Structural,Magnetic and Optical Properties of BiFe1−xNbxO3

2016-11-24DatedReceivedonMarch292016AcceptedonMay182016

(Dated:Received on March 29,2016;Accepted on May 18,2016)

Structural,Magnetic and Optical Properties of BiFe1−xNbxO3

(Dated:Received on March 29,2016;Accepted on May 18,2016)

Nb doped multiferroic BiFe1−xNbxO3(0<x<0.05)polycrystalline powders have been synthesized by using a sol-gel method.The effect of Nb dopant on the structural,magnetic and optical properties is investigated.According to the X-ray diffraction data and the result of Rietveld refinement,all the samples maintain the R3c phase,while the lattice parameters a,c,the cell volume V and the Fe−O−Fe bond angle change.The remnant magnetization enhances by appropriate Nb doping due to the decreasing of the grain size.Meanwhile,Nb dopant leads to the narrowing of the band gap of BiFe1−xNbxO3samples.

Bismuth ferrite,Crystal structure,Magnetic property,Band gap

I.INTRODUCTION

In the last decade,multiferroic materials have attracted great attention because of their magnetoelectric coupling between the(anti)ferromagnetism, (anti)ferroelectricity and(anti)ferroelasticity and the potential applications in spintronics and information storages[1−3]. Among multiferroic materials,bismuth ferrite(BiFeO3)is one of the most extensively studied multiferroic materials with high ferroelectricity transition temperature(TC≈1100 K)and antiferromagnetism N´eel temperature(TN≈643 K)[4].Besides,BiFeO3is a semiconductor,band gap of 2.16 eV, characterized as distorted perovskite-like rhombohedral structure with the space group R3c[5]. The shift of Bi3+ascribed to the stereochemically active Bi 6s2lone pair induces the ferroelectricity with large polarization about 100µC/cm2[6,7].Meanwhile,due to the Dzyaloshinskii-Moriya interactions[8],a long range cycloidal spiral spin structure along the[110]hexdirection with a period of 62−64 nm superposes on a G type antiferromagnetic structures[9,10].However,the large leakage current density caused by charge defects and the weak magnetic property induced by the spacemodulated spin structure limit its applications.

Chemical doping is an effective method to modify the crystal and the spin structures and improve the magnetoelectric properties of BiFeO3[11−13].Substitution of Bi3+with trivalent cations of rare earth elements can suppress the formation of iron rich phases,such as Bi2Fe4O9,and increase the remanent electrical polarization[14].The partial substituting of Fe3+site with aliovalent cations of Ti4+and Zn2+can effectively decrease the leakage current[15].Moreover,cationic substitution of Bi3+and Fe3+can also induce the so called“chemical pressure”,which leads to a significant structural distortion and enhances the magnetic property[16−18].

Nb doped BiFeO3attracts many researchers'attention,because it can be a good promotion in the ferroelectric properties.Singh and Yadav suggested that the magnetic enhancement in Nb doped BiFeO3ceramics was due to the coexistence of Fe2+/Fe3+[19],while Jun et al.proposed that the origin of the magnetic increase was the canting of the antiferromagnetically ordered spins by a structural distortion[20].Godara and Kumar fabricated the Ba and Nb codoped BiFeO3nanoparticles and non-specifically considered that the magnetic enhancement was related to Fe−O−Fe bond angle and the uncompensated spins on surface of nanosized particles[21].Cheng et al.investigated the La and Nb codoped BiFeO3thin films and attributed the magnetic moment enhance to the doping of La[14]. Although reasonable mechanisms for the magnetic enhancement had been proposed,experimental evidences were still absent.In this work,we synthesize Nb doped BiFeO3nanoparticles by a sol-gel method and investigate the structural,magnetic and optical properties in detail.

II.EXPERIMENTS

Polycrystalline BiFe1−xNbxO3(0≤x≤0.05)powders were prepared by a sol-gel method. Stoichiometric amounts of Bi(NO3)3·5H2O,Fe(NO3)3·9H2O and niobium oxalate were dissolved in dilute nitric acid.And calculated amounts of tartaric acid were added as a complexing agent.The resultant solution was dried at 150°C with continuous stirring and grinded in an agate mortar to obtain xerogel powders.The xerogel powders were preheated to 300°C for 1 h to remove excess hydrocarbons and NOximpurities and annealedat 600°C for 2 h.The X-ray diffraction patterns were examined by a Bruker D8 ADVANCE X-ray diffractometer with Cu Kα radiation(λ=1.5418˚A,Ni filter) with the scanning rate of 0.6°/min in a step size of 0.02°.Field effect scanning electron microscopy(Nova NanoSEM430)was used to study morphology of the samples.X-ray photoelectron spectra(XPS)were collected by a Kratos Axis Ultra DLD photoelectron spectrometer with Al Kα source(hν=1486.6 eV,with power setting of 10 mA×12 kV)in a vacuum of 7×10−7Pa. Magnetic hysteresis loops were carried out on a vibrating sample magnetometer(VSM)in a physical property measurement system(PPMS,Quantum Design).The UV-Visible(UV-Vis)absorption spectra over a range of 350−800 nm wavelength were measured by an Ocean Optical Fiber Spectrometer(USB4000).

∗Author to whom correspondence should be addressed.E-mail: xichen@scut.edu.cn.

FIG.1 X-ray diffraction pattern of BiFe1-xNbxO3at room temperature.The inset depicts the fusion of(104)and(110) peaks.The intensities are normalized for plotting.

III.RESULTS AND DISCUSSION

Figure 1 reveals the XRD patterns of all samples.No trace of any impurity phases appears,which indicates a single phase of the samples.The XRD patterns of pure BiFeO3could be labeled in a rhombohedral perovskite structure with R3c phase.With the increasing of Nb doping concentration x,the(104)and(110)peaks tend to merge together when x≤0.01 as shown in the inset of Fig.1.Similar fusions also appear between(006)and (202),(116)and(112),(018)and(300),(208)and(220) peaks.When x>0.01,the(104)and(110)peaks have been fully integrated into a single peak.It is hard to conclude that Nb substitution for Fe in BiFeO3has affected the structural transition of the parent compound, since the fusion of(104)and(110)peaks is very common in the BiFeO3nanoparticles due to the decreasing of the particle size[22].

To clarify the reason of the fusion of(104)and(110) peaks,we first use the Debye-Scherrer formula Eq.(1) to calculate the average grain sizes D of the samples.

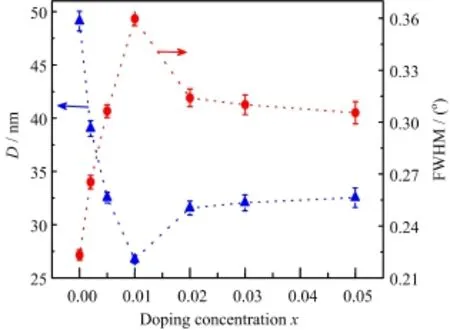

FIG.2 The FWHM and the average grain size D as the functions of the doping concentration x.

where K is a constant usually taking the value of 0.89 for XRD,γ is X-ray wavelength,and B is the full width at half maximum(FWHM)of the diffraction peak at the diffraction angle 2θ.With an increasing x,the average grain size D decreases rapidly when x≤0.01 and slowly increases as x>0.01 as shown in Fig.2.Obviously the fusion of the diffraction peaks is mainly related to the decreasing of the average grain sizes.

The trend of D and FWHM are further supported by FESEM characterization.The surface microstructures of different Nb doped BiFeO3compositions are shown in Fig.3.Well developed particles can be observed in all the samples.The shapes of all particles are roughly spheroidal and only some of them are irregular and agglomerated.The average particle size of pure BiFeO3is about 150−250 nm,while it decreases with the increasing doped Nb concentration x.The smallest particle size about 50 nm appears at x=0.01 and the particles agglomerate because of the high surface energy[23].The reduction in the particle size could be attributed to the addition of aliovalent Nb ions into the BiFeO3lattice,which could inhibit grain growth.The phenomenon that the particle size firstly decreases and then increases in the Nb doped ceramics[19].

To investigate the crystal structure of the Nb doped samples in detail,we perform the Rietveld refinement to analysis the XRD patterns with GSAS program.For all samples,R3c phase is used and the Rietveld refinement factors Rwpare less than 0.055 and χ2are approximately equal to 2.0.This indicates that using R3c phase to fit the XRD data is very consistent.For the samples with x>0.01,other typical doped BiFeO3phases like Pbnm and Pm3m phases[4]are also checked.However, the refinement results based on these phases are not better than the result on R3c phase.Figure 4 presents thebest refinement results of the BiFe1−xNbxO3(x=0.00, 0.01,0.03,0.05),respectively.Although some diffraction peaks of the samples(x>0.01)merge with the adjacent peaks,the crystal structures maintain the rhombohedral perovskite structure with R3c phase.Similar results are also observed in Ca doped BiFeO3nanoparticles[22].

FIG.3 FESEM images of BiFe1-xNbxO3(x=0.00,0.002,0.01,0.02,0.03,0.05).

FIG.4 The rietveld-refined XRD pattern of BiFe1-xNbxO3.(a)x=0.00,Rwp=0.0529,χ2=2.092,a=0.55871(3)nm, c=1.38860(7)nm.(b)x=0.01,Rwp=0.0535,χ2=1.956,a=0.55963(7)nm,c=1.38642(6)nm.(c)x=0.03,Rwp=0.0547, χ2=2.002,a=0.56124(9)nm,c=1.38403(2)nm.(d)x=0.05,Rwp=0.0530,χ2=1.989,a=0.56072(6)nm,c=1.38438(6)nm.

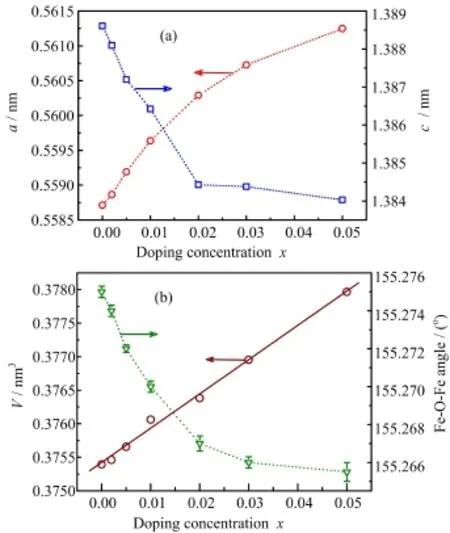

FIG.5 The Nb doping concentration x dependence of(a) the lattice parameters a,c,and(b)the cell volume V,the Fe-O-Fe bond angle of the R3clattices.

Figure 5 demonstrates the lattice parameters a,c, the cell volume V and Fe−O−Fe bond angle as a function of the Nb concentration x.The evolution of the lattice parameters again confesses us to the fact that Nb has been a good substitution for Fe in the crystal lattice.As illustrated in the Fig.5(a),the lattice parameter c exhibits a trend of linear decrease in the range of x≤0.02 and then slightly decreases with the further increase of x.On the other hand,the lattice parameter a increases as Nb concentration x increases.The cell volume V increases almost linearly with the doping concentration x shown in Fig.5(b).The increase of the cell volume V(0.7%for x=0.05)suggests that not only Nb5+with the ionic radius r=0.0640 nm but also Nb4+with r=0.0680 nm are involved to replace Fe3+with r=0.0645 nm.The Fe−O−Fe bond angle decreases with x increasing similarly to the lattice parameter c. Compared to pure BiFeO3,the Fe−O−Fe bond angle of the sample with x=0.05 decreases 0.009(5)°in total. Similar relationship between the Fe−O−Fe bond angle and the lattice parameter c was also reported in the Ca doped nanoparticles[22].

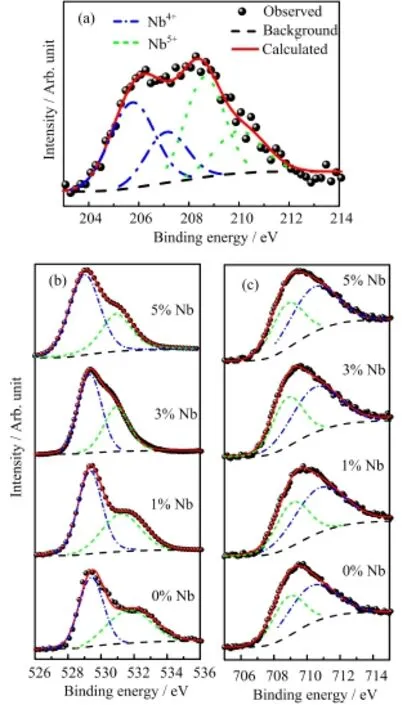

FIG.6(a)Nb XPS spectra of the BiFe0.95Nb0.05O3.(b) Typical O 1s and(c)decomposed Fe 2p XPS spectra of BiFe1-xNbxO3.(x=0.00,0.01,0.03,0.05).The core level binding energies were aligned with respect to C1s peak (284.6 eV).

In order to observe the valence state of Nb in the samples,the XPS was applied to the samples and the result is illustrated in Fig.6(a).The binding energy of Nb 3d spectrum can be deconvolutionized into two doublet peaks of 3d5/2and 3d3/2,which are located at 205.7, and 207.1,208.6,and 210 eV,corresponding to NbO2and Nb2O5respectively[24].The XPS peaks separation between two doublet is 1.4 eV and intensity ratio is about 3:2,which can be attributed to 2J+1 splitting pattern for Nb.This confirms the coexistence of Nb4+and Nb5+as we suggested above.

The O 1s XPS peak can be fitted with two Gaussians curves,whose peaks positions are near 529.1 and 530.5 eV displaying in the Fig.6(b).The lower binding energy peak corresponds to the crystal O ions and the higher binding energy peak can be attributed to the oxygen vacancy(VO)[22].As confirmed by the XPS patterns,the oxygen vacancies(VO)are presented and reduce with Nb concentration.The doping of high-valence cations can depress the oxygen vacancies which has been reported in Ti4+and Nb5+doped BiFeO3samples[15,19].According to the results calculated by XPS data,the ratio of Fe3+to Fe2+of BiFe0.95Nb0.05O3is 1.4(4),which is nearly the same as pure BiFeO31.4(5), as displayed in the Fig.6(c).The constant ratio of Fe3+to Fe2+indicates that the Nb doping does not cause the variation of the valence state of Fe ion.

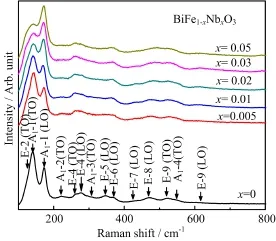

Raman scattering spectra can be used to study the vibrational properties of BiFeO3,which is sensitive to the structure distortions.Based on group theory,there are 13 Raman active modes of the rhombohedral with the space group R3c:Γ=4A1+9E.Since each mode can be divided into longitude and transverse modes(LO and TO modes),26 modes are expected[25].According to calculations,the low frequency Raman vibrational modes of E-2(TO),A1-1(TO),A1-1(LO)are perceived as closely relative with the covalent Bi−O bonds [26],while the high frequency region of the E modes are closely linked to the vibrations of Fe−O bonds [27].The room temperature Raman spectra for the BiFe1−xNbxO3samples are illustrated in Fig.7.The assignment of the vibration modes is based on Ref.[28]. Since Nb doping does not cause significant changes in the crystal structure of BiFeO3(the increase of cell volume V is 0.7%for x=0.05),the Raman vibration modes do not have any observable shifts in our samples.The peak intensity of A1-1(LO)Raman peak at 172 cm−1increases rapidly with the increasing concentration x of Nb.However,the A1-1(TO)mode at 140 cm−1gets weaker gradually with increasing x.E-2(TO)Raman peak of pure BiFeO3is not prominent and difficult to be observed while it appears when x≥0.03.It is known that the variation in the intensity of the Raman vibration mode is related to the electronic polarizability.The remarkable intensity variations of E-2(TO),A1-1(TO), A1-1(LO)modes reveal the significant redistributions of the electronic cloud in Bi−O bond with Nb doping[29]. Meanwhile,the A1-1(LO)Raman peak is overlapping with Bi off-center displacement induced by the activation of Bi6s2lone pair.The variation of the A1-1(LO) mode with Nb dopant leads to displacement of Bi,which might affect the ferroelectric properties of BiFeO3[28].

FIG.7 RamanscatteringspectraforBiFe1-xNbxO3(0≤x≤0.05)at room temperature.

FIG. 8 Selected magnetic hysteresis loops for BiFe1-xNbxO3at room temperature. The inset(a) shows the variation of the remanent magnetization Mrwith the doping concentration x. The inset(b)presents the relationship between the remanent magnetization Mrand FWHM.The straight line in the inset(b)is a linear fitting line of the data.

The hysteresis loops of the BiFe1−xNbxO3specimens are measured at room temperature with maximum magnetic field of 7T and selected curves(x=0,0.01,0.05) are displayed in Fig.8.The M-H curve of pure BiFeO3is almost linear with a small remanent magnetization Mr=0.0111 emu/g.Comparing to the pure BiFeO3, both remanent magnetization and coercive field of the doped samples are enhanced.The remanent magnetization Mr as the function of the doping concentration x is depicted in the inset(a)of Fig.8.Mrincreases linearly with the x to 0.1420 emu/g for x=0.01 and starts to decrease as more Nb is doped.

It is well known that the ratio of Fe3+to Fe2+might be modified by a chemical doping,which could enhance the magnetic property of BiFeO3[19−21].However we do not observe the significant changes of proportion of Fe3+to Fe2+.Evidently the variaty of Fe3+to Fe2+can not be the main reason for the magnetic improvement of our samples.It is widely accepted that BiFeO3has G-type antiferromagnetic order superimposed with a spiral spin structure of long period(62−64 nm)and the weak ferromagnetism is related to the Dzyaloshinskii-Moriya interactions[8].The microscopic crystal structural distortions have an impact on the DM interaction and thus the spin cycloid arrangement.The lattice parameters a,c,the cell volume V of Nb doped BiFeO3change are illustrated in the Fig.5,this reveals microscopic crystal structural distortions and effects on the the spin cycloid arrangement.On the other hand,the sensitivity of the superexchange interaction to bond distances and angles is well known.This strongly indicatesthat the changes in the Fe−O local environment would influence the superexchange interaction and the magnetization[30].Thus the modification of Fe−O−Fe bond angle,displayed in Fig.5(b),could also have contribution to the observed weak ferromagnetism in the experimental samples in some degree.

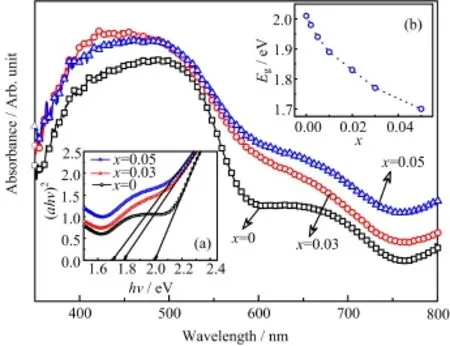

FIG. 9 Selected UV-Vis absorbance spectra of BiFe1-xNbxO3. The inset(a)depicts the(αhν)2versus hν plot of samples.The inset(b)displays the variation of the band gap Egwith x.

According to N´eel's theory,the magnetic moment and the ferromagneticlike behavior in antiferromagnetic particles are due to the uncompensated spin between the two sublattices at the particle surfaces[31−33].In this case the net moment of an antiferromagnetic particle is proportional to the surface area.Thus the remanent magnetization will be inversely proportional to the radius of the particle.The inset(b)of Fig.8 displays an approximately linear relationship between the remanent magnetization Mrand the FWHM of(012) XRD diffraction peak.Obviously the enhancement of the magnetic property of the Nb doped BiFeO3samples is mainly attributed to the large ratio of surface to volume induced by the reduction of the particles size(size effect).

Optical property can reveal variation in the band gap in the visible region. The selected room temperature UV-Vis absorbance spectra of BiFe1−xNbxO3(x=0,0.03,0.05)samples are shown in the Fig.9.Broad absorbance peaks are observed around 510,470,and 450 nm for x=0,0.03,and 0.05 samples,respectively. In the wavelength range 470−600 nm,the changes of the absorption edge suggest a strong transition corresponding to electronic transitions,which involves a charge transfer between O2p state valence band and Fe3d states conduction band[34].

The energy band gap for BFO samples can be calculated by classical Tauc's relation as given by αhν=C(hν−Eg)n,where α is the absorption coefficient, h is Planck constant,ν is the light's frequency,Egis the energy band gap,and C is a constant[35].For a direct band gap material,the parameter n should equal to 2 [36].The plots of(αhν)2versus hν for the selected samples(x=0,0.03,0.05)are displayed in the inset(a)of Fig.9.The extrapolations of the linear region of these plots to(αhν)2=0 give the corresponding direct energy band gap of these samples that can be found to be 2.01, 1.78,and 1.70 eV for x=0,0.03,and 0.05 samples respectively.

The inset(b)of Fig.9 exhibits the doping concentration x dependence of the band gap Eg.With x increasing,Egdecreases monotonously.The decrease in band gap in doped BiFeO3is ascribed to the impurity band levels(substitution ions,defect,etc.)between valance band and conduction band[37,38].By doping Nb into BiFeO3,the Nb donor band is introduced in the forbidden band,which leads to the narrowing of band gap. The oxygen vacancies lead to the decrease of the band gap in Ca doping BiFeO3[22].But Nb doping inhibits the generation of oxygen vacancies,which can be seen in Fig.6(b),and the reduction of oxygen vacancies can not cause the narrowing of band gap of the Nb doping samples.In addition,it was reported that the band gap reduction was related to the decrease of Fe−O−Fe bond angle and appearance of micro-strain in the Ca doped BiFeO3nanoparticles[22].This might be another reason of the band gap reduction by Nb dopant.Compared to the pure BiFeO3,both the particle size and the band gap of Nb doped samples decrease,which might lead to a potential application in the field of photocatalysis[39, 40].

IV.CONCLUSION

In summary,multiferroic BiFe1−xNbxO3(0≤x≤0.05) with R3c crystalline structure has been synthesized successfully by a sol-gel route.As the doping concentration x increases,the average grain size decreases.Rietveld refinements of the XRD spectra demonstrate that the lattice parameter c and the Fe−O−Fe bond angle decrease with x increases while the lattice parameter a and the cell volume V increase.The XPS reveals the coexistence of Nb4+and Nb5+in the doped samples. The Raman scattering spectra indicate that Nb dopant can cause the change of Bi−O covalent bond.Because the grain size decreases,remanent magnetization Mrenhances.The UV-Vis absorbance spectra present that the band gap reduces 0.3 eV due to the Nb dopant.

V.ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China(No.11304098 and No.11504113).

[1]M.Fiebig,J.Phys.D 38,23(2005).

[2]W.Eerenstein,N.D.Mathur,and J.F.Scott,Nature 442,759(2006).

[3]S.M.Selbach,T.Tybell,M.A.Einarsrud,and T. Grande,Adv.Mater.20,3692(2008).

[4]G.Catalan and J.F.Scott,Adv.Mater.21,2463 (2009).

[5]K.A.McDonnell,N.Wadnerkar,N.J.English,M. Rahman,and D.Downling,Chem.Phys.Lett.572,78 (2013).

[6]S.Ram and A.H.Nicola,Chem.Mater.13,2892 (2001).

[7]J.B.Neaton,C.Ederer,U.V.Waghmare,N.A. Spaldin,and K.M.Rabe,Phys.Rev.B 71,014113 (2005).

[8]C.Ederer and N.A.Spaldin,Phys.Rev.B 71,060401 (2005).

[9]I.Sosnowska,T.P.Neumaier,and E.Steichele,J.Phys. C 15,4835(1982).

[10]I.Sosnowska,M.Loewenhaupt,W.I.F.David,and R. M.Ibberson,Physica B 180,117(1992).

[11]G.L.Yuan,S.Wing,J.M.Liu,and Z.G.Liu,Appl. Phys.Lett.89,052905(2006).

[12]V.L.Mathe,J.Magn.Magn.Mater.263,344(2003).

[13]B.C.Luo,C.L.Chen,Z.Xu,and Q.Xie,Phys.Lett. A 374,4265(2010).

[14]Z.X.Cheng,X.L.Wang,S.X.Dou,H.Kimura,and K.Ozawa,Phys.Rev.B.77,092101(2008).

[15]G.D.Hu,S.H.Fan,C.H.Yang,and W.B.Wu,Appl. Phys.Lett.92,192905(2008).

[16]G.Catalan,K.Sardar,N.S.Church,F.S.James,J.H. Richard,and A.T.R.Simon,Phys.Rev.B 79,212415 (2009).

[17]Y.N.Zheng,Y.J.Wu,Z.X.Qiu,and X.J.Chen, Chin.J.Chem.Phys.26,157(2013).

[18]G.L.Yuan,S.Wing,and H.L.W.Chan,J.Phys.D 40,1196(2007).

[19]H.Singh and K.L.Yadav,Mater.Chem.Phys.132, 17(2012).

[20]Y.K.Jun,W.T.Moon,C.M.Chang,H.S.Kim,H. S.Ryu,J.W.Kim,K.H.Kim,and S.H.Hong,Solid State Commun.135,133(2005).

[21]S.Godara and B.Kumar,J.Ceram.Int.41,6912 (2015).

[22]X.Wang,S.Y.Wang,W.F.Liu,X.J.Xi,H.Zhang, F.Guo,X.L.Xu,M.Li,L.Liu,C.Zhang,X.Li,and J.B.Yang,J.Nanopart Res.17,209(2015).

[23]A.Watcharapasorn and S.Jiansirisomboon,Ceram. Int.34,769(2008).

[24]M.K.Bahl,J.Phys.Chem.Solids 36,485(1975).

[25]J.Hlinka,J.Pokorny,S.Karimi,and I.M.Reaney, Phys.Rev.B 83,020101(2011).

[26]M.K.Singh,S.Ryu,and H.M.Jang,Phys.Rev.B 72, 132101(2005).

[27]N.Jeon,D.Rout,I.W.Kim,and S.J.L.Kang,Appl. Phys.Lett.98,072901(2011).

[28]L.S.Chen,Y.H.He,J.Zhang,Z.Q.Mao,Y.J.Zhao, and X.Chen,J.Alloys Compd.604,327(2014).

[29]G.W.Chantry,The Raman Effect,Vol.1,New York: Marcel Dekker.Inc,(1971).

[30]S.Hussain S,S.K.Hasanain,G.H.Jaffari,S.Faridi,F. Rehman,T.A.Abbas,and S.I.Shah,J.Am.Ceram. Soc.96,3141(2013).

[31]T.J.Park,G.C.Papaefthymiou,A.J.Viescas,A. R.Moodenbaugh,and S.S.Wong,Nano Lett.7,766 (2007).

[32]L.N´eel,Compt.Rend.252,4075(1961).

[33]A.Jaiswal,R.Das,K.Vivekanand,P.M.Abraham, S.Adyanthaya,and P.Poddar,J.Phys.Chem.C 114, 2108(2010).

[34]H.Zhang,W.F.Liu,P.Wu,X.Hai,S.Y.Wang,G.Y. Liu,and G.H.Rao,J.Nanopart Res.16,2205(2013).

[35]J.Tauc,Amorphous and Liquid Semiconductors,New York:Plenum Press(1974).

[36]D.H.Wang,W.C.Goh,M.Ning,and C.K.Ong,Appl. Phys.Lett.88,212907(2006).

[37]C.Sunil,A.Manisha,P.C.Sati,C.Sandeep,S.C. Katyal,and K.Manoj,Ceram.Int.39,6399(2013).

[38]C.H.Yang,D.Kan,I.Takeuchi,V.Nagarajan,and J. Seidel,Phys.Chem.Chem.Phys.14,15953(2012)

[39]T.Soltani and M.H.Entezari,J.Mol.Catal.A 377, 197(2013).

[40]T.Xian,H.Yang,J.F.Dai,Z.Q.Wei,J.Y.Ma,and W.J.Feng,Mater.Lett.65,1573(2011).

Hui-min Xian,Yi-quan Du,Jiang Zhang,Xi Chen∗

Department of Physics,South China University of Technology,Guangzhou 510006,China

杂志排行

CHINESE JOURNAL OF CHEMICAL PHYSICS的其它文章

- Hydrodeoxygenation of Anisole over Ni/α-Al2O3Catalyst

- Surface Chemistry of Ga(CH3)3on Pd(111)and Effect of Pre-covered H and O

- Photo-depositing Ru and RuO2on Anatase TiO2Nanosheets as Co-catalysts for Photocatalytic O2Evolution from Water Oxidation

- Efficient Removal Phenol Red over Ternary Heterostructured Ag-Bi2MoO6/BiPO4Composite Photocatalyst

- Highly Efficient and Selective Removal of Pb(II)ions by Sulfur-Containing Calcium Phosphate Nanoparticles

- Combination Computing of Support Vector Machine,Support Vector Regression and Molecular Docking for Potential Cytochrome P450 1A2 Inhibitors