失造成。

表3 不同预处理方式对红枣品质的影响Table3 Effects of different pretreatments on quality of Chinese jujube

3 结 论

经响应面优化出分段间歇微波耦合热风干燥最佳工艺条件为:间歇比1为4(5 s/15 s)、水分转换点为1 g/g、第二段间歇比为 6(5 s/25 s),此时干燥时间最短为625.27 min,能耗最低为5 128 kJ,维生素C保留最多为419 mg/(100 g),经验证,模型预测误差在<5%,结果非常可靠。

采用热烫、高压二氧化碳(HPCD)及油酸乙酯(AEEO)+冷冻的预处理方式联合最佳干燥工艺,比较不同预处理方式对红枣干燥速率、干燥能耗以及品质的影响。研究发现,AEEO+预冻处理后样品的干燥速率最高(P<0.05)、能耗最低(P<0.05),但由于内容物(维生素C与酚类、酮类)流失及氧化,干燥后红枣品质较差;HPCD处理能稳定红枣内维生素C、酚类及酮类等成分,因此相对其他预处理组,该组内营养成分保留较多并且抗氧化性较强(P<0.05),品质较高(P<0.05)。热烫处理后红枣干燥速率及能耗较高(P<0.05),且干燥后红枣品质较差(P<0.05),但热烫处理可以减轻干燥后红枣褐变程度。综上,尽管AEEO+预冻处理后红枣干燥速率高,干燥能耗低,但是AEEO+预冻处理样品时间较长。综合考虑干燥过程与预处理过程,HPCD可作为一种高品质红枣干燥预处理技术。

[1] Fang S Z, Wang Z F, Hu X S, et al. Hot-air drying of whole fruit Chinese jujube (Zizyphus jujubeMiller): physicochemical properties of dried products[J]. Food Science and Technology, 2009, 44(9): 1415-1421.

[2] 闫忠心,鲁周民,刘坤,等. 干制条件对红枣香气品质的影响[J]. 农业工程学报,2011,27(1):389-392. Yan Zhongxin, Lu Zhoumin, Liu Kun, et al. Effects of drying conditions on Chinese jujube aroma components[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(1): 389-392. (in Chinese with English abstract)

[3] 于静静,毕金峰,丁媛媛. 不同干燥方式对红枣品质特性的影响[J]. 现代食品科技,2011,27(6):610-614. Yu Jingjing, Bi Jinfeng, Ding Yuanyuan. Effect of drying treatment methods on the quality properties of Red Jujube[J]. Modern Food Science and Technology, 2011, 27(6): 610-614. (in Chinese with English abstract)

[4] Zielinska M, Sadowskia P, Błaszczak W. Combined hot air convective drying and microwave-vacuum drying of blueberries (Vaccinium corymbosumL.): Drying kinetics and quality characteristics[J]. Drying Technology, 2016, 34(16): 665-684.

[5] 刘小丹,张淑娟,贺虎兰,等. 红枣微波-热风联合干燥特性及对其品质的影响[J]. 农业工程学报,2012,28(24):280-286. Liu Xiaodan, Zhang Shujuan, He Hulan, et al. Drying characteristics and its effects on quality of jujube treated by combined microwave-hot-air drying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(24): 280-286. (in Chinese with English abstract)

[6] 刘聪,海妮,张英. 红枣不同部位中有效成分含量的比较研究[J]. 现代食品科技,2014,30(3):258-261. Liu Cong, Hai Ni, Zhang Ying. The content variation of phytochemicals in different parts of Chinese jujube from different cultivars[J]. Modern Food Science and Technology, 2014, 30(3): 258-261. (in Chinese with English abstract)

[7] 于静静,马涛,毕金峰,等. 冬枣变温压差膨化干燥预处理研究[J]. 食品与机械,2010,26(5):144-147. Yu Jingjing, Mao Tao, Bi Jinfeng, et al. Explosion puffing drying pretreatment on jujube at variable temperature and pressure[J]. Food and Machinery, 2010, 26(5): 144-147. (in Chinese with English abstract)

[8] Anetr J, Timothyj M, Larysap B, et al. Accelerated drying of button mushrooms, Brussels sproutsand cauliflower by applying power ultrasound and its rehydration properties[J]. Journal of Food Engineering, 2007, 81(3): 88-97.

[9] 龙婉蓉,郭蕴涵,赵翠萍,等. 高密度CO2预处理对樱桃番茄干燥的影响[J]. 食品工业科技,2012,33(4):387-390. Long Wanrong, Guo Yunhan, Zhao Cuiping, et al. Effect of dense phase carbon dioxide pretreatment on drying cherry tomato[J]. Science and Technology of Food Industry, 2012, 33(4): 387-390. (in Chinese with English abstract)

[10] Clark D E, Sutton W H. Microwave processing of materials[J]. Annual Review of Materials Science, 1996, 26(1): 299-331.

[11] GB 5009.3-2010. 食品中水分的测定[S].

[12] Fang S Z, Wang Z F, Hu X S, et al. Energy requirement and quality aspects of Chinese jujube (Zizyphus jujubaMiller) in hot air drying followed by microwave drying[J]. Journal of Food Process Engineering, 2011, 34(2): 491-510.

[13] Estürk O, Soysal Y. Drying properties and quality parameters of dill dried with intermittent and continuous microwaveconvective air treatments[J]. Journal of Agricultural Sciences, 2010, 16(1): 26-36.

[14] 郭蕴涵,汪政富,赵翠萍,等. 高压二氧化碳浸渍速冻胡萝卜片工艺及产品品质的研究[J]. 食品工业科技,2012,33(16):240-245. Guo Yunhan, Wang Zhengfu, Zhao Cuiping, et al. Study on high pressure carbonic maceration(HPCM) freezing process and quality of carrot slices[J]. Science and Technology of Food Industry, 2012, 33(16): 240-245. (in Chinese with English abstract)

[15] Ade-Omowaye B I O, Rastogi N K, Angersbach A, et al. Effects of high hydrostatic pressure or high intensity electrical field pulse pre-treatment on dehydration characteristics of red paprika[J]. Innovative Food Science & Emerging Technologies, 2001, 2(1): 1-7.

[16] Zhu B M, Wen X S, Wei G D. Effect of pre-treatments on drying characteristics of Chinese jujube (Zizyphus jujubaMiller)[J]. International Journal of Agricultural and Biological Engineering, 2014, 7(1): 94-102.

[17] 陈健凯,林河通,林艺芬,等. 基于品质和能耗的杏鲍菇微波真空干燥工艺参数优化[J]. 农业工程学报,2014,30(3):277-284. Chen Jiankai, Lin Hetong, Lin Yifen, et al. Optimized technology ofPleurotus eryngiiby microwave-vacuum drying based on quality and energy consumption[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(3): 277-284. (in Chinese with English abstract)

[18] Roig M G, Bello J F, Rivera Z S, et al. Studies on the occurrence of non-enzymatic browning during storage of citrus juice[J]. Food Research International, 1999, 32(9): 609-619.

[19] Zhao D, An K, Ding S, et al. Two-stage intermittent microwave coupled with hot-air drying of carrot slices: Drying kinetics and physical quality[J]. Food and Bioprocess Technology, 2014, 7(8): 2308-2318.

[20] Liu H, Cao J, Jiang W. Evaluation and comparison of vitamin C, phenolic compounds, antioxidant properties and metal chelating activity of pulp and peel from selected peach cultivars[J]. Lebensmittel-Wissenschaft und Technologie -Food Science and Technology, 2015, 63(2): 1042-1048.

[21] Sarsavadia P N. Development of a solar-assisted dryer and evaluation of energy requirement for the drying of onion[J]. Renewable Energy, 2007, 32(15): 2529-2547.

[22] Kou X, Chen Q, Li X, et al. Quantitative assessment of bioactive compounds and the antioxidant activity of 15 jujube cultivars[J]. Food Chemistry, 2015, 173: 1037-1044.

[23] Zhang H, Jiang L, Ye S, et al. Systematic evaluation of antioxidant capacities of the ethanolic extract of different tissues of jujube (Ziziphus jujubaMill.) from China[J]. Food and Chemical Toxicology, 2010, 48(6): 1461-1465.

[24] Doymaz I, Ismail O. Drying characteristics of sweet cherry[J]. Food and Bioproducts Processing, 2011, 89(1): 31-38.

[25] Arévalo-Pinedo A, Murr F E X. Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin[J]. Journal of Food Engineering, 2007, 80(1): 152-156.

[26] Doymaz I. Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples[J]. Food and Bioproducts Processing, 2010, 88(2): 124-132.

[27] Damar S, Balaban M O. Review of dense phase CO2technology: microbial and enzyme inactivation, and effects on food quality[J]. Journal of Food Science, 2006, 71(1): R1-R11.

[28] Kumar C, Karim M A, Joardder M U H. Intermittent drying of food products: A critical review[J]. Journal of Food Engineering, 2014, 121: 48-57.

[29] Arévalo-Pinedo A, Murr F E X. Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin[J]. Journal of Food Engineering, 2007, 80(1): 152-156.

[30] López J, Uribe E, Vega-Gálvez A, et al. Effect of air temperature on drying kinetics, vitamin C, antioxidant activity, total phenolic content, non-enzymatic browning and firmness of blueberries variety O Neil[J]. Food and Bioprocess Technology, 2010, 3(5): 772-777.

[31] Butz P, Koller W, Tauscher B, et al. Ultra-high pressure processing of onions: Chemical and sensory changes[J]. LWT-Food Science and Technology, 1994, 27(5): 463-467.

[32] 吴宇宽,刘章武. 红枣红色素提取方法的优化研究[J]. 现代食品科技,2008,24(3):265-267. Wu Yukuan, Liu Zhangwu. Optimization of red pigment extraction from jujube[J]. Modern Food Science and Technology, 2008, 24(3): 265-267. (in Chinese with English abstract)

[33] Krapfenbauer G, Kinner M, Gössinger M, et al. Effect of thermal treatment on the quality of cloudy apple juice[J]. Journal of Agricultural and Food Chemistry, 2006, 54(15): 5453-5460.

[34] Verbeyst L, Bogaerts R, Van der Plancken I, et al. Modelling of vitamin C degradation during thermal and high-pressure treatments of red fruit[J]. Food and Bioprocess Technology, 2013, 6(4): 1015-1023.

[35] Ade-Omowaye B I O, Taiwo K A, Eshtiaghi N M, et al. Comparative evaluation of the effects of pulsed electric field and freezing on cell membrane permeabilisation and mass transfer during dehydration of red bell peppers[J]. Innovative Food Science & Emerging Technologies, 2003, 4(2): 177-188.

[36] Ungar Y, Osundahunsi O F, Shimoni E. Thermal stability of genistein and daidzein and its effect on their antioxidant activity[J]. Journal of Agricultural and Food Chemistry, 2003, 51(15): 4394-4399.

[37] Meng J F, Fang Y L, Qin M Y, et al. Varietal differences among the phenolic profiles and antioxidant properties offour cultivars of spine grape (Vitis davidiiFoex) in Chongyi County (China)[J]. Food Chemistry, 2012, 134(4): 2049-2056.

[38] Liu Y, Chen H B, Zhao Y Y, et al. Quantification and stability studies on the flavonoids of Radix Hedysari[J].Journal of Agricultural and Food Chemistry, 2006, 54(18): 6634-6639.

[39] Chen J, Sun H, Wang Y, et al. Stability of apple polyphenols as a function of temperature and pH[J]. International Journal of Food Properties, 2014, 17(8): 1742-1749.

[40] Kamiloglu Ö, Ercisli S, Sengül M, et al. Total phenolics and antioxidant activity of jujube (Zizyphus jujubeMill.) genotypes selected from Turkey[J]. African Journal of Biotechnology, 2009, 8(2): 303-307.

Effects of pretreatment on characteristics and qualities of Chinese jujube drying by segmented intermittent microwave coupled with hot air

Luo Dongsheng1,2,3, Zhu Yuli1,2,3, Wang Mei4, Hu Xiaosong1,2,3, Wu Jihong1,2,3※

(1.College of Food Science & Nutritional Engineering, China Agricultural University,Beijing100083,China; 2.National Engineering & Technology Research Centre for Fruits & Vegetable Processing,Beijing100083,China; 3.Key Laboratory of Fruits and Vegetables Processing, Ministry of Agriculture,Beijing100083,China; 4.Hami Vocational and Technical College,Hami100875,China)

This research was aimed to explore the optimal drying process of Chinese jujube by segmented intermittent microwave coupled with hot air drying (IM&AD) and to study the influence of different drying pretreatment technologies on drying rate, unit energy consumption and quality of jujube. The drying pretreatment technologies included dipping in alkaline emulsion ethyl oleate solution followed by slow freezing at -18 ℃ (AEEO + freeing), high pressure carbon dioxide (HPCD), and hot water blanching (HWB). Firstly, to obtain the best drying process, intermittent ratio in the first drying stage (IR1), transition point in moisture content between the 2 stages of drying (TPMC), and intermittent ratio in the second drying stage (IR2) were set as the independent variables, and the drying time, unit energy consumption and vitamin C content after drying were set as the dependent variables. According to central composite design of the response surface technology, the obtained optimal process parameters were IR1 of 4 (the ratio of runtime to stand-by time of microwave oven was 5 s : 15 s), TPMC of 1, and IR2 of 6 (5 s : 25 s). On this condition, the drying time was the shortest (625.27 min), the unit energy consumption was the minimum (5 128 kJ) and the vitamin C content after drying was the maximum (419 mg/(100 g)). Then, to know the effect of drying pretreatment technologies on quality, Chinese jujube samples were dried respectively by 3 pretreatment technologies combined with the best drying process. The results implied that the special epidermis structure of Chinese jujube may be damaged during drying pretreatments, and especially the method of AEEO + freeing led to the moisture in Chinese jujube much more easily diffused and evaporated. So the drying rate was obviously improved and the energy consumption was reduced. Correspondingly, with regard to drying rate, the AEEO + freeing groups were the maximum, followed by the HPCD groups and the HWB groups, and the control groups were the minimum. The unit energy consumption was different: The AEEO + freeing groups were the minimum and the HWB groups were the maximum. There were rich amino acids, saccharides, vitamin C and polyphenols in Chinese jujube. So the browning occurred easily during pretreatment and drying process including enzymatic browning and non-enzymatic browning. The results showed that the HWB groups could inhibit enzyme activity and reduce the enzymatic browning degree, while the AEEO + freeing and HPCD groups would enhance enzymatic browning degree by breaking the cell membrane. So the browning degree of HWB groups was the minimum (P<0.05). In addition, a closely positive correlation was observed between the browning and drying time. The brightness of Chinese jujube changed obviously after drying process compared with the control group, but there were no significant differences between the 3 pretreatment groups (P>0.05). The red was the characteristic color of Chinese jujube, and it became darker with drying time continuing due to oxidation reaction. The HPCD pretreatment resulted in the highest vitamin C content, total flavonoids and phenolics retention, and oxidation resistance value. It was mainly due to the acidic condition provided by carbon dioxide in HPCD, which could make vitamin C, flavonoids and phenolics more stable than others. Meanwhile, these components had a potent antioxidant activity, so the HPCD groups had a stronger antioxidant ability. The results show that the IM&AD combined with the HPCD is advanced technology to dry Chinese jujube, and the data in this study can promote this technology to be applied widely.

drying, optimization; quality control; Chinese jujube; pretreatment; segmented intermittent microwave coupled with hot air drying

10.11975/j.issn.1002-6819.2017.07.034

TS255.36

A

1002-6819(2017)-07-0261-07

2016-08-30

2017-03-27

国家科技支撑计划课题(2012BAD36B07)

罗东升,博士生,主要从事果蔬加工、食品风味化学方面研究。北京 中国农业大学食品科学与营养工程学院,100083。

Email:ldsxnsp@163.com

※通信作者:吴继红,教授,博士,博士生导师,主要从事食品非热加工,食品风味化学、食品质量控制方面研究。北京 中国农业大学食品科学与营养工程学院,100083。

Email:wjhcau@hotmail.com