离心泵作透平异向倾斜叶片与隔舌降噪分析

2016-10-29代翠孔繁余董亮夏斌柏宇星

代翠 孔繁余 董亮 夏斌 柏宇星

摘要: 为降低离心泵反转作液力透平流体诱发的内外场噪声,基于倾斜程度由叶片和隔舌分摊的思想,建立了理想情况下叶片与隔舌异向倾斜角度关系式,提出了在保证性能前提下联合倾斜叶片与隔舌的主动控制降噪方法。在验证内场噪声计算方法和壳体结构有限元模型的基础上,分别基于声学边界元法(Boundary Element Method,BEM)和声学有限元的自动匹配层技术(Finite Element Method/Automatically Matched Layer,FEM/AML)对3组不同倾斜角度透平进行了内外场噪声数值研究,分析倾斜隔舌以及联合倾斜叶片与隔舌的降噪效果。结果表明:隔舌倾斜一定角度后,透平效率在全流量范围内均增加,增加幅度约为0.67%~1.81%;同时倾斜叶片与隔舌后,透平效率与常规透平基本相同,大流量效率有小幅增加。单纯倾斜隔舌透平总声压级降低3.86%~5.93%,总声功率级降低0.83%~11.34%;在倾斜叶片和隔舌的联合作用下透平总声压级降低4.45%~7.19%,总声功率级降低1.08%~12.15%,联合作用的降噪效果更佳。关键词: 降噪; 离心泵; 液力透平; 异向倾斜; 自动匹配层

中图分类号: TB535; TH311文献标志码:A文章编号:10044523(2016)04062308

DOI:10.16385/j.cnki.issn.10044523.2016.04.009

引言

离心泵反转作液力透平是一种回收液体余压能的理想方法,可以将高压液体能转化为轴的旋转机械能,进而驱动其他耗能机械[13]。离心泵作透平噪声有机械引起的和流体诱发的噪声,机械噪声的控制方面(如阻振、隔振、吸振、吸声等)已取得长足进步,而流体诱发噪声更为复杂[4]。

当前,降低流体诱发噪声成为国内外工程技术领域研究的热点和难点。降低声源强度是进行噪声控制最为根本的方法,主要分为两类:主动降噪和被动降噪。主动降噪方法主要是通过改进叶片形态、叶轮形状、叶片和管道材料等来降低叶轮机械的噪声;被动降噪方法是尽量少地使叶轮机械发出的噪声向外界传播[5]。Dong等[6]利用粒子成像测速、压力与噪声测量等手段研究了叶轮与隔舌间隙对离心泵流体诱发噪声的影响,指出增大间隙使得叶轮尾迹对于离心泵噪声的贡献可忽略,与刚度有关的隔舌振动对于离心泵噪声的贡献显著,可以通过增大间隙、加大隔舌刚度以及在隔舌处贴阻尼片等改变蜗壳形状的方式降低离心泵结构的辐射噪声。Neise[7]发现可以在叶片上开槽等方式来降低噪声。吴仁荣[8]和黄国富等[910]较全面地分析了离心泵低噪声的水力设计方法,给出了一些相关设计原则。黄俊雄等[11]数值研究了有无短叶片离心泵的旋转偶极子噪声辐射特性,指出长短叶片结构能够改变声能在频域上的分布,进而降低总声压级。谈明高等[12]讨论了叶片数对离心泵振动噪声的影响。王勇等[13]试验研究了叶片包角对离心泵空化振动和噪声的影响。丁剑等[1415]通过试验研究了不同叶片包角及出口宽度对离心泵流动噪声的影响,考虑到性能给出了最优方案。祝磊等[1617]讨论了叶轮与隔舌间隙以及阶梯隔舌对泵引发振动的压力脉动、径向力和扭矩特性的影响规律。

现有研究主要通过优化叶轮或蜗壳几何参数,改进叶轮或蜗壳形状来降低离心泵流体诱发噪声,关于离心泵反转作透平工况下流体诱发噪声的特性及降噪研究较少。且文献中普遍采用间接边界元方法对内外声场同时求解,未考虑壳体内外介质不同的特性。本文在研究如何通过减小叶轮与隔舌动静干涉程度、降低同相位脉动水动力作用面积的基础上,提出了在保证性能前提下联合倾斜叶片与隔舌的主动控制降噪方法。在对内场噪声和壳体结构模态验证的基础上,分别采用BEM方法与FEM/AML方法对比分析了倾斜隔舌以及异向倾斜叶片和隔舌对离心泵作透平内外声场的降噪效果,证实其对协同提升水力和噪声性能的可行性。

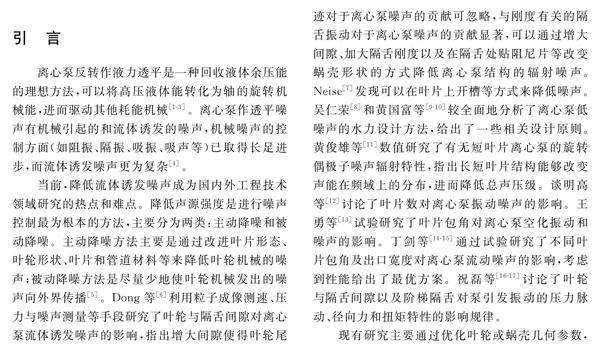

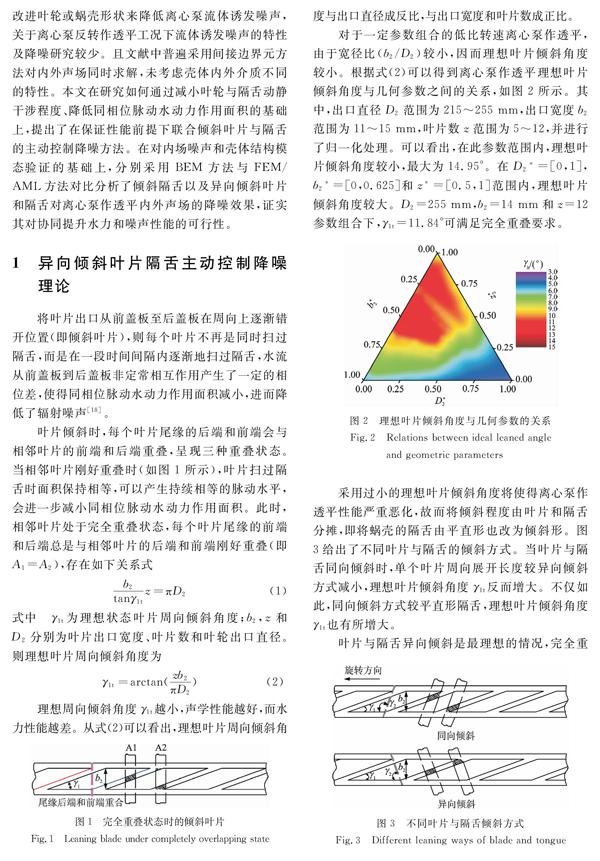

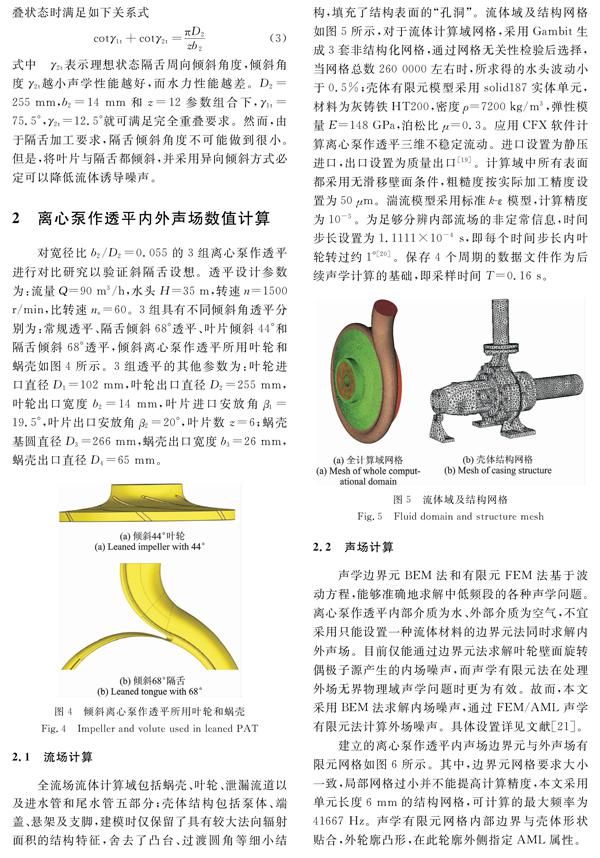

1异向倾斜叶片隔舌主动控制降噪理论将叶片出口从前盖板至后盖板在周向上逐渐错开位置(即倾斜叶片),则每个叶片不再是同时扫过隔舌,而是在一段时间间隔内逐渐地扫过隔舌,水流从前盖板到后盖板非定常相互作用产生了一定的相位差,使得同相位脉动水动力作用面积减小,进而降低了辐射噪声[18]。

Abstract: Aiming at reducing fluidinduced noise in interior/exterior noise of centrifugal pump as turbine (PAT), based on the blade and tongue′s paying their leaning share, the angle formula associated with counterleaning blade and tongue in ideal condition was derived. Meanwhile, the noisereduction activecontrol approach was put forward by joint leaning blade and tongue, without losing hydraulic performance. In the validation of calculation method of interior noise and finite element model of casing structure, the boundary element method (BEM) and finite element method/automatically matched layer technology (FEM/AML) was respectively used to study interior and exterior noise for three PATs by varying the shape of tongue. The noise reduction effects by leaning tongue as well as joint leaning blade and tongue were subsequently analyzed. Researches show that the leaned tongue can significantly improve PAT′s efficiency over an overall flow range, with an increase of 0.67%~1.81%. While, PAT′s original performance can be maintained by joint leaning blade and tongue, with a slight increase in larger flow rates. Simply by leaning tongue, the total sound pressure level of PAT can be reduced by 3.86%~5.93%, and the total sound power level can be lowered by 0.83%~11.34%. Under the joint action, the total sound pressure level is reduced by 4.45%~7.19%, and the total sound power level is lowered by 1.08%~12.15%. The noise reduction effect of joint action is better.

Key words: noise reduction; centrifugal pump; hydraulic turbine; counter lean; automatically matched layer