地铁列车空调机组中椭圆管换热器的应用

2016-12-13张子杨张春路

李 剑 蒋 奎 张子杨 张春路

(1.中车青岛四方机车车辆股份有限公司,266111,青岛; 2.河北轨道运输职业技术学院,050021,石家庄;3.同济大学机械与能源工程学院制冷与低温工程研究所,201804,上海∥第一作者,高级工程师)

地铁列车空调机组中椭圆管换热器的应用

李 剑1蒋 奎2张子杨3张春路3

(1.中车青岛四方机车车辆股份有限公司,266111,青岛; 2.河北轨道运输职业技术学院,050021,石家庄;3.同济大学机械与能源工程学院制冷与低温工程研究所,201804,上海∥第一作者,高级工程师)

地铁列车空调机组功耗约占列车牵引动力的40%,合理有效提高列车空调机组能效比(COP)是降低地铁能耗的重要课题。提出了将椭圆管换热器应用于地铁列车空调的设想,通过建立仿真模型,对原设计采用圆管换热器的制冷系统与采用椭圆管换热器的制冷系统进行了对比。结果表明:将冷凝器和蒸发器都用椭圆管优化后,制冷系统COP提升了12.4%,制冷量提升了12.6%,可以选择小号的压缩机来进一步降低成本。此外,对φ7 mm强化管蒸发器优化的制冷系统进行了分析,结果表明,采用强化管蒸发器的制冷系统性能也有改善,略次于采用椭圆管蒸发器的制冷系统。因此,椭圆管换热器应用于地铁列车空调机组中,对制冷系统性能改善显著,对降低地铁列车能耗有重要意义。

地铁列车; 空调机组; 椭圆管换热器

First-author′s address CRRC Qingdao Sifang Co.,Ltd.,266111,Qingdao,China

为保证车厢适宜的温度与湿度,地铁列车空调机组的配备必不可少,其消耗功率约占地铁列车牵引动力的40%。然而,地铁列车空调机组的COP(能效比)只有2.2~2.3,远低于同类住宅空调机组的COP[1]。在大力倡导节能减排的今天,如何通过合理有效的设计改进来优化地铁列车空调系统至关重要。本文从换热器层面入手,考虑将原设计的圆管换热器替换为椭圆管换热器。椭圆管换热器对管外绕流而言将脱体绕流点延迟,可减小管外压降;对管内流动而言,管道当量直径减小,对换热是有利的[2];同时,椭圆管管间距减小使得同样的空间可以布置更多的换热管。已有试验证明,椭圆管换热器的风侧阻力、导热系数、换热效率等各项性能均优于圆管换热器[3]。椭圆管应用于制冷剂-空气换热器,可使管外空气侧压降减小,换热器换热能力加强[4-6],使蒸发温度升高、冷凝温度降低,可提高空调系统COP。因此,本文提出将椭圆管换热器应用于地铁列车空调机组中,通过在制冷空调系统通用仿真平台GREATLAB[7]中进行系统仿真,比较原设计的圆管换热器与椭圆管换热器的性能参数,验证该方案的可行性。

1 圆管换热器系统仿真与标定

本文研究的轨道车辆空调为双制冷剂回路,每个制冷剂回路的设计相同。单回路制冷系统流程如图1所示。

注:数字表示建模时的部件/流路顺序

蒸发器和冷凝器均为翅片管换热器仿真模型,采用分布参数模型[8]可以更好地反应换热器内制冷剂和空气不均匀流动对于换热器及系统性能的影响。该模型在求解中将翅片管换热器模型按换热器结构分解为以下四个层次:换热器模型、流路模型、换热管模型和微元模型。计算时,由微元模型开始,根据控制体内制冷剂和空气的状态,选取相应的换热关联式,自下而上完成换热器仿真。

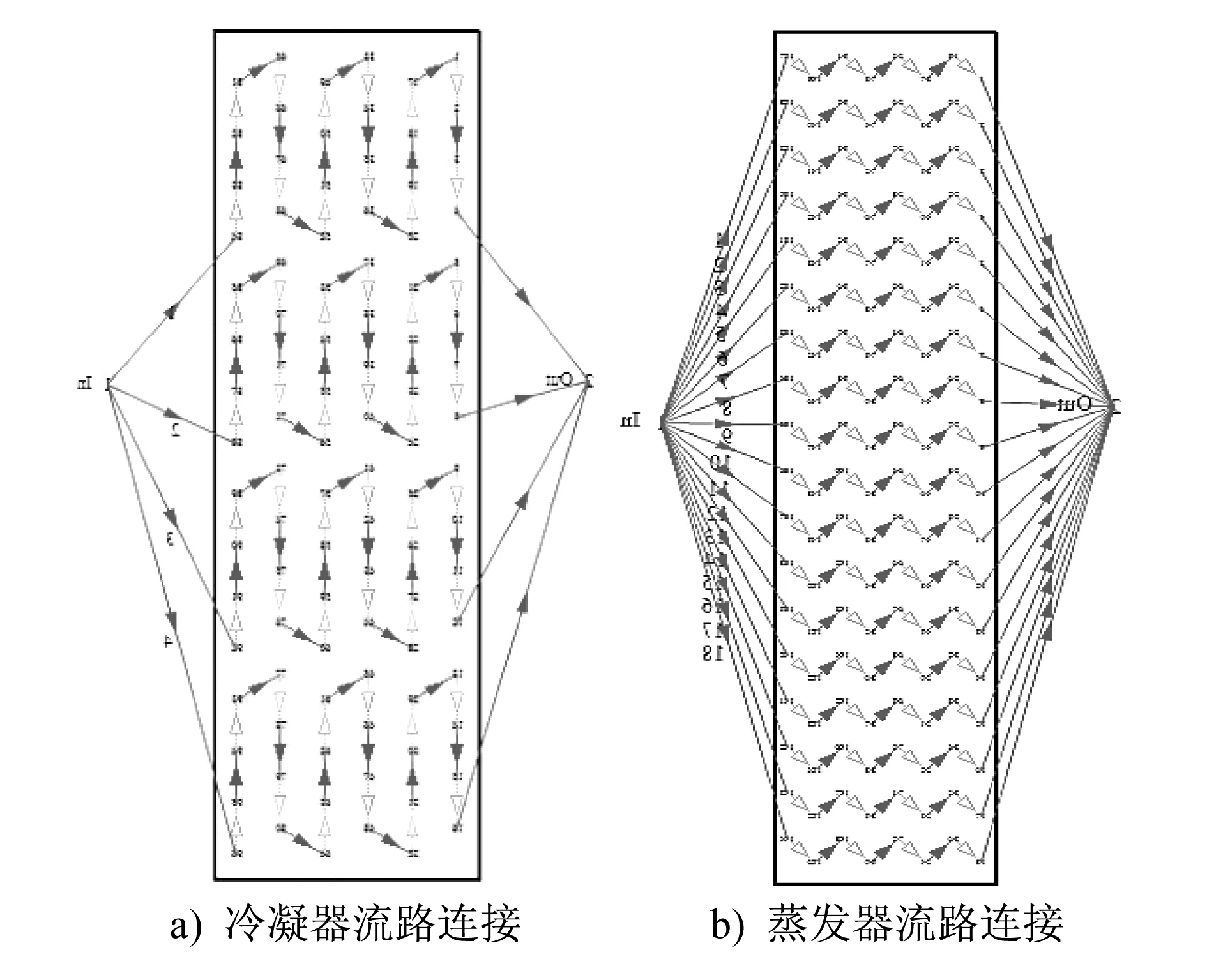

基于上述分布参数模型,可以快速便捷地完成实际换热器模型的仿真。先按照实际设计完成流路连接(见图2),再输入换热器结构参数及制冷剂侧空气侧工况参数,就可完成换热器模型仿真,求解制冷剂和空气的出口状态、压降和换热量。

图2 圆管系统换热器流路连接

压缩机模型采用压缩机厂商广泛采用的AHRI 10系数模型:

式中:

y——压缩机的冷量、能效比、功耗、质量流量等性能参数;

c1~c10——常数项;

Te——蒸发温度;

Tc——冷凝温度。

蒸发器、冷凝器两侧风机采用效率模型,输入风量及功耗;膨胀阀采用控制模型,即压缩机吸气过热度为定值(换热器、压缩机、膨胀阀等部件模型详见文献[8])。名义工况下机组性能仿真结果与试验结果的对比如表1所示。

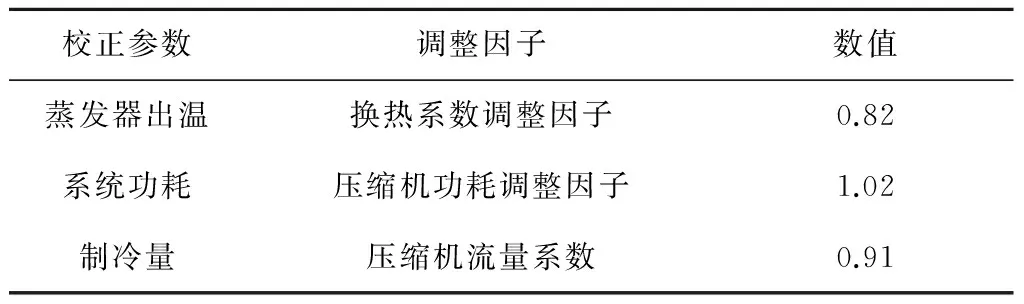

在此基础上,根据试验结果对仿真模型进行标定,使得在名义工况下模型主要性能参数与试验结果一致,从而保证后续优化结果的精度。模型标定结果如表2所示。

表2 模型标定

2 椭圆管冷凝器

2.1 椭圆管冷凝器设计

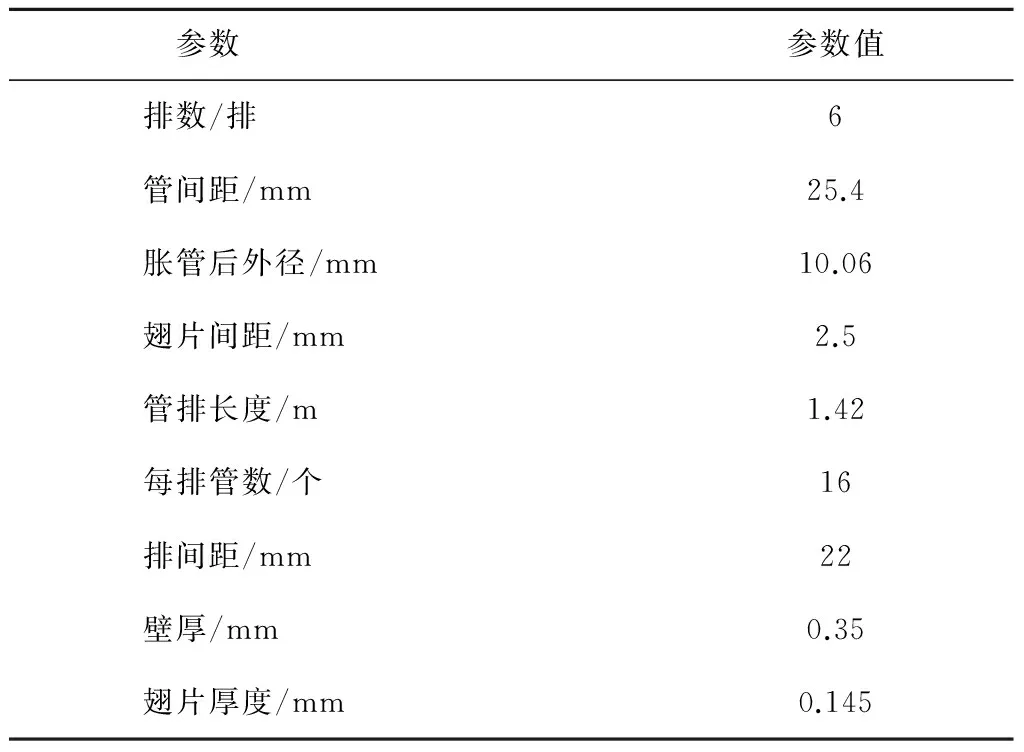

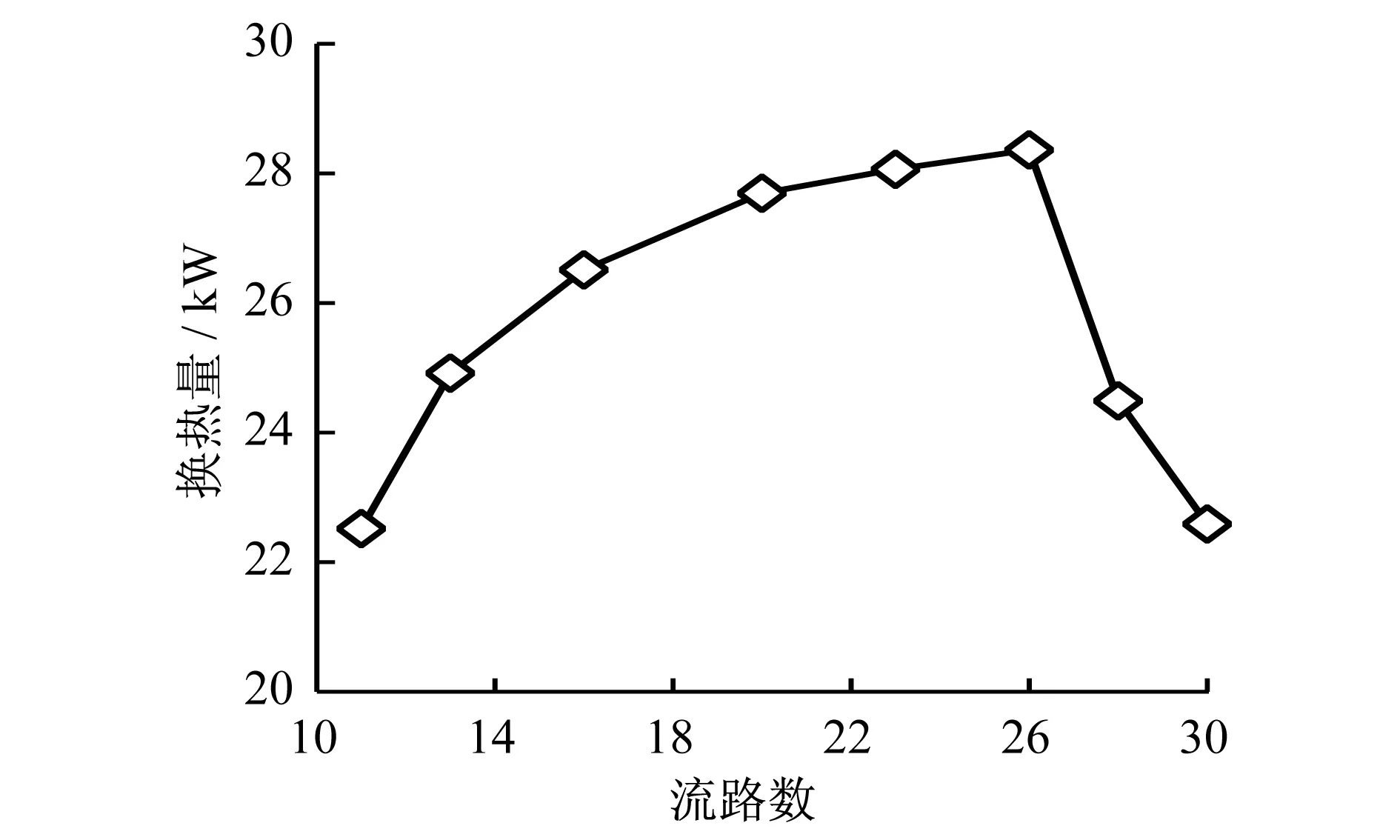

原有的圆管冷凝器设计参数与椭圆管冷凝器设计参数(管的类型皆为螺旋槽强化管)分别如表 3、表 4[7]所示。由表3、表4可知,椭圆管冷凝器管间距减小,在保持冷凝器高度不变的情况下,每排管数可以增加至22;椭圆管冷凝器排间距变化较小,排数不变。对椭圆管冷凝器流路进行重新优化设计,各流路数下换热量对比如图3所示。可见,11流路下换热量最大,故选取11流路连接形式。

表3 原有的圆管冷凝器设计参数

表4 椭圆管冷凝器设计参数

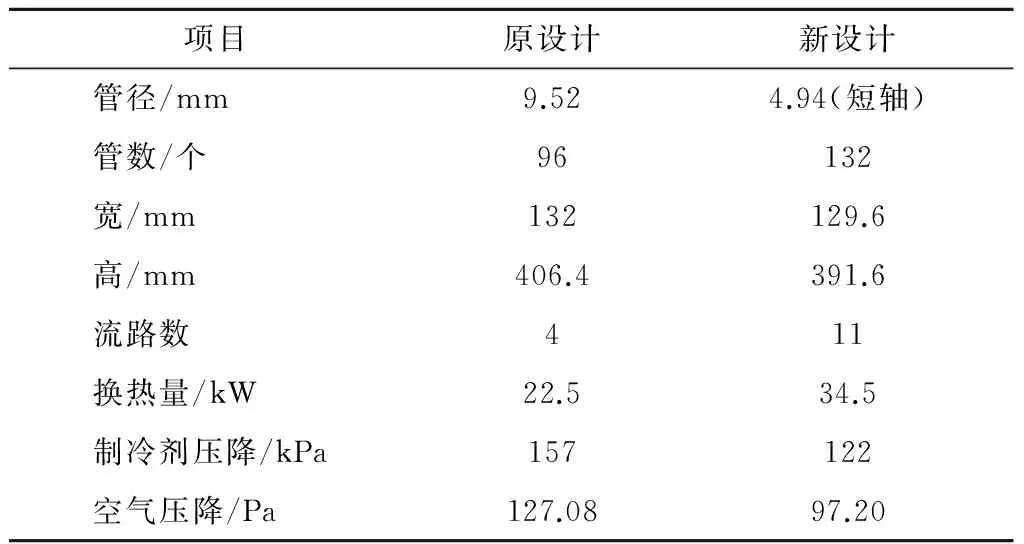

原设计与新设计对比如表5所示。显然,椭圆管冷凝器换热量有明显提高(+53%),空气侧压降也有下降(-24%)。可以根据风机曲线模型对冷凝器侧风机的风量、功耗重新匹配(风量将会增大)。

表5 原设计和新设计的冷凝器性能参数对比

2.2 采用椭圆管冷凝器的制冷系统

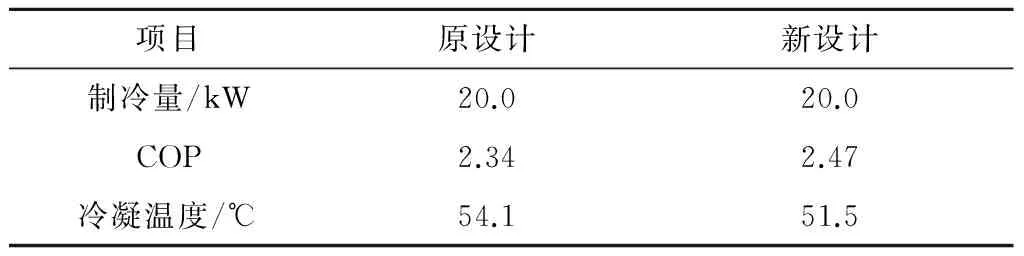

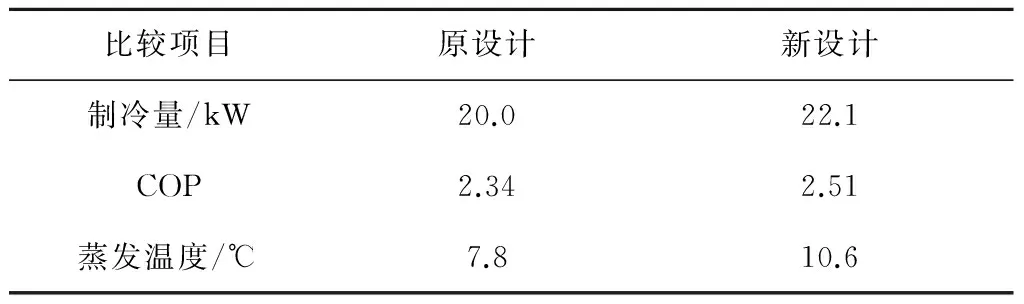

将原设计中的冷凝器替换为新的椭圆管冷凝器,并匹配相应的风机,对制冷系统进行仿真。原设计与新设计性能对比如表6所示。可见,用椭圆管冷凝器代替圆管冷凝器后,制冷量几乎不变的情况下,COP提升了6%左右。

表6 原设计和新设计的制冷系统性能比较一

3 椭圆管蒸发器

3.1 椭圆管蒸发器设计

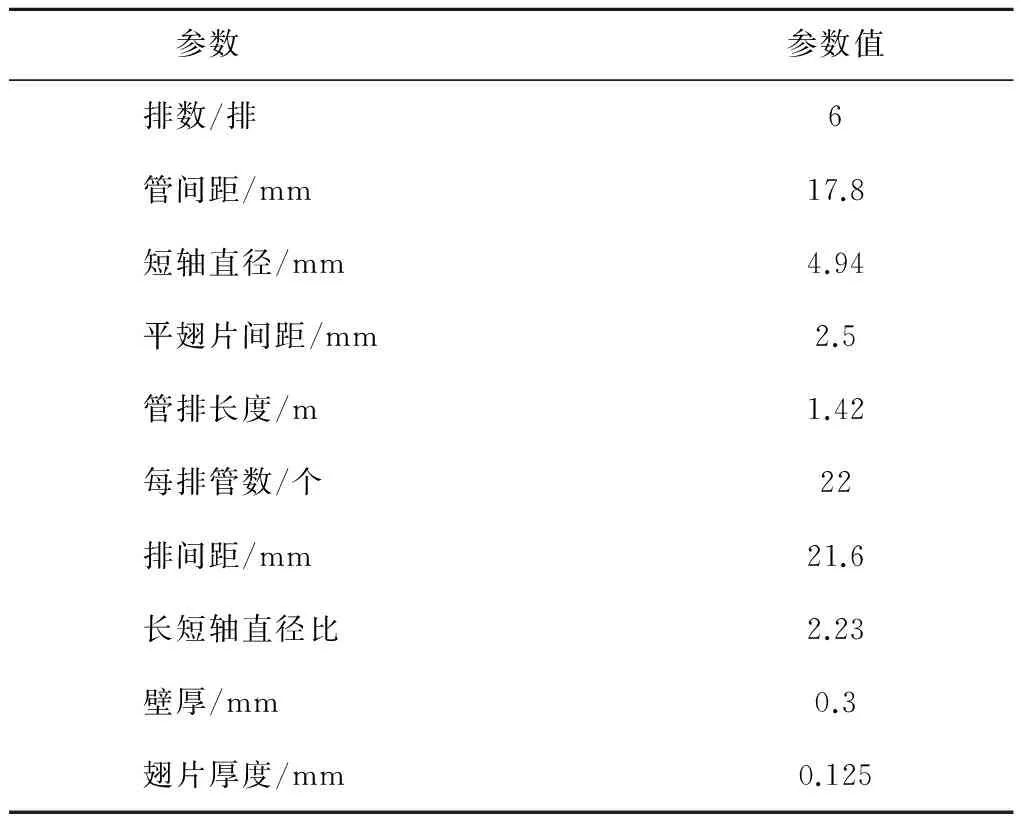

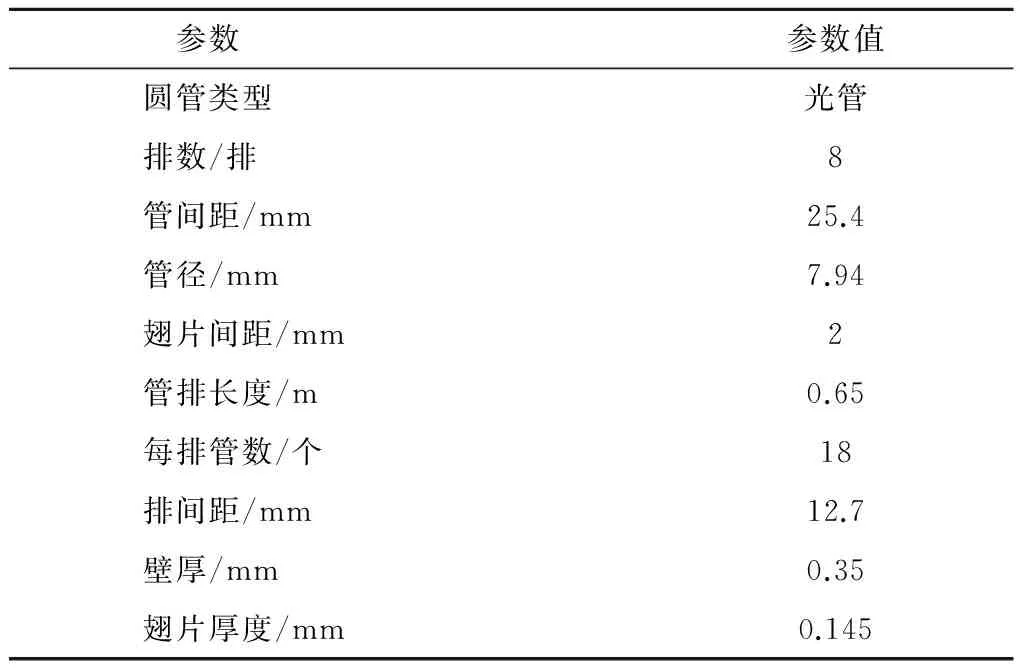

原有的圆管蒸发器设计参数与椭圆管蒸发器设计参数分别如表7、表8所示。

表7 圆管蒸发器设计参数

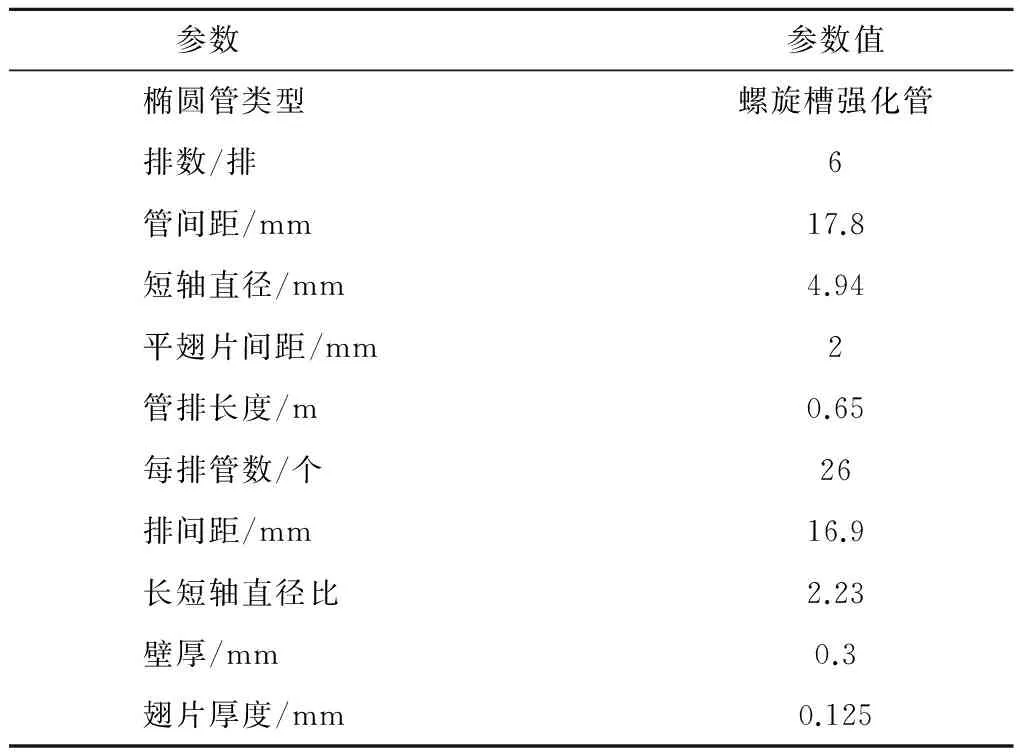

由表8计算可得,在保持蒸发器高度、宽度不变的情况下,采用椭圆管蒸发器,排数可由原来的8排变为6排,每排管数由19增加至26。重新设计换热器流路,椭圆管蒸发器各流路数的换热量如图4所示。可见,26流路时换热量最大。因此,选择26流路下的椭圆管蒸发器。

表8 椭圆管蒸发器设计参数

图4 椭圆管蒸发器各流路数的换热量

表9为原设计与新设计的比较。显然,椭圆管蒸发器换热量有明显提高(+37%),空气侧压降也有下降(-25%)。因此,可根据风机曲线模型对蒸发器侧风机的风量、功耗重新匹配(风量将会增大)。新设计将光管改为强化管,虽然每一流路只走6根管,少于原设计的8根管,但制冷剂侧压降仍为26.6 kPa,高于原设计的12.8 kPa。由于原设计的制冷剂侧压降不大,所以制冷剂压降升高对制冷系统的影响比较小。

3.2 采用椭圆管蒸发器的制冷系统

将原设计中的蒸发器替换为新的椭圆管蒸发器,并匹配相应的风机,对制冷系统进行仿真。原设计与新设计的制冷系统性能对比如表10所示。可见,用椭圆管蒸发器代替圆管蒸发器后,制冷系统性能改善显著,制冷量增加了10.3%,COP提升了7.3%。

表9 原设计和新设计的蒸发器性能参数对比

表10 原设计和新设计的制冷系统性能比较二

4 压缩机重新选型

将冷凝器和蒸发器都替换为椭圆管后,对椭圆管换热器与原设计的圆管换热器相比较,如表11所示。

表11 椭圆管换热器与圆管换热器比较

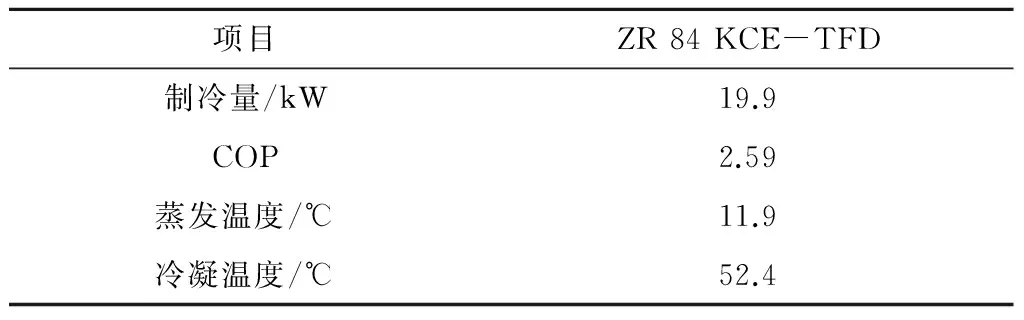

由于冷凝器和蒸发器优化后,制冷量提升了12.6%,因此可以选择小号的压缩机来降低成本。同时,由于压缩机流量减少,换热器的相对换热面积增大,换热温差减小,COP可进一步提升。原设计中压缩机型号为ZR 94 KCE-TFD,现选择小两号的ZR 84 KCE-TFD型压缩机,其性能见表12。

表12 重新选型的椭圆管换热器的压缩机性能表

表12中,小两号压缩机系统COP下降是因为在轨交空调的工况下,ZR 84 KCE-TFD的效率只有ZR 94 KCE-TFD的90%。

5 φ7 mm强化管蒸发器

5.1 强化管蒸发器设计

考虑到椭圆管换热器在生产工艺上的复杂性,本文对地铁列车空调机组蒸发器的优化提出另一种方案:将原有的圆管蒸发器的光管替换为φ7 mm螺旋槽强化管。其具体结构参数如表13所示。

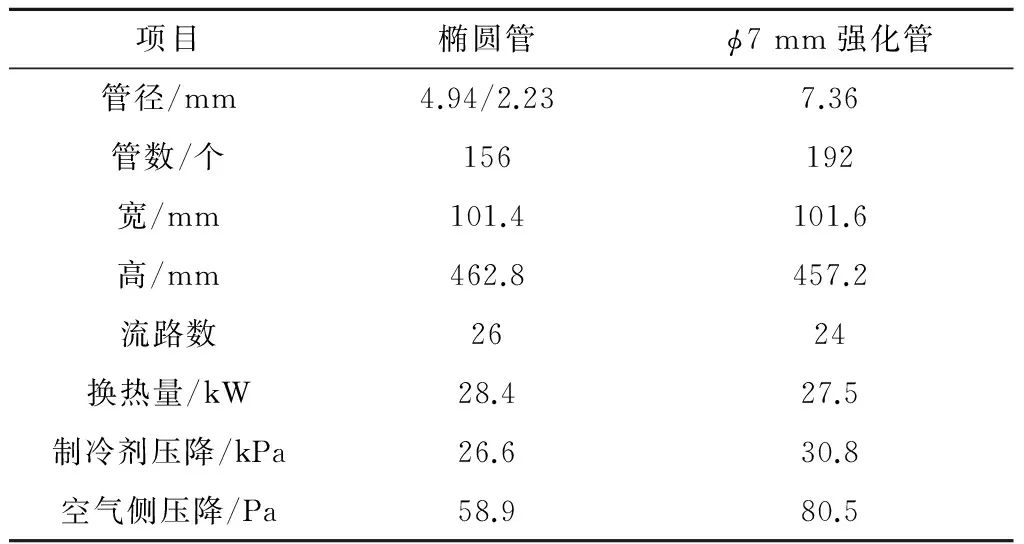

根据表13参数,在保持蒸发器尺寸不变的情况下,每排管数可以由原来的18增加至24,排间距不变,排数不变。重新设计换热器流路,各流路数所对应的换热量如图5所示。由图5可见,24流路时换热量最大,故选择24流路下的强化管蒸发器。

表13 φ7 m强化管蒸发器设计参数

图5 强化管蒸发器各流路数的换热量

将椭圆管蒸发器与φ7 mm强化管蒸发器进行比较,如表14所示。可以看出,φ7 mm强化管蒸发器换热性能与椭圆管蒸发器换热性能接近,但是空气侧压降比椭圆管蒸发器大,与原设计接近,风机风量功耗与原设计保持一致。

5.2 采用强化管蒸发器的制冷系统

将原设计中的蒸发器替换为φ7 mm强化管蒸发器,对制冷系统进行仿真。两种蒸发器优化设计方案比较如表15所示。

表14 蒸发器优化设计比较

表15 蒸发器优化的制冷系统性能比较

在制冷系统中将冷凝器替换为椭圆管冷凝器,两种方案的性能对比如表16所示。

表16 两种换热器优化方案系统性能比较

由表16可知,蒸发器和冷凝器都换为椭圆管是最佳组合;采用椭圆管冷凝器与φ7 mm强化管蒸发器的制冷系统的COP提升也较为显著;制冷量有增长,但不足以换小一号的压缩机(若压缩机换为小一号的ZR 90 K3E-TWD,制冷量将降为19.42 kW)。

6 结语

本文提出了将椭圆管换热器用于地铁列车空调的设想,通过建立仿真模型,对原设计的采用圆管换热器的制冷系统与采用椭圆管冷凝器和椭圆管蒸发器后的制冷系统进行对比。结果表明,采用椭圆管冷凝器,COP提升了6%左右;椭圆管蒸发器代替圆管蒸发器后,制冷量增加了10.3%,COP提升了7.3%;将冷凝器和蒸发器都用椭圆管后,COP提升了12.4%,制冷量提升了12.6%,可以选择小号的压缩机来进一步降低成本。考虑到椭圆管换热器在生产工艺上的复杂性,本文对φ7 mm强化管蒸发器的制冷系统也作了分析,结果表明,采用强化管蒸发器的制冷系统性能也有提高,制冷量提升4.4%,COP提升3.4%,但整体性能不如采用椭圆管蒸发器。综合以上分析,椭圆管换热器应用于地铁列车空调机组中,对制冷系统性能改善显著,对降低地铁列车能耗有重要意义。

[1] 杨亮,高洁,张春路.某地铁列车空调制冷系统的仿真与优化[J].制冷学报,2014,35(6):53.

[2] 章熙民,任泽霈,梅飞鸣.传热学[M].北京:中国建筑工业出版社,2007.

[3] 贾宁,王正烘,杨楚鹏,等.椭圆管换热器在洁净间的应用[J].建筑节能,2015(7):119.

[4] SUN L,YANG L,SHAO L L,et al.Overall thermal performance oriented numerical comparison between elliptical and circular finned-tube condensers[J].International Journal of Thermal Sciences, 2014,89:234.

[5] KIM Nae-Hyun,LEE Kang-Jong,JEONG Yeong-Bin. Airside performance of oval tube heat exchangers having sine wave fins under wet condition[J].Applied Thermal Engineering,2014,66(1-2):580.

[6] HAN H,HE Y L,LI Y S,et al.A numerical study on compact enhanced fin-and-tube heat exchangers with oval and circular tube configurations[J].International Journal of Heat and Mass Transfer,2013,65:686.

[7] 张春路.制冷空调系统通用仿真平台GREATLAB使用手册与实例分析[M].北京:化学工业出版社,2015.

[8] 张春路.制冷空调系统仿真原理与技术[M].北京:化学工业出版社,2012.

(Continued from Special Commentary)

“The 13thFive-Year Plan” works out a more ambitious blueprint for China′s economic and social developments. It points to comprehensively building a moderately prosperous society, achieves the first Centenary Goal, and fully reflects the five development concepts of “innovation, harmonization, green, openness and sharing”. Its main line is the structural reform of the supply front.

In the 25 special columns of “The 13thFive-Year Plan Outline”, the five aspects of technological innovation, structure upgrading, infrastructural facilities, ecological environment and improving people′s livelihood, etc. are involved. Among them, the objective set for rail transit is that within five years, China will improve and perfect the modern integrated transportation system. The main key projects constructions in the rail transport field are described as follows. The high-speed railway mileage in service will reach 30 000 km, linking more than 80% major cities. The intercity railway networks of the urban agglomerations of Beijing-Tianjin-Hebei, the Yangtze River Delta, the Pearl River Delta, the middle reaches of the Yangtze River, the Central Plains, the Chengdu-Chongqing, and the Shandong peninsula will be basically completed. The main skeleton of intercity rail networks of other urban agglomerations will be constructed. The demonstration project of urban areas (suburbs) railways will be implemented. The rail transit networks of super cities and mega cities will be perfected and optimized. The urban rail transit networks of those cities with more than 3 million populations will be sped up to be formed. The additional urban rail transit mileage in service will reach about 3 000 km. “Four ‘Along’s (along coasts/rivers/borders/the Belt and Road) Channels”— The high-speed railways along coasts and along rivers will be basically run-through. The railways along borders, such as the railway from Hetian to Ruoqiang, the railway along the border in Northeast China and the Sichuan-Tibet railway, etc., will be constructed. Push on the constructions of cross-border passageways linking with neighboring countries around China and the passages along “The Belt and Road”. Build the logistics platform of international trains of important node cities, such as Urumqi and Lanzhou. Construct the Shenzhen-Zhongshan Channel (the dual-channel of highway and railway from Shenzhen to Zhongshan, its subject engineering′s being the dual-purpose bridge of highway and railway with more cost-effective). “The 13thFive-Year Plan Outline” also points out that in urbanization areas, intercity railways and urban areas (suburbs) railways should be greatly developed, and using existing railways to run intercity trains should be encouraged, so as to form backbone networks of multi-level rail transit and high-efficiently connect large- medium-small cities and towns. Thus, during the period of “the 13thFive-Year Plan”, the topic words of rail transport development are “perfection and optimization”.

The intercity rail transit constructions are of great significance for advancing the new type of urbanization, the industrial structure adjustment and the technology development of the railway industry itself. The development of the high-speed rail and railway freight will not only greatly promote “the Belt and Road Initiative” constructions, but also improve the capability of independent innovation of China′s railways. Perfecting and optimizing the rail transit networks of mega cities, and speeding up to make the urban rail transit of those cities with more than 3 million people form networks are vitally interrelated with building a harmonious and livable cities and improving the people′s livelihood. “The 13thFive-Year Plan Outline” has indicated the direction and the road for our rail transit field. Our mission is both glorious and arduous. Let us work together to produce a satisfactory answer to the motherland and the people.

(Translated by SUN Zheng)

Application of Oval Tube Heat Exchanger in Air-conditioning Units of Metro Vehicles

LI Jian, JIANG Kui, ZHANG Ziyang, ZHANG Chunlu

The power consumption of air-conditioning units installed in metro vehicles accounts for about 40% of the total traction power, it is important to improve effectively the COP (coefficient of performance) of AC (air-conditioning) units installed in metro vehicles. The application of an oval tube heat exchanger in the AC units of metro vehicles is proposed, and a simulation model is built to compare the system optimized by the oval tube exchanger with the original system. The results show that system COP will be increased by 12.4% and cooling capacity be increased by 12.6% if the oval tube is applied in both evaporator and condenser. Meanwhile, a smaller compressor can be chosen to further reduce the cost. If it maintains the same efficiency, the system COP will be about 2.80, promoted by 19.7%. The system optimized by enhanced heat exchanger tube (7 mm) is analyzed, thus the system COP will also be promoted only one step short of the system with oval tube. The application of oval tube heat exchanger in AC units of metro vehicles results in significant promotion of the system COP and plays a critical role in reducing energy consumption.

metro vehicle; air-conditioning system; oval tube heat exchanger

U 270.38+3

10.16037/j.1007-869x.2016.04.024

2015-11-19)