3D打印机

2016-09-20编者按

·编者按·

3D打印机

·编者按·

3D打印(3D Printing)是一种快速成形技术,它以数字化模型为基础,运用粉末状金属或塑料等打印技术沉积材料,通过逐层打印的方式构造物体,所用设备即3D打印机(3D printer)。一般来说,通过3D打印获得一件物品需要经历建模、分层、打印和后期处理4个主要阶段,3D打印技术主要包括光固化成型法(SLA)、选择性激光烧结技术(SLS)、熔积成型法(FDM)、分层实体制造法(LOM)等。

第一台商用3D打印机出现在1986年,但3D打印技术的真正确立是以美国麻省理工大学的Scans和Cima等人于1991年申报的关于3D打印的专利为标志。3D打印机目前在建筑设计领域、磨具制造领域、医学领域、航空航天领域、家电和食品领域等得到广泛应用。截至2012年,生物科技公司和学界就一直在研究3D生物打印技术在组织工程中的应用,也就是说,用喷墨技术来生产身体组织和器官。2016年2月15日提前在线发表在《Nature Biotechnology》杂志上的一篇论文中,美国维克森林大学(Wake Forest University)再生医学研究所的科学家报告了他们研发出的一款3D生物打印机。使用这种“集成型组织—器官打印机”(Integrated Tissue-Organ Printer),研究人员成功地打印出了大尺寸的“活”的组织,包括一个外耳形状的软骨、下颚骨、头盖骨以及肌肉组织。把这些组织移植到老鼠身上后,这些组织都能够长时间地存活下来,并且逐渐“融入”到了周围的组织里。这项新的突破使科学家距离3D打印出组织甚至器官,并将其用于临床治疗又近了一步。

本专题得到张李超副教授(华中科技大学)的大力支持。

·热点数据排行·

截至2016年7月4日,中国知网(CNKI)和Web of Science(WOS)的数据报告显示,以“3D打印机”为词条可以检索到的期刊文献分别为1178条与684条,本专题将相关数据按照:研究机构发文数、作者发文数、期刊发文数、被引用频次进行排行,结果如下。

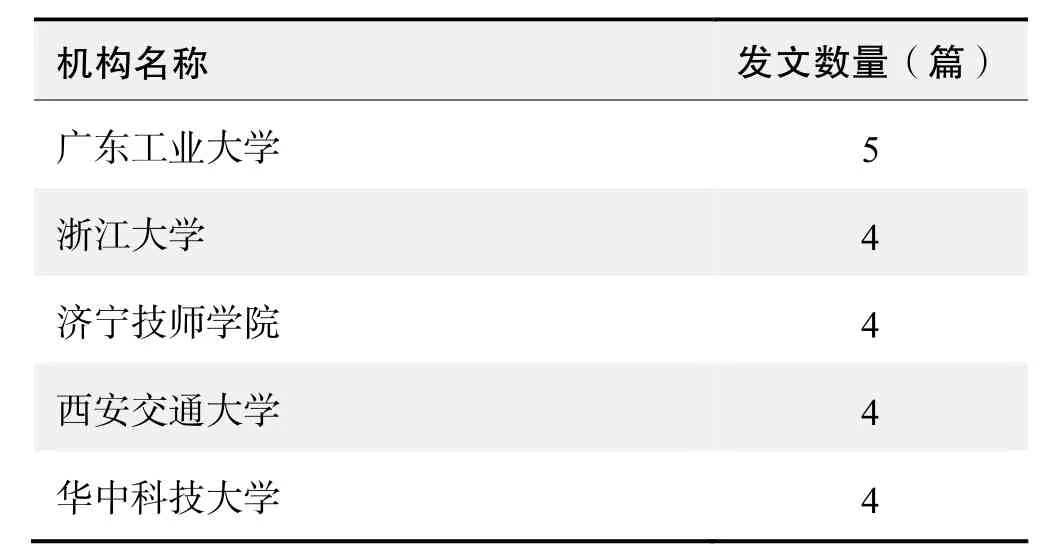

研究机构发文数量排名(CNKI)

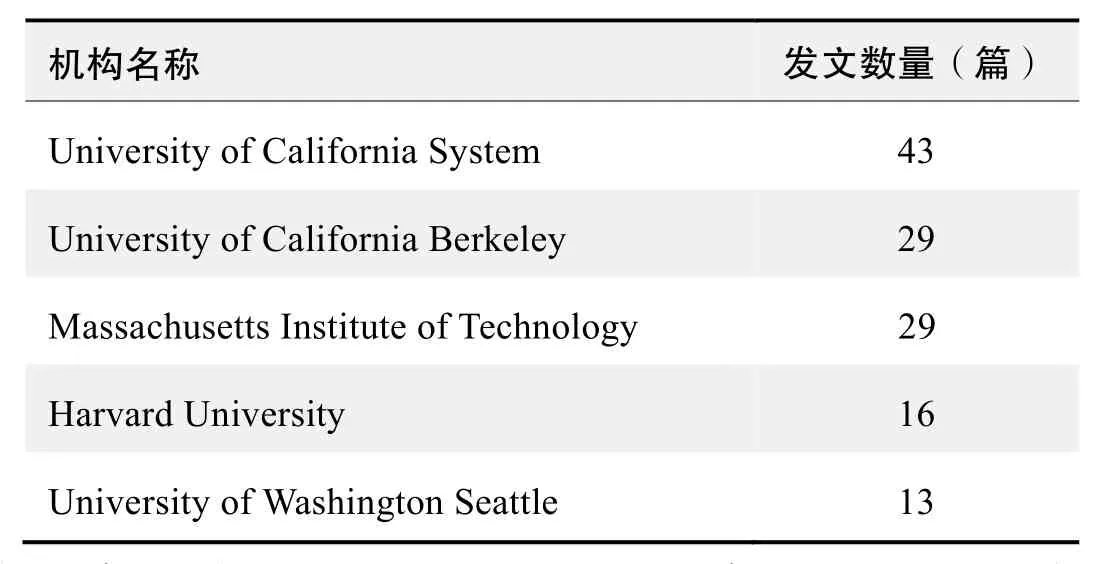

研究机构发文数量排名(WOS)

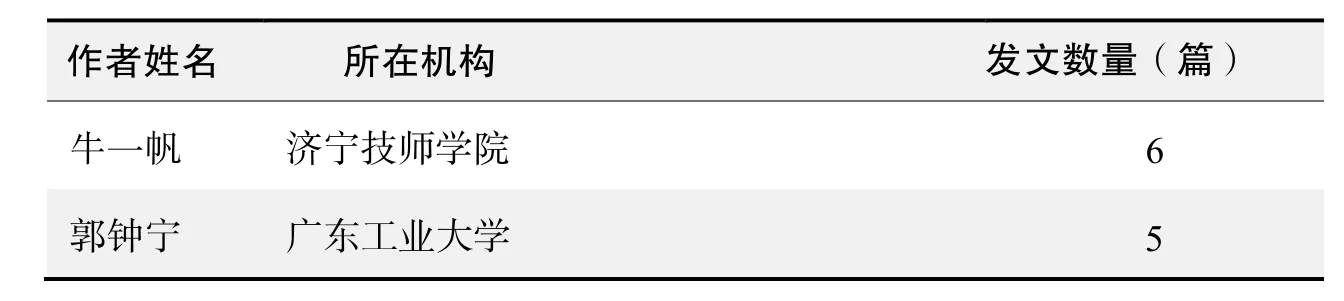

作者发文数量排名(CNKI)

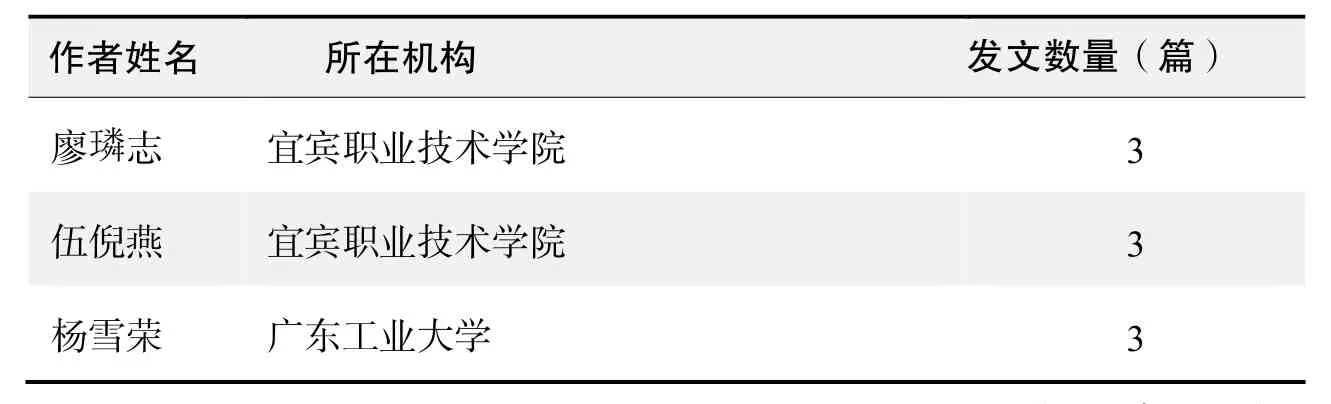

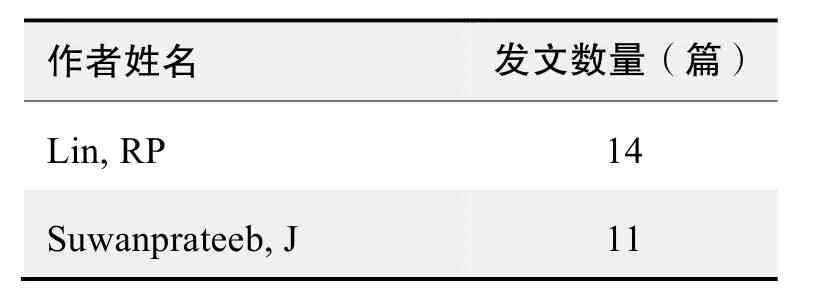

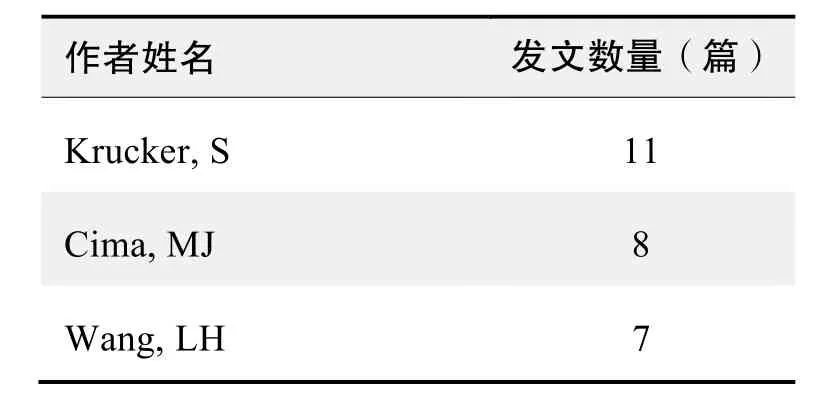

作者发文数量排名(WOS)

(数据来源:中国知网、Web of Science,检索时间:2016-07-04)

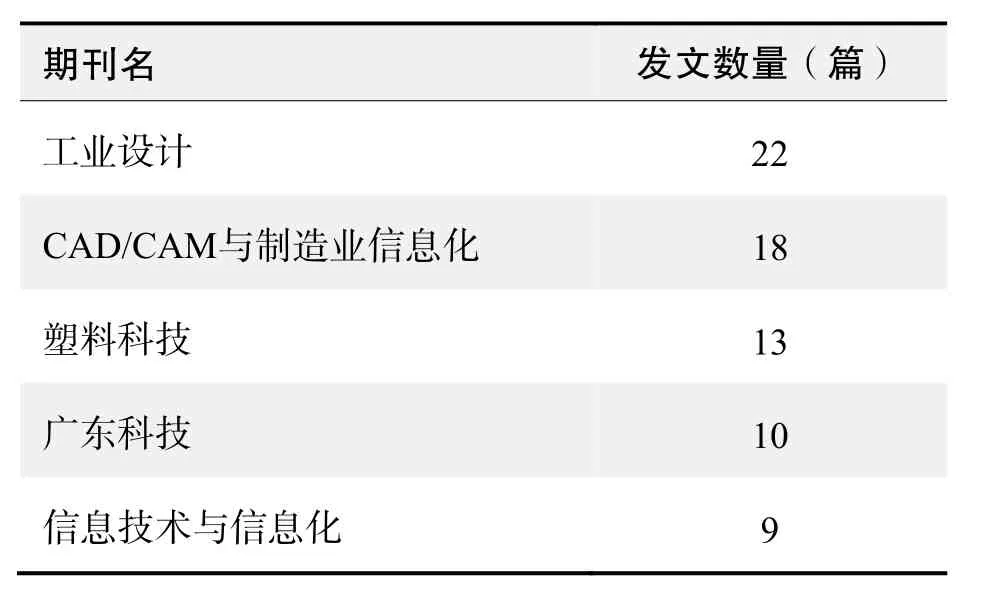

期刊发文数量排名(CNKI)

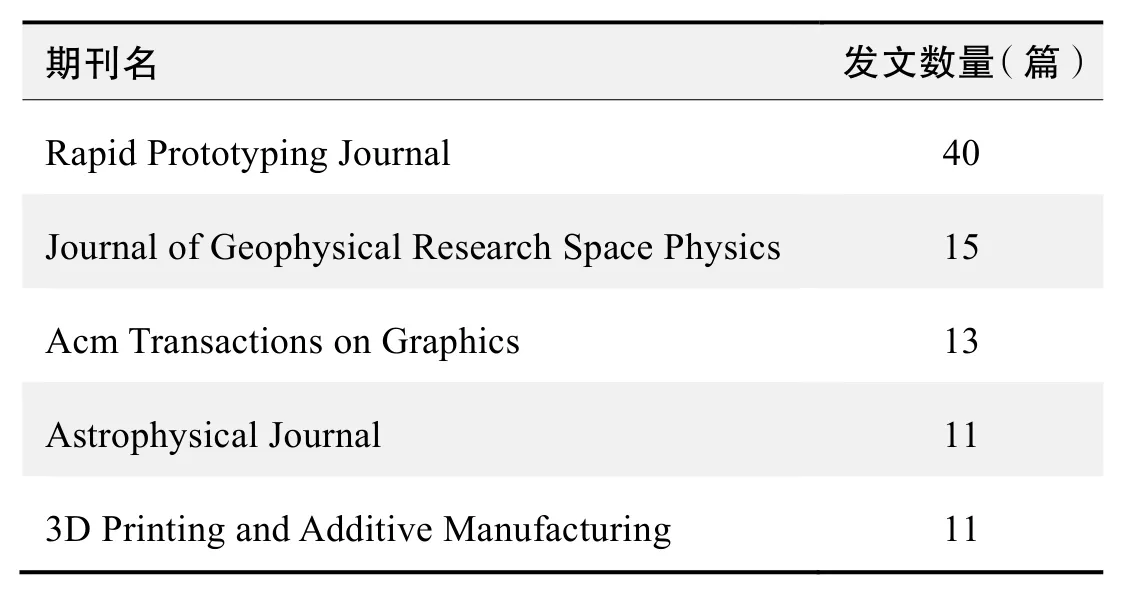

期刊发文数量排名(WOS)

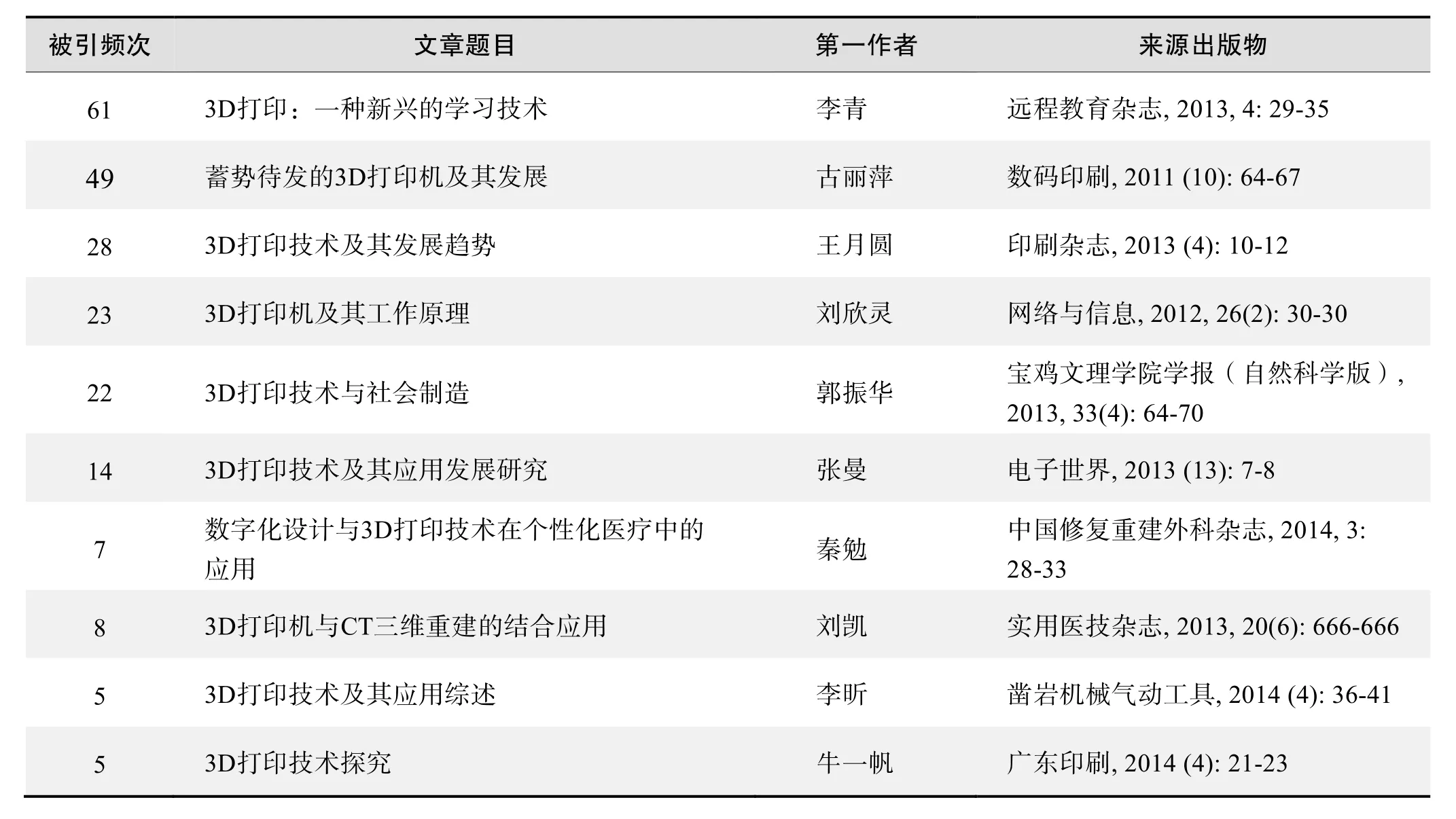

根据中国知网(CNKI)数据报告,以“3D打印机”为词条可以检索到的高被引论文排行结果如下。

国内数据库高被引论文排行

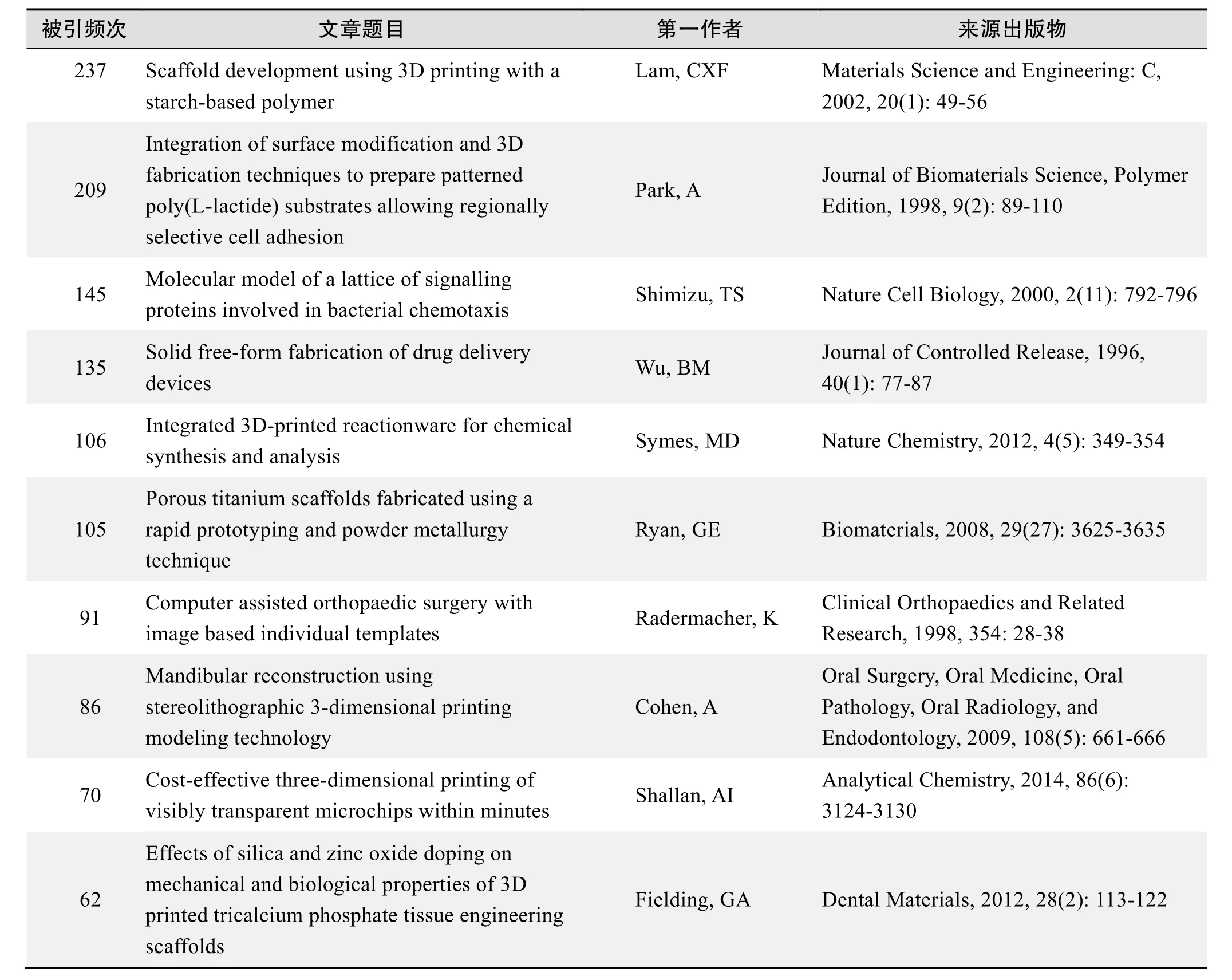

根据Web of Science统计数据,以“3D打印机”为词条可以检索到的高被引论文排行结果如下。

国外数据库高被引论文排行

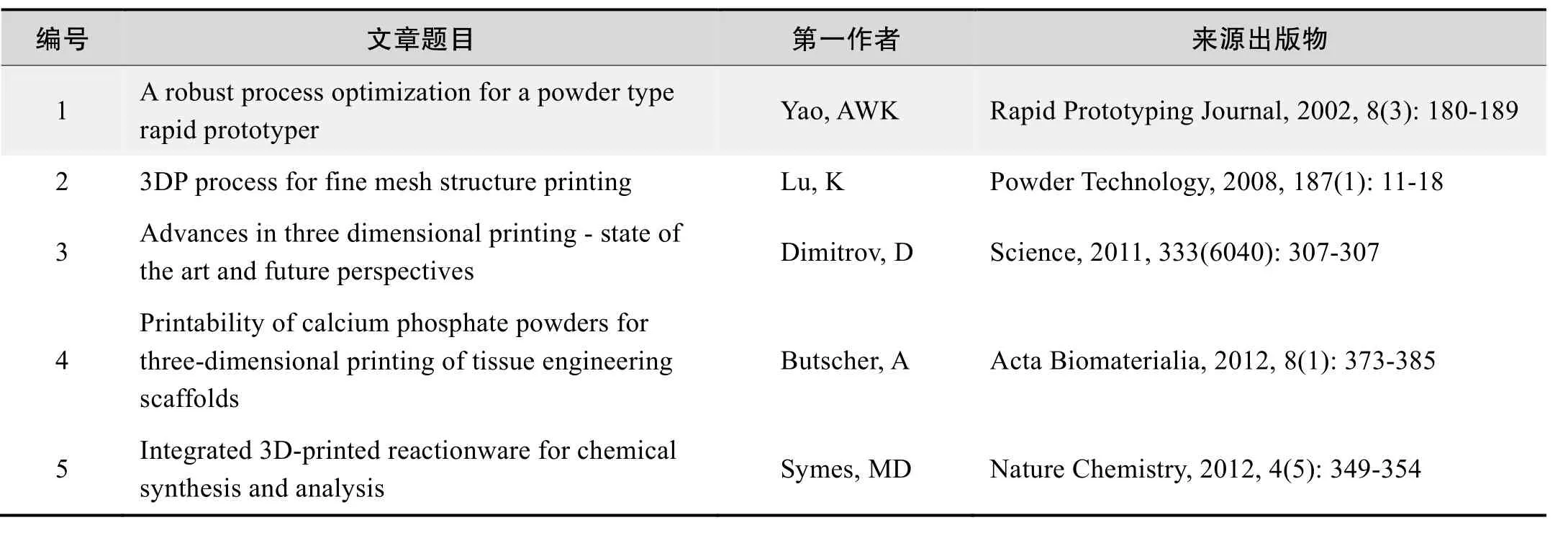

·经典文献推荐·

基于Web of Science检索结果,利用Histcite软件选取LCS(Local Citation Score,本地引用次数)TOP 50文献作为节点进行分析,得到本领域推荐的经典文献如下。

本领域经典文献

来源出版物:Rapid Prototyping Journal, 2002, 8(3):180-189

3DP process for fine mesh structure printing

Lu, K; Reynolds, WT

Abstract: Three dimensional printing (3DP)is a unique technique for creating complex shapes. However, printing feature sizes at less than 500 pm with high integrity and intricate structures have not been possible. In this study,TiNiHf shape memory alloy (SMA)powder was printed into 3D mesh structures of 300 mu m wire width. Effects of printing layer thickness and binder saturation level on the integrity and dimensional accuracy of the 3D mesh structures were evaluated. 35 gin printing layer thickness and 170% binder saturation level offer the highest mesh structure integrity. Also, 35 pm printing layer thickness results in the smallest dimensional deviation from the designed 200 gin mesh width with the smallest standard deviation. Overall, 35 gm printing layer thickness and 170% binder saturation level are the most preferred printing condition for the designed 3D mesh structure.

3D printing; mesh structure; printing layer thickness; binder saturation level; integrity; dimensional accuracy

来源出版物:Powder Technology, 2008, 187(1): 11-18

Advances in three dimensional printing - state of the art and future perspectives

Dimitrov, D; Schreve, K; de Beer, N

Abstract: Purpose: This paper surveys the current state and capabilities of three dimensional printing (3DP). A comprehensive review of 3D Printing applications is presented. The scope of the applications includes design,manufacturing, the medical field and architecture.Design/methodology/approach:Alargevarietyof manufacturing applications such as rapid pattern making and rapid tooling using the 3DP process directly or as core technology, as well as further implications in design and engineering analysis, medicine, and architecture are presented and evaluated. Findings: Some research issues are also discussed. An attempt, based on the state of the art,to show weaknesses and opportunities, and to draw conclusions about the future of this important process rounds up this paper. Research limitations/implications-The scope of this research survey is limited to evaluation and comparison of processes that may be characterised as 3D printing technologies. Practical implications: The study is very useful as a basis for matching evaluated 3D printing machine and process capabilities to user requirements, and forms a framework on which future comparative studies can build. Originality/value: A comprehensive overview of the capabilities of 3DP processes is presented and evaluated. It shows the application of 3D printing beyond concept modelling. The paper is valuable for researchers as well as individuals, who require adequate and relevant comparative information during decision making.

关键词:modelling; print media; rapid prototypes

来源出版物:Science, 2011, 333(6040): 307-307

Printability of calcium phosphate powders for three-dimensional printing of tissue engineering scaffolds

Butscher, A; Bohner, M; Roth, C; et al.

Abstract: Three-dimensional printing (3DP)is a versatile method to produce scaffolds for tissue engineering. In 3DP the solid is created by the reaction of a liquid selectively sprayed onto a powder bed. Despite the importance of the powder properties, there has to date been a relatively poor understanding of the relation between the powder properties and the printing outcome. This article aims at improving this understanding by looking at the link between key powder parameters (particle size, flowability,roughness, wettability)and printing accuracy. These powder parameters are determined as key factors with a predictive value for the final 3DP outcome. Promising results can be expected for mean particle size in the range of 20-35 μm,compaction rate in the range of 1.3-1.4, flowability in the range of 5-7 and powder bed surface roughness of 10-25 μm. Finally, possible steps and strategies in pushing the physical limits concerning improved quality in 3DP are addressed and discussed.

关键词:three-dimensional printing (3DP); tissue engineering;calcium phosphates (CaP); powder flowability; powder wettability

来源出版物:Acta Biomaterialia, 2012, 8(1): 373-385

Integrated 3D-printed reactionware for chemical synthesis and analysis

Symes, MD; Kitson, PJ; Yan, J; et al.

Abstract: Three-dimensional (3D)printing has the potential to transform science and technology by creating bespoke, low-cost appliances that previously required dedicated facilities to make. An attractive, but unexplored,application is to use a 3D printer to initiate chemical reactions by printing the reagents directly into a 3D reactionware matrix, and so put reactionware design,construction and operation under digital control. Here,using a low-cost 3D printer and open-source design software we produced reactionware for organic and inorganic synthesis, which included printed-in catalysts and other architectures with printed-in components for electrochemical and spectroscopic analysis. This enabled reactions to be monitored in situ so that different reactionware architectures could be screened for their efficacy for a given process, with a digital feedback mechanism for device optimization. Furthermore, solely by modifying reactionware architecture, reaction outcomes can be altered. Taken together, this approach constitutes a relatively cheap, automated and reconfigurable chemical discovery platform that makes techniques from chemical engineering accessible to typical synthetic laboratories.

来源出版物:Nature Chemistry, 2012, 4(5): 349-354

·推荐综述·

3D打印机在各领域的发展前景

赵秋云,楚恩惠

13D打印机的原理

3D打印机(3D Printers)又称三维打印机,是一位名为恩里科·迪尼(Enrico Dini)的发明家设计的一种神奇的打印机。它的神奇之处在于,可以根据需要,使用3D辅助设计软件,打印出需要的构造复杂的小汽车或者是简单的鞋子。3D打印机的原料多种多样,如橡胶、塑料、蜡质材料甚至是金属,可以利用各种原料直接打印三维立体模型,也可以通过创新设计出符合人类需求的各种形状的产品。3D打印机不同于传统的去除材料加工技术,它是通过连续的物理层创建的,隶属于添加剂制造技术的一种。与其他的添加剂制造技术相比较,3D打印机目前具有高运行速度,超低价格、易用性等明显的优点。具体的过程是,以通过计算机建模软件建构的三维模型,根据工艺要求在第一构建体中,再按照一定的规律把有序序列的单位进行离散,它通常是在Z方向离散到一定厚度时,把原来的三维CAD模型变成一系列的层片,基于每个层所述,输入处理参数,由系统的轮廓信息来生成数控代码,最后将连接起打印出的一系列片层,并形成一个三维模型。首先通过建模软件模型内置,构建成一个立体的分区步骤模型进一步横截面以引导逐一层面打印。

23D打印的意义

2.1制造工艺的深刻变革

3D打印的特点并不是利用去除多余的材料进行深加工,而是通过对逐层的聚集材料进行加工处理,因而这种制作工艺也就被称作聚集制造或加工制造。这也改进了利用对原材料进行切削、组装等进行生产的深加工模式,也节省了一些材料与加工时间,从而带来了制造工艺的深刻革新。

2.2制造技术的重大飞跃

3D打印技术是近年来新起的一种高新科技技术,它综合运用了CAD/CAM 技术、激光智能技术、电子化工以及材料科学等诸多方面的技能知识,3D打印技术的持续革新将会推进包含智能制造技术、新材料技术等新型技术的飞跃发展。

2.3制造模式的历史革命

作为一种新型的加工工艺技术,3D打印将会扭转第二次工业革命以来产生的,以装配生产线为标志的大规模生产方式的局面,使产品生产向个性化、私人定制化转变。3D打印机的推广运用将能够减少产品市场化所需的时间,既不需要大规模的生产线,也不需要存储大量的产品零部件,更不需要大量的生产工人。用户们只需要简单的下载设计图案,便可在较短的时间内通过3D打印将产品打印出来。

33D打印机的发展前景

由于迅速成型技术在目前市场上占据着一定的主导地位,3D打印机在生产应用方面也有着巨大的发展前景。3D新型打印技术在医疗方面、交通工具、食品、艺术和教育教学方面都能够得到普遍的运用。

3.1医学领域的发展前景

随着科技的日渐成熟,3D打印已经开始涉足医学领域。3D打印能够制造出适合人体的某些定制器官,目前,有些科研人员已经用3D打印机打印出了简单的活体组织器官,如皮肤、肌肉等。相关人员介绍,如肾脏、肝脏、甚至心脏等较大的身体器官也都有可能在不久的将来被打印出来。美国生物科技公司Organovo于2014年11 月18日对外宣布:其通过3D打印的肝脏exVive3D进入上市前的临床试验结果,并将向医药公司出售3D打印肝脏,打印出来的3D肝类似于六边形,大小却只有几毫米,但能像真实人体肝脏一样自行产生蛋白质,而且其活性期超过6周,这也给生物试验带来了巨大的空间。试想一下,在不久的将来的,3D新型打印技术不仅能够运用于肝脏组织,还能制造出一系列完整的3D打印器官。从需要器官移植的人体取一部分组织,提取需要的成分,通过3D打印技术,打印出的器官再移植在自己的身体上,不仅能够和机体很好地相融合在一起,而且如果生物打印机可以使用患者自身的干细胞打印器官,就能够减少器官移植后机体产生排斥反应的可能性。另外,打印器官不像克隆技术,存在伦理道德问题,所以,在医学领域利用好3D打印技术,极可能开启器官移植的新时代。

3.2生活领域的发展前景

近几年,3D打印在生活领域也已经有了很大的进展。2014年9月,在美国芝加哥举行的2014国际制造技术展览会上Local Motors展示了一辆3D打印的汽车。这辆名为Strati的3D打印汽车的制造采用了直接数字化制造技术,通身都是用3D打印机打印出来的,包括机身以及零部件,完成历史性的首驾驶。打造这款车采用了3D打印技术,以纳米制造的方式在数字化制造环境中完成,在其前大灯,后视镜和挡风玻璃电子零件增加碳纤维,以提高其强度。这辆零部件耗资约3500美元制作周期为44小时的3D打印汽车,可以达到80 km/h的最高速度。这种新的制造方式不仅颠覆现有的生产模式,而且也改变了消费者的使用体验。3D打印的汽车仅仅是冰山一角,为未来尖端技术的汽车制造工艺奠定了基础,这种新技术的引入是3D打印技术的未来发展,蕴含着巨大的能量,甚至对工业生产影响深远。另外,各式各样的美味食物也能被3D打印机打印出来。前段时间,在哈工大(威海)实验室里诞生了一台以液态巧克力为油墨的巧克力3D打印机,体验用户们只需要加入巧克力液或巧克力块就可以打印出他们想要的任何造型,与国外的相关技术相比,这款巧克力3D打印机具有无限供料、低温成型、成本较低等明显优势。

3.3科技领域的发展前景

近日,澳大利亚某华裔研究员采用一种3D新型打印技术制造出了全球首个打印出来的飞机引擎。这一翻天覆地的变革有望能够降低飞机的制造成本,从而使飞机更轻更省油。相关专家指出,研究表明,飞机的精密零件也能适用被3D打印技术制造,并且认为这是一项颠覆性的科技。这个项目的闪光点在于这里应用的是钛、镍、锡等金属或轻金属,在整个制作过程中,研究人员将一个破旧的飞机引擎进行有序的拆分扫描,进行激光切割打印,最后再重新组装。有一位名Graham Sortino的美国工程师正在致力于改变发动机的制造方式。他一直在开发能够完全开源的液体燃料火箭发动机,而且最为重要的是,这个发电机是完全可以被3D打印的。能够随时快速的进行修改设计发动机部件,并且能以比传统制造更为便宜的方式制造出所需的部件,这是激发他使用3D打印发动机的主要原因。他采用金属材料作为原料,这让对开源部件的设计进行修改变得更加容易。

3.4艺术领域的发展前景

3D打印技术与艺术似乎总是如影随形,设计师们将设计的各种形象利用3D打印的形式完美呈现出来。而在动漫领域,3D打印动画也有着普遍的应用前景,如已经上映的大型迪斯尼动画《超能战队》,它的制作过程中就充分运用了3D打印以及3D扫描等技术。还有《通灵男孩诺曼》打破了使用黏土原料手工制作人物面部表情的传统方式,而是采用3D打印技术来制作角色表情。通过计算机对已建好的面部表情的素材库,利用不同的排序最终生成了大概150万个不同的角色面部表情。

3.5教育领域的发展前景

3D打印对于教师教学和学生学习方面具有及其重要的价值,它能够更加真实呈现出特定的事物,从而使学生获得深入的感知领悟。在激发提升学生的创造力上,3D打印技术的演示教学正是一个合适的解决方案,3D打印技术在基础教育中最引人注目的应用在于学生可以利用技术创造出完全属于自己的东西,如在科学课、历史课上,学生可以制作像化石、文物之类的易碎品,通过快速原型设计和生产工具,学习化学的学生可以打印出复杂的蛋白质和其他分子模型,这与我们看到的3D分子设计模型库中的展示十分类似,而设计专业的学生能够通过3D打印更快速的实现并检验自己的设计作品。

4结语

凭借着这种数字化的制造,3D打印机将会取代传统的制造业所采用的各种各样的机械,对制造业的生产方式也将造成颠覆性的改变。更为重要的是,它不需要那种大规模的流水生产线,因为计算机和3D打印机的联合,使得这种重复变得简单而方便。随着3D新型打印技术在尺寸与精度上的迅速发展,3D打印将会越来越多地运用到更广泛的领域,加上新能源、互联网和其他一些新材料,就可以在各个领域研究开发人们需要的产品,造福于社会。♦

【作者单位:河南师范大学】

(摘自《软件导刊》2015年第5期)

·高被引论文摘要·

被引频次:61

3D打印:一种新兴的学习技术

李青,王青

3D打印是最近两年开始流行的一种快速成形技术,它以数字模型文件为基础,通过逐层打印的方式来构造物体。目前,已经有学者尝试将它应用于教学中,取得了一定成果。从文献研究入手,介绍了3D打印机的原理和3D打印技术的发展现状;呈现了3D打印在各学科教学中的创造性应用,并列举了三个典型案例加以剖析;进一步分析了其在学习环境中的角色、主要应用模式和创新性用法;最后讨论了目前3D打印应用于教学的前景、优势和不足。

关键词:3D打印;学习技术;教育创新;教学资源

来源出版物:远程教育杂志, 2013, 4: 29-35

被引频次:49

蓄势待发的3D打印机及其发展

古丽萍

摘要:3D打印机作为3D领域的一种前瞻性产品,目前成为一种潮流正迅猛发展。3D打印机被称之为改变未来世界新的创造性科技,不仅改变了许多工厂的生产方式,给制造业带来一场革命,还将进入到我们的家庭,给工业生产和我们的生活带来巨大的革命性改变。

关键词:模型表面;三维地形;蓄势;彩色打印;打印速度;血管网络;三维立体;实体模型;辅助设计软件;打印设备

来源出版物:数码印刷, 2011 (10): 64-67

被引频次:28

3D打印技术及其发展趋势

王月圆,杨萍

摘要:近年来,3D打印技术在工业产品设计,特别是数字产品模型制造领域的应用正在成为一种潮流和热门话题。桌面级3D打印设备的逐渐成熟和应用开始推动全球3D打印市场的兴起,全球工业分析公司(Global Industry Analysis Inc)的研究报告预测2018年全球3D打印市场将达到29.9亿美元。

关键词:3D打印技术;应用需求;发展趋势

来源出版物:印刷杂志, 2013 (4): 10-12

被引频次:23

3D打印机及其工作原理

刘欣灵

摘要:3D打印是添加剂制造技术的一种形式,在添加剂制造技术中三维对象是通过连续的物理层创建出来的。3D打印机相对于其他的添加剂制造技术而言,具有速度快,价格便宜,高易用性等优点。3D打印机就是可以“打印”出真实3D物体的一种设备,功能上与激光成型技术一样,采用分层加工、迭加成形,即通过逐层增加材料来生成3D 实体,与传统的去除材料加工技术完全不同。称之为“打印机”是参照了其技术原理,因为分层加工的过程与喷墨打印十分相似。

关键词:三维对象;制造技术;物理层;工作原理;打印速度;易用性;模型表面;彩色打印;原型制造;实体模型

来源出版物:网络与信息, 2012, 26(2): 30-30

被引频次:22

3D打印技术与社会制造

郭振华,王清君,郭应焕

摘要:综述3D打印技术的基本概念、发展简史、打印过程原理、应用领域、广泛影响以及面临的问题等。以发展史为基础,利用历史的、分析与综合的方法进行了论述。在3D打印技术得到广泛应用的情况下,制造业也许不再运用工厂这种将人力、资金、设备等生产要素大规模集中化的生产方式,而是转变为一种以3D打印机为基础、更加灵活、所需投入更少的生产方式。《经济学人》将这种趋势称之为“社会制造”,并认为这种新型的生产方式,有望促成第三次工业革命。指出3D打印技术作为第三次工业革命的重要标志之一,已引发了世人对3D打印的强烈关注。3D打印技术必将改变人类未来的生产与生活方式。3D打印技术必将创造一个崭新的世界。

关键词:3D打印技术;社会制造;协同制造;3D打印服务;第三次工业革命

来源出版物:宝鸡文理学院学报:自然科学版, 2013,33(4): 64-70

被引频次:14

3D打印技术及其应用发展研究

张曼

摘要:通过分析3D打印机的原理,总结了几种典型的3D打印技术,分析其市场应用和发展方向,得出3D打印技术的发展会引领第三次工业革命的发展。

关键词:3D;打印机;3D打印技术

来源出版物:电子世界, 2013(13): 7-8

被引频次:7

数字化设计与3D打印技术在个性化医疗中的应用

秦勉,刘亚雄,贺健康,等

摘要:目的:总结将数字化设计与3D打印技术应用于个性化医疗中的研究进展。方法:回顾分析西安交通大学及其合作单位近年来将数字化设计与3D打印技术在个性化医疗中应用的相关研究资料和临床文献,并进行综合整理分析。结果基于3D打印技术,根据患者具体病变设计并制造个性化内植物,能满足不同患者病变形状与功能的需要,解决人体组织的个性化修复问题,降低对医生经验水平的依赖,得到越来越多外科医生认可。西安交通大学在国内最早开发出商用3D打印机,对个性化医用内植物的设计及制造进行了深入研究,已形成了完整的工艺流程,制定了产品质量标准,并成功应用于临床试验。结论:3D打印技术制造的个性化医用内植物能实现个性化匹配,满足患者对功能和美学的要求,同时具有定位准确、连接稳定、强度高等优点。因此该技术在个性化内植物制造与应用方面有广泛应用前景。

关键词:3D打印技术;个性化医疗;医用内植物;临床应用

来源出版物:中国修复重建外科杂志, 2014, 3: 28-33

被引频次:8

3D打印机与CT三维重建的结合应用

刘凯,张学燕

摘要:随着3D技术的发展及3D打印机的普及,我们现在可以将螺旋CT三维重建的图像“打印”出来,形成真正的三维实物。3D打印机与螺旋CT三维重建的结合应用的一大优势是不需要额外的建模过程。但是现在还面临着软件接口及打印成本等问题需要解决。

关键词:三维重建;软件接口;打印成本;图像分辨率;文件格式;成像方式;DICOM;软件开发;数字图像;计算机工作站

来源出版物:实用医技杂志, 2013, 20(6): 666-666

被引频次:5

3D打印技术及其应用综述

李昕

摘要:随着近年来信息技术和材料科学的迅猛发展,3D打印技术在航天、建筑、医疗、制造业等的应用日益普及,已逐步进入到人们的日常工作与生活中。本文对3D打印技术的起源、工作原理及应用现状作一简单介绍,并就其优缺点及发展前景进行了较全面的论述。

关键词:3D打印;3D打印机;快速成型

来源出版物:凿岩机械气动工具, 2014 (4): 36-41

被引频次:5

3D打印技术探究

牛一帆

摘要:3D打印技术是将三维数字模型分解成若干层平面切片,然后由3D打印机把粉末状、液状或丝状可粘合材料按切片图形逐层叠加,最终堆积成完整物体的技术。文章对3D打印的技术原理、步骤、常用材料、主要技术、发展及建议进行了深层次的探讨。与传统制造技术相比,3D打印技术有很多优势,目前已广泛应用于建筑、工业设计等领域。该技术将会带来全球制造业经济的重大变革。

关键词:3D打印;三维数字模型;平面切片;叠加成型;模型制造

来源出版物:广东印刷, 2014 (4): 21-23

被引频次:237

Scaffold development using 3D printing with a starch-based polymer

Lam, CXF; Mo, XM; Teoh, SH; et al.

Abstract: Rapid prototyping (RP)techniques have been utilised by tissue engineers to produce three-dimensional (3D)porous scaffolds. RP technologies allow the design and fabrication of complex scaffold geometries with a fully interconnected pore network. Three-dimensional printing (3DP)technique was used to fabricate scaffolds with a novel micro- and macro-architecture. In this study, a unique blend of starch-based polymer powders (cornstarch,dextran and gelatin)was developed for the 3DP Process. Cylindrical scaffolds of five different designs werefabricated and post-processed to enhance the mechanical and chemical properties. The scaffold properties were characterised by scanning electron microscopy (SEM),differential scanning calorimetry (DSC), porosity analysis and compression tests.

关键词:three-dimensional printing; rapid prototyping;starch-based scaffolds; tissue engineering

来源出版物:Materials Science and Engineering: C, 2002,20(1): 49-56

被引频次:209

Integration of surface modification and 3D fabrication techniques to prepare patterned poly(L-lactide)substrates allowing regionally selective cell adhesion

Park, A; Wu, B; Griffith, LG

Abstract: Regeneration of organizationally complex tissue requires regulation of spatial distributions of particular cell types in three dimensions. Ln this paper we demonstrate an integration of polymer processing and selective polymer surface modification using methods suitable for construction of three-dimensional polymer scaffolds which may aid such cell organization. Specifically, the surfaces of degradable polyesters were modified with poly(ethylene-oxide)(PEO)-poly(propylene-oxide)(PPO)copolymers using a process compatible with a solid free-form fabrication technique, the 3Dp(TM)printing process. We demonstrate inhibition of cell (hepatocyte and fibroblast)adhesion to regions of twodimensional poly(lactide)(PLA)substrates modified with PEO-PPO-PEO copolymers. We further show that PEOPPO-PEO-modified surfaces which are not adhesive for hepatocytes or fibroblasts can be made selectively adhesive for hepatocytes by covalent linkage of a carbohydrate ligand specific for the hepatocyte asialoglycoprotein receptor to the PEO chain ends. Our approach may be generally useful for creating regionally selective,microarchitectured scaffolds fabricated from biodegradable polymers, for spatial organization of diverse cell types.

关键词:polyethylene oxide; hepatocytes; polylactic acid;tissue engineering

来源出版物:Journal of Biomaterials Science, Polymer Edition, 1998, 9(2): 89-110

被引频次:145

Molecular model of a lattice of signalling proteins involved in bacterial chemotaxis

Shimizu, TS; Le Novere, N; Levin, MD; et al.

Abstract: Coliform bacteria detect chemical attractants by means of a membrane-associated cluster of receptors and signalling molecules. We have used recently determined molecular structures, in conjunction with plastic models generated by three-dimensional printer technology, to predict how the proteins of the complex are arranged in relation to the plasma membrane. The proposed structure is a regular two-dimensional lattice in which the cytoplasmic ends of chemotactic-receptor dimers are inserted into a hexagonal array of CheA and CheW molecules. This structure creates separate compartments for adaptation and downstream signalling, and indicates a possible basis for the spread of activity within the cluster.

来源出版物:Nature Cell Biology, 2000, 2(11): 792-796

被引频次:135

Solid free-form fabrication of drug delivery devices

Wu, BM; Borland, SW; Giordano, RA; et al.

Abstract: Three-dimensional printing (3DP)is used to create resorbable devices with complex concentration profiles within the device. 3DP is an example of a solid free-form fabrication method where both the macro- and microstructure of the device can be controlled since objects are built by addition of very small amounts of matter. Application of this novel technology for fabrication of polymeric drug delivery systems is described in this article. The drug concentration profile is first specified in a computer model of the device which is then built using the 3DP process. Complex drug delivery regimes can be created in this way, such as the release of multiple drugs or multiphasic release of a single drug. This study demonstrates several simple examples of such devices and several construction methods that can be used to control the release of the drugs. Two dyes are used as model drugs in a matrix of biocompatible polymers. The dye release rate and release time are controlled by either specifying the position of the dye within the device or by controlling the local composition and microstructure with the 3DP process,The mechanism of resorption can also be controlled by manipulating the composition and microstructure of the device during construction. Polyethylene oxide and polycaprolactone were selected as matrix materials and methylene blue and alizarin yellow were used as drug models. Devices with erosion and diffusion controls are described in this report. Spectrophotometric analysis of dye release yielded reproducible results.

来源出版物:Journal of Controlled Release, 1996, 40(1):77-87

被引频次:106

Integrated 3D-printed reactionware for chemical synthesis and analysis

Symes, MD; Kitson, PJ; Yan, J; et al.

Abstract: Three-dimensional (3D)printing has the potential to transform science and technology by creating bespoke, low-cost appliances that previously required dedicated facilities to make. An attractive, but unexplored,application is to use a 3D printer to initiate chemical reactions by printing the reagents directly into a 3D reactionware matrix, and so put reactionware design,construction and operation under digital control. Here, using a low-cost 3D printer and open-source design software we produced reactionware for organic and inorganic synthesis,which included printed-in catalysts and other architectures with printed-in components for electrochemical and spectroscopic analysis. This enabled reactions to be monitored in situ so that different reactionware architectures could be screened for their efficacy for a given process, with a digital feedback mechanism for device optimization. Furthermore, solely by modifying reactionware architecture,reaction outcomes can be altered. Taken together, this approach constitutes a relatively cheap, automated and reconfigurable chemical discovery platform that makes techniques from chemical engineering accessible to typical synthetic laboratories.

来源出版物: Nature Chemistry, 2012, 4(5): 349-354

被引频次:105

Porous titanium scaffolds fabricated using a rapid prototyping and powder metallurgy technique

Ryan, GE; Pandit, AS; Apatsidis, DP; et al.

Abstract: One of the main issues in orthopaedic implant design is the fabrication of scaffolds that closely mimic the biomechanical properties of the surrounding bone. This research reports on a multi-stage rapid prototyping technique that was successfully developed to produce porous titanium scaffolds with fully interconnected pore networks and reproducible porosity and pore size. The scaffolds' porous characteristics were governed by a sacrificial wax template,fabricated using a commercial 3D-printer. Powder metallurgy processes were employed to generate the titanium scaffolds by filling around the wax template with titanium slurry, In the attempt to optimise the powder metallurgy technique,variations in Slurry concentration, compaction pressure and sintering temperature were investigated. By altering the wax design template, pore sizes ranging from 200 to 400 pm were achieved. Scaffolds with porosities of 66.8 +/-3.6% revealed compression strengths of 104.4 +/- 22.5 MPa in the axial direction and 23.5 +/- 9.6 MPa in the transverse direction demonstrating their anisotropic nature. Scaffold topography was characterised using scanning electron microscopy and microcomputed tomography. Three-dimensional reconstruction enabled the main architectural parameters such as pore size, interconnecting porosity, level of anisotropy and level of structural disorder to be determined. The titanium scaffolds were compared to their intended designs, as governed by their sacrificial wax templates. Although discrepancies in architectural parameters existed between the intended and the actual scaffolds, overall the results indicate that the porous titanium scaffolds have the Properties to be potentially employed in orthopaeclic applications.

来源出版物: Biomaterials, 2008, 29(27): 3625-3635

被引频次:91

Computer assisted orthopaedic surgery with image based individual templates

Radermacher, K; Portheine, F; Anton, M; et al.

Abstract: Recent developments in computer assisted surgery offer promising solutions for the translation of the high accuracy of the preoperative imaging and planning into precise intraoperative surgery. Broad clinical application is hindered by high costs, additional time during intervention,problems of intraoperative man and machine interaction, and the spatially constrained arrangement of additional equipment within the operating theater, An alternative technique for computerized tomographic image based preoperative three-dimensional planning and precise surgery on bone structures using individual templates has been developed, For the preoperative customization of these mechanical tool guides, a desktop computer controlled milling device is used as a three-dimensional printer to mold the shape of small reference areas of the bone surface automatically into the body of the template. Thus, the planned position and orientation of the tool guide in spatial relation to bone is stored in a structural way and can be reproduced intraoperatively by adjusting the position of the customized contact faces of the template until the location of exact fit to the bone is found, No additional computerized equipment or time is needed during surgery, The feasibility of this approach has been shown in spine, hip, and knee surgery, and it has been applied clinically for pelvic repositioning osteotomies in acetabular dysplasia therapy.

来源出版物:Clinical Orthopaedics and Related Research,1998, 354: 28-38

被引频次:86

Mandibular reconstruction using stereolithographic 3-dimensional printing modeling technology

Cohen, A; Laviv, A; Berman, P; et al.

Abstract: Mandibular reconstruction can be challenging for the surgeon wishing to restore its unique geometry. Reconstruction can be achieved with titanium bone plates followed by autogenous bone grafting. Incorporation of the bone graft into the mandible provides continuity and strength required for proper esthetics and function and permitting dental implant rehabilitation at a later stage. Precious time in the operating room is invested in plate contouring to reconstruct the mandible. Rapid prototyping technologies can construct physical models from computer-aided design via 3-dimensional (3D)printers. A prefabricated 3D model is achieved, which assists in accurate contouring of plates and/or planning of bone graft harvest geometry before surgery. The 2 most commonly used rapid prototyping technologies are stereolithography and 3D printing (3DP). Three-dimensional printing is advantageous to stereolithography for better accuracy,quicker printing time, and lower cost. We present 3 clinical cases based on 3DP modeling technology. Models were fabricated before the resection of mandibular ameloblastoma and were used to prepare bridging plates before the first stage of reconstruction. In 1 case, another model was fabricated and used as a template for iliac crest bone graft in the second stage of reconstruction. The 3DP technology provided a precise, fast, and cheap mandibular reconstruction, which aids in shortened operation time (and therefore decreased exposure time to general anesthesia,decreased blood loss, and shorter wound exposure time)and easier surgical procedure.

来源出版物:Oral Surgery, Oral Medicine, Oral Pathology,Oral Radiology, and Endodontology, 2009, 108(5): 661-666

被引频次:70

Cost-effective three-dimensional printing of visibly transparent microchips within minutes

Shallan, AI; Smejkal, P; Corban, M; et al.

Abstract:One-stepfabricationoftransparent three-dimensional (3D)microfluidic to millifluidic devices was demonstrated using a commercial 3D printer costing $2300 with 500 mL of clear resin for $138. It employs dynamic mask projection stercolithography, allowing fast concept-to-chip time. The fully automated system allows fabrication of models of up to 43 mm × 27 mm × 180 mm (x × y × z)at printing speeds of 20 mm/h in height regardless of the design complexity. The minimal cross sectional area of 250 pm was achieved for monolithic microchannels and 200 pm for positive structures (templates for soft lithography). The colorless resin's good light transmittance(>60% transmission at wavelengths of >430 nm)allows for on-chip optical detection, while the electrically insulating material allows electrophoretic separations. To demonstrate its applicability in microfluidics, the printer was used for the fabrication of a micromixer, a gradient generator, a droplet extractor, and a device for isotachophoresis. The mixing and gradient formation units were incorporated into a device for analysis of nitrate in tap water with standard addition as a single run and multiple depth detection cells to provide an extended linear range.

来源出版物:Analytical Chemistry, 2014, 86(6): 3124-3130

被引频次:62

Effects of silica and zinc oxide doping on mechanical and biological properties of 3D printed tricalcium phosphate tissue engineering scaffolds

Fielding, GA; Bandyopadhyay, A; Bose, S; et al.

Abstract: Objectives: To evaluate the effects of silica (SiO2)(0.5 wt%)and zinc oxide (ZnO)(0.25 wt%)dopants on the mechanical and biological properties of tricalcium phosphate (TCP)scaffolds with three dimensionally (3D)interconnected pores. Methods: Scaffolds were created with a commercial 3D printer. Post sintering phase analysis was determined by X-ray diffraction. Surface morphology of the scaffolds was examined by field emission scanning electron microscopy (FESEM). Mechanical strength was evaluated with a screw driven universal testing machine. MTT assay was used for cellular proliferation characteristics and cellular morphology was examined by FESEM. Results:Addition of dopants into TCP increased the average density of pure TCP from 90.8 +/- 0.8% to 94.1 +/- 1.6% and retarded the beta to alpha phase transformation at high sintering temperatures, which resulted in up to 2.5 fold increase in compressive strength. In vitro cell-materials interaction studies, carried out using hFOB cells, confirmed that the addition of SiO2and ZnO to the scaffolds facilitated faster cell proliferation when compared to pure TCP scaffolds. Significance: Addition of SiO2and ZnO dopants to the TCP scaffolds showed increased mechanical strength as well as increased cellular proliferation.

来源出版物:Dental Materials, 2012, 28(2): 113-122

·推荐论文摘要·

小型化智能3D打印机设计

李光军,覃晓

摘要:3D打印是一种新型的技术,与传统的去除材料加工技术不同,3D打印技术是指通过连续的物理层叠加,逐层增加材料来生成三维实体的技术;无需机械加工或模具,就能直接从计算机图形数据中生成任何形状的物体,使得许多精密的模型都能够实现,为了让其能够普及,让更多的人能够使用这种技术,有必要利用信息技术来改进3D打印机使其更加智能化、简单化、实用化。文章主要研究通过以AVR单片机的Arduino ATMega2560作为硬件核心并支持上位机或者solidworks等制图软件的小型智能化3D打印机设计,通过制图软件设计模型、输入设备设定参数、从单片机或存储卡读取数据、并由单片机控制打印机打印、通过显示屏显示。

关键词:Arduino ATMega2560;3D打印机;智能化;便捷

来源出版物:信息通信, 2016(4): 97-98

3D打印机网络服务的智能云平台设计

万伟康,赵康,王文博,等

摘要:近年来,3D打印技术在国内外兴起,应用范围不断拓展,然而国内对于3D打印技术的应用开发以及服务提供还是远远不够的,为此提出了3D打印人性化控制界面开发(无线控制监测终端)、蓝牙短距离协议接入、Internet远程控制以及云服务平台搭建的解决方案,应用于教育教学或者产品展示,以及3D打印云平台的建设方面。经过实际运行,平台取得了较好的效果。

关键词:物联网;3D打印;远程控制;智能化平台;云服务

来源出版物:单片机与嵌入式系统应用, 2016, 16(3): 19-22

FDM 3D打印机半导体制冷温控设计及其冷却实验研究

靳一帆,万熠,张冰,等

摘要:针对熔融沉积(fused deposition modeling,FDM)3D打印过程中打印大斜率小截面结构时,因散热不良引起的层错位和坍塌问题,对传统FDM 3D打印机PID温度控制方案中存在的问题进行了分析,将半导体制冷技术应用于3D打印过程温度控制之中,设计开发了一种功率可调型半导体制冷系统,对不同散热条件下发生层错位和坍塌问题的角度范围进行了测量和对比。研究结果表明,所设计的半导体制冷系统冷端温度最低可达3.1℃,其热端温度可控制在65℃以下,改善了大斜率小截面结构3D打印过程的散热条件;采用该制冷系统后打印试样发生层错位和坍塌的角度范围比无散热条件时发生上述问题的角度范围减小了50%以上,比普通风扇冷却条件下发生上述问题的角度范围减小了25%以上。

关键词:半导体制冷;熔融沉积;大斜率小截面;温度控制

来源出版物:机电工程, 2016, 33(2): 45-48

联系邮箱:万熠,wanyi@sdu.edu.cn

Kossel 3D打印机精度影响因素及微调方法研究

袁泽林,方辉,黄纪刚,等

摘要:Kossel 3D打印机是一种并联式开源打印机,具有快速打印、噪音小、能自我复制、扩展性好的优点。但是在其装配和使用过程中,微调是一个比较困难又对其性能、打印精度影响较大的问题。为解决这一问题,在对Kossel打印机进行结构分析的基础上,研究了其Arduino控制器Marlin固件的运动参数,分析了该型打印机的精度影响因素,并对打印平台微调的调平方法和调运动参数方法进行了分析和实验验证,提出了该型打印机微调方案,为进一步提升打印精度提供了可行的技术支持。

关键词:并联式3D打印机;Kossel;Marlin;Arduino;调平;运动参数

来源出版物:制造技术与机床, 2016(4): 21-27

基于开源型3D打印机(RepRap)打印部件的机械性能研究

赖月梅

摘要:目前针对该开源型3D打印机打印产品的力学性能研究还相当的缺乏,无法满足工业或者受力部件的打印指导。本文为验证Rep Rap原型打印机或者其衍生版本打印机的真实受力环境可用性,对其打印的部件进行了基本的力学性能测试,从而得到能够反映其打印质量的拉伸强度、延伸率以及弹性模量,进而对该类型3D打印机用户提供打印标准及指导。根据实验结果,ABS 和PLA材料打印试样的平均拉伸强度分别为28.2 MPa和58.1 MPa,所对应的平均弹性模量为1533 MPa和3500 MPa。通过与商用打印机打印试样的力学性能结果对比,可以明显看出开源型打印机不仅在结构建造上面具有可调谐,组装成本低的优点,并且其在力学功能性方面也有其可比较性。

关键词:Rep Rap;抗拉强度;弹性模量;ABS树脂材料;聚乳酸(PLA)

来源出版物:科技通报, 2015, 31(8): 235-239

联系邮箱:赖月梅,13979118563@ 139.com

熔融沉积成型3D打印机混色装置的研究

韩善灵,李志勇,肖宇,等

摘要:当前基于熔融沉积成型的桌面级3D打印机的大部分打印头装置只能打印一种颜色的耗材,打印出来的物体颜色单一,为了解决这一问题,在分析了整个3D打印头装置的基础上,运用TRIZ理论对3D打印头进行了创新设计,设计出一种双进料单挤出的打印头装置,该打印头装置能将两种颜色的耗材融化混合,并从同一喷嘴挤出,实现混色打印。运用UG有限元模块对所设计机构进行了温度场的模拟分析,最终对装置进行了试验,验证了温度场分析的正确性,达到了混色要求,为3D打印机混色装置的进一步研究提供了理论依据。

关键词:熔融沉积成型;3D打印机;TRIZ理论;混色;UG;温度场

来源出版物:机械设计与制造, 2015(11): 116-118

对3D打印机喷头XYZ三个方向位置控制的优化设计探究

王瑞玲

摘要:本文提出了对喷头XYZ三个方向位置控制的优化方案,并对其进行了理论数据论证;本文对3D打印机完整的基本功能列写了各个部位的功能设计及具体实现,并提出了一些使3D打印机能够更有效利用的措施。

关键词:3D打印机;快速成型;XYZ三个方向位置控制来源出版物:电子测试, 2014 (1X): 1-2

联系邮箱:唐元家, angyuanjia028@163.com

3D printed microfluidic circuitry via multijet-based additive manufacturing

Sochol, RD; Sweet, E; Glick, CC; et al.

Abstract: The miniaturization of integrated fluidic processors affords extensive benefits for chemical and biological fields, yet traditional, monolithic methods of microfabrication present numerous obstacles for the scaling of fluidic operators. Recently, researchers have investigated the use of additive manufacturing or “threedimensional (3D)printing” technologies - predominantly stereolithography - as a promising alternative for the construction of submillimeter-scale fluidic components. One challenge, however, is that current stereolithography methods lack the ability to simultaneously print sacrificial support materials, which limits the geometric versatility of such approaches. In this work, we investigate the use of multijet modelling (alternatively, polyjet printing)- a layer-by-layer, multi-material inkjetting process - for 3D printinggeometricallycomplex,yetfunctionally advantageous fluidic components comprised of both static and dynamic physical elements. We examine a fundamental class of 3D printed microfluidic operators, including fluidic capacitors, fluidic diodes, and fluidic transistors. In addition, we evaluate the potential to advance on-chip automation of integrated fluidic systems via geometric modification of component parameters. Theoretical and experimental results for 3D fluidic capacitors demonstrated that transitioning from planar to non-planar diaphragm architectures improved component performance. Flow rectification experiments for 3D printed fluidic diodes revealed a diodicity of 80.6 +/- 1.8. Geometry-based gain enhancement for 3D printed fluidic transistors yielded pressure gain of 3.01 +/- 0.78. Consistent with additional additive manufacturing methodologies, the use of digitallytransferrable 3D models of fluidic components combined with commercially-available 3D printers could extend the fluidic routing capabilities presented here to researchers in fields beyond the core engineering community.

来源出版物:Lab on a Chip, 2016, 16(4): 668-678

联系邮箱:Sochol, RD; rsochol@umd.edu

3D printed microfluidic devices with integrated valves

Rogers, CI; Qaderi, K; Woolley, AT; et al.

Abstract: We report the successful fabrication and testing of 3D printed microfluidic devices with integrated membrane-based valves. Fabrication is performed with a low-cost commercially available stereolithographic 3D printer. Horizontal microfluidic channels with designed rectangular cross sectional dimensions as small as 350 μm wide and 250 μm tall are printed with 100% yield, as are cylindrical vertical microfluidic channels with 350 μmdesigned (210 μm actual)diameters. Based on our previous work [Rogers et al., Anal. Chem. 83, 6418 (2011)], we use a custom resin formulation tailored for low non-specific protein adsorption. Valves are fabricated with a membrane consisting of a single build layer. The fluid pressure required to open a closed valve is the same as the control pressure holding the valve closed. 3D printed valves are successfully demonstrated for up to 800 actuations.

来源出版物:Biomicrofluidics, 2015, 9(1): 016501

联系邮箱:Woolley, AT; atw@byu.edu

Fabrication of extended-release patient-tailored prednisolone tablets via fused deposition modelling (FDM)3D printing

Skowyra, J; Pietrzak, K; Alhnan, MA; et al.

Abstract: Rapid and reliable tailoring of the dose of controlled release tablets to suit an individual patient is a major challenge for personalized medicine. The aim of this work was to investigate the feasibility of using a fused deposition modelling (FDM)based 3D printer to fabricate extended release tablet using prednisolone loaded poly(vinyl alcohol)(PVA)filaments and to control its dose. Prednisolone was loaded into a PVA-based (1.75 mm)filament at approximately 1.9% w/w via incubation in a saturated methanolic solution of prednisolone. The physical form of the drug was assessed using differential scanning calorimetry (DSC)and X-ray powder diffraction (XRPD). Dose accuracy and in vitro drug release patterns were assessed using HPLC and pH change flow-through dissolution test. Prednisolone loaded PVA filament demonstrated an ability to be fabricated into regular ellipse-shaped solid tablets using the FDM-based 3D printer. It was possible to control the mass of printed tablet through manipulating the volume of the design (R-2 = 0.9983). On printing tablets with target drug contents of 2,3, 4, 5, 7.5 and 10 mg, a good correlation between target and achieved dose was obtained (R-2 = 0.9904)with a dose accuracy range of 88.7%-107%. Thermal analysis and XRPD indicated that the majority of prednisolone existed in amorphous form within the tablets. In vitro drug release from 3D printed tablets was extended up to 24 h. FDM based 3D printing is a promising method to produce and control the dose of extended release tablets, providing a highly adjustable, affordable, minimally sized, digitally controlledplatformforproducingpatient-tailored medicines.

关键词:rapid prototyping; fused filament fabrication; FFF; personalized; patient-specific; 3D printer

来源出版物:European Journal of Pharmaceutical Sciences, 2015, 68: 11-17

联系邮箱:Alhnan, MA; MAlbedAlhnan@uclan.ac.uk

In-body tissue-engineered aortic valve (Biovalve type VII)architecture based on 3D printer molding

Nakayama, Y; Takewa, Y; Sumikura, H; et al.

Abstract: In-body tissue architecturea novel and practical regeneration medicine technologycan be used to prepare a completely autologous heart valve, based on the shape of a mold. In this study, a three-dimensional (3D)printer was used to produce the molds. A 3D printer can easily reproduce the 3D-shape and size of native heart valves within several processing hours. For a tri-leaflet, valved conduit with a sinus of Valsalva (Biovalve type VII), the mold was assembled using two conduit parts and three sinus parts produced by the 3D printer. Biovalves were generated from completely autologous connective tissue,containing collagen and fibroblasts, within 2 months following the subcutaneous embedding of the molds (success rate, 27/30). In vitro evaluation, using a pulsatile circulation circuit, showed excellent valvular function with a durability of at least 10 days. Interposed between two expanded polytetrafluoroethylene grafts, the Biovalves (N=3)were implanted in goats through an apico-aortic bypass procedure. Postoperative echocardiography showed smooth movement of the leaflets with minimal regurgitation under systemic circulation. After 1 month of implantation, smooth white leaflets were observed with minimal thrombus formation. Functional, autologous,3D-shaped heart valves with clinical application potential were formed following in-body embedding of specially designed molds that were created within several hours by 3D printer.

关键词:tissue engineering; heart valve; 3D printer;connective tissue; surgery

来源出版物:Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2015, 103(1): 1-11

联系邮箱:Nakayama, Y; ny@ncvc.go.jp

PDMS lab-on-a-chip fabrication using 3D printed templates

Comina, G; Suska, A; Filippini, D; et al.

Abstract: The fabrication of conventional PDMS on glass lab-on-a-chip (LOC)devices, using templates printed witha commercial (2299 US$)micro-stereo lithography 3D printer, is demonstrated. Printed templates replace clean room and photolithographic fabrication resources and deliver resolutions of 50 μm, and up to 10 μm in localized hindrances, whereas the templates are smooth enough to allow direct transfer and proper sealing to glass substrates. 3D printed templates accommodate multiple thicknesses,from 50 μm up to several mm within the same template,with no additional processing cost or effort. This capability is exploited to integrate silicone tubing easily, to improve micromixer performance and to produce multilevel fluidics with simple access to independent functional surfaces,which is illustrated by time-resolved glucose detection. The templates are reusable, can be fabricated in under 20 min,with an average cost of 0.48 US$, which promotes broader access to established LOC configurations with minimal fabrication requirements, relieves LOC fabrication from design skills and provides a versatile LOC development platform.

来源出版物:Lab on a Chip, 2014, 14(2): 424-430

联系邮箱:Filippini, D; danfi@ifm.liu.se

Innovations in 3D printing: A 3D overview from optics to organs

Schubert, C; van Langeveld, MC; Donoso, LA

Abstract: 3D printing is a method of manufacturing in which materials, such as plastic or metal, are deposited onto one another in layers to produce a three dimensional object, such as a pair of eye glasses or other 3D objects. This process contrasts with traditional ink-based printers which produce a two dimensional object (ink on paper). To date, 3D printing has primarily been used in engineering to create engineering prototypes. However, recent advances in printing materials have now enabled 3D printers to make objects that are comparable with traditionally manufactured items. In contrast with conventional printers, 3D printing has the potential to enable mass customisation of goods on a large scale and has relevance in medicine including ophthalmology. 3D printing has already been proved viable in several medical applications including the manufacture of eyeglasses, custom prosthetic devices and dental implants. In this review, we discuss the potential for 3D printing to revolutionise manufacturing in the same way as the printing press revolutionised conventional printing. The applications and limitations of 3D printing are discussed;the production process is demonstrated by producing a set of eyeglass frames from 3D blueprints.

来源出版物:British Journal of Ophthalmology, 2014,98(2): 159-161

联系邮箱:Donoso, LA; ldonoso@vision-research.org

Low cost lab-on-a-chip prototyping with a consumer grade 3D printer

Comina, G; Suska, A; Filippini, D

Abstract: Versatile prototyping of 3D printed lab-on-a-chip devices, supporting different forms of sample delivery,transport, functionalization and readout, is demonstrated with a consumer grade printer, which centralizes all critical fabrication tasks. Devices cost 0.57US$ and are demonstrated in chemical sensing and micromixing examples, which exploit established principles from reference technologies.

来源出版物:Lab on a Chip, 2014, 14(16): 2978-2982

联系邮箱:Filippini, D; danfi@ifm.liu.se

Physical models of renal malignancies using standard cross-sectional imaging and 3-Dimensional printers: A pilot study

Silberstein, JL; Maddox, MM; Dorsey, P; et al.

Abstract: OBJECTIVE: To construct high-fidelity, patient customized, physical, 3-dimensional (3D)models of renal units with enhancing renal lesions identified on crosssectional imaging, which may aid patients, trainees, and clinicians in their comprehension, characterization,localization, and extirpation of suspicious renal masses. METHODS: Specialized software was used to import patient's diagnostic computerized tomography cross-sectional imaging into 3D printers and create physical 3D models of renal units with enhancing in situ lesions. Patients and trainees had the opportunity to manipulate the individualized model before surgical resection. Sterolithography additive manufacturing, a technique in which an ultraviolet laser is used to cure a photosensitive resin in sequential horizontally oriented layers, was used to build the models (Medical Modeling Inc., Golden, CO). Normal renal parenchyma was printed with a clear translucent resin, and red translucent resin delineated suspicious lesions. Renal vasculature and the proximal collecting system were printed in some models. RESULTS: We constructed 5 physical models of renal units with suspected malignancies before surgery. All patients successfully underwent partial nephrectomy (4 robotic and 1 open). Average ischemia time was 21 minutes, nephrometry score was 6.8, and all margins were negative. Anecdotally, patients, their families, and trainees consistently stated that the modelsenhanced their comprehension of the renal tumor in relation to surrounding normal renal parenchyma and hilar structures and improved understanding of the goals of the surgery. CONCLUSION: Preoperative physical 3D models using available printing techniques can be constructed and may potentially influence both patients' and trainees' understanding of renal malignancies.

来源出版物:Urology, 2014, 84(2): 268-273

联系邮箱:Silberstein, JL; jsilbers@tulane.edu

Engineering anatomically shaped vascularized bone grafts with hASCs and 3D-printed PCL scaffolds

Temple, JP; Hutton, DL; Hung, BP; et al.

Abstract: The treatment of large craniomaxillofacial bone defects is clinically challenging due to the limited availability of transplantable autologous bone grafts and the complex geometry of the bones. The ability to regenerate new bone tissues that faithfully replicate the anatomy would revolutionize treatment options. Advances in the field of bone tissue engineering over the past few decades offer promising new treatment alternatives using biocompatible scaffold materials and autologous cells. This approach combined with recent advances in three-dimensional (3D)printing technologies may soon allow the generation of large, bioartificial bone grafts with custom, patient-specific architecture. In this study, we use a custom-built 3D printer to develop anatomically shaped polycaprolactone (PCL)scaffolds with varying internal porosities. These scaffolds are assessed for their ability to support induction of human adipose-derived stem cells (hASCs)to form vasculature and bone, two essential components of functional bone tissue. The development of functional tissues is assessed in vitro and in vivo. Finally, we demonstrate the ability to print large mandibular and maxillary bone scaffolds that replicate fine details extracted from patient's computed tomography scans. The findings of this study illustrate the capabilities and potential of 3D printed scaffolds to be used for engineering autologous, anatomically shaped, vascularized bone grafts.

关键词:3D printing; patient-specific; bone scaffolds;vascularized bone; tissue engineering

来源出版物:Journal of Biomedical Materials Research Part A, 2014, 102(12): 4317-4325

联系邮箱:Grayson, WL; wgrayson@jhmi.edu

3D-printed fluidic devices enable quantitative evaluation of blood components in modified storage solutions for use in transfusion medicine

Chen, CP; Wang, YM; Lockwood, SY; et al.

Abstract: A fluidic device constructed with a 3D-printer can be used to investigate stored blood components with subsequent high-throughput calibration and readout with a standard plate reader.

来源出版物:Analyst, 2014, 139(13): 3219-3226

联系邮箱:Spence, DM; dspence@chemistry.msu.edu

A 3D bioprinting system to produce human-scale tissue constructs with structural integrity

Kang, HW; Lee, SJ; Ko, IK

Abstract: A challenge for tissue engineering is producing three-dimensional (3D), vascularized cellular constructs of clinically relevant size, shape and structural integrity. We present an integrated tissue-organ printer (ITOP)that can fabricate stable, human-scale tissue constructs of any shape. Mechanical stability is achieved by printing cell-laden hydrogels together with biodegradable polymers in integrated patterns and anchored on sacrificial hydrogels. The correct shape of the tissue construct is achieved by representing clinical imaging data as a computer model of the anatomical defect and translating the model into a program that controls the motions of the printer nozzles, which dispense cells to discrete locations. The incorporation of microchannels into the tissue constructs facilitates diffusion of nutrients to printed cells, thereby overcoming the diffusion limit of 100-200 mm for cell survival in engineered tissues. We demonstrate capabilities of the ITOP by fabricating mandible and calvarial bone, cartilage and skeletal muscle. Future development of the ITOP is being directed to the production of tissues for human applications and to the building of more complex tissues and solid organs.

来源出版物:Nature Biotechnology, 2016, 34(3): 312-319

联系邮箱:Atala, A; aatala@wakehealth.edu

编辑:王微

A robust process optimization for a powder type rapid prototyper

Yao, AWK; Tseng, YC

Rapid Prototyping (RP)technology is being widelyusedindiverseareasincludingmold manufacturing. However, the quality of RP parts is significantly affected by the property of adopted material and process parameters of the rapid prototyper. The aim of this paper is to investigate the powder material and to optimize the process parameters for Zcorp 402 3DP rapid fabricator. Taguchi's method was employed to investigate the possible process parameters including binder setting saturation value (shell & core), layer thickness, and location of made-up parts. The experimental result shows that these optimal parameters can shorten parts building time and reduce the use of powder and glue about 20 per cent for ZP100 and 10 per cent for ZP11. Additionally, the quality of RP parts is also improved dramatically. The observation of experiments also shows that the parts made by ZP11 powder is difficult to clean up because of its starch-based property.