聚乙烯醇-壳聚糖复合海绵的制备及性能

2016-12-30魏端丽姚炜钦喻湘华李亮

魏端丽,姚炜钦,喻湘华,李亮*

1.武汉工程大学邮电与信息工程学院,湖北武汉430074;

2.武汉工程大学材料科学与工程学院,湖北武汉430074

聚乙烯醇-壳聚糖复合海绵的制备及性能

魏端丽1,2,姚炜钦2,喻湘华2,李亮2*

1.武汉工程大学邮电与信息工程学院,湖北武汉430074;

2.武汉工程大学材料科学与工程学院,湖北武汉430074

为了进一步提高聚乙烯醇-壳聚糖复合海绵的性能,在聚乙烯醇与甲醛的缩醛化反应过程中加入壳聚糖,并使其与其他原料反应制备聚乙烯醇-壳聚糖复合海绵.分别改变配方中发泡剂和壳聚糖的含量,合成了一系列组分不同的聚乙烯醇-壳聚糖复合海绵,研究了发泡剂含量和壳聚糖含量对复合海绵结构、吸水能力和膨胀率的影响,并采用扫描电子显微镜对复合海绵的结构与微观形貌进行表征,测试了改性海绵对大肠杆菌和金黄色葡萄球菌的免疫能力.研究结果表明,选用曲拉通X-405作为发泡剂,当壳聚糖含量为聚乙烯醇质量的10%时,所制备的复合海绵效果最佳,复合海绵具有明显的蜂窝状多孔结构,其吸水率可达到858%.抗菌实验证明,与纯的聚乙烯醇海绵相比,复合海绵对金黄色葡萄球菌具有较好的免疫能力.

聚乙烯醇;壳聚糖;海绵;多孔结构

1 引言

随着现代科技的不断发展和生活水平的不断提高,人们对于海绵性能的要求也越来越苛刻,高分子材料在生活中的应用越来越普及,尤其是具有良好生物特性的高分子,如聚乙烯醇[1-5]、壳聚糖[6-12]等都在制备海绵的过程中得到了重要的应用.在与人体接触的过程中,聚乙烯醇和壳聚糖均不会发生毒性反应,也没有排斥现象,而且作为海绵的基体材料,聚乙烯醇含有丰富的亲水集团,为海绵的吸水能力做出了贡献.壳聚糖更是一种具有良好生物相容性的天然高分子,因此在这方面的应用也较为广泛[13-15].然而,人工制备的壳聚糖海绵中常用到有毒性的交联剂,如戊二醛,这严重影响了海绵[16-17]在生物医学方面的应用.因此,本文采用聚乙烯醇海绵为主要基质材料,在缩醛化反应过程中直接添加壳聚糖粉末,使壳聚糖均匀的附着在聚乙烯醇泡沫表面和空隙中.

本研究通过制备含有不同含量的壳聚糖和发泡剂的聚乙烯醇-壳聚糖复合海绵(PVF-CS),比较了壳聚糖用量和发泡剂用量对复合海绵各项性能的影响,初步探讨了改性复合海绵的抗菌性,最终确认了壳聚糖的最佳用量.

2 实验部分

2.1 制备不同组成的PVF-CS复合海绵

配置质量分数为15%的PVA溶液,溶解至澄清,分别按所取PVA质量的0%、5%、10%、15%及20%称取壳聚糖,加入到溶液中,充分搅拌,逐一加入0.12 g曲拉通X-405、一定量的硫酸和甲醛,继续搅拌20 min~25 min,倒入模具中,50℃~70℃烘烤成型,最后取出用蒸馏水洗净晾干,得到5组不同壳聚糖含量的PVA-CS复合海绵,编号为CS0、CS5、CS10、CS15、CS20.同理确定壳聚糖含量,分别取0 mL、0.04 mL、0.08 mL、0.12 mL、0.16 mL曲拉通X-405,重复上述实验方法,制备出5组不同发泡剂含量的PVF-CS复合海绵,编号为X0、X0.04、X0.08、X0.12、X0.16.

2.2 复合海绵吸水率和吸水速率的测定

将干燥的海绵剪切成统一大小的正方体,分别测量其质量m1和体积V,将其完全浸没于蒸馏水中,至海绵体积不再变化且结构中无气泡,记下此时的时间t和此时的质量m2,计算吸水率和吸水速率见式(1)和式(2).

2.3 复合海绵膨胀率的测定

将完全脱水的复合海绵整理成同样的大小,在外界施加同样大小的力,使其压缩至形状不再改变,记下此时的体积V1,将薄片完全浸没于水中至体积不再变化,记下体积V2,计算膨胀率见式(3).

2.4 表面形貌的测定

将CS0、CS10、CS20、X0、X0.08、X0.12复合海绵干燥至恒重,观察其外观形貌,并在扫描电镜下观察.

2.5 复合海绵抗菌性能的测试

称取牛肉膏3.0 g、蛋白胨10.0 g、NaCl 5.0 g放入烧杯中,加入蒸馏水,加热使其溶解,倒入三角瓶中并稀释至1 000 mL,琼脂的量按上述配制溶液体积的2.0%直接加入到三角瓶中,用1 mol/L NaOH调节pH为7.6,加塞包装,将上述培养基以0.103 MPa、121℃、20 min高压蒸汽灭菌1 h.测试分为2组,一组接种金黄色葡萄球菌,另一组接种大肠杆菌,同时将所制备的聚乙烯醇-壳聚糖复合海绵剪碎放置在接种后的培养皿中心,在相同条件下置于培养箱1 d.观察其形貌变化,以抑菌环直径大小评价海绵抗菌性能.

3 结果与讨论

3.1 复合海绵吸水率及吸水速率的比较

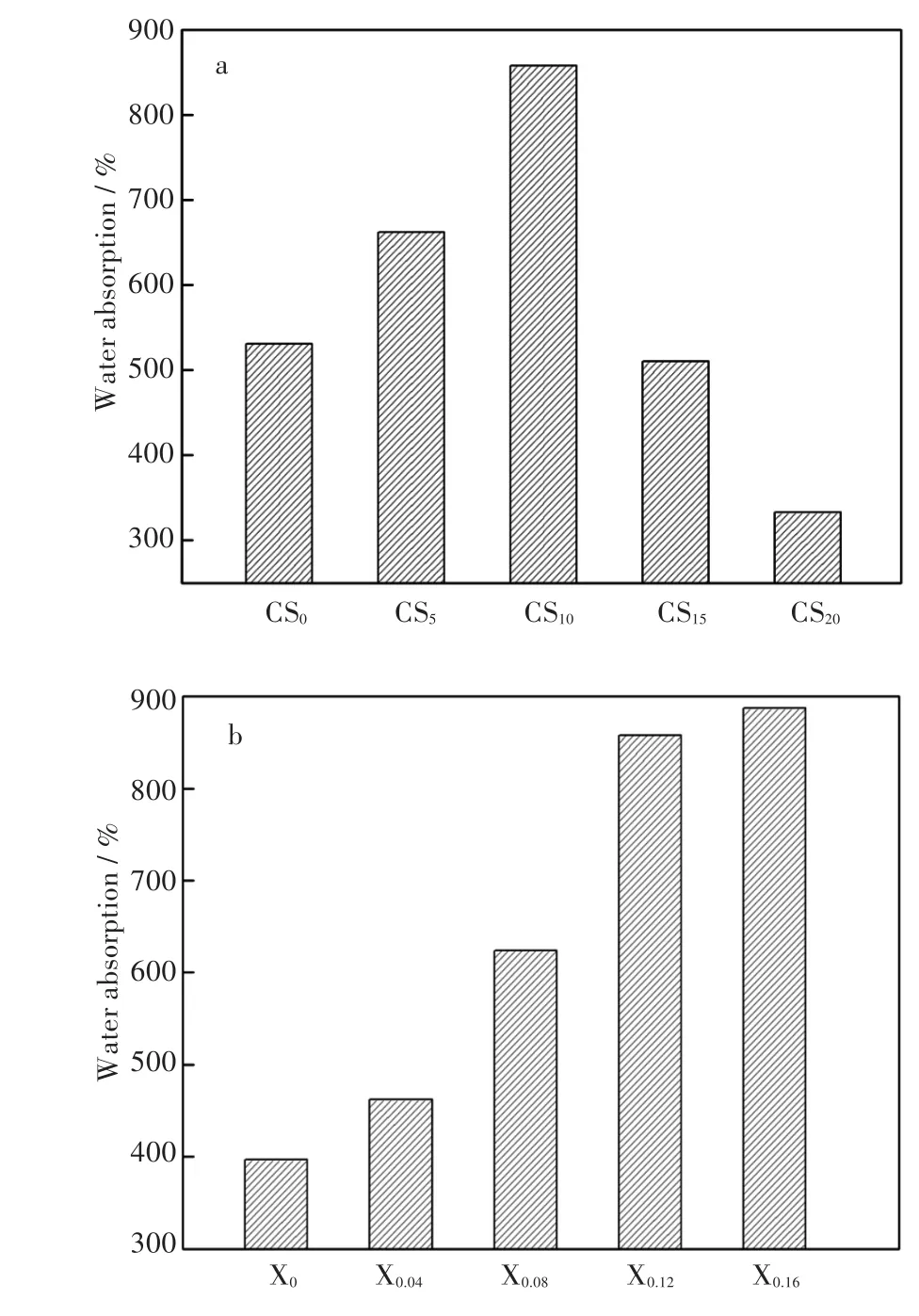

复合海绵吸水率随发泡剂用量的增加而增加,吸水速率变化不明显,这是由于海绵吸水速率由基质材料决定.当壳聚糖含量为PVA量的10%时,所制得的复合海绵吸水率和吸水速率均达到最大值,吸水率最大可达到858%,继续增大壳聚糖的量,其吸水率和吸水速率均下降,见表1和图1.这是因为本实验采用物理共混法,壳聚糖黏附在海绵空隙间,占据了一定空间,而后期清洗中,部分壳聚糖脱落,复合海绵空隙率增大,此时壳聚糖含量还不足以影响吸水速率,但壳聚糖含量过大时,阻碍了缩醛反应,且黏附的壳聚糖使得复合海绵外露羟基数减小,故吸水率和吸水速率均下降.

表1 不同组成的PVF-CS海绵吸水速率Tab.1Water adsorption rate of PVF-CS sponges with different composition

图1 加入(a)不同质量比的壳聚糖/聚乙烯醇与(b)不同体积的发泡剂制备的PVF-CS海绵的吸水率Fig.1Water absorption of PVF-CS sponges prepared with(a)different mass ratios of chitosan/PVA and(b)different volumes of vesicant

3.2 复合海绵膨胀率的比较

不同组成PVF-CS复合海绵的膨胀率表现出与其吸水率相似的规律,复合海绵膨胀率随发泡剂用量的增加而增加,当壳聚糖含量为PVA用量的10%时,复合海绵的膨胀率最大,继续增加壳聚糖的量,膨胀率出现明显下降,见图2.这是由于壳聚糖含量较高时,影响到缩醛化反应,复合海绵内部呈现胶状,网状空间结构被破坏,故而膨胀率先增高后降低.

3.3 PVF-CS复合海绵的空隙结构

图2 加入(a)不同质量比的壳聚糖/聚乙烯醇与(b)不同体积的发泡剂制备的PVF-CS海绵的膨胀率Fig.2Swelling degree of PVF-CS sponges prepared with(a)different mass ratios of chitosan/PVA and(b)different volumes of vesicant

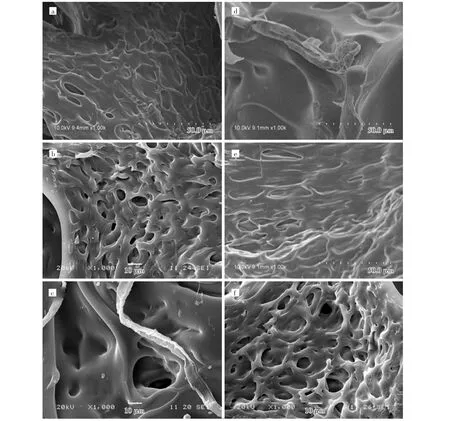

随着发泡剂用量的增加,复合海绵的三维网状结构逐渐变得明显,空隙也随之增大;而当壳聚糖含量为PVA量的10%时,所制得的复合海绵具有蜂窝状结构,空隙明显,立体结构完整,孔与孔之间相互贯通,且大孔上附有小孔,这一结构决定了复合海绵优异的吸水性能和膨胀性能,与之前实验结果相符,见图3.

3.4 海绵的抑菌性能

PVA缩甲醛纯海绵没有出现抑菌圈,说明纯的PVA缩甲醛海绵对金黄色葡萄球菌无抑菌作用,见图4(a);而PVF-CS复合海绵对金黄色葡萄球菌出现了最大直径为22.5 mm的抑菌圈,见图4(b),对大肠杆菌没有出现抑菌圈,见图4(c),说明PVF-CS海绵相对于传统的PVA缩甲醛海绵,对金黄色葡萄球菌有一定的抑菌作用,对大肠杆菌的抑菌作用不佳.

图3 (a)CS0、(b)CS10、(c)CS20、(d)X0、(e)X0.08、(f)X0.12海绵的SEM图Fig.3SEM images of(a)CS0,(b)CS10,(c)CS20,(d)X0,(e)X0.08and(f)X0.12sponges

图4 (a)PVA缩甲醛纯海绵与(b、c)PVF-CS海绵的抗菌图Fig.4Antibacterial ability of(a)PVA sponge and(b,c)PVF-CS sponge

4 结语

本研究制备了PVF-CS复合海绵,其具有蜂窝状三维立体多孔网状结构.壳聚糖和发泡剂含量对复合海绵性能的影响如下:

1)发泡剂和壳聚糖的用量对复合海绵吸水率有着重要的影响,但对复合海绵吸水速率的影响不大.当m(CS)=10%m(PVA)时,复合海绵的吸水率达到最大值(858%).复合海绵的膨胀率与海绵吸水率成对应关系,吸水率高的海绵膨胀率也大.

2)PVF-CS复合海绵相比传统的聚乙烯醇缩甲醛海绵在抗菌性方面有重大提高,尤其是对金黄色葡萄球菌具有较好的免疫能力.

[1]KARIMI A,NAVIDBAKHSH M.Mechanical properties of PVA material for tissue engineering applications[J]. Materials technology,2014,29(2):90-100.

[2]KARIMIA,NAVIDBAKHSHM,FAGHIHIS. Measurement of the mechanical failure of polyvinyl alcohol sponge using biaxial puncture test[J].Journal of biomaterials and tissue engineering,2014,4(1):46-50.

[3]SALAAM A D,MISHRA M,NYAIRO E,et al. Electrospun polyvinyl alcohol/nanodiamond composite scaffolds:morphological,structural,andbiological analysis[J].Journalofbiomaterialsandtissue engineering,2014,4(3):173-180.

[4]CHATELIN S,BERNAL M,DEFFIEUX T,et al. Anisotropicpolyvinyl alcohol hydrogel phantomfor shear wave elastography in fibrous biological soft tissue:a multimodality characterization[J].Physics in medicine and biology,2014,59(22):6923.

[5]KARIMIA,NAVIDBAKHSHM,YOUDEFIH. Mechanical properties of polyvinyl alcohol sponge under different strain rates[J].International journal of materials research,2014,105(4):404-408.

[6]YOUNESI,RINAUDOM.Chitinandchitosan preparation from marine sources.structure,properties and applications[J].Marine drugs,2015,13(3):1133-1174.

[7]IKINCI G,SENEL S,AKINCIBAY H,et al.Effect of chitosanonaperiodontalpathogenporphyromonas gingivalis[J].International journal of pharmaceutics,2002,235(1):121-127.

[8]CHEN Y M,CHUNG Y C,WOAN WANG L,et al. Antibacterialpropertiesofchitosaninwaterborne pathogen[J].Journal of environmental science and health,part A,2002,37(7):1379-1390.

[9]PARVEZ S,RAHMAN M M,KHAN M A,et al. Preparation and characterization of artificial skin using chitosan and gelatin composites for potential biomedical application[J].Polymer bulletin,2012,69(6):715-731.

[10]HUANG X,WANG Y,CAI J P,et al.Sustained release of 5-fluorouracil from chitosan nanoparticles surface modified intra ocular lens to prevent posterior capsule opacification:an in vitro and in vivo study[J].Journal of ocular pharmacology and therapeutics,2013,29(2):208-215.

[11]HAN D,YAN L,CHEN W,et al.Preparation of chitosan/graphene oxide composite film with enhanced mechanical strength in the wet state[J].Carbohydrate polymers,2011,83(2):653-658.

[12]PREGO C,TORRES D,ALONSO M J.The potential of chitosan for the oral administration of peptides[J]. Expert opin drug deliv,2005,2:843-854.

[13]TIRKISTANILFAA.Thermalanalysis of some chitosan schiff bases[J].Polymer degradation and stability,1998,60(1):67-70.

[14]VAZQUEZN,CHACONM,MEANA A,et al. Keratin-chitosanmembranesasscaffoldfortissue engineering of human cornea[J].Stem cells,2015,22(3):355-366.

[15]TSAI R Y,KUO T Y,HUNG S C,et al.Use of gum arabic to improve the fabrication of chitosangelatin-based nanofibers for tissue engineering[J]. Carbohydrate polymers,2015,115:525-532.

[16]MEHBUB M F,LEI J,FRANCO C,et al.Marine sponge derived natural products between 2001 and 2010:trendsandopportunitiesfordiscoveryof bioactives[J].Marine drugs,2014,12(8):4539-4577.

[17]RUAN C,AI K,LI X,et al.A superhydrophobic sponge with excellent absorbency and flame retardancy[J].Angewandte chemie international edition,2014,53(22):5556-5560.

本文编辑:苗变

Synthesis and Properties of Polyvinyl Alcohol-Chitosan Composite Sponges

WEI Duanli1,2,YAO Weiqin2,YU Xianghua2,LI Liang2*

1.College of Post and Telecommunication,Wuhan Institute of Technology,Wuhan 430074,China;2.School of Materials Science and Engineering,Wuhan Institute of Technology,Wuhan 430074,China

To improve the properties of polyvinyl alcohol-chitosan composite sponge,polyvinyl alcohol(PVA)sponge modified by chitosan(PVF-CS)was prepared by adding chitosan powder during the acetalation reaction of PVA and formaldehyde.A series of PVF-CS composite sponges with different composition were prepared by changing the content of vesicant and chitosan.The effects of the content of vesicant and chitosan on the pore morphology,water absorbability,absorbed speed of water and swelling degree were studied.Moreover,the Scanning Electron Microscopy was carried out to characterize the structure and morphology of the as-prepared sponge.The antibacterial abilities to Escherichia coli and Staphylococcus aureus were tested.The result indicates the as-prepared sponge possesses the optimal property when Triton X-405 is used as vesicant and the mass ratio of chitosan/PVA is 10%,and the water absorbability of the composite sponge with honeycomb porous scaffold can reach 858%.The antibacterial experiments show that the antibacterial ability of PVF-CS to the Staphylococcus aureus is better than that of pure PVA sponge.

polyvinyl alcohol;chitosan;sponge;porous structures

O633

A

10.3969/j.issn.1674-2869.2016.06.007

文章编号:1674-2869(2016)06-0549-05

2016-05-23

国家自然科学基金(51403167);武汉工程大学第十一届大学生校长基金(2016029)

魏端丽,硕士,助教.E-mail:394663348@qq.com

*通讯作者:李亮,博士,教授.E-mail:msell08@163.com