CFD modeling of a headbox with injecting dilution water in a central step diffusion tube☆

2016-05-26XuYangJinsongZengKefuChenYuchengFeng

Xu Yang,Jinsong Zeng*,Kefu Chen,Yucheng Feng

State Key Laboratory of Pulp and Paper Engineering,School of Light Industry and Food Science,South China University of Technology,Guangzhou 510640,China

1.Introduction

The headbox is the heart of a paper machine,which delivers a well dispersed suspension with sufficient micro-turbulence to minimize fiber flocculation[1].To attain higher operational speeds,headbox designs have progressed from open-air headboxes with agitating rolls to the more modern high-speed hydraulic types[2].

Hydraulic headboxes do not rely on air pressure to make the flow uniform.Instead,they utilize the hydraulic pressure created by a high flow velocity.To a large degree,the dispersion of fibers at the headbox discharge determines the uniformity and quality of the sheets produced.Modern headbox systems can fine-tune the basis weight through computer-controlled slice adjustments and dilution systems that compensate for pro file variations in the machine direction and cross direction[3].The uniformity in the slice flow begins with the headbox header.To obtain uniform nozzle flow,cross- flow headers must be designed using the theory of fluid mechanics[4].Scott[5]has proposed that a new headbox design must provide a narrower basis weight response(basis weight responding range)compared with that achieved by a slice bending system.In addition to providing advancements in profiling,headbox designs decouple the basis weight profiling from the fiber orientation profile response.Controlling the consistency allows better basis weight profiling(profile variations in the machine direction and cross direction)than that achieved by slice bending.To understand the effect of design and operation of the headbox on fiber orientation,several fundamental studies have examined the orientation distribution of suspended fibers as they pass through a transparent laboratory headbox. Ullmar and Norman [6,7] measured the fiber orientation distribution in the plane of paper at headbox exit by electronically imaging suspended nylon fibers. These studies examined the effect of mean flow through the headbox, contraction ratio, and fiber concentration.

The pulp suspensions through the headbox are non-Newtonian fluids.They are continuous fiber networks with structure and strength attributing to the interactions between neighboring fibers.To create motion throughout the suspension,the shear stresses imposed on the suspension must be greater than the network strength,measured as the suspension yield stress[8].Fiber suspensions exhibit nonlinear viscoelastic properties,such as shear thinning[9].Beyond the yield point,however,the pulp suspensions display unique and poorly characterized rheological properties[10].

Constructing a flow model to predict the flow behavior of pulp fiber suspensions is important in this area because an accurate modeling strategy can reduce the costs of experiments and prototype equipment when designing headboxes.Advanced flow models for complex systems,particularly those with high consistency, have not been developed to the degree required for completely characterizing the flow of fiber suspensions, although some attempts have been reported for extremely diluted suspensions[11].Various attempts to model headboxes involve numerous simplifications. Hamalainen [12] assumed that the flow could be described in two dimensions and a homogenization model was used for the tubes. Aidun and Kovacs [13] considered only a portion of a headbox. Even with these simplifications, these models produced useful results.

Headbox designs are closely associated with the theory of fluid mechanics.Computational fluid dynamics(CFD)has been used to model the turbulent flow of pulp fiber suspensions in pipes and headboxes.Bakker and Fasano[14]were the first to model the pulp flow in a stock chest with a side entering impeller using CFD.Experimentally validated fiber flow models,which may use CFD based on the finite elements method and compare pressure drop results,are essential for detailed descriptions of fiber flows.The k-ε turbulence model is extensively applied,with some restrictions.For example,the Reynolds number must be sufficiently high and the turbulence has to be uniform within boundary layers.Beyond the restrictions,the works using the k-ε turbulence model are useless[15].These assumptions limit the accuracy of the model because they are not always satisfied.A suspension is described as a pseudo-homogeneous one-phase fluid,the model still can be applicable for simulation under certain conditions although it does not account for the existence of particles/ fiber structures or for the variations in the consistency of the flow field.All of the suspension components always undergo complex turbulent motion.Moreover, the turbulence parameters in the k-ε model are functions of fiber type and concentration[16].

In a more recent study[17],the fiber orientation distribution was measured in the plane of paper and in that of contraction at several locations along the axis of a headbox.The fiber orientation distributions were measured over a range of inlet flow rates.When the turbulent dispersion is neglected,the theoretically predicted fiber orientation distribution significantly is beyond the degree of fiber alignment compared to experimental data [17,18]. Therefore, predicting the fiber orientation in the headbox flow must account for the effects of fluid turbulence.James et al. developed a theoretical model for the orientation distribution of fibers moving in a turbulent planar contraction, compared to experimental measurements in literature, and then used the model to explore the effects of headbox design and operation[19].

This work aims to analyze the hydrodynamics of the headbox with injecting dilution water in central step diffusion tube using numerical simulation.The results are expected to ensure the design and scale-up of a new efficient headbox with medium-highs peed,and provide a better consistency distribution.Based on the flow channel of headbox in engineering practice,a scale model of an industrial headbox is designed using the standard k-ε turbulence models with turbulent flows-species transport approach to examine the flow field,and the outlet consistency curve of slice channel is found.In the hydrodynamic headbox,diluted water will affect the consistency,turbulence kinetic energy,turbulence intensity,and turbulence dissipation rate of the flow channel.

2.Experimental and Validation

2.1.Experimental

The experimental set-up is shown in Fig.1,consisting of a main stream tank made of stainless steel,a scale Plexiglass headbox model,pumps 1 and 2,a polypropylene tank for collecting water,two valves,and two electromagnetic flow meters.The tanks and model are self-made,and the valves and flow meters are obtained from Dongchi Measurement&Control Technology Co.,Ltd.in Ningbo City of China.The scale headbox model is composed of a manifold head,a step diffusion tube,an equalizing chamber,a turbulence generator,and a slice channel.The main stream tank measures approximately 3.0×1.5×2.5 m with a partition in the middle to transport different consistency pulp through pump 1(type KZ125-350, flow rate 350 m3·h−1,head 50 m)and pump 2(type KZ80-265, flow rate 265 m3·h−1,head 60 m).The side of a manifold head with a large and small end is connected to a step diffusion tube.The main stream is pumped to the large end of the manifold head through pump 2.The back flow crossing the manifold head directly returns to the right portion of the main stream tank when the polyamide particles,used as tracers,are added to measure the flow field.When Rhoda mine B(Dantec Dynamics A/S),a fluorescent dye,is added to determine the consistency,the back flow no longer returns to the right portion of the mainstream tank and is drained out.The diluted water from the left portion of the mainstream tank is pumped into the injector inlet of the manifold head through pump 1.The main stream is mixed with diluted water,passing through the step diffusion tube,equalizing chamber,turbulence generator and slice channel in turn.The mixed flow out of the slice channel is injected into the collection tank.When the flow is used to determine the mixing consistency,it would discharge from the collection tank;when the flow is used to measure the flow field,it would return to the main stream tank to save the tracer and water.

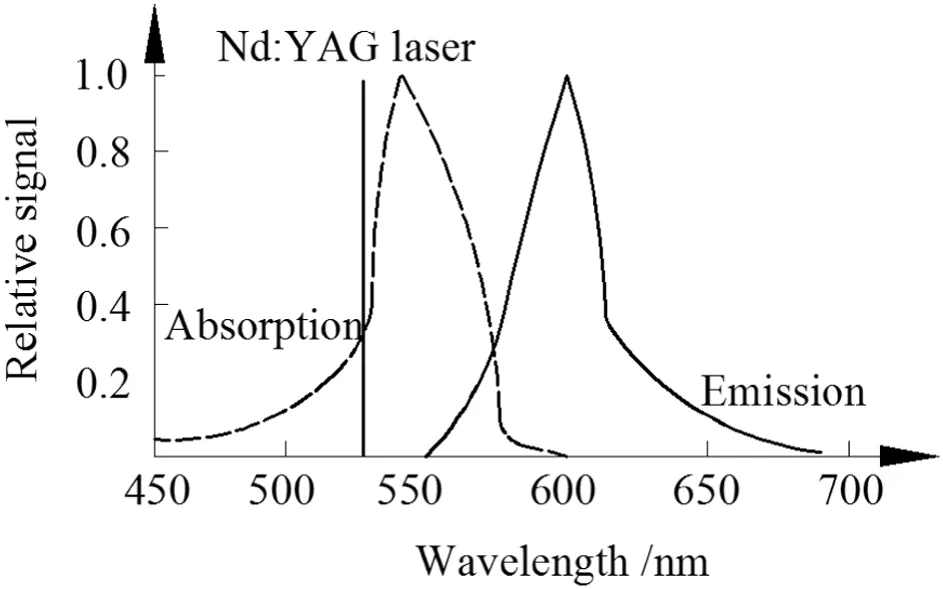

To acquire information about the flow field,a two-dimensional particle image velocimetry (PIV) system is combined with a planar laser induced fluorescence module, which is a non-intrusive optical device(Dantec Dynamics PIV System, Marketec Technology Limited, Hong Kong) to measure the movement of small tracer particles with a charge coupled device (CCD) camera, a pulsed laser light, a computer, and a monitor [20]. In this study, CCD camera is used to record images of particles in the illuminated plane. The image data are analyzed using the Dynamics Studio imaging platform (Marketec Technology Limited,Hong Kong) [20]. In these measurements, the laser and the CCD are perpendicular to the side and bottom of the plexiglass headbox, and the CCD is placed under the equalizing chamber or slice channel of headbox to assess their flow field separately. Tomeasure the outlet consistency, a liquid and gas laser induce fluorescence module for Dynamic Studio(type 80S85) and a Starter Kit for concentration measurements (type 80 × 133) are used with the laser and CCD near the outlet. Rhodamine B and a colored filter are used in the consistency measurements instead of the tracer and single-pass filter in the flow field measurements.The colored filter filters the green light while imaging the fluorescent particles,while the single pass filter retains the green light.The absorption and emission spectra of the fluorescent dye gathered in the experiment are shown in Fig.2.The energy absorption spectrum is measured between 460 and 590 nm,with a peak at approximately 520 nm.This characteristic makes the marker very well suited for experiments using a high-frequency Nd:YAG laser(λ=532 nm).Furthermore,the fluorescence spectrum(between 550 and 650–670 nm)does not greatly interfere with the absorption spectrum.By filtering the signal through an appropriate filter with a cut-off at approximately 550/570,the laser light can be blocked,allowing only the fluorescence to reach the sensor.At low concentrations,absorption phenomena are very weak and local concentrations are determined from the re-emitted fluorescence.

Fig.1.Scheme of experimental set up.

It indicates that the fluorescence intensity is approximately proportional to the consistency and the magnitude of the consistency can be determined directly.

Fig.2.Absorption(dotted line)and emission(solid line)spectra of Rhoda mine 6B in water.

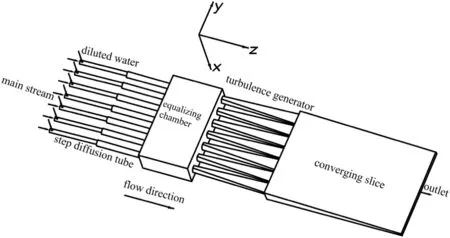

In the experiment,the flux at the inlet,the back flow for manifold header,and the diluted water is controlled by an electromagnetic flow meter and a valve.In addition,1%and 0.3%Rhoda mine B solution represent 1%and 0.3%pulp suspensions,respectively.The 1%(by mass)pulp is used as the primary stream,and the 0.3%pulp is used as the diluted water to be injected.The frequency conversion controls the flow rate of main stream ranged from 6 m·s−1to 20 m·s−1,and the frequency conversion controls the flow rate of diluted water ranged from 12 m·s−1to 40 m·s−1.The large-end inlet of the manifold head measures 57 mm in diameter,and its small-end back flow measures 20 mm in diameter.Seven outlets measuring 20 mm in diameter are located on the side of the manifold head.The diameter of diluted water inlet is 8 mm.The small and large pipes of step diffusion tubes measure 20 and 30 mm in diameter,respectively,and 250 mm in length.The inside of the equalizing chamber measures approximately 510×250×170 mm.The cross-section transition of the turbulence generator is from a circular diameter of 35mm to rectangle with dimensions of 55×18 mm;this part measures 400 mm long.The rectangular outlet of slice channel measures 550×18 mm in area and 700 mm in length.To decrease the computational domain and improve the data describing the other parts of the headbox except the manifold header,the computational model shown in Fig.3treats the flow from the seven step diffusion tubes as equal flux,because the speeds in the manifold header are equal and the step diffusion tubes are the same sizes.Therefore,the computational model includes only the step diffusion tube,the equalizing chamber,the turbulence generator,and the slice channel.

2.2.Computational model

Simulations are carried out in CFD code ANSYS 12.0 and the sizes of the scale model are the same as the vessel sizes in the experiment.The computational model captured the main features of the headbox other than the manifold header,including the step diffusion tube,equalizing chamber,turbulence generator,and slice channel.The computation domain spans from x=−57.5 mm to x=57.5 mm,from y=−235 mm to y=235 mm,and from z=−560 mm to z=1290 mm.The diluted sites locate at the step diffusion tubes injecting diluted water,10 mm from the inlet of the main stream,as shown in Fig.3.The manifold head is complicated and this structure keeps the flow entering the step diffusion tube with equal speed while assuming that the fluxes entering the seven step diffusion tubes in the model are equal,as shown in Fig.3.In the model,the mainstream entering the inlet of the seven-step diffusion tube is mixed with diluted water from its top,then passing though the step diffusion tube,equalizing chamber,turbulence generator and slice channel.The flow out of the slice channel is ejected.

Fig.3.Computational domain of the headbox model.

There are some advantages for triangle/tetrahedral unstructured mesh,such as flexible distribution,good adaption,and convenience to refine locally,so it can be used to compute complicated region of CFD model.In this paper,the geometrical model with irregular design is rather complicated,so the unstructured tetrahedral meshes are used to simulate the flow field,and a viscous flow with a triangular mesh is used on the model wall.To model the turbulence,a standard k-ε model is combined with mass diffusion in turbulent flow species transport approach in mixing flow simulations of the viscous model.Semi-implicit method for pressure linked equation schemes are used for pressure velocity coupling,whereas standard is used as the spatial discretization method for pressure.A second-order implicit scheme is used for advancing the time.Residual values below 10−4are selected as the convergence criteria for the pulp flow.The computational time is approximately two days when using a dual-core 4-GHz CPU.

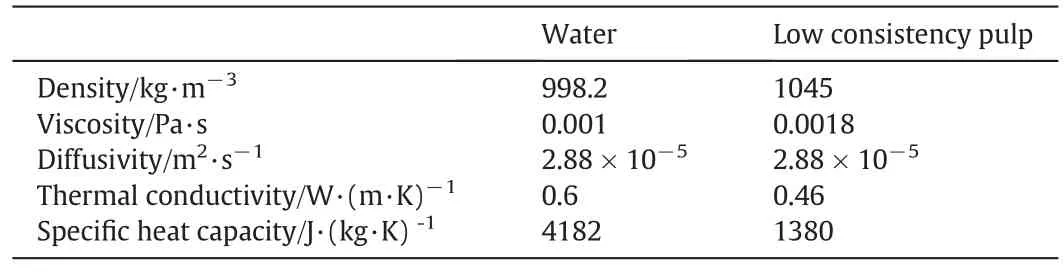

Low consistency pulp is a kind of non-Newtonian viscoplastic fluid.When its shear stress is greater than yield stress,the viscoplastic fluid has the same hydromechanical characteristics as the Newtonian fluid.Furthermore,the low consistency pulp flow in the headbox with medium-high speed is fully developed turbulence.The shear stress is greater than yield stress and its viscosity is constant,the same as the Newtonian fluid[1].The low consistency pulp flow is considered as a mixture containing two fluids:water and low consistency pulp.Table 1 lists the simulation parameters for CFD model when the consistency of the diluted pulp is 0.3%and the main stream is 1%.

Table 1 Simulation parameters for CFD model

2.3.Conservation equation

2.3.1.Mass conservation equation

To calculate the mixing of the two fluids in the desired proportion,a species transport model is implemented influent,which is a type of transport model.The model predicts the local mass fraction of each species(Yi)by solving a convection diffusion equation for the it h species[21].This mass conservation equation has the following general form.

The sum of mass conservation equations species is the continuity equation.

2.3.1.1.Momentum conservation equation.The momentum equation for the mixture is obtained by summing the individual momentum equations for all phases.It can be expressed as

2.3.1.2.Energy conservation equation.The energy equation for the mixture takes the form of

2.4.Species transport in the energy equation

2.5.Transport equations for the standard k-ε model

The k-ε turbulence model is high Reynolds number model.The low consistency pulp flow in the headbox with medium-high speed is a fully developed turbulence with high Reynolds number,which is not based on certain restrictions of k-ε turbulence model.When the shear stress of the low consistency pulp flow with medium-high speed is greater than yield stress,it follows the same linear law as the Newtonian fluid in hydrodynamics characteristics.In PERA GLOBAL Company's ANSYS tutorial[22],if the phases are discrete,their density scale is 1,or the particles are dispersed,the single phase k-ε turbulence model can be used in the mixture.Thus the k-ε turbulence model works well in this water-pulp emulsion flow.

The turbulence kinetic energy(k)and its rate of dissipation(ε)are obtained from the following transport equations[21].

The turbulent(or eddy)viscosity(μt)is computed by combining k and ε

where Cμis a constant.The model constants(C1ε,C2ε,Cμ,σkand σε)have following default values:C1ε=1.44,C2ε=1.92,Cμ=0.09,σk=1.0,and σε=1.3.

2.6.Validation

In the PIV experiment,velocity vectors are measured.To make the comparison between CFD predictions and experimental values convenient,the water content is considered as the standard to be compared,the sum of water content and pulp consistency are set to be 1.Figs.4 and 5 show the results obtained from the PIV experiment and simulation.In Fig.4,the partial flow fields of the equalizing chamber include velocity vectors at the location x=0,−0.23 m<y<−0.14 m,0.12 m<z<0.22 m,and velocity magnitude at x=0,−0.230 m<y<−0.140 m,z=0.150 m.In Fig.5,the partial flow fields of the slice channel include velocity vectors at x=0.030 m,−0.23 m <y<−0.13 m,1.16 m<z<1.26 m,and velocity magnitude at x=0.030 m,−0.230 m<y<−0.130 m,z=1.200 m.In Figs.4(a)and 5(a),the left is simulation results and the right is experimental results.It can be clearly seen that the flow fields for the PIV experiments and CFD simulations are similar,and the differences of velocity magnitude between the PIV experiments and CFD simulations are small.

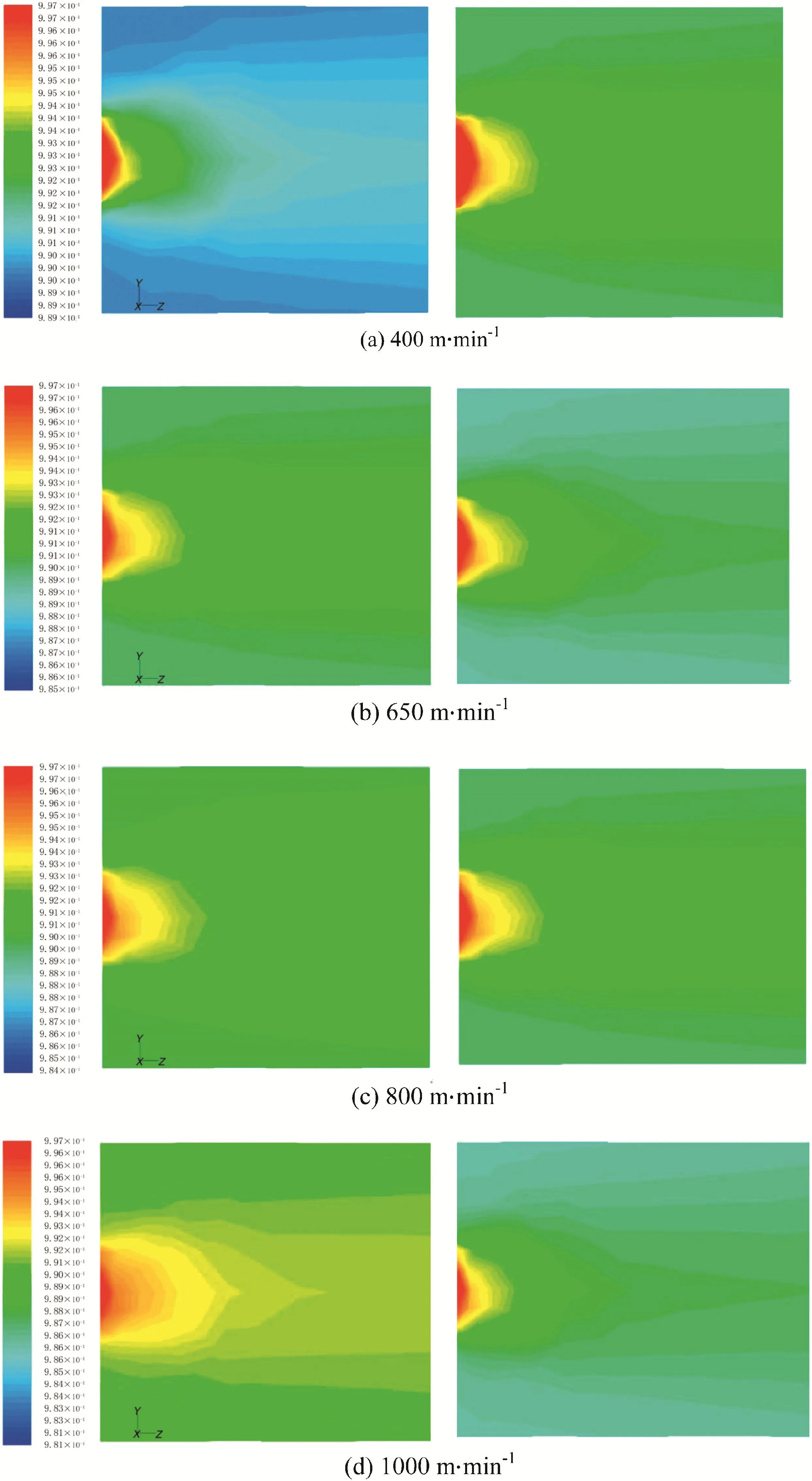

In the LIF experiment,the pulp consistency is measured.The CFD predictions and experimental values are compared.For convenience,the water content is also considered as a standard.Figs.6 and 7 show the results of the LIF experiment and simulation.To make a better comparison,the mixing regime of the diluting water and the mainstream is chosen in the step diffusion tube,as shown in Fig.6.The change trends between the CFD predictions and the experimental values are similar;the consistency is the largest in the injecting site;the consistency drops gradually as the flow goes on.And the largest difference for water content happens at 400,800 m·min−1speed,the second are for 650 m·min−1and 1000 m·min−1speeds,and the least difference is at 800 m·min−1speed.

Fig.4.Part equalizing chamber for simulation and PIV at800m·min−1.(a)Velocity vectors at the location x=0,−0.23m<y<−0.14m,0.12m<z<0.22m.(b)Velocity magnitude at the location x=0,−0.230 m<y<−0.140 m,z=0.150 m.

Fig.5.Part slice channel for simulation and PIV at 800m·min−1.(a)Velocity vectors at the location x=0.030m,−0.23m<y<−0.13m,1.16m<z<1.26m.(b)Velocity magnitude at the location x=0.030 m,−0.230 m<y<−0.130 m,z=1.200 m.

To make further comparison,the water content of the outlet is shown in Fig.7 for various speeds respectively.In Fig.7, “EXP”represents the “experiment”,and “SIM”represents simulation.The curve of trends for the CFD predictions and the experimental values were similar.And the largest differences between the experimental values and the simulation results were 5 × 10−5for 400 m·min−1speed,4× 10−5for 1000 m·min−1speed,2× 10−5for 650 m·min−1speed,and1×10−5for800m·min−1speed,revealing good agreement between the CFD predictions and the experimental values.

3.Results and Discussion

3.1.Turbulent kinetic energy,turbulent intensity and turbulent dissipation rate at(x=0,y=0)

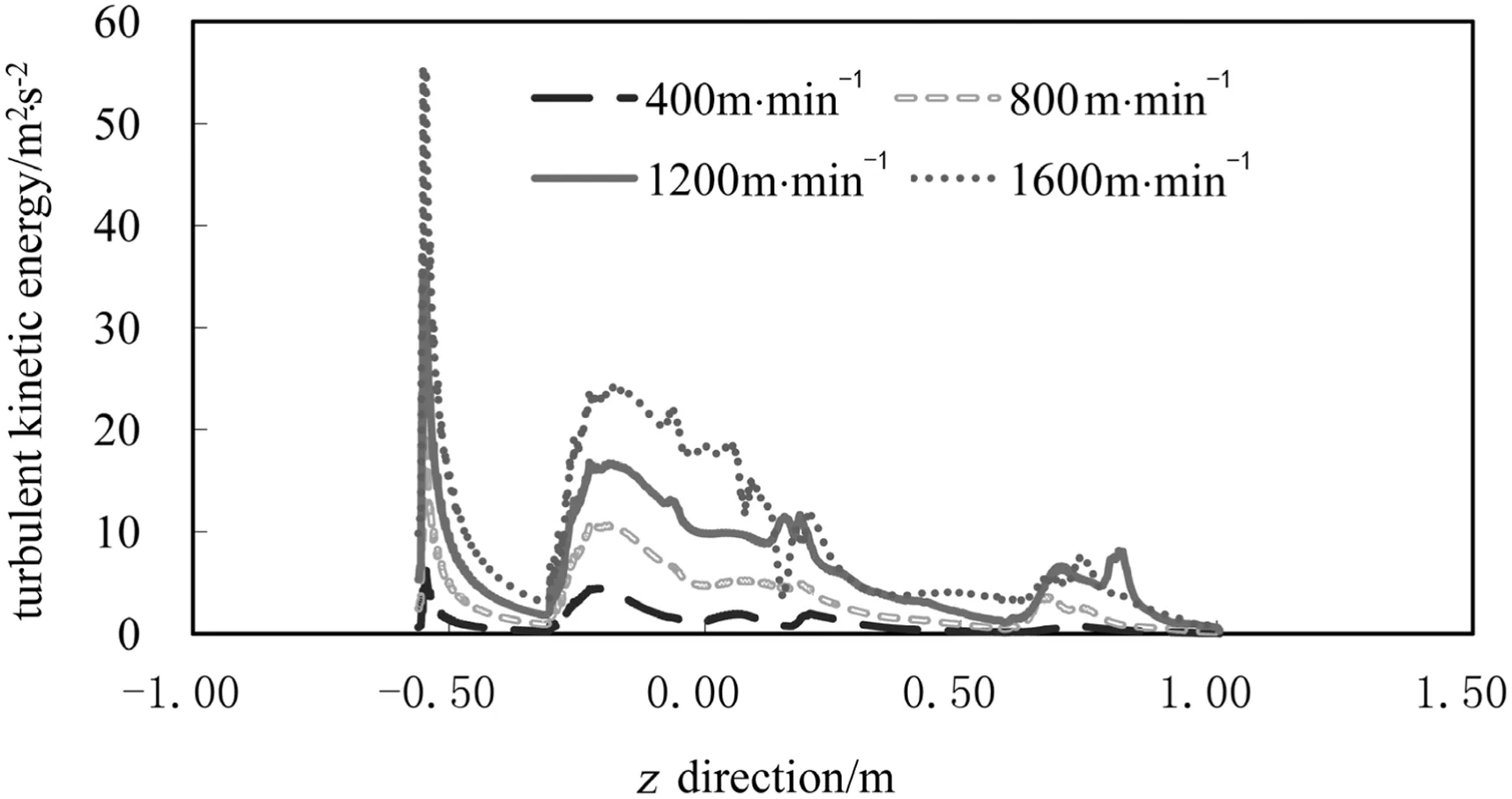

When diluted water is injected into the primary stream near the inlets,a mixed flow forms.The turbulent kinetic energy at the location(x=0,y=0)is shown in Fig.8.The peaks appear in places such as the areas between the thick and thin pipes of the step diffusion tube,and in particular,the turbulent kinetic energy increases sharply near the inlets where the diluted water is injected into the main stream,and the velocities of the diluting water are as twice as that of the main stream.As the mixed flow enters the thick pipes of the step diffusion tube,the turbulent kinetic energy begins to dissipate and decline.In the equalizing chamber,the turbulent kinetic energy of mixed flow becomes calm and steady.When the mixed flow enters the turbulence generator,a gradual decline in the turbulent kinetic energy is observed due to the gradual change in shape from a circle to a rectangle.Between the turbulence generator and the slice channel,a small increase in the turbulent kinetic energy is observed because the cross-sectional dimensions change significantly.For different speeds tested(400,800,1200,and 1600 m·min−1),the trends in the turbulent kinetic energy are nearly the same.Moreover,the turbulent kinetic energy increases with speed.

教师是教学活动的设计者与引导者,其自身的观念与行为对教学活动的开展起到决定性的作用.有一部分教师已经认识到化学与生活实际相结合的重要性.然而,不同职称、不同年龄层的教师对这一教学理念的接受程度是不一样的.教师对生活化的教学方法接受程度越高,那么他的教学设计就会有更多的生活化体现,这样的课堂会更加轻松,学生更容易接受,对知识点的掌握也会更加牢固.少部分教师依旧拘泥于传统的教学方法,以课本为绝对的主体,那么学生只能是学习有限的理论知识,化学的应用性、趣味性得不到体现,学生学习起来也缺乏乐趣,单纯是当成一门课程来完成.

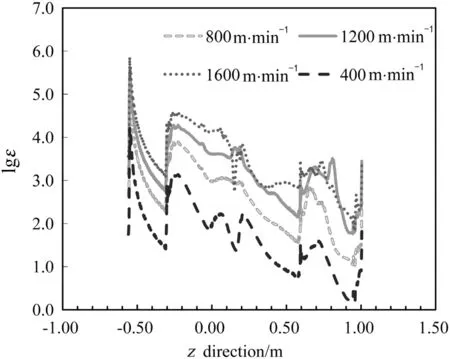

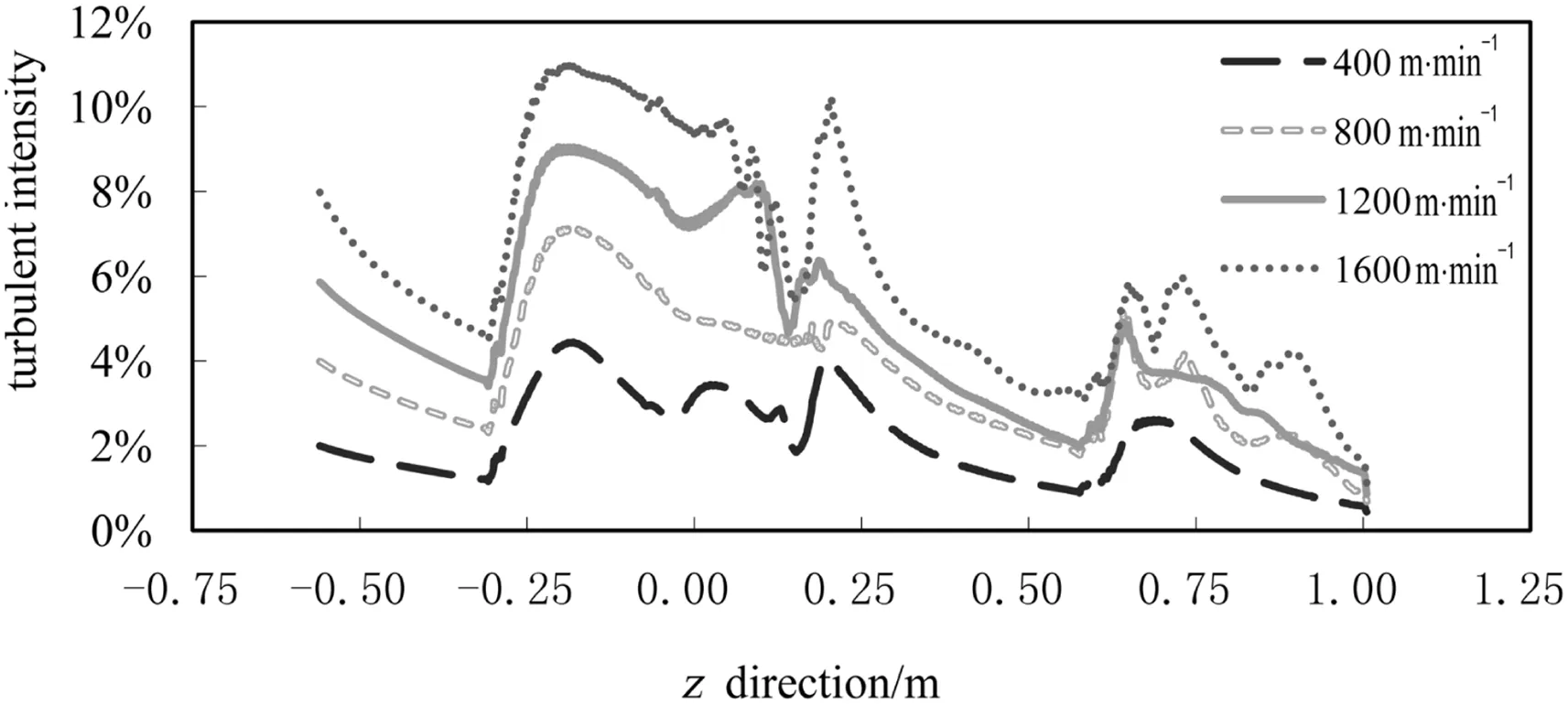

As shown in Fig.9,the intensity of the turbulence behaves similarly to the curve for the turbulent kinetic energy.However,the turbulence dissipation rate is very low,thus lg-scaled y axis is used,as shown in Fig.10,where ε represents the turbulence dissipation rate.Except for the peak associated with the injection of diluted water,the values between the thick and thin pipes of the step diffusion tube are greater than those in the other parts,and the turbulence dissipation rate becomes slightly higher as the speed increases.“lg ε”also behaves similarly to the curve for the turbulent kinetic energy.

3.2.Turbulence kinetic energy, turbulent intensity and turbulent dissipation rate at(x=0,y=200)

Fig.6.Water content of the mixing regime in the step diffusion tube for simulation(left)and LIF(right)in headbox model.(a)400 m·min−1.(b)650 m·min−1.(c)800 m·min−1.(d)1000 m·min−1.

Fig.7.Water content of the outlet for simulation and PIV in headbox model.(a)400 m·min−1.(b)650 m·min−1.(c)800 m·min−1.(d)1000 m·min−1.

Fig.8.Turbulent kinetic energy with different speeds for x=0,y=0.

Fig.9.Turbulent intensity with different speeds for x=0,y=0.

Fig.10.Turbulent dissipation rate with different speeds for x=0,y=0.

Fig.11.Turbulent kinetic energy with different speeds for x=0,y=200.

Fig.12.Turbulent intensity with different speeds for x=0,y=200.

Fig.13.Turbulent dissipation rate with different speeds for x=0,y=200.

At x=0 mm and y=200 mm,diluted water is not injected into the main stream near the inlets of the step diffusion tube,but the flow field is affected by the mixed flow forming at x=0 mm,y=0 mm,z=−550 mm,where the dilution water is injected.The turbulent kinetic energy at different speeds is shown in Fig.11,and the peaks in those locations appear between the thick and thin pipes of the step diffusion tube.When the mixed flow enters the thick pipes of the step diffusion tube,the turbulent kinetic energy begins to dissipate and decline because of the added flow area.In the equalizing chamber with larger space,the turbulent kinetic energy of the mixed flow becomes calm and steady.When the mixed flow enters the turbulence generator,a sharp decline in the turbulent kinetic energy is observed.A small increase in the turbulent kinetic energy is observed between the turbulence generator and the slice channel because the sectional dimension changes significantly.At different speeds tested(400,800,1200,and 1600 m·min−1),the trends for the turbulent kinetic energy are nearly the same.Moreover,the turbulent kinetic energy increases with the speed.In contrast to that at x=0 and y=0,the turbulent kinetic energy at x=0 and y=200 is lower,because the diluting water is not injected into the main stream at x=0 mm and y=200 mm.

As shown in Fig.12,the intensity of the turbulence behaves similarly to the turbulent kinetic energy curve,and unlike that at x=0 and y=0,the turbulent intensity at x=0 and y=200 is lower.The dissipation rate of the turbulence is low except in the areas between the thick and thin pipes of the step diffusion tubes,bet ween the turbulence generator and the slice channel.Turbulent dissipation rate increases with speed,as shown in Fig.13.Compare to that at x=0 and y=0,the turbulent dissipation rate at x=0,y=200 is lower.In order to compare the turbulence dissipation rates at different speeds,log-scaled y axis is also used.

3.3.Velocity vector distribution(yz plain)

Based on the velocity vectors shown in Fig.14,stronger swirls are observed in the equalizing chamber and the front part of the slice channel relative to other places in the XY plane.In the equalizing chamber,swirls of different sizes keep the pulp suspended and mixed uniformly for longer periods.Furthermore,because of the multiple branch pipes present in the equalizing chamber and slice channel,back flow is clearly observed and marked with the three ellipse circle.A mixed transitional period is observed in the slice channel due to additional swirls derived from the injection flow.

3.4.Consistency,turbulent kinetic energy,turbulence intensity and turbulence dissipation rate in y direction

As shown in Fig.15,x=0 and z=−50 mm is near the site adding dilution water.The water content at the middle tube is much higher than that in any of the other step diffusion tubes due to added dilution water.As the pulp suspensions proceed,the differences in the water content continuously decrease because of fluid mixing.At x=0 and z=900 mm and x=0 and z=1000 mm the water content curves are similar.Consequently,the flow pattern becomes increasingly more stable before leaving the headbox.Turbulent kinetic energy,turbulence intensity and turbulence dissipation rate decrease continuously from x=0 and z=−50 mm to x=0 and z=1000 mm due to the diffusion of the species.Their fluctuations also decrease continuously,and at the central site in particular,the change is distinct,as shown in Figs.16,17 and 18.

Fig.14.Velocity vectors of equalizing chamber and slice channel(yz plain).

Fig.15.Water content in different z location(x=0).

Fig.16.Turbulence kinetic energy in different z location(x=0).

Fig.17.Turbulence intensity in different z location(x=0).

Fig.18.Turbulent dissipation rate in different z location(x=0).

3.5.Consistency of outlet

The main stream is injected with the dilution water at the central step diffusion tube of the headbox,and the water content of the outlet varies with the speed.The relationship between the speed and water content of the outlet is shown in Fig.19.At 800 m·min−1,the water content at the center of the outlet is the highest,followed by that at 1200 m·min−1.The difference in water content between 400 m·min−1and 1600 m·min−1is small.The two distribution curves are flatter than the curves for 800 and 1200 m·min−1.Therefore,the water content does not increase with the speed.

Fig.19.Water content of outlet in y direction.

To clarify the functional relationship between the speed and water content at the outlet,the following reasoning is applied.

For abscissa value x(outlet)and ordinate value(water content)y,according to Fig.19,

Therefore,the distribution of the water content at the outlet of the slice lip is ideally normal at different speeds.According to the normal distribution,the corresponding probability statistics are as follows.

As shown in Fig.19,the center of the abscissa value is 0,μ=0.Then the probability statistics are altered to

According to the probability statistics,the effect on the effective concentration scale is±3σ.The effect can be derived from Eq.(19)as follows:at the speed of 800 m·min−1,σ =0.0407 m;at 1000 m·min−1,σ =0.0422 m;at 1200 m·min−1,σ =0.0488 m;at 1600 m·min−1,σ =0.0570 m;at 400 m·min−1,σ =0.0571 m.

The value of σ represents the part of flow field affected by effective concentration range.Thus for all the speeds,∣± 3σ∣< 235 is to be attained,which does not exceed the width of the computation model.

For the headbox model studied,the pro files are related only to σ value.The σ values at 400 and 1600 m·min−1are very close,so the pro files at 400 and 1600 m·min−1are basically the same.The σ value at 800 m·min−1is the smallest among different speeds,while the water content is the highest,which will keep better consistency distribution in the water dilution controlling system,and ensure the design and scale-up of a new efficient headbox.Furthermore,for the medium-high speed headbox model,better consistency distribution cannot be achieved when the speed is very high or very small.The sizes and the structure of the headbox model are most appropriate for 800 m·min−1.

4.Conclusions

In this study,a scale model of an industrial headbox is derived to predict the water content distribution,turbulent kinetic energy,turbulence intensity,and turbulence dissipation rate of pulp suspension passing through the flow field.The proposed headbox model is solved using standard k-ε turbulence models with the diffusion in turbulent flows species transport approach.The model accurately predicts the experimentally flow characteristics of a pulp suspension with diluted water added.

The model indicates that the turbulent kinetic energy,turbulence intensity,and turbulence dissipation rate at x=0,y=0 and x=0,y=200 increase with the flow speed.The equalizing chamber and the front of the slice channel maintained uniform distribution of pulp suspension.In the cross direction,as the flow moves forward,the difference in the water content decreases continuously,whereas the turbulent kinetic energy,turbulence intensity,and turbulence dissipation rate maintain stable.The water content at the outlet has a normal function distribution across the width of the cross direction.Furthermore,the distribution characteristic depends primarily on the structure of the headbox and the speed of flow.

[1]K.F.Chen,Pulp suspensions fluid dynamics in wet end of paper machine, first ed.Chinese Light Industry Press,Beijing,1986 1–15.

[2]K.F.Chen,Pulp and paper machinery and equipment,second ed.Chinese Light Industry Press,Beijing,2011 60–80.

[3]R.A.Reese,Hydraulic headboxes in pulp and paper manufacture, first ed.The joint Textbook Committee of the Paper Industry,TAPPI Press,Atlanta,1991 887–990.

[4]A.D.Trufitt,Design aspects of mani-fold flow spreaders, first ed.Canadian Pulp Paper Association,Montreal,1975 80–89.

[5]B.P.Scott,A new headbox design featuring consistency pro filing decoupled from fiber orientation response,TAPPI J.1(78)(1995)89–95.

[6]M.Ullmar,B.Norman,Observation of fiber orientation in a headbox nozzle at low consistency,TAPPI proceedings,engineering and papermakers conference,Anaheim 1997,pp.1110–1117.

[7]M.Ullmar,On fiber orientation mechanisms in a headbox nozzle(M.S Thesis)Royal Insititute of Technology,Stockholm,1998.

[8]C.Ford,F.Ein-Mozaffari,C.P.J.Bennington,Simulation of mixing dynamics in agitated pulp stock chests using CFD,AIChE J.1(52)(2006)3562–3569.

[9]T.Wikstrom,Flow and rheology of pulp suspensions at medium consistency(Ph.D.Thesis)Chalmers University of Technology,Goteborg,2002.

[10]C.P.J.Bennington,Mixing pulp suspensions(Ph.D.Thesis)University of British Columbia,New York,1988.

[11]P.J.Krochak,J.A.Olson,D.M.Martinez,Fiber suspension flow in a tapered channel:the effect of flow/ fiber coupling,Int.J.Multiphase Flow 7(35)(2009)678–683.

[12]J.Hamalainen,Mathematical modeling and simulation of fluid flows in the headbox of paper machines(Ph.D.Thesis)University of Jyvaskyla,Jyvaskyla,1993.

[13]C.K.Aidun,A.Kovacs,Hydrodynamics of the forming section:the origin of on uniform fiber orientation,TAPPI J.78(11)(1995)22–28.

[14]A.Bakker,J.B.Fasano,A computational study of the flow pattern in an industrial paper pulp stock chest with a side-entering impeller,AIChE 89(293)(1997)118–124.

[15]Chemical engineering module user's guide,COMSOL AB, first ed.Chemical Industry and Engineering Society of China,Stockholm,Sweden,2007 30–38.

[16]A.F.Carla,A.P.Fernando,P.J.F.Garcia,M.G.Rasteiro,Modeling the turbulent flow of pulp suspensions,Ind.Eng.Chem.Res.,4(50)(2011)9735–9742.

[17]X.Zhang,Fiber orientation in a headbox(M.S Thesis)Mechanical Engineering Department,The University of British Columbia,Columbia,2001.

[18]J.A.Olson,The motion of fibers in turbulent flow,stochastic simulation of isotropic homogeneous turbulence,Int.J.Multiphase Flow 6(27)(2001)2083–2103.

[19]A.James,A.Olson,B.Ian Frigaard,A.Candice Chan,P.Jari,Modeling a turbulent fiber suspension flowing in a planar contraction:the one-dimensional headbox,Int.J.Multiphase Flow 2(30)(2004)51–66.

[20]J.S.Zeng,K.F.Chen,J.Li,CFD simulation of dis chargers' dilution-zone in high consistency bleaching tower,Can.J.Chem.Eng.1(89)(2011)475–483.

[21]Fluent Inc.,Fluent 6 user's guide,Lebanon,USA,2001 5–10.

[22]http://www.e-works.net.cn(PERA GLOBAL Company's ANSYS tutorial).

猜你喜欢

杂志排行

Chinese Journal of Chemical Engineering的其它文章

- An investigation on dissolution kinetics of single sodium carbonate particle with image analysis method

- Rapid synthesis of CNTs@MIL-101(Cr)using multi-walled carbon nanotubes(MWCNTs)as crystal growth accelerator☆

- Hydrodynamic cavitation as an efficient method for the formation of sub-100 nm O/W emulsions with high stability

- Isobaric vapor–liquid equilibrium for binary system of aniline+methyl-N-phenyl carbamate☆

- Proposal and evaluation of a new norm index-based QSAR model to predict pEC50and pCC50activities of HEPT derivatives☆

- Correlation of the mean activity coefficient of aqueous electrolyte solutions using an equation of state