Engineering the Smart Factory

2016-12-09HarrisonRobertVERADanielandAHMADBilal

Harrison Robert, VERA Daniel, and AHMAD Bilal

Engineering the Smart Factory

Harrison Robert, VERA Daniel, and AHMAD Bilal

The fourth industrial revolution promises to create what has been called the smart factory. The vision is that within such modular structured smart factories, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralised decisions. This paper provides a view of this initiative from an automation systems perspective. In this context it considers how future automation systems might be effectively configured and supported through their lifecycles and how integration, application modelling, visualisation and reuse of such systems might be best achieved. The paper briefly describes limitations in current engineering methods, and new emerging approaches including the cyber physical systems (CPS) engineering tools being developed by the automation systems group (ASG) at Warwick Manufacturing Group, University of Warwick, UK.

index terms—smart factory, Industry 4.0, automation systems, cyber-physical systems, engineering, lifecycle

1 Introduction

Current automation systems engineering methods are frequently criticised, e.g., for poorly supporting reuse and their inability to effectively validate automation solutions across supply chains. There is also poor integration between real system and virtual system representations, which need to be closely integrated throughout the automation system lifecycle from specification and design through commissioning, validation, operation and reuse of systems.

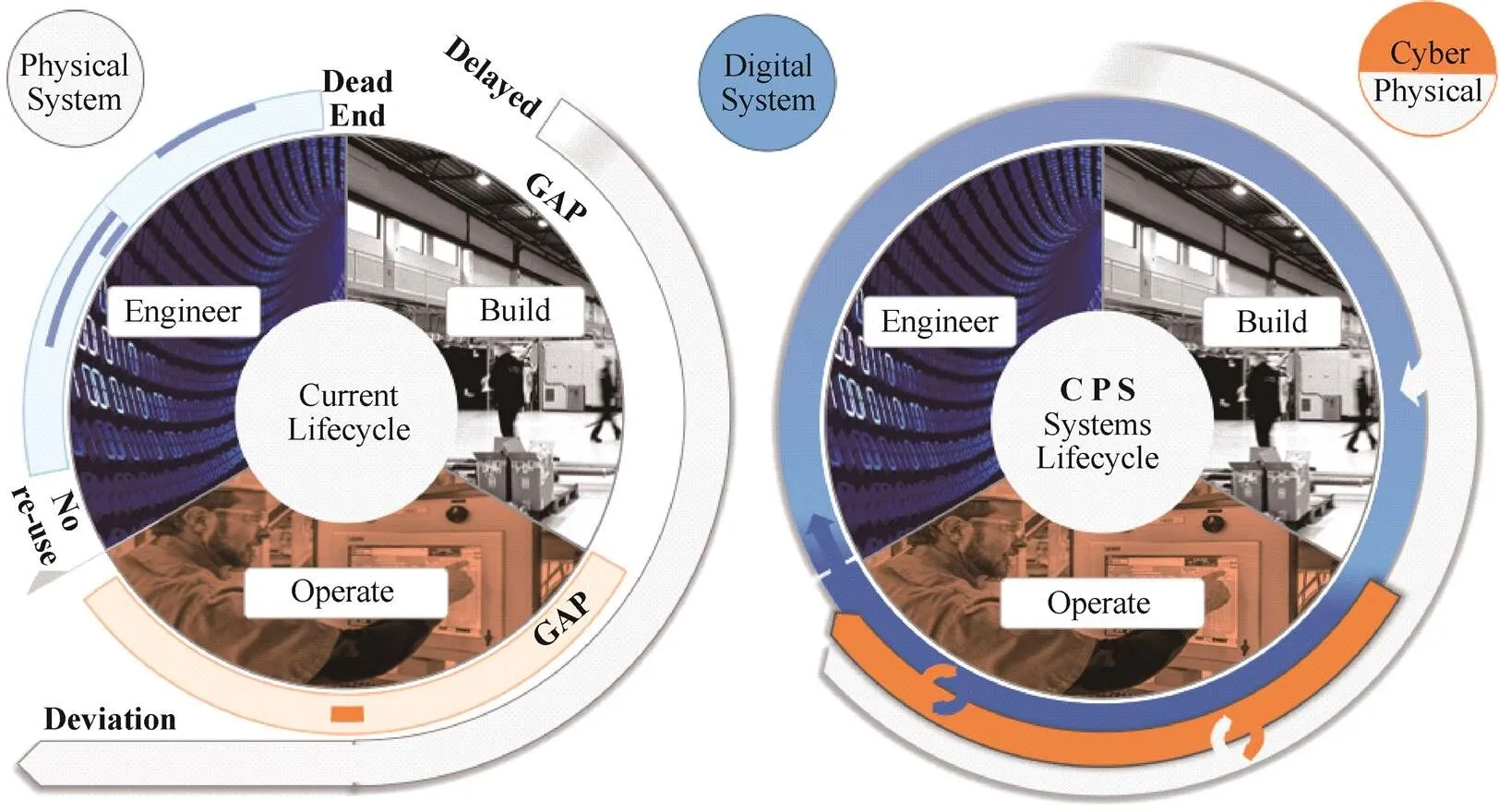

The left-hand side of Fig. 1 shows a typical example of the current system lifecycle. The engineering process is disjointed, and there are gaps between the various digital models of system aspects. The majority of current tools are vendor-specific and support largely closed control environments. They generally offer good point-solution functionality, are well supported and can deliver robust operational systems, but with limited agility. These factors lead to delays and ultimately to poor lifecycle uses of information, and lessons learned are not fed back to subsequent iterations of the system. There is typically poor reuse, and systems often lack commonality, needlessly deviating from a common standard. The right-hand side of Fig. 1 shows a vision of the CPS system’s lifecycle where the engineering build and operational phases are seamlessly integrated. Lessons learned are fed back into subsequent refinements of the system. The cyber and physical aspects are seamlessly integrated with the digital model continuously updated to and from the physical system.

Cyber physical systems are distributed, heterogeneous systems connected via networks, and usually associated with the concept of the Internet of Things (IoT)[1]. The increasing availability and use of distributed industrial CPS devices and systems could radically change the nature of manufacturing and provide new opportunities to develop more effective, finer grained and self-configuring automation systems. A closely associated initiative is the Industry 4.0 platform, a specialisation within the IoT and Services, it facilitates the vision of the smart factory where CPS monitor physical processes, create a virtual copy of the physical world and make decentralised decisions[2].

Realising CPS for industrial automation implies the need for engineering tools capable of supporting distributed systems and is coupled to a major shift in emphasis from traditional monolithic, specialism-based, isolated engineering tools and methods towards integrated, Cloud-based tool/system infrastructures based around an Internet of Services and associated data. CPS also implies a combination of physical and virtual representations where physical devices and functionality are represented in data form and can be visualised virtually with the data model maintained in correspondence to the physical system throughout their lifecycle.

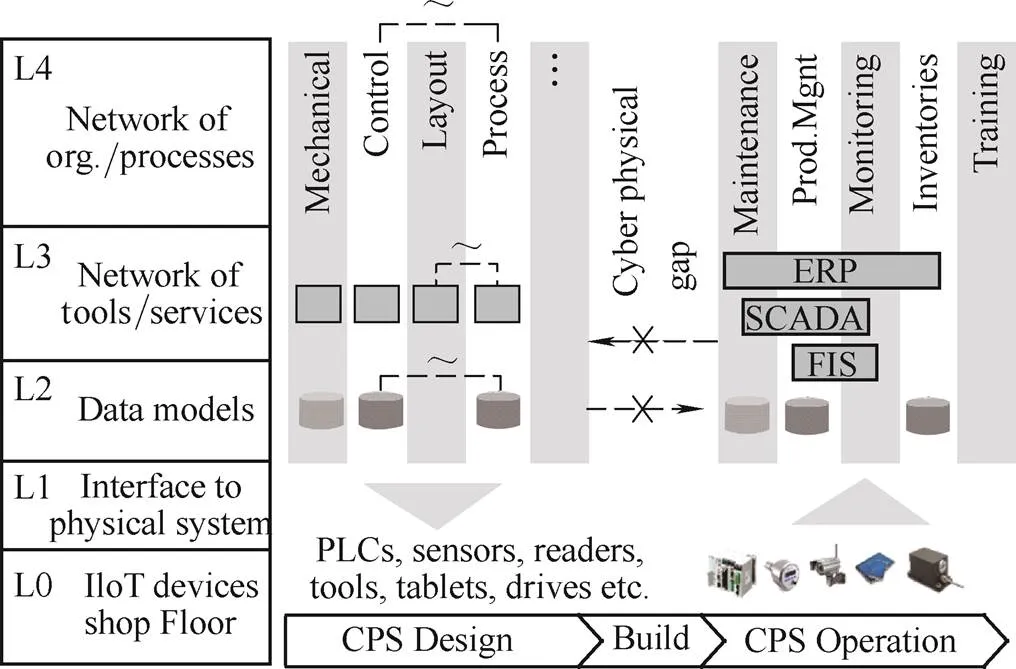

Fig. 2 shows conceptually how in a CPS context the virtual engineering of a manufacturing system can be related to its physical implementation through the design and build phases and how subsequent run-time optimization can be achieved through feeding back information related to the product, process and production resources. An approach that supports a common distributed engineering model is important so that knowledge can be captured and engineering reuse facilitated.

Fig. 1. Current state and future vision for the smart factory lifecycle

Fig. 2. Virtual engineering related to physical implementation in a CPS context

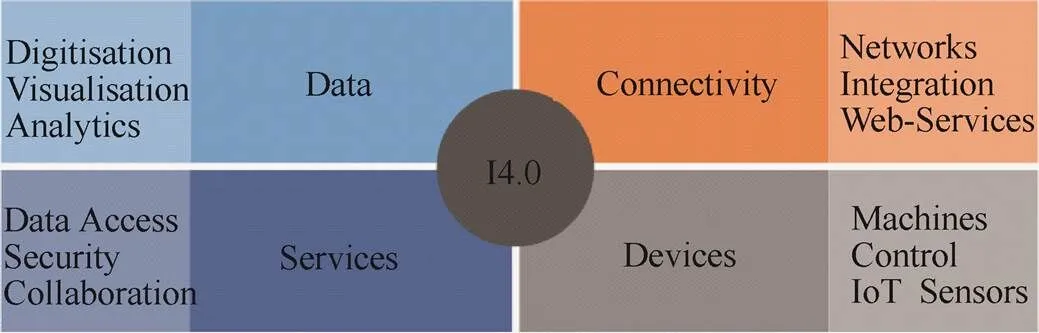

2 Enablers for the Smart Factor

A reference architecture is a general model that provides a framework for the structuring, development, integration and operation of systems[4]. The Industry 4.0 Reference Architecture model is very broad in that it aims to permit homogeneous consideration of the product to be manufactured and the production facility, with their interdependencies. The adoption of a component-based approach is at the heart of the recently published RAMI reference model of Industry 4.0, which features logically nestable components[2]. Four key aspects of Industry 4.0 are highlighted in Fig. 3, namely, the devices which compose the system, the connectivity to enable their integration, well targeted services, and appropriate data, e.g., as a foundation for digitisation, visualisation and analytics.

Fig. 3. Key underlining aspects of Industry 4.0

From a connectivity perspective, industrial communication systems, such as a suitable fieldbus or industrial Ethernet, are available to establish communication among the distributed components. In the vision of CPS every component (be it for control, business or engineering functionality) is potentially able to interact with any other component. This enables a strong horizontal and vertical integration not only within automation systems and their associated machine/system builders, but also more widely to enable integration and collaboration across the supply chain and throughout the lifecycle. For realising such an automation network, the question arises of how this communication is provided with high interoperability[5].

In terms of device connectivity, the factory of the future will be heavily based on Internet and Web technologies and as devices become able to natively offer Web services, they will provide an interoperability layer that leads to easier coupling with other components despite of the high heterogeneity. Device profile for Web services (DPWS)[6], OPC-UA[7]and representational state transfer (REST) are three of the emerging technologies for realising Web service-enabled device connectivity[8–12].

Data exchange among mechanical plant engineering, electrical design, process engineering, process control engineering, HMI development, PLC programming and other engineering tools is currently difficult[3]. Furthermore, from a lifecycle perspective, there are significant gaps in the consistent use of information throughout the lifecycle phases, and although the concept of the smart factory is well understood where consistency between physical and virtual representations of production systems would be maintained at all lifecycle phases, in reality a largely fragmented information modelling environment currently exists. AutomationML (AML) is a promising neutral data format based on XML for the storage and exchange of plant engineering information modules, to interconnect heterogeneous engineering tools from different fields, e.g., mechanical plant engineering, electrical design and PLC systems. AML is essentially combination of existing standard data formats for the storage of different aspects of engineering information.

3 ASG Engineering Environment: vueOne

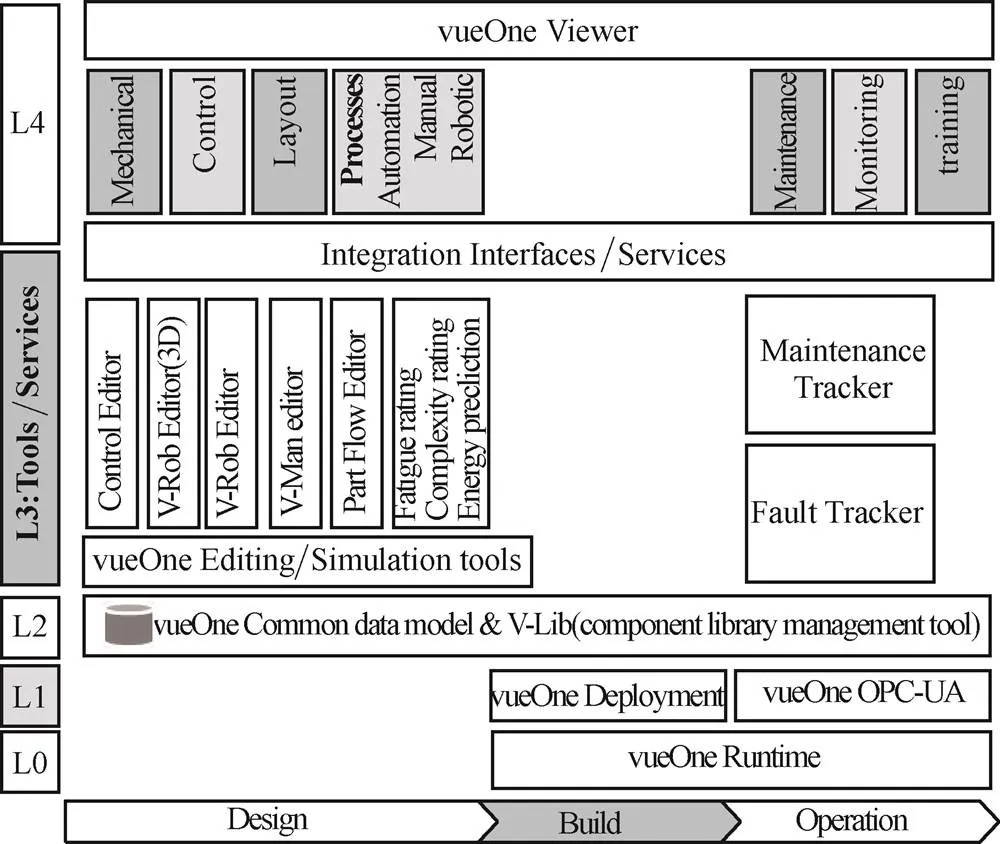

The ASG is focusing on the design and implementation of automation systems engineering tools and methods adapted to the specific nature of CPS in particular, and that contribute more generally to achieving the goals of Industry 4.0 on the KDCM, Arrowhead and 3Deployment projects, see Acknowledgements section. The ASG’s research is delivering an engineering software environment, called vueOne, part of which is currently being used to support Ford’s virtual engineering activity in powertrain assembly in the UK. vueOne is now also being used to support engineering of battery and electric motormake-like-production systems in partnership with a range of automation companies.

Fig. 4 provides a descriptive framework for introducing the ASG’s research. It illustrates the general architecture of the systems engineering environment and highlights the main functionalities to support key phases of the automation systems lifecycle. A layered representation is used. The top level relates to organizations within the supply chain and engineers within departments. The left part of Fig. 4 relates to system design with stakeholders feeding data models related to specific aspects of automation systems, e.g., for layout, mechanical engineering, control systems, and process and product definition through the use of domain- or user-specific representations associated with particular engineering tools or services. Each data model is then deployed at the physical level to achieve mechanical build, machine programming, and production system configuration. The operational phase of the system is shown on the right-hand side of Fig. 4. Information generated by the production system is either fed back to the machine controllers themselves or propagated to higher levels of engineering support, analysis, and management.

Fig. 4 also serves to highlight gaps in the engineering process, in particular where fragmented data models, incompatible software environments, and poor communication and collaboration between engineering organizations exist. In particular, there is a large disconnect between the design and operational phases of production systems.

Fig.4. Industry 4.0 oriented engineering framework

Industry 4.0 and other CPS paradigms rely largely on seamless connectivity and interfacing between organisations and people, computational resources (e.g., databases and application servers), software environments, shop floor level devices, sensors and mobile devices[4]. The vueOne engineering environment design is based on three types of conceptually defined interfaces: a) organisation level interfaces enabling communication of information between engineers within or across organisations, b) software level connectivity allowing exchange of data between engineering tools, and c) cyber to physical environment connectivity which focus on the configuration and connectivity with components on PLC-based control or embedded devices.

Fig.5. vueOne engineering environment overview

4 Demonstrating the Smart Factory

A key aspect of the approach adopted at WMG is forming a pipeline to progressively develop and then maximize the impact of innovative automation systems. The approach shown conceptually in Fig. 7 is to develop proof-of-concept systems from bench-top demonstrators through full-scale pilot implementations to make-like production lines and ultimately to factory installation, working closely with industry partners at all phases of this activity.

Fig. 6. An example of common data model usage across the lifecycle

Fig. 7. Pipeline to progressively develop and maximize the impact of innovative systems

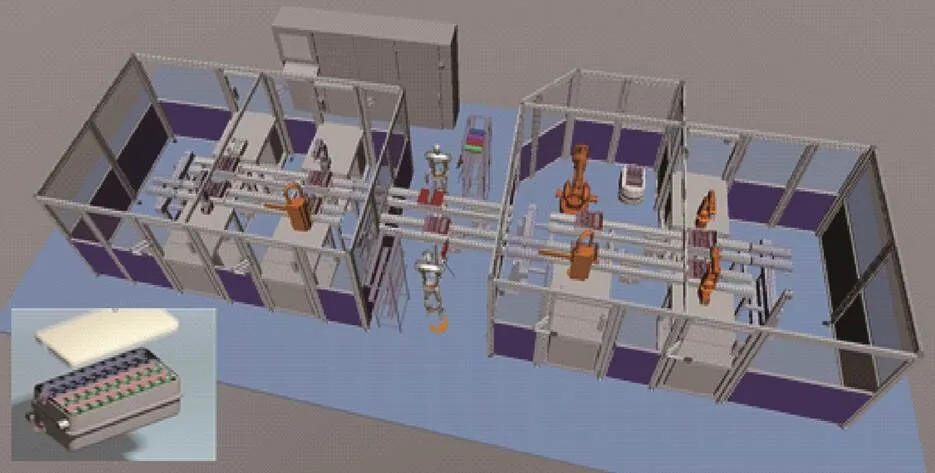

A full-scale automation system workbench (ASW) is installed at WMG to support the research and development activities of ASG (see Fig. 8). It is a modular and reconfigurable system and hence the application can be progressively changed as new requirements emerge. Machine stations can be exchanged physically and also virtually, i.e., new virtual stations model can be swapped in (and out) in place of physical stations.

Fig. 8. Automation system workbench (ASW)

The ASW features state-of-the-art control system and automation equipment from leading vendors, e.g., Siemens, Bosch-Rexroth, Rockwell Automation, ABB, Schneider Electric, Mitsubishi, Festo, and SMC. The system has been implemented to support the latest control system design and programming standards. The ASW aims to provide a full-scale demonstrator for new manufacturing automation methods, tools and technologies with the objective to support the entire lifecycle, e.g., enabling the digital validation, verification and visualisation, control code generation and cloud-based engineering services. The ASW is also used with industrial collaborators (e.g., JLR, Ford and their supply chains) for demonstration of product assembly. The ASW is currently configured to carry out a battery sub-module assembly demonstration as a part of an Innovate UK project. The product assembly consists of 18 650 form-factor cylindrical cells to be assembled into a sub-module incorporating bus-bars and an integrated cooling system.

5 Conclusion and Future Work

This paper has reviewed some of the common limitations in present automation systems engineering and considered what capabilities are needed for future smart factory systems engineering. The tools being implemented by the Automation Systems Group at WMG have been used as examples of solutions providing an integrated engineering environment with a common data model extending across lifecycle phases. Future research will apply and evaluate this approach across a range of applications and also focus on increasing the openness of the approach as standards related to Industry 4.0 become more mature.

The author gratefully acknowledges the support for this work from UK EPSRC, through the Knowledge-Driven Configurable Manufacturing (KDCM) research project under the Flexible and Reconfigurable Manufacturing Initiative, from Innovate UK on the Direct Digital Deployment project, and from ARTEMIS on the Arrowhead project.

[1] IEEE. Cyber physical systems: Design challenges[C]//Orlando, FL,USA, 5–7 May, 2008: 363–369.

[2] VDI/VDE Society. Reference Architecture Model Industrie 4.0 (RAMI4.0): Status Report[R/OL]. (2016-06-01). http://www.zvei.org/Downloads/Automation/5305%20Publikation%20GMA%20Status%20Report%20ZVEI%20Reference%20Architecture%20Model.pdf.

[3] AICHER T, SCHUTZD, VOGEL-HEUSERB. Consistent engineering information model for mechatronic components in production automation engineering[C]//, Dallas, TX, USA, 29 Oct–1 Nov, 2014: 2532–2537.

[4] Industrie 4.0 Working Group.[R/OL]. (2016-06-01) National Academy of Science and Engineering of Germany, 2013. http://www.acatech.de/.../Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf on 1 June 2016.

[5] ZÜHLKED OLLINGERL. Agile automation systems based on cyber-physical systems and service-oriented architectures[J]., 2012, 1: 567–574.

[6] JAMMESF MENSCHA, SMIT H. Service-oriented device communications using the devices profile for web services[C]//, Grenoble, France, Nov 28–2 Dec, 2005: 1–8.

[7] MAHNKEW, LEITNER SH, DAMMM.[M]. Springer, 2009.

[8] KARNOUSKOSS, SAVIOD, SPIESSP, et al. Real-world service interaction with enterprise systems in dynamic manufacturing environments[M]., Springer, 2010: 423–457.

[9] DELAMERIM, LASTRAJLM. Loosely-coupled automation systems using device-level SOA[C]//, Vienna, Austria, 23–27 Jul., 2007: 743–748.

[10] OPC Foundation. Interoperability for Indsutrie 4.0 and the Internet of Things[R/OL]. [2014-05-21]. (2016-06-01). https://opcfoundation.org/wp-content/uploads/2016/05/OPC-UA-Interoperability-For-Industrie4-and-IoT-EN-v5.pdf.

[11] IZAGUIRREM J A G, LOBOVA, LASTRAJ L M.OPC-UA and DPWS interoperability for factory floor monitoring using complex event processing[C]//Lisbon, Portugal, 26–29 July, 2011: 205–211.

[12] XU X. From cloud computing to cloud manufacturing[J]., 2012, 28(1): 75–86.

[13] HARRISONR, VERAD, AHMADB. Engineering methods and tools for cyber–physical automation systems[J].2016, 104(5): 973–985.

[14] KONG X, AHMAD B, HARRISON R, et al. Realising the open virtual commissioning of modular automation systems[C]//, Athens, Greece, 28–30 Sep., 2011: paper No. 45.

Biographical notes

HARRISON Robert, is a professor of Automation Systems atand Head of the Automations Systems Group at WMG, with a research focus in the areas of smart factories, systems engineering and industrial automation. The Automation Systems Group, a team of around 25 researchers are undertaking internationally leading research into new generations of pilot production systems, advanced automation systems and associated lifecycle support tools for manufacturing automation. Prof. HARRISON’S research interests include manufacturing automation from the business, technical and social perspectives, and virtual engineering tools and related engineering services, particularly within the automotive and aerospace sectors. He is the author of around 150 peer-reviewed international journal and conference papers and gives frequent national and international presentations in academic and commercial contexts.

E-mail: Robert.Harrison@warwick.ac.uk

VERA Daniel is currently a Senior Research Fellow at the. Daniel has a PhD (use of VR technologies to support virtual planning and validation of engine assembly processes), which was followed by more than 12 years of experience in the design, development and deployment of digital solutions to support the mechanical and manufacturing engineering industry. Dr. Vera is author of over 20 international peer-reviewed international journal and conference publications, and his search currently focuses on the practical implementation of Industry 4.0 concept and the deployment of technologies to practically support Cyber Physical System Lifecycle.

AHMAD Bilal received the M.Sc. degree in Mechatronics and the Ph.D. degree in Automation Systems from. Dr Ahmad is working as a Senior Research Fellow at. His research interests are in the area of industrial automation and controls engineering. He has worked on a number of projects in collaboration with automotive manufacturers, machine builders and control vendors to develop tools and methods to support lifecycle engineering of industrial automation systems. He has previously worked as a Research Associate and University Teacher at.

© Chinese Mechanical Engineering Society and Springer-Verlag Berlin Heidelberg 2016

Received July 5, 2016; revised September 1, 2016; accepted September 8, 2016

10.3901/CJME.2016.0908.109, available online at www.springerlink.com; www.cjmenet.com

E-mail: Robert.Harrison@warwick.ac.uk

杂志排行

Chinese Journal of Mechanical Engineering的其它文章

- Surface Topography and Roughness of High-speed Milled AlMn1Cu

- Exploring Local Regularities for 3D Object Recognition

- Exploring Barriers and Opportunities in Adopting Crowdsourcing Based New Product Development in Manufacturing SMEs

- Development of the Supply Chain Oriented Quality Assurance System for Aerospace Manufacturing SMEs and Its Implementation Perspectives

- Collaborative Simulation Method with Spatiotemporal Synchronization Process Control

- Simulation Based Energy-resource Efficient Manufacturing Integrated with In-process Virtual Management