均质压力对玉米淀粉机械力化学效应的影响

2017-01-17李贵萧侯汉学代养勇董海洲

李贵萧,牛 凯,侯汉学,张 慧,代养勇,董海洲

(山东农业大学食品科学与工程学院,泰安 271018)

均质压力对玉米淀粉机械力化学效应的影响

李贵萧,牛 凯,侯汉学,张 慧,代养勇※,董海洲

(山东农业大学食品科学与工程学院,泰安 271018)

为了研究均质压力对玉米淀粉微观结构及理化性质的影响,该文以玉米淀粉为原料,通过 X-射线衍射(X-ray diffraction,XRD)、扫描电镜(scanning electron microscope,SEM)、快速黏性分析仪(rapid visco analyser,RVA)、偏光显微镜(polarizing microscope,PLM)、激光共聚焦显微镜(confocal laser scanning microscopy,CLSM)等手段研究不同压力(20、60、100、140 MPa)下淀粉结构及性质变化,并探究其相互关系,揭示均质压力对淀粉颗粒机械力化学效应。结果表明:均质压力处理对玉米淀粉结构及性质产生显著影响。经20~140 MPa处理后,与原淀粉相比,中央腔及孔道结构模糊,粒径、糊化黏度减小,结晶度下降,水溶指数和透光率呈上升趋势。20~100 MPa范围内,随均质压力增大,淀粉颗粒形貌逐渐破坏,球状凸起结构增加,100 MPa处理时中心球体最为明显,且与60 MPa相比,结晶度变大,膨胀度显著下降。当140 MPa处理时,颗粒内部球状凸起、碎片及孔洞结构显著减少,偏光十字破坏,糊化焓降低。可见不同均质压力对淀粉颗粒的无定形区、亚结晶区和结晶区产生不同程度的机械力化学作用,导致淀粉颗粒内部依次发生了聚集和团聚效应。该结果为研究淀粉化学活性及生产高性能变性淀粉提供理论支撑。

压力;淀粉;物理特性;化学特性;机械力化学效应;结构;均质

0 引 言

机械力化学是利用机械能诱发化学反应及诱导材料组织、结构、性能变化,进而对材料进行改性处理的科学,是目前较为活跃的研究领域之一[1]。机械力化学就是把机械力的能量(碾轧、剪切、高压、摩擦等)转化为化学能的过程,其对物质作用过程通常分为三个阶段,依次是受力阶段、聚集阶段、团聚阶段[2]。国内外对淀粉机械力作用研究主要集中在球磨等方面[3],目前研究结果表明,高压微射流、球磨等处理可明显破坏淀粉结构,刘斌等采用混合液态载体研究高压微射流均质玉米淀粉的微细化效果,结果显示二元组分载料介质具有更强的冲击作用[4];Jitranut L等研究干磨和湿磨可破坏米粉凝胶等理化特性[5];贺永朝等对高压均质改性淮山药淀粉及其消化性进行研究,结果显示均质处理导致淮山药淀粉颗粒表面破损,结晶度降低,淀粉消化性提高[6],但对此变化发生的化学机理研究不够清晰。

本文利用高压均质对物料产生强烈的撞击、振荡、剪切和气穴等机械力作用[7],以玉米淀粉为原料,利用扫描电镜(scanning electron microscope,SEM)、X-射线衍射(X-ray diffraction,XRD)、差示扫描量热仪(differential scanning calorimetry,DSC)、激光共聚焦显微镜(confocal laser scanning microscopy,CLSM)等手段研究不同压力下高压均质对玉米淀粉微观结构及理化性质的影响,并揭示不同均质压力对淀粉颗粒机械力化学效应的影响,为了解高压加工处理对淀粉质食品品质的影响提供理论支撑,同时为研究淀粉物理改性新技术提供理论基础。

1 材料与方法

1.1 材料与仪器

玉米淀粉(含水率13.06%,粗蛋白质量分数0.39%,粗脂肪质量分数0.34%):山东诸城兴贸玉米开发有限公司;8-氨基芘基-1,3,6三磺酸三钠盐(APTS):美国sigma-aldrich公司。

Nicolet is5傅立叶变换红外光谱仪(美国热电尼高力公司);LXJ-BⅡ低速大容量多管离心机(上海安亭科学仪器厂);RVA-Eritm黏度分析仪(瑞典波通仪器公司);D8 ADVANCE型X射线衍射仪(德国BRUKER-AXS有限公司);T6新世纪紫外可见分光光度计(北京普析通用仪器有限责任公司);ZKY-303S型高压均质机(北京中科浩宇科技发展有限公司);B-383POL热台偏光显微镜(意大利康帕斯公司);QUANTA FEG250扫描电子显微镜(美国FEI公司)。

1.2 试验方法

1.2.1 高压均质淀粉的制备

取200 g玉米淀粉(干基),配成质量分数为18%的淀粉乳,搅拌均匀,利用高压均质机分别经20、60、100、140 MPa压力处理30 min,待压力稳定后收集样品,40 ℃通风干燥48 h,研磨、过200目筛,密封备用。

1.2.2 水溶指数和膨胀度的测定

准确称取 9g玉米淀粉于烧杯中,配成质量分数为2.0%的淀粉乳450 mL,85 ℃水浴糊化30 min,3 000 r/min离心30 min。将上清液倾出于已恒质量烧杯中,称量并记录,然后于 1 05 ℃烘干至恒质量,称其质量为溶解的淀粉质量A,称取离心后沉淀物质量为膨胀淀粉质量P,计算水溶指数和膨胀度。公式如下[8-9]

式中:A为上清液烘干恒量后的质量,g;W为绝干样品质量,g;P为离心后沉淀物质量,g。

1.2.3 透光率的测定

称取0.5 g玉米淀粉,配成质量分数为1%的淀粉乳50 mL,沸水浴糊化30 min。糊化完成后冷却至30 ℃,利用分光光度计于650 nm波长下测定吸光度,以蒸馏水为空白,平行3次,计算淀粉糊的透光率[10]。

1.2.4 糊化特性的测定

根据样品的含水率,得所需淀粉样品质量和去离子水量[11],采用快速黏度分析仪进行测定。将样品与水于RVA样品盒中充分混合。测定过程中温度控制如下:50 ℃保持1 min,3.7 min 后上升至95 ℃,95 ℃保持2.5 min,3.8 min后下降至50 ℃,50 ℃保持 2 min。起始10 s内搅拌器转速为960 r/min,以后保持160 r/min[12]。

1.2.5 热力学特性分析

称取5 mg淀粉样品于铝制密封坩埚中,加入15 µL去离子水,25 ℃平衡过夜。升温速率为5 ℃/min,升温温度为10~99 ℃,记录升温过程的DSC曲线。保护气为氮气,流速为60 mL/min。同时记录胶凝起始温度(To)、峰值温度(Tp)、终止温度(Tc)和胶凝焓变(ΔH)。

1.2.6 X-射线衍射分析

采用X-衍射仪测定结晶特性。测试条件:特征射线CuKα,管压为40 kV,电流为100 mA,扫描速率为4°/min,测量角度2θ=5°~40°,步长为0.02°,发散狭峰为1°,防发散狭峰为1°,接受狭峰为0.16 mm[8,13]。

1.2.7 扫描电镜观察

试样经40 ℃干燥12 h,均匀涂在模具上,离子溅射喷涂铂金后,采用扫描电镜进行观察。

1.2.8 偏光显微镜观测淀粉颗粒形态

将样品配成1%淀粉乳置于载玻片上,盖上盖玻片后于光学显微镜下观察,记录淀粉在偏振光源下的形貌特征。

1.2.9 激光共聚焦显微镜(CLSM)分析

取10 mg样品与新鲜配制的15 µL 10 mmol/L APTS(8-氨基芘基-1,3,6三磺酸三钠盐,8-Aminopyrene-1,3,6-trisulfonic acid,trisodium salt)(醋酸为溶剂)及15 µL 1 mol/L氰基硼氢化钠混合,于30 ℃反应15 h,用1 mL去离子水清洗5次,将淀粉颗粒悬浮于100 µL 50%甘油、水混合液中,取一滴悬浮液于CLSM观察[14]。

1.2.10 激光粒度法测定淀粉颗粒粒径

采用LS-POF激光粒度分析仪测定淀粉的粒级分布。将玉米淀粉悬浮于去离子水中,将待测液倒入样品池中超声波分散20 s后测定。根据激光衍射法进行自动分析,得粒径分布图和平均粒径数据,每个样品重复4次。

1.2.11 热稳定性(thermogravimetric analyzer,TGA)分析

采用TA-60热重分析仪测定样品的热稳定性,测试条件:试样质量5 mg,升温速率25 ℃/min,温度范围25~600 ℃,N2为保护气。

1.2.12 红外光谱扫描

将淀粉样品和溴化钾于 1 05 ℃干燥至恒质量,称取1 mg样品于玛堪研钵中,加入150 mg溴化钾粉末,于红外灯下研磨均匀,装入压片模具中抽真空压制成簿片。采用傅立叶红外光谱仪对淀粉样品进行扫描和测定,波长范围为400~4 000 cm-1,扫描次数为32,分辨率为4 cm-1。

1.2.13 数据处理

试验数据重复3次,采用Excel、Origin8.5软件进行数据处理。

2 结果与分析

2.1 均质压力对玉米淀粉颗粒形貌的影响

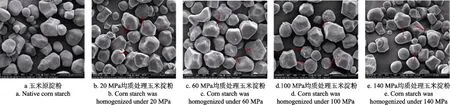

采用扫描电子显微镜分别对不同压力处理的玉米淀粉颗粒进行观察,其颗粒形态变化见图1。

玉米原淀粉多数呈现椭圆形,表面较光滑,形状大小不均,部分为多角形,少数呈无规则形状[15]。在扫描电镜下,可观察到淀粉颗粒表面有微细状针孔结构。由图1可知,由于剪切力作用,导致淀粉颗粒表面出现很多碎片;同时颗粒出现很多孔洞结构,可见高压均质的空化效应也对淀粉微细状针孔结构产生强烈的作用力,使淀粉颗粒的孔道增大[4]。

由图1还可看出,20~100 MPa均质处理后,部分颗粒表面出现球状突起,且随着压力增大,凸起结构呈增加趋势。当140 MPa均质处理时,淀粉颗粒凸起结构、碎片及孔洞结构减少,且表面光滑度增加。此外,由于表面光滑且体积小的淀粉颗粒中直链淀粉含量多,结构稳定性高[14],所以高压均质对其作用不显著。同时淀粉颗粒在绿色植物组织中分布部位不同,其结构和硬度不同[16],所以不同淀粉颗粒对机械力敏感程度存在差异(见图1)。

2.2 均质压力对玉米淀粉颗粒内部微观结构的影响

CLSM可用于观察淀粉颗粒内部微观结构。由图2可看出,淀粉颗粒中心亮度低的部位为中央腔,颗粒内部暗线为孔道结构,且孔道长度存在差异[14]。

由图2可知,玉米原淀粉中央腔及孔道结构清晰可见,而随着均质压力的增大,部分颗粒该结构逐渐变得模糊,推断高压均质对淀粉颗粒无定形区产生了机械力作用,导致颗粒内部发生形变[4];当压力为60 MPa时,部分颗粒中央开始出现球状结构,100 MPa时中心球体明显增大(与图1对应),说明在60 MPa开始有聚集的趋势,而100 MPa时淀粉颗粒内部明显发生了聚集;当压力为140 MPa时,球体消失,部分淀粉颗粒破坏,推断该阶段聚集形成的球体结构破坏,淀粉进入了团聚阶段。

图1 均质压力处理玉米淀粉颗粒的扫描电镜图(×2 000倍)Fig.1 SEM of corn starch modified by different homogenizing pressures(×2 000)

图2 均质压力处理玉米淀粉颗粒的激光共聚焦显微图(×1 600倍)Fig.2 CLSM of corn starch modified by different homogenizaion pressures(×1 600)

2.3 均质压力对玉米淀粉颗粒偏光十字的影响

淀粉由结晶区和非结晶区组成,结晶区淀粉分子链呈有序排列,而非结晶区淀粉分子链呈无序排列,因两者密度和折射率存在差别而产生各向异性现象,从而形成偏光十字,该双折射现象的强度取决于颗粒的大小以及结晶度和微晶取向[17],图3显示了不同均质压力对淀粉颗粒双折射现象的影响。

图3 均质压力处理玉米淀粉颗粒的偏光显微图(×400倍)Fig.3 PLM of corn starch modified by different homogenizing pressures(×400)

由图3可知,原淀粉颗粒偏光十字清晰完整,多数呈垂直交叉的正十字型,交叉点接近于淀粉粒心,表明玉米原淀粉多数近似球状晶体[18]。经20~100 MPa均质处理后,大部分淀粉颗粒仍具有偏光十字,结合图4b猜测该阶段机械力主要作用于无定形区和亚微晶结构,对晶体结构破坏作用较弱。而140 MPa处理后,部分颗粒结构已破坏、偏光十字变得模糊,表明该处理破坏了部分结晶结构,导致结晶区和非结晶区差异性不明显,从而使双折射特性减弱[19],结合图2e可推断晶体结构参与了聚集小球的形成。

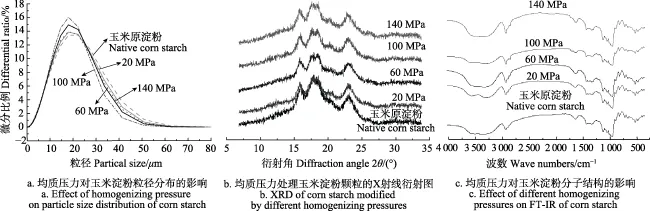

2.4 均质压力对淀粉颗粒粒径分布的影响

淀粉粒径大小直接影响糊化特性、透光率等理化性质,是决定淀粉品质的重要因素[20]。由图4a可知,高压均质后粒径为7.4~24.9 µm的小颗粒分布显著增多,而粒径为24.9~61.9 µm的大颗粒分布显著减少,当压力为100 MPa时变化最为明显,推断可能是经高压均质处理后淀粉颗粒内部聚集形成更加紧密的结构,导致粒径减小;同时也可能是在均质作用下部分以粒团形式存在的淀粉颗粒相互分散[21]。但当压力为140 MPa时,粒径呈现增大趋势,推断淀粉颗粒内部结构变疏松或颗粒间发生团聚。

图4 均质压力对玉米淀粉粒径分布、分子结构影响和X射线衍射图Fig.4 Particle size distribution,FT-IR and XRD of corn starch modified by different homogenizing pressures

2.5 均质压力对玉米淀粉晶体结构的影响

淀粉是一种天然的多晶体系,由有序的结晶区和无序的非结晶区两部分组成[22]。采用 X -衍射分析淀粉衍射峰的强度和大小,能反映其结晶区域的变化程度。

淀粉颗粒内部结构稳定性顺序为:无定形区结构最弱,其次是靠近无定形区的亚结晶区结构,结晶区结构最强;结晶区的结构决定淀粉的构型[22]。玉米淀粉在15.3°、17.1°、18.2°、23.5°有明显的衍射峰,为典型的A型晶体结构[23]。由图4b可知,与原淀粉相比,高压均质后衍射峰型未变,仍为A型晶体结构,但峰强度减小,尤其是亚微晶结构的弥散峰面积明显减小,同时淀粉结晶度下降,说明淀粉晶体晶格有序化程度降低[17]。当压力为60 MPa时,结晶度最低(20.3%),结合图3推断该受力过程可能破坏了亚微晶结构,但当压力达到100 MPa时结晶度增大至23.2%,推断该现象可能与淀粉颗粒内部发生聚集形成球状结构(见图1)有关,同时该过程也使淀粉颗粒结构更加紧密,导致粒径减小(见图4a)。当压力达到140 MPa时,结晶度又降低至19.7%,结合图2推断该处理破坏了淀粉颗粒部分结晶结构,使结构疏松度增大,导致粒径增大(见图4a)。

2.6 均质压力对玉米淀粉分子结构的影响

由图4c(红外图谱)可知,淀粉在2 930、1 660、1 160、1 080、930 cm-1处具有较强的吸收谱带。谱图中1 080 cm-1处的峰源于淀粉的C-O伸缩振动、C-C和O-H的弯曲振动及糖苷键 C -O-C不对称伸缩振动叠加[24-25],文献认为1 160、1 082 cm-1处红外吸收与淀粉结晶结构有关,而1 000 cm-1处吸收与淀粉无定形区结构有关[26]。由图4c可知,均质处理后未出现新的吸收峰,各特征基团的吸收峰位置未发生变化,说明机械力化学作用下淀粉分子结构并未被破坏。

2.7 均质压力对玉米淀粉糊化特性影响

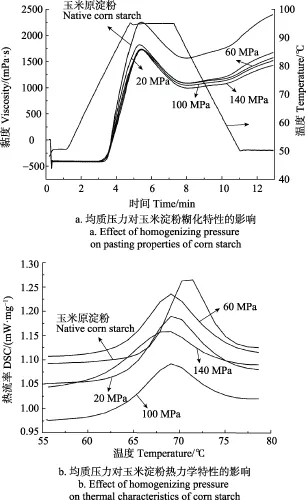

RVA测定是淀粉从吸水溶胀到颗粒结构因剪切力作用受到破坏,导致淀粉分子浸出的过程[27]。经不同均质压力处理后糊化特性结果见图5a。

由图5a可知,经高压均质后,峰值黏度、谷值黏度、终值黏度均呈现下降趋势,且谷值黏度与终值黏度随均质压力的增加而降低。这表明高压均质显著破坏了淀粉颗粒无定形区结构,导致峰值黏度呈下降趋势[28];与原淀粉相比,聚集、团聚后结晶区更加紧密,形成的“ghost”结构体积较小,所以谷值黏度、终值黏度也呈现下降趋势(见图5a)[29]。

图5 均质压力对玉米淀粉糊化特性和热力学特性的影响Fig.5 Effect of homogenizing pressure on pasting properties and thermal characteristics of corn starch

2.8 均质压力对玉米淀粉热力学特性的影响

由图5b可知,经均质处理后,糊化峰明显呈现逐渐左移的现象,说明淀粉糊化温度逐渐呈下降趋势,推断其可能与高压均质处理依次破坏了无定形区、靠近无定形区的亚结晶区及结晶结构有关。由图5b还可看出,当压力为0~100 MPa时,峰高变化不明显,焓变由原来的10.80 J/g缓慢下降至10.50 J/g左右,当140 MPa处理时,与原淀粉相比峰高有减小的趋势,表明该阶段糊化焓明显减小(10.05 J/g),可见该阶段对部分双螺旋结构破坏较为明显[13,30](与图3、图4b显示结晶度破坏相一致),使淀粉分子间相互作用力减弱。

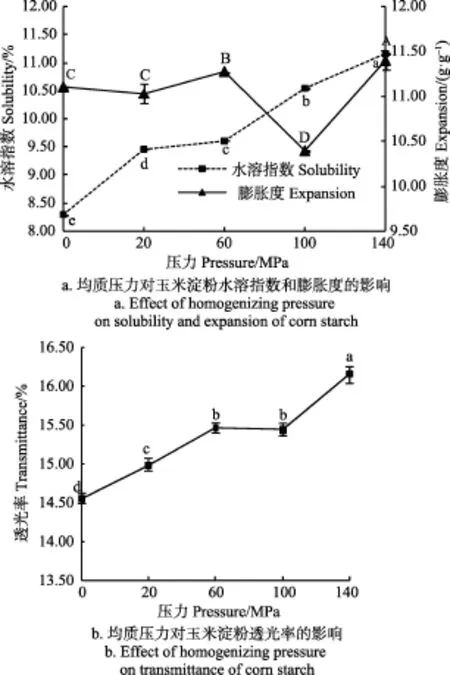

2.9 均质压力对玉米淀粉水溶指数和膨胀度影响

水溶指数与膨胀度反映了淀粉与水分子之间相互作用力的大小[9],玉米淀粉经不同压力处理后,在 8 5 ℃的水溶指数与膨胀度如图6a所示。

由图6a可知,由于高压均质对无定形区产生破坏作用,导致直链淀粉溶出率增加,所以水溶指数呈上升趋势[8]。与原淀粉相比,当20~60 MPa均质时,淀粉颗粒处于受力阶段,无定形区松动,导致淀粉膨胀度略有上升。当100 MPa均质时,膨胀度显著下降至10.38 g/g,可见在该阶段淀粉结构更紧密,与水的结合能力下降,导致淀粉膨胀度下降。当140 MPa均质时,由于破坏了淀粉颗粒部分结晶结构(见图3、图4b),结晶区结构疏松度增大,水分子与羟基结合机会增多,导致膨胀度又显著(P=0.01003<0.05)增大(11.39 g/g)[9]。

图6 均质压力对玉米淀粉水溶指数、膨胀度和透光率的影响Fig.6 Effect of homogenizing pressure on solubility,expansion and transmittance of corn starch

2.10 均质压力对玉米淀粉透光率影响

透光率是淀粉糊所表现出的重要外在特征之一,直接关系到淀粉类产品的外观和用途,进而影响到产品的可接受性[31]。研究表明,透光率与淀粉的水溶指数和淀粉的糊化度呈正相关[32],由于高压均质对无定形区产生破坏作用,导致淀粉的水溶指数和淀粉糊化度增大(见图6a),所以淀粉透光率逐渐增大(见图6b)。但当压力为100 MPa时,处于聚集阶段的淀粉颗粒内部结构更紧密,不易吸水,因此透光率未增大(见图6b)。

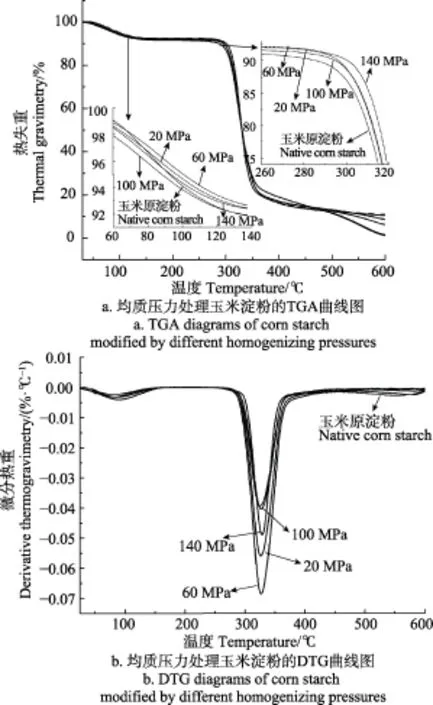

2.11 均质压力对玉米淀粉热稳定性的影响

图7a、b分别为淀粉经不同均质压力处理后TGA(热失重分析)和DTG(热失重速率分析)曲线图谱。

由图7a可看出,玉米淀粉的TGA曲线主要有两个失重阶段,分别为60~150 ℃和260~390 ℃。在60~150 ℃阶段质量略有下降,这主要是挥发性组分及吸附水的散失所致[33];而260~390 ℃阶段失重明显,应该与淀粉糖类有机物热解逸散有关[34]。60~150 ℃阶段,100 MPa均质处理后的淀粉剩余百分率最低(见图7a),说明该阶段内部结构紧密,与水的结合能力弱,吸附水最易散失。260~390 ℃阶段,均质处理后淀粉失重起始温度升高,当140 MPa处理最为明显(见图7a),可见均质处理后(尤其是淀粉团聚后)淀粉热稳定性增强。

图7 均质压力处理玉米淀粉的TGA和DTG曲线图Fig.7 TGA and DTG diagrams of corn starch modified by different homogenizing pressures

由图7b可知,与原淀粉相比,温度在260~390 ℃时,高压均质后淀粉失重速率呈现先增加后减小再增加的趋势,60 MPa处理时失重速率最大,100 MPa速率明显减小,140 MPa处理时失重速率又增大。推断受力阶段,无定形区和亚微晶结构受到破坏(见图3、图4b),所以淀粉热解快[8];而聚集时因内部形成球状,结构变得紧密,所以淀粉热解慢[35];当淀粉发生团聚时,因部分结晶区受到破坏,结构又变疏松,因此失重速率又开始增大。

3 结 论

研究结果表明,高压均质的强剪切作用和“空化效应”对玉米淀粉结构和性质产生了显著影响,即高压均质对淀粉颗粒产生了机械力作用。

1)经20~60 MPa压力处理,中央腔及孔道结构模糊,内部开始有球状凸起结构,无定形区及亚微晶结构受到破坏(受力阶段)。

2)当100 MPa处理时,与60 MPa处理相比,淀粉颗粒内部聚集形成球状结构,导致结晶度上升,热稳定性增强;同时膨胀度、黏度特征值、糊化温度下降(聚集阶段)。

3)当压力为140 MPa时,颗粒内部球状凸起、碎片及孔洞结构显著减少,偏光十字破坏,糊化焓降低,晶体结构受到破坏,淀粉颗粒发生团聚(团聚阶段)。

4)由于高压均质处理破坏了玉米淀粉颗粒结构,所以该机械力作用对淀粉理化性质产生显著影响。

[1] 荣华伟,方莹. 机械力化学研究进展[J]. 广东化工,2006,33(10):33-36. Rong Huawei,Fang ying. The research and development of mechano-chemistry[J]. Guangdong Chemical Industry,2006,33(10):33-36.(in Chinese with English abstract)

[2] Saranu S,Selve S,Kaiser U,et al. Effect of large mechanical stress on the magnetic properties of embedded Fe nanoparticles[J]. Beilstein Journal of Nanotechnology,2011,2(2):268-75.

[3] 郝征红,张炳文,郭珊珊,等. 振动式超微粉碎处理时间对绿豆淀粉理化性质的影响[J]. 农业工程学报,2014,(18):317-324. Hao Zhenghong,Zhang Bingwen,Guo Shanshan,et al. Influence on physical and chemical properties of Mung bean starch by vibration superfine grinding time[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2014,30(18):317-324.(in Chinese with English abstract)

[4] 刘斌,张媛,冯涛,等. 混合液态载体对高压射流均质玉米淀粉颗粒微细化的影响[J]. 食品科学,2013,34(17):78-81. Liu Bing,Zhang Yuan,Feng Tao,et al. Effect of mixed liquid carrier on the crystalline structure of corn starch granules after high pressure jet homogenization[J]. Food Science,2013,34(17):78-81.(in Chinese with English abstract)

[5] Jitranut L,Jirarat A. Effects of dry-milling and wet-milling on chemical,physical and gelatinization properties of rice flour[J]. Rice Science,2016,23(5):274-281.

[6] 贺永朝,吴枭锜,宋洪波,等. 高压均质改性淮山药淀粉及其消化性的研究[J]. 现代食品科技,2016,32(5):227-233. He Yongzhao,Wu Xiaoqi,Song Hongbo,et al. Effect of high-pressure homogenization on the properties and digestibility of dioscorea opposita starch[J]. Modern Food Science and Technology,2016,32(5):227-233.(in Chinese with English abstract)

[7] 孟爽,马莺,刘天一. 应用高压均质技术制备玉米淀粉-硬脂酸复合物[J]. 哈尔滨工业大学学报,2015,47(4):52-57. Meng Shuang,Ma Ying,Liu Tianyi. Corn starch-stearic acid complexes prepared by high pressure homogenization technology[J]. Journal of Harbin Institute of Technology,2015,47(4):52-57.(in Chinese with English abstract)

[8] Sukhija S,Singh S,Riar C S. Physicochemical,crystalline,morphological,pasting and thermal properties of modified lotus rhizome(Nelumbo nucifera) starch[J]. Food Hydrocolloids,2016,60:50-58.

[9] Abegunde O K,Mu Taihua,Chen Jingwang,et al. Physicochemical characterization of sweet potato starches popularly used in Chinese starch industry[J]. Food Hydrocolloids,2013,33(2):169-177.

[10] 涂宗财,余莉,尹月斌,等. 动态高压微射流对马铃薯直链淀粉性质和结构的影响[J]. 食品与发酵工业,2014,40(3):46-51. Tu Zongcai,Yu Li,Yin Yuebin,et al. Effects of dynamic high-pressure microfluidization on the structural and physicochemical properties of potato amylose starches[J]. Food and Fermentation Industries,2014,40(3):46-51.(in Chinese with English abstract)

[11] Gerits L R,Pareyt B,Delcour J A. Wheat starch swelling,gelatinization and pasting:Effects of enzymatic modification of wheat endogenous lipids[J]. LWT-Food Science and Technology,2015,63(1):361-366.

[12] Tong Chuan,Chen Yaling,Tang Fufu,et al. Genetic diversity of amylose content and RVA pasting parameters in 20 rice accessions grown in Hainan,China[J]. Food Chemistry,2014,161(11):239-245.

[13] Warren F J,Gidley M J,Flanagan B M. Infrared spectroscopy as a tool to characterise starch ordered structure-a joint FTIR-ATR,NMR,XRD and DSC study[J]. Carbohydrate Polymers,2016,139:35-42.

[14] 陈佩. 不同链/支比玉米淀粉的形态及其在有/无剪切力下糊化的研究[D]. 广州:华南理工大学,2010:79-80. Chen Pei. Morphology and Gelatinization of Corn Starches with Different Amylose/Amylopectin Content under Shearless and Shear Conditions[D]. Guangzhou:South China University of Technology,2010:79-80.(in Chinese with English abstract)

[15] Wang Shaoqing,Wang Linlin,Fan Wenhao,et al. Morphological analysis of common edible starch granules by scanning electron microscopy[J]. Food Science,2011,32(15):74-79.

[16] 蒲华寅. 等离子体作用对淀粉结构及性质影响的研究[D].广州:华南理工大学,2013:30-46. Pu Huayin. Effects of Plasma on Structure and Properties of Starch[D]. Guang zhou:South China University of Technology,2013:30-46.(in Chinese with English abstract)

[17] 张斌,罗发兴,黄强,等. 不同直链含量玉米淀粉结晶结构及其消化性研究[J]. 食品与发酵工业,2010(8):26-30. Zhang Bin,Luo Faxing,Huang Qiang,et al. Crystalline structures and digestibility of corn starches with different amylose/amylopectin content[J]. Food and Fermentation Industries,2010(8):26-30.(in Chinese with English abstract)

[18] Arráiz H,Barbarin N,Pasturel M,et al. Starch granules identification and automatic classification based on an extended set of morphometric and optical measurements[J]. Journal of Archaeological Science:Reports,2016,7:169-179.

[19] 周海宇,任瑞林,包亚莉,等. 高静压酯化木薯淀粉结构及其理化性质的研究[J]. 现代食品科技,2016,32(2):107-112. Zhou Haiyu,Ren Ruilin,Bao Yali,et al. Structural and physicochemical properties of tapioca starch modified by esterification under high hydrostatic pressure[J]. Modern Food Science and Technology,2016,32(2):107-112.(in Chinese with English abstract)

[20] Asmeda R,Noorlaila A,Norziah M H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour[J]. Food Chemistry,2015,191(3):261-262.

[21] 夏宁,龚倩,王金梅,等. 微射流均质处理对碎米淀粉性质影响的研究[J]. 食品工业科技,2012,33(10):151-153. Xia Ning,Gong Qian,Wang Jinmei,et al. Preparation and characterization of broken rice starch by high pressure homogenization[J]. Science and Technology of Food Industry,2012,33(10):151-153.(in Chinese with English abstract)

[22] 张明. 湿热协同微波处理对淀粉理化性质及消化性的影响[D]. 广州:华南理工大学,2014:3-8. Zhang Ming. Effect of Heat-moisture Combined withMicrowave Treatment on Physicochemical and Digestibility Property of Starch[D]. Guang zhou:South China University of Technology,2014:3-8.(in Chinese with English abstract)

[23] Bian Linlin,Chung H J. Molecular structure and physicochemical properties of starch isolated from hydrothermally treated brown rice flour[J]. Food Hydrocolloids,2016,60:345-352.

[24] Flores M A,Jimnez E M,Mora-escobedo R. Determination of the structural changes by FT-IR,Raman,and CP/MAS 13C NMR spectroscopy on retrograded starch of maize tortillas[J]. Carbohydrate Polymers,2012,87(1):61-68.

[25] Wani I A,Jabeen M,Geelani H,et al. Effect of gamma irradiation on physicochemical properties of Indian Horse Chestnut (Aesculus indica Colebr.) starch[J]. Food Hydrocolloids,2014,35(1):253-263.

[26] Jiang Qianqian,Gao Wenyuan,Li Xia,et al. Effect of acid-ethanol on the physicochemical properties of Dioscorea opposita Thunb and Pueraria thomsonii Benth starches[J]. Starch/Starke,2011,635:302-310.

[27] Cozzolino D,Roumeliotis S,Eglinton J. Relationships between starch pasting properties,free fatty acids and amylose content in barley[J]. Food Research International,2013,51(2):444-449.

[28] Liu Chengmei,Liang Ruihong,Dai Taotao,et al. Effect of dynamic high pressure microfluidization modified insoluble dietary fiber on gelatinization and rheology of rice starch[J]. Food Hydrocolloids,2016,57:55-61.

[29] Carrillo-Navas H,Rosa A D L,Gómez-Luría D,et al. Impact of ghosts on the viscoelastic response of gelatinized corn starch dispersions subjected to small strain deformations[J]. Carbohydrate polymers,2014,110(38):156-162.

[30] Oliveira M M D,Tribst A A L,Oliveira R A D,et al. Effects of high pressure processing on cocoyam,Peruvian carrot,and sweet potato:Changes in microstructure,physical characteristics,starch,and drying rate[J]. Innovative Food Science &Emerging Technologies,2015,31:45-53.

[31] 高伦江,曾顺德,曾志红,等. 蕉藕淀粉与薯类淀粉特性对比研究[J]. 中国粮油学报. 2016,31(1):17-20. Gao Lunjiang,Zeng Shunde,Zeng Zhihong,et al. Comparative study on properties of canna starch and potato starch[J]. Journal of The Chinese Cereals and Oils Association,2016,31(1):17-20.(in Chinese with English abstract)

[32] Li Wenhao,Gao Jinmei,Wu Guiling,et al. Physicochemical and structural properties of A-and B-starch isolated from normal and waxy wheat:Effects of lipids removal[J]. Food Hydrocolloids,2016,60:364-373.

[33] 石海信,方丽萍,王爱荣,等. 微波辐射下木薯淀粉结构与性质的变化[J]. 食品科学,2015,36(3):68-74. Shi Haixin,Fang Liping,Wang Airong,et al. Variations in structure and properties of cassava starch after microwave irradiation[J]. Food Science,2015,36(3):68-74.(in Chinese with English abstract)

[34] Szymońska J,Molenda M,Wieczorek J. Study of quantitative interactions of potato and corn starch granules with ions in diluted solutions of heavy metal salts[J]. Carbohydrate Polymers,2015,134:102-109.

[35] 卢麒麟,黄彪,唐丽荣,等. 机械力化学作用下纳米淀粉的制备与性能[J]. 中国粮油学报,2014,29(11):24-29. Lu Qilin,Huang Biao,Tang Lirong,et al. Preparation and characterization of starch nanoparticles by mechanochemistry[J]. Journal of the Chinese Cereals and Oils Association,2014,29(11):24-29.(in Chinese with English abstract)

Effects of homogenizing pressure on mechanochemical properties of corn starch

Li Guixiao,Niu Kai,Hou Hanxue,Zhang Hui,Dai Yangyong※,Dong Haizhou

(College of Food Science and Engineering,Shandong Agricultural University,Tai’ an 271018,China)

Starch,as one of the most abundant natural polymers,is available,sustainable and non-toxic. However,it has not exhibited great development potential and application prospect in the food processing fields due to the low transparency and solubility. Mechanochemistry is the treatment process of converting the mechanical energy,such as grinding,shearing,pressure and friction,into chemical energy,during which the structure and properties of materials are changed. In order to improve the properties of starch and expand its application fields,corn starch was processed by high pressure homogenization. High pressure homogenization could produce strong shearing,vibration,cavitation effects,and so on,which was a complex process that could change the structure and properties of materials. In this research,corn starch was used as raw material,and was processed at the homogenizing pressures of 20,60,100 and 140 MPa successively to analyze the changes of microstructure and physicochemical properties. The mechanochemical effects of homogenizing pressure on corn starch were revealed. In this study,the structure and properties of corn starch modified by different homogenizing pressures,such as crystallinity and morphology structure,were analyzed by X-ray diffraction(XRD),polarizing microscope(PLM),scanning electron microscope(SEM) and confocal laser scanning microscopy(CLSM). The physicochemical properties of starch,including solubility,swelling power,transmittance,gelatinization properties and thermal characteristics,were studied by rapid visco analyzer(RVA) and differential scanning calorimetry(DSC),and so on. And the relationships and mechanisms between structure and properties were revealed. The results showed that compared with native corn starch,the granule appearance of modified starch had changed. There occurred the spherical structure with the increase of the pressure from 20 to 100 MPa,and this phenomenon was the most pronounced when the homogenizing pressure was 100 MPa. The XRD showed that corn starch had an A type pattern with sharp peaks of 15.3°,17.1°,18.2° and 23.5°,respectively. And the type of corn starch modified by different homogenizing pressures was not changed. However,the crystallinity decreased after homogenization treatment. When the homogenizing pressure was 140 MPa,the results from PLM showed the crystalline structure of corn starch was damaged. The results demonstrated that crystalline regions of starch granule were destroyed at the pressure of 140 MPa. In addition,as the homogenizing pressure increased from 20 to 140 MPa,the average particle sizes of corn starch granules decreased. And it revealed that high pressure homogenization had reduced the particle sizes of starch through cavitation and shearing. Meanwhile,the properties of gelatinization weakened gradually,including the peak intensity,low viscosity,final viscosity and gelatinization temperature. Whereas,with the increasing of homogenizing pressure,the solubility and transmittance of corn starch modified by different homogenizing pressures showed a significant increase. To sum up,the present results reveal that the influence of high pressure homogenization on the structure and properties of corn starch is obvious. And different homogenizing pressures have different mechanochemical effects on the amorphous,sub-crystalline regions and crystalline regions of starch granule,and typical aggregation and agglomeration effects occur successively in starch granules.

pressure;starch;physical properties;chemical properties;mechanochemical effects;structure;homogenization

10.11975/j.issn.1002-6819.2017.01.037

TS231

A

1002-6819(2017)-01-0271-07

李贵萧,牛 凯,侯汉学,张 慧,代养勇,董海洲. 均质压力对玉米淀粉机械力化学效应的影响[J]. 农业工程学报,2017,33(1):271-277.

10.11975/j.issn.1002-6819.2017.01.037 http://www.tcsae.org

Li Guixiao,Niu Kai,Hou Hanxue,Zhang Hui,Dai Yangyong,Dong Haizhou. Effects of homogenizing pressure on mechanochemical properties of corn starch[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2017,33(1):271-277.(in Chinese with English abstract)doi:10.11975/j.issn.1002-6819.2017.01.037 http://www.tcsae.org

2016-06-15

2016-10-26

国家自然科学基金项目(31471619);山东省自然科学基金项目(ZR2014JL020)

李贵萧,女,山东陵县人,主要从事粮油加工方面的研究。泰安山东农业大学食品科学与工程学院,271018。Email:1159823746@qq.com

※通信作者:代养勇,男,山东聊城人,副教授,博士,主要从事粮油加工方面的研究。泰安 山东农业大学食品科学与工程学院,271018。Email:dyyww@163.com