人工林杨木增强-染色复合改性材的性能*

2017-03-08许茂松吕文华王雪玉

许茂松 吕文华 王雪玉

(中国林业科学研究院木材工业研究所 北京 100091)

人工林杨木增强-染色复合改性材的性能*

许茂松 吕文华 王雪玉

(中国林业科学研究院木材工业研究所 北京 100091)

【目的】 探讨人工林杨木增强-染色复合改性方法及改性材性能,为人工林杨木资源的高效开发利用提供技术支持。【方法】 将相同质量分数的酸性大红G水溶液、酸性湖蓝A水溶液、酸性大红G和酸性湖蓝A与水溶性树脂型增强改性剂MUF复配得到的增强-染色复合改性剂,分别对人工林杨木进行真空加压浸渍处理,得到DG、DA、MUF-DG和MUF-DA4种染色改性材,测试其强度、颜色、耐水色牢度等性能。【结果】 1) DA和DG染色材的质量增加率分别为-1.69%和-0.65%,密度分别为0.352和0.365 g·cm-3; MUF-DA和MUF-DG增强-染色复合改性材的质量增加率分别为42.64%和54.27%,密度分别为0.445和0.510 g·cm-3。与DA染色材相比,MUF-DA增强-染色复合改性材的密度、抗弯弹性模量、抗弯强度和抗压强度分别提高26.42%,6.76%,17.63%和54.32%; 与DG染色材相比,MUF-DG增强-染色复合改性材的密度、抗弯弹性模量、抗弯强度和抗压强度分别提高39.73%,8.58%,18.82%和57.18%。2) DA染色材和MUF-DA增强-染色复合改性材染色前后的明度指数差(ΔL*)、红绿指数差(Δa*)和黄蓝指数差(Δb*)均为负值,MUF-DA增强-染色复合改性材的Δa*值更小、ΔL*和Δb*值均更大,蓝色调更明显; DG染色材和MUF-DG增强-染色复合改性材染色前后的Δa*为正值、ΔL*和Δb*为负值,MUF-DG增强-染色复合改性材的Δa*、ΔL*和Δb*值均更大,红色调更明显; MUF-DA和MUF-DG增强-染色复合改性材的色饱和度差(ΔC*)均显著大于相应的DA和DG染色材。3) DA和DG染色材水浸前后的总色差ΔE*分别为12.92和8.30 NBS,MUF-DA和MUF-DG增强-染色复合改性材水浸前后的总色差ΔE*分别为5.94和6.93 NBS,增强-染色复合改性材水浸前后颜色溶蚀程度较小。4) DA和DG染色材与未处理材的红外光谱图形态基本一致,MUF-DA和MUF-DG增强-染色复合改性材与MUF增强改性材的红外光谱图形态基本一致,没有新的吸收峰产生,吸收峰强度也无明显变化。【结论】 1) 染料的加入对树脂的增强改性作用影响较小,经增强-染色复合改性处理后人工林杨木的力学性能明显提高; 2) 与纯染色材相比,增强-染色复合改性材的颜色更鲜明饱满,染色效果更好,且酸性大红G与树脂复配染色效果优于酸性湖蓝A; 3) 与纯染色材相比,增强-染色复合改性材耐水色牢度较好,其中酸性湖蓝A与树脂复配改性材的耐水色牢度提高明显; 4) 傅里叶红外光谱(FTIR)分析表明,染料与MUF复配染色过程中没有新的基团生成,随树脂固化沉积于木材内部的染料与MUF和木材之间没有产生新的化学结合。

人工林杨木; 增强-染色复合改性剂; 浸渍处理; 性能; 红外分析

随着天然林资源锐减以及木材资源消耗增加,木材的供需矛盾日益尖锐。为缓解这一矛盾,必须大力发展并高效利用人工林木材资源。我国人工林面积居世界首位,其中杨树约占人工林总面积的20%,为我国重要的工业用材(吕建雄等, 2014)。然而,由于人工林杨木存在密度小、强度低、尺寸不稳定、材色单调、花纹不清晰、装饰性差等缺点,大大限制了其应用(杨晓飞等, 2014)。因此,为了充分利用好我国丰富的人工林杨木资源,实现其高附加值利用,有必要研发出一种可使人工林杨木各项性能得到全面改善的木材改性技术。

研究表明,树脂浸渍改性可有效提高木材的尺寸稳定性、力学强度、抗生物劣化等性能(Dekaetal., 2002; Furunoetal., 2004; Wanetal., 2006),但在实际应用过程中存在渗透性差、游离甲醛超标、储存期短、不能重复利用以及成本高等问题(黄艳辉等, 2011)。常用水溶性染料在木质材料内部的渗透和固着过程相互矛盾,渗透性好的染料与处理材的结合力小,抗流失性差,耐光、耐候性不好,染色过程产生大量废水,带来环境危害,同时单纯染色难以满足产品多性能要求(刘毅等, 2011; 吕晓慧等, 2012)。本研究将木材的功能性改良与染色处理相结合,采用自制低甲醛水溶性树脂型增强改性剂MUF与水溶性酸性染料复配制得增强-染色复合改性剂,对人工林杨木进行真空加压浸渍处理,拟使改性后的杨木密度增大、强度提高、染着性和耐水性得到明显改善,在增强其物理力学性能的同时,赋予其良好的装饰性,大大提高其产品价值。

1 材料与方法

1.1 试验材料

试材: 大青杨(Populusussuriensis),试材尺寸: 300 mm(L)×20 mm(R)×20 mm(T)。染料: 酸性大红G(C.I. Acid Red 1,分子质量509.42)和酸性湖蓝A(C.I. Acid Blue 7,分子质量690.80),购自北京广春染料厂。树脂型增强改性剂: 自制,三聚氰胺、甲醇、甲醛、尿素的摩尔比为1∶2.3∶2.3∶1.2,无色透明,黏度10 mPa·s(23 ℃),固体含量58.6%,pH 7.5~8,水溶解倍数≥7。

1.2 浸渍处理

将酸性大红G和酸性湖蓝A分别配制成质量分数为0.5%的染料水溶液DG和DA; 将增强改性树脂稀释成质量分数为20%的树脂溶液,得到树脂型增强改性剂MUF; 在20%树脂溶液中分别加入质量分数为0.5%的酸性大红G和酸性湖蓝A,制得增强-染色复合改性剂MUF-DG和MUF-DA。采用真空(-0.1 MPa,40 min)→吸药→卸真空→加压(1.0 MPa,2 h)→卸压工艺,分别对人工林杨木进行真空加压浸渍处理,得到DG、DA、MUF、MUF-DG和MUF-DA改性材,将各处理材先气干至50%含水率,再采用梯度升温的较软基准进行人工干燥,调整至10%含水率,备用。

1.3 性能测试与分析

1.3.3 耐水色牢度测试 将各改性材绝干测色,再分别浸入等量蒸馏水中浸泡6 h后绝干测色,通过染色材水浸前后的颜色差异考察其颜色溶蚀程度。

1.3.4 FTIR分析 傅里叶红外光谱仪,溴化钾(KBr)压片法,扫描次数32次,分辨率4 cm-1,扫描范围4 000~400 cm-1,比较分析未处理材、增强改性材和增强-染色复合改性材谱图变化。

2 结果与分析

2.1 增强-染色复合改性材的物理力学性能

由表1可知,纯染色材DA和DG的质量增加率分别为-1.69%和-0.65%,密度分别为0.352和0.365 g·cm-3; MUF-DA和MUF-DG增强-染色复合改性材的质量增加率分别为42.64%和54.27%,密度分别为0.445和0.510 g·cm-3。由于部分木材抽提物可被染料水溶液溶解析出(韦双颖等, 2008),致使水溶液染色材的密度反而比素材略有降低。DG染色材的质量增加率和密度大于DA染色材,MUF-DG增强-染色复合改性材的质量增加率和密度也大于MUF-DA增强-染色复合改性材,说明酸性大红G在水溶液和树脂溶液中的上染性比酸性湖蓝A好,分析认为是由于酸性大红G的分子质量小于酸性湖蓝A,因而更容易向木材内部渗透。

表1 改性杨木的密度和质量增加率*括号内为该数据标准偏差,下同。The data in bracket is standard deviation.The same below.

经增强-染色处理后,杨木的抗弯弹性模量、抗弯强度和抗压强度等性能均明显提高。由图1可知,与纯染色材DA相比,MUF-DA增强-染色复合改性材的抗弯弹性模量、抗弯强度和抗压强度分别提高6.76%,17.63%和54.32%; 与纯染色材DG相比,MUF-DG增强-染色复合改性材的抗弯弹性模量、抗弯强度和抗压强度分别提高8.58%,18.82%和57.18%。增强-染色复合改性材与纯树脂增强改性材的力学性能基本一致,表明染料对树脂的增强改性作用几乎没有影响。

2.2 增强-染色复合改性材的颜色

经不同染料溶液浸渍处理后,杨木颜色变化显著。由表2可知,DA和MUF-DA改性材,ΔL*、Δa*和Δb*均为负值,表明处理后杨木颜色蓝色调增多; MUF-DA增强-染色复合改性材的Δa*值更小、ΔL*和Δb*值均更大,表明其蓝色调增加得更多。DG和MUF-DG改性材,Δa*均为正值,ΔL*和Δb*均为负值,Δa*正值越大颜色越红,说明红染效果明显; MUF-DG复合染色材的Δa*、ΔL*和Δb*值均更大,说明其红色调增加得更多。所有染色杨木的颜色饱和度都明显上升,染色后的ΔC*均为正值,但MUF-DG和MUF-DA增强-染色复合改性材的ΔC*显著大于相应的DG和DA纯染色材,说明增强-染色复合改性材的颜色更为饱满艳丽。与纯染色材相比,增强-染色复合改性材的总色差ΔE*稍小,分析认为可能主要是因为水染过程中水的抽提作用使杨木明度下降较大所致。观察处理后的实际染色效果,纯染色材存在染料聚集、染色不均、内外色差大等现象; 增强-染色复合改性材整体颜色并无明显差异,匀染性良好。综上,增强-染色复合改性材的颜色更为鲜明、饱满、均匀,总体染色效果更好。

图1 改性杨木与未处理材的力学性能Fig.1 The mechanical properties of modified and untreated poplar woods

改性材ModifierL∗a∗b∗C∗ΔL∗Δa∗Δb∗ΔC∗ΔE∗DA3623(506)-624(832)-3134(993)3278(768)-5797(203)-953(246)-4728(306)1651(290)7550(259)MUF⁃DA5071(654)-2392(700)-2395(1079)345(578)-4349(361)-2721(161)-3989(280)1823(221)6513(212)DG3154(548)2383(969)-163(1212)2416(861)-6266(237)2054(223)-1757(211)789(212)6832(220)MUF⁃DG4773(776)4461(704)727(1186)4519(731)-4647(411)4132(286)-867(205)2892(336)6295(292)

2.3 增强-染色复合改性材的耐水色牢度

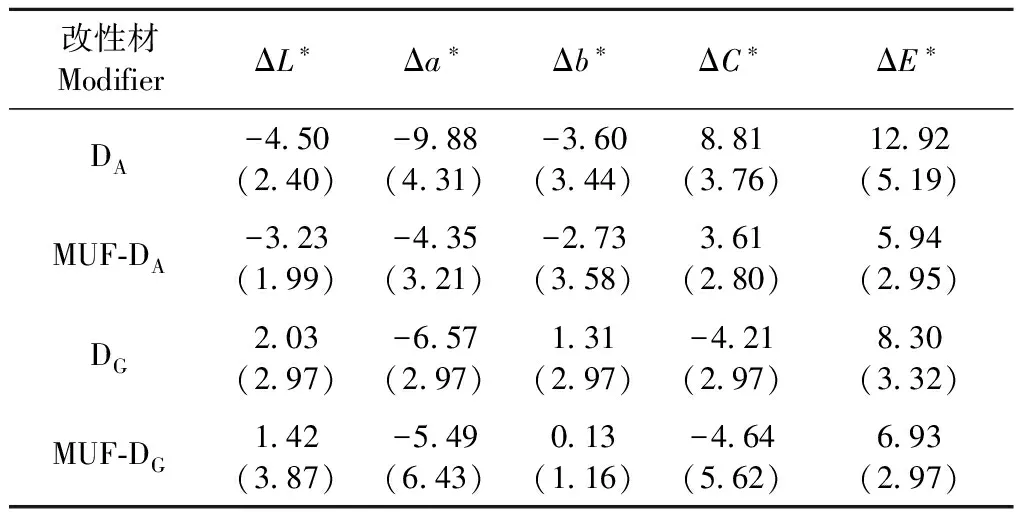

不同染色杨木水浸前后的颜色变化如表3所示,DA和DG染色材水浸前后的总色差ΔE*分别为12.92和8.30 NBS,颜色溶蚀明显。李红等(2005)研究表明,酸性染料与木材主要通过物理吸附作用结合使其容易水溶析出,DA染色材水浸前后的色差大于DG染色材,分析认为主要是染料分子结构和分子质量的不同引起固色效果的差异(邓邵平等, 2008),酸性湖蓝A比酸性大红G的分子质量更大,使其在木材中的渗透性和固着性更差(王传贵等, 2014)。MUF-DA和MUF-DG增强-染色复合改性材水浸前后的总色差ΔE*分别为5.94和6.93 NBS,颜色溶蚀程度均小于相应纯染色材,分析认为染料与树脂增强改性剂复配浸入木材后,具有良好耐水性能的三聚氰胺脲醛树脂在固化过程中对染料进行了有效固定,从而使染色木材的耐水色牢度明显提高。

表3 染色杨木水浸前后的颜色变化

2.4 FTIR分析

图2 改性杨木与未处理材的FTIR光谱Fig.2 FTIR spectra of modified and untreated poplar woods

3 讨论

本研究中,基于酸性大红G的增强-染色复合改性杨木的密度、抗弯弹性模量、抗弯强度和抗压强度分别比纯染色材DG提高了39.73%,8.58%,18.82%和57.18%; 基于酸性湖蓝A的增强-染色复合改性杨木的密度、抗弯弹性模量、抗弯强度和抗压强度分别比纯染色材DA提高了26.42%,6.76%,17.63%和54.32%。增强-染色复合改性材的各项力学性能比未处理材明显提高,与纯树脂增强改性材力学性能基本一致,表明染料对树脂的增强改性作用几乎没有影响,这与郑雅娴等(2016a) 对钩叶藤(Plectocomiapierreana)材增强-染色复合改性及性能研究的结果基本一致。

酸性染料在木材工业中应用广泛,但耐水性较差,在一定程度上影响了染色材利用(顾丽莉等, 2001)。郑雅娴等(2016b)认为树脂对酸性染料的渗透和分散有明显促进作用。本研究中,增强-染色复合改性剂在木材中的渗透性和匀染性良好,增强-染色复合改性材比纯染色材颜色更为均匀,色泽更为艳丽。本研究得出酸性染料-MUF复合染色材耐水色牢度较好,这与前人得出的酸性染料染色后木材耐水性较差(顾丽莉等, 2001; 韦双颖等, 2008)的结果相反。分析其原因:一方面树脂型改性剂中含有大量—NH2,可与酸性染料中磺酸基—RSO3-反应生成盐,形成稳定的离子键(段新芳等, 2003; 顾继友等, 2007); 另一方面树脂型改性剂自身交联缩聚形成高聚物,并与纤维素上的羟基发生交联反应,形成三维网状结构,使染料与树脂一同固着于木材内部(方桂珍等, 1997),从而提高了染色材耐水色牢度。

木材树脂浸渍增强处理可提高软质木材的物理力学性能(Dekaetal., 2002),木材染色可提高木材的装饰性(顾丽莉等, 2001)。本研究将木材的功能性改良与染色处理相结合,在提高其物理力学性能的同时,赋予其良好的装饰性,全面改善了人工林杨木的各项性能。增强-染色复合改性剂,不仅能在染色的同时进行多功能改性,而且还有望解决染色材色牢度差等问题。但是,增强-染色复配体系的机制以及增强-染色复合改性材的耐光色牢度还有待进一步研究。

4 结论

将自制水溶性树脂型增强改性剂MUF分别与酸性大红G和酸性湖蓝A复配得到增强-染色复合改性剂,通过真空加压浸渍处理,对人工林杨木进行增强-染色复合改性,结果表明: 1) 染料的加入对树脂的增强改性作用影响较小,增强-染色复合改性杨木的密度、抗弯弹性模量、抗弯强度和抗压强度均比未处理材明显提高; 2) 与纯染色材相比,增强-染色复合改性材的颜色更为均匀,色泽更为艳丽,总体上MUF-染料复合改性的染色效果更好; 3) 酸性大红G和酸性湖蓝A与MUF树脂溶液复配后,在木材中的耐水色牢度均明显提高,MUF树脂对耐水色牢度较差的酸性湖蓝A的固色作用更为明显; 4) FTIR分析表明,染料与MUF复配染色过程中没有新基团生成,说明随树脂固化沉积于木材内部的染料与木材组分和起增强改性作用的MUF树脂之间没有产生新的化学结合。

邓邵平,叶翠仙,陈孝云,等. 2009. 3种助剂对染色单板耐水色牢度的影响及其FTIR分析. 福建林学院学报,29(1): 45-48.

(Deng S P,Ye C X,Chen X Y,etal. 2009. Study on the effect of color fastness of water about three dyeing auxiliary to dyed veneer and its mechanism analysis by FTIR methods. Journal of Fujian College of Forestry,29(1): 45-48. [in Chinese])

段新芳,孙芳利,朱 伟,等. 2003. 壳聚糖处理对木材染色的助染效果及其机理的研究. 林业科学,39(6): 126-130.

(Duan X F,Sun F L,Zhu W,etal. 2003. Effects of wood dyeing pretreated with chitosan and its mechanism for color improvement by chitosan. Scientia Silvae Sinicae,39(6): 126-130. [in Chinese])

方桂珍,李 坚,刘一星,等. 1997. 三聚氰胺-甲醛与木材的交联作用. 林业科学,33(3): 252-258.

(Fang G Z,Li J,Liu Y X,etal. 1997. Cross-linking effect between wood and melamine-formaldehyde. Scientia Silvae Sinicae,33(3): 252-258. [in Chinese])

顾继友,孟黎鹏,韦双颖,等. 2007. 壳聚糖后处理染色单板的耐水和耐光颜色稳定性. 东北林业大学学报,35(10): 26-32.

(Gu J Y,Meng L P,Wei S Y,etal. 2007. Color fastness of the dyed veneer treated by chitosan. Journal of Northeast Forestry University, 35(10): 26-32. [in Chinese])

顾丽莉,罗 云,刘 静,等. 2001. 木材染色研究. 林产化学与工业,21(2): 49-52.

(Gu L L,Luo Y,Liu J,etal. 2001. The research of wood dyeing. Chemistry and Industry of Forest Products,21(2): 49-52. [in Chinese])

黄艳辉,费本华,余 雁,等. 2011. 木材低分子量树脂改性研究进展.安徽农业大学学报,38(6): 863-866.

(Huang Y H,Fei B H,Yu Y,etal. 2011. Advance in low molecular weight resin modification of wood. Journal of Anhui Agricultural University,38(6): 863-866. [in Chinese])

李 红,于志明. 2005. 染料与木材结合机理的研究. 北京林业大学学报,27 (4): 78-81.

(Li H,Yu Z M. 2005. Combinative mechanism between dyestuff and wood. Journal of Beijing Forestry University, 27(4): 78-81. [in Chinese])

刘 毅,郭洪武,邵灵敏,等. 2011. 室内环境下染色单板的光变色过程. 东北林业大学学报,39(10): 74-76.

(Liu Y,Guo H W,Shao L M,etal. 2011. Analysis of photo-discoloration of dyed veneers in indoor environments. Journal of Northeast Forestry University, 39(10): 74-76. [in Chinese])

刘君良,李 坚,刘一星,等. 2000. PF预聚物处理固定木材压缩变形的机理. 东北林业大学学报,28(4): 16-20.

(Liu J L,Li J,Liu Y X,etal. 2000. Study on the fixation mechanism of compressive deformation of wood by PF resin treatment. Journal of Northeast Forestry University,28(4): 16-20. [in Chinese])

吕建雄,徐 康,刘 元,等. 2014. 速生人工林杨木增强改性的研究进展. 中南林业科技大学学报,34 (3): 99-103.

(Lü J X,Xu K,Liu Y,etal. 2014. Research progresses on reinforced modification of poplar wood from fast growing plantation. Journal of Central South University of Forestry and Technology,34(3): 99-103. [in Chinese])

吕晓慧,朱林峰. 2012. 速生杨木材染色处理工艺的研究. 中南林业科技大学学报,32(1): 70-74.

(Lü X H,Zhu L F. 2012. Study on dyeing treatment technology of fast-growing poplar wood. Journal of Central South University of Forestry and Technology,32(1): 70-74. [in Chinese])

王传贵,裴韵文,张双燕,等. 2014. 不同染料对棕榈藤材的影响及机理分析. 林产化学与工业,34(4): 121-125.

(Wang C G,Pei Y W,Zhang S Y,etal. 2014. Effect of different dyes on rattan and its dyeing mechanism. Chemistry and Industry of Forest Products,34(4): 121-125. [in Chinese])

韦双颖,王 砥,顾继友. 2008. 酸性染料在桦木中的渗透与吸附. 东北林业大学学报,36(3): 45-48.

(Wei S Y,Wang D,Gu J Y. 2008. Permeability and adsorption of acid dyes in birch wood. Journal of Northeast Forestry University,36(3): 45-48. [in Chinese])

杨晓飞,韩英磊. 2011. 杨木资源的高效利用. 木材加工机械,22(5): 36-38.

(Yang X F,Han Y L. 2011. The modification and efficient utilization of poplar wood. Wood Processing Machinery,22(5): 36-38. [in Chinese])

郑雅娴,吕文华,许茂松. 2016a. 钩叶藤材的增强-染色复合改性及其性能研究. 南京林业大学学报: 自然科学版,40(2): 155-159.

(Zheng Y X,Lü W H,Xu M X,etal. 2016. Research of strengthening-dyeing modification ofPlectocomiapierreanacane and its properties. Journal of Nanjing Forestry University: Natural Science Edition,40(2): 155-159. [in Chinese])

郑雅娴,吕文华,许茂松. 2016b. 增强-染色复合改性杨木的耐水色牢度. 东北林业大学学报,44(2):39-41.

(Zheng Y X,Lü W H,Xu M X,etal. 2016. Research of strengthening-dyeing modification ofPlectocomiapierreanacane and its properties. Journal of Northeast Forestry University,44(2): 39-41. [in Chinese])

Deka M,Saikia C N,Baruah K K. 2002. Studies on thermal degradation and termite resistant properties of chemically modified wood. Bioresource Technology,84(2): 151-157.

Furuno T,Imamura Y,Kajita H. 2004. The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Science and Technology, 37(5): 349-361.

Lang Q,Chen H Y,Pu J W. 2013. Wood modification using a urea-formaldehyde prepolymer. Wood and Fiber Science,45(2): 1-8.

Wan H,Kim M G. 2006. Impregnation of southern pine wood and strands with low molecular weight phenol formaldehyde resins for stabilization of oriented strandboard. Wood and Fiber science, 38(2):314-324.

(责任编辑 石红青)

Properties of Strengthening-Dyeing-Combined Modified Plantation Poplar Wood

Xu Maosong Lü Wenhua Wang Xueyu

(ResearchInstituteofWoodIndustry,CAFBeijing100091)

【Objective】In order to provide the technical support for the efficient exploitation and utilization of plantation poplar wood resources, this study investigated the method of strengthening-dyeing-combined modification of plantation poplar wood and the properties of the modified wood. 【Method】The acid red G aqueous solution, the acid blue A aqueous solution, and the acid red G and the acid blue A blended individually with water soluble strengthening modifier (i.e. MUF resin), all of the same dye mass fraction, were used to modify the plantation poplar wood through the vacuum-pressure impregnation treatment, and the DA, DG, MUF-DAand MUF-DGdyed wood were obtained respectively. The physical and mechanical properties, color and colorfastness to water of all the dyed wood were measured.【Result】Results showed that: 1) The weight percent gain of the DA, DG, MUF-DAand MUF-DGdyed wood were -1.69%, -0.65%, 42.64% and 54.27%, and their density were 0.352, 0.365, 0.445 and 0.510 g·cm-3, respectively. Compared with those of the DAdyed wood, the density, modulus of elasticity (MOE), modulus of rupture (MOR), and compressive strength of the MUF-DAmodified wood increased by 26.42%, 6.76%, 17.63%, and 54.32% respectively. As compared with those of the DGdyed wood, the density, MOE, MOR, and compressive strength of the MUF-DGmodified wood increased by 39.73%, 8.58%, 18.82%, and 57.18% respectively. 2) The light index difference (ΔL*), green-red index difference (Δa*) and yellow-blue index difference (Δb*) of the DAand MUF-DAwere all negative, and the MUF-DA’s Δa*was lower, its ΔL*and Δb*were higher, so its blue tone was more obvious. As for the DGand MUF-DG, the ΔL*and Δb*were negative and the Δa*was positive, and the ΔL*, Δa*and Δb*of the MUF-DGwere all higher, so its red tone was more obvious. The color saturation difference (ΔC*) of the MUF-DAand MUF-DGwere much higher than those of the DAand DG. 3) The total color difference (ΔE*) of the DAand DGafter water erosion test were 12.92 and 8.30 NBS, while those of the MUF-DAand MUF-DGdecreased to 5.94 and 6.93 NBS respectively. 4) The IR spectra of the DAand DGdyed wood were similar to that of the untreated wood, and the spectra of the MUF-DAand MUF-DGmodified wood were similar to that of the MUF strengthened wood, no new absorption peak was observed and the peak intensity was almost unchanged. 【Conclusion】1) The acid dyes had minor effects on the reinforcement function of MUF resin, and their combined modification could significantly improve the density, MOR, MOE, and the compressive strength of plantation poplar wood. 2) Compared with the simple dyed wood, the color of strengthening-dyeing combined wood was more vivid and showed better dyeing effect, especially the effect of MUF-DGwas the best. 3) The colorfastness to water of the strengthening-dyeing combined wood was better than that of the simple dyed wood, especially the effect of MUF-DAwas the best. 4) FTIR analysis showed that no new chemical group generated during the strengthening-dyeing combined modification process, and there was no new chemical bonding produced between the wood components and dye which deposited with MUF resin and fixed in wood.

plantation poplar wood; strengthening-dyeing combined modifier; impregnation treatment; properties; FTIR analysis

10.11707/j.1001-7488.20170110

2016-09-11;

2016-02-25。

中央级公益性科研院所基本科研业务费专项资金(CAFYBB2014MB003)。

S781.7

A

1001-7488(2017)01-0082-06

*吕文华为通讯作者。