施工工艺流程的改革潜力

2016-12-21

施工工艺流程的改革潜力

Potential for Revolutionising the Construction Process

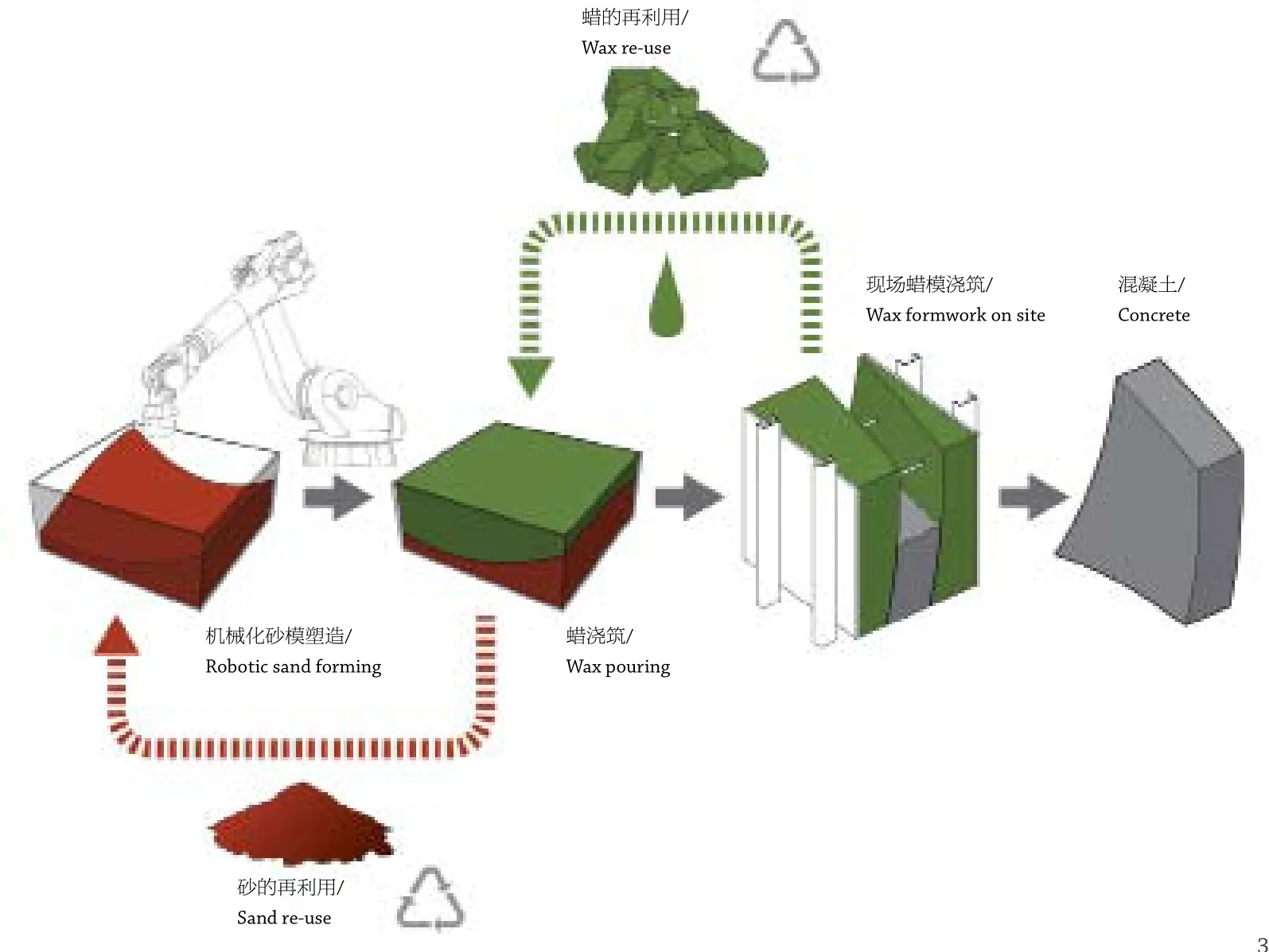

3 具有可持续性、无废物产生的机械化模具制作、蜡模浇筑及混凝土自由造型过程/A robotic forming method, wax formwork and free-form concrete characterize a sustainable, waste-less process

4 现场装配:可用常规方法/On site assembly: compatible with conventional methods.

5 可调节模具驱动/Adjustable mold actuation

无废自由模板构造技术将现有工艺与材料以新的方式相结合,利用可重复使用、数字化制造的蜡模板,来制造非重复性自由形式的现浇混凝土结构。与研磨一次性应用的膨胀聚苯乙烯块或使用诸如胶合板等受低曲率限制的弯曲片材相比,可重复使用的蜡模板既节省材料也节约能量。创建一个由机器人驱动的自由形式模具,形成可再熔的蜡阴模,将其作为混凝土模板放置在现场。该过程可以通过计算机辅助制造来补充,改善复杂审美应用所产生的复杂形状。该技术使得复杂的自由几何形状现代建筑产品可以使用在材料消耗、能效和可用性方面高度优化的设计来制造。

The Wasteless Free-Form Formwork construction technology combines existing processes and materials in a new way to fabricate non-repetitive free-form cast-on-site concrete structures using re-usable and digitally-fabricated wax formwork. The re-usable wax formwork saves material and energy compared to milling expanded polystyrene blocks for single-use applications or using flexed sheets of material such as plywood which are limited to low curvatures. A robotically actuated free form mold is created forming a remeltable wax negative which is placed on-site as concrete formwork. The process can be complemented through computer-aided manufacturing that improves the creation of complex shapes of aesthetically sophisticated applications. The technology enables complex and free-form geometries of contemporary architectural production to be fabricated using designs that are highly optimized in terms of material consumption, energy efficiency and usability.