引燃柴油量及喷射间隔对直喷天然气发动机排放的影响

2016-05-17李孟涵李国祥邵思东

李孟涵,张 强,李国祥※,邵思东

(1.山东大学能源与动力工程学院,济南 250061;2.潍柴动力内燃机可靠性国家重点实验室,潍坊 261001)

引燃柴油量及喷射间隔对直喷天然气发动机排放的影响

李孟涵1,张 强1,李国祥1※,邵思东2

(1.山东大学能源与动力工程学院,济南 250061;2.潍柴动力内燃机可靠性国家重点实验室,潍坊 261001)

为优化直喷天然气发动机的喷射策略,在一台六缸电控直喷天然气发动机上,用试验方法研究了引燃柴油量及柴油/天然气喷射间隔对发动机HC、CO和NOx排放的影响。试验结果表明:喷射间隔一定时,HC排放随引燃柴油喷射量的增加而降低;在引燃柴油喷射量为4.0 mg时,HC排放随喷射间隔的增加而增加;引燃柴油喷射量在6.0~11.5 mg范围内,HC排放在喷射间隔从0.5 ms变化到1.1 ms时,变化较小;喷射间隔增加到1.4 ms时,HC排放升高趋势明显。CO排放随引燃柴油喷射量的变化规律为先降低后升高;在不同的柴油喷射量下增加喷射间隔,CO排放均降低。NOx排放随引燃柴油喷射量的增加先降低后升高;在喷射间隔为0.5 ms时,NOx排放相对较小,在喷射间隔为1.4 ms时,NOx排放最高。增加引燃柴油喷射量有利于HC的减排,对CO排放的影响较小,但会导致NOx排放的恶化;增加喷射间隔会促使HC和NOx排放的升高,但CO排放有所降低。

发动机;柴油机;燃油喷射;引燃柴油量;喷射间隔;天然气发动机;排放性

李孟涵,张 强,李国祥,邵思东.引燃柴油量及喷射间隔对直喷天然气发动机排放的影响[J].农业工程学报,2016,32(6):95-100. doi:10.11975/j.issn.1002-6819.2016.06.013 http://www.tcsae.org

Li Menghan,Zhang Qiang,Li Guoxiang,Shao Sidong.Effects of diesel injection quantity and injection interval on emission characteristics of directly injected natural gas engine[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2016,32(6):95-100.(in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.06.013 http:// www.tcsae.org

0 引言

研发并推广高效清洁的气体燃料发动机燃烧技术是实现燃料多元化、减少温室气体排放、减少有害污染物排放的有效途径[1-5]。在中国,严重的雾霾天气、特殊的能源消费结构和高速的社会经济发展形势对天然气发动机的研究提出了更紧迫的要求。柴油引燃直喷天然气发动机采用柴油和天然气两套共轨系统,在上止点附近首先喷入一定量的引燃柴油,经过一定的喷射间隔,主燃料天然气由同一喷射器喷入气缸后,被引燃柴油火焰点燃[6-9]。由于换气和压缩过程与柴油机类似,且天然气主要的燃烧模式为扩散燃烧,该型发动机可以实现动力性和排放性的兼顾[10-13]。

自二十世纪八十年代以来,国内外科学家对柴油引燃直喷天然气发动机的排放控制方法进行了广泛的研究。目前,比较常用的方法有:废气再循环[14],天然气成分优化[15-16]以及喷射策略优化[17-18]。其中,废气再循环技术会增加发动机结构的复杂性,并且,由于天然气的氢含量高,燃烧产生的大量水蒸气会通过废气再循环进入冷却器及发动机,造成冷却器及发动机燃烧系统的腐蚀,降低发动机的使用寿命,导致发动机维护成本的提高[19-25]。另外,通过添加惰性气体、氢气等组分优化天然气成分的排放控制技术仍处于试验室研究阶段,实际应用中涉及的氢气等优化成分的生产、储存、供给等问题亟待解决。因此,喷射策略优化依然是最经济实用的排放控制方法。对于柴油引燃直喷天然气发动机,引燃柴油喷射量及柴油/天然气喷射间隔与主燃料天然气的引燃和后续的扩散燃烧过程密切相关,继而影响到发动机的HC、CO及NOx排放,是该型发动机排放控制的关键参数。然而至今为止对于柴油引燃直喷天然气发动机喷射策略优化的研究多集中于喷射时刻和喷射压力,对于引燃柴油喷射量及柴油/天然气喷射间隔对排放的影响缺乏系统的研究。

本文以电控双共轨六缸高压直喷天然气发动机为研究对象,通过试验研究了引燃柴油喷射量及柴油/天然气喷射间隔对发动机HC、CO及NOx排放的影响,对柴油引燃直喷天然气发动机的排放控制和喷射策略优化提供理论指导。

1 试验装置及试验方案

1.1 试验装置

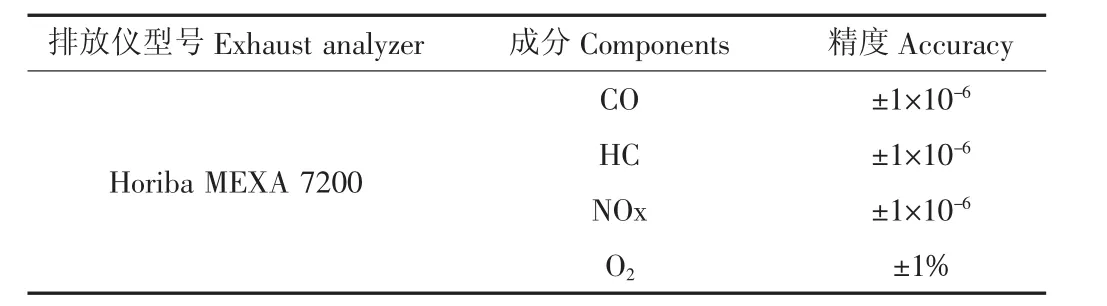

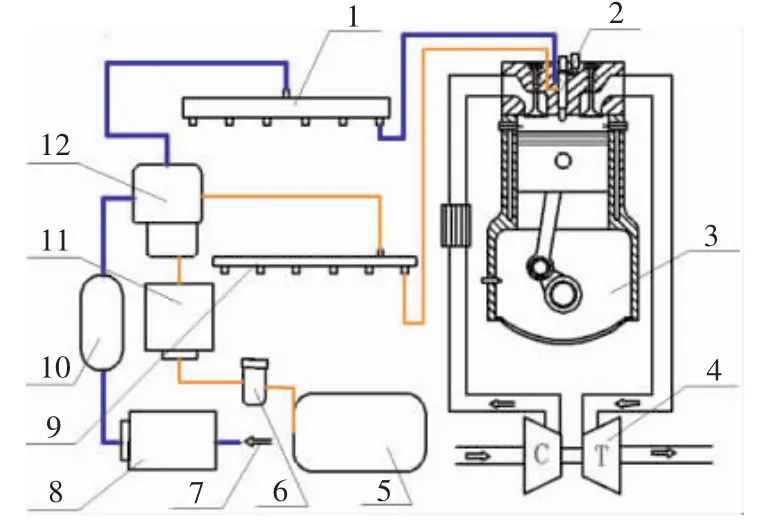

试验发动机在原柴油机基础上改装而成,其缸径为126 mm,行程为155 mm,压缩比为17。电控系统为自主开发,在原柴油机电子控制单元(electric control unit,ECU)基础上集成了天然喷射控制模块,使电控系统可以灵活控制柴油及天然气的喷射。增加了天然气供给系统、天然气共轨喷射系统和集成调压模块,为适应同心双轴针喷射器的安装要求,原柴油机的缸盖设计也相应更改。所采用的排放测试设备及精度如表1所示。测试用排放分析仪的采样方法为全流稀释定容采样法,HC排放的测试方法为氢离子火焰法,CO排放的测量方法为不分光红外法,NOx排放的测量方法为化学发光法。试验工况稳定5 min后开始各种排放数值的测量,并对每个工况点进行3次取样,取3次的平均值作为最终的排放结果。

表1 排放分析仪主要技术参数Table 1 Exhaust gas analyzer and main specifications

图1 试验台架布置图Fig.1 Layout of test bed

1.2 试验方案

试验中保持进气温度为22℃,环境压力为101 kPa,柴油轨压设定为18 MPa,为保证喷射器的密封性,天然气的轨压比柴油轨压略低,为17.5 MPa。测试工况点发动机转速设定为1 275 r/min,平均有效压力为0.54 MPa(25%负荷),为十三点工况中较为典型的低转速低负荷工况。为测试柴油喷射量(diesel injection quantity,DIQ)和柴油/天然气喷射间隔(SDN,separation between diesel and natural gas injection)的影响,在整个试验过程中,天然气喷射提前角固定在8°,试验在4.0、6.0、8.5、11.5 mg 4种引燃柴油喷射量和0.5、0.8、1.1、1.4 ms 4种喷射间隔下进行,4种引燃柴油喷射量对应的喷射脉宽(diesel pulse width,DPW)分别为0.25、0.3、0.5和0.7 ms,柴油喷射提前角根据引燃柴油喷射脉宽和喷射间隔的值进行调整,天然气喷射脉宽(natural gas pulse width,GPW)根据柴油喷射脉宽和固定的平均有效压力进行调整。

2 结果与分析

2.1 HC排放

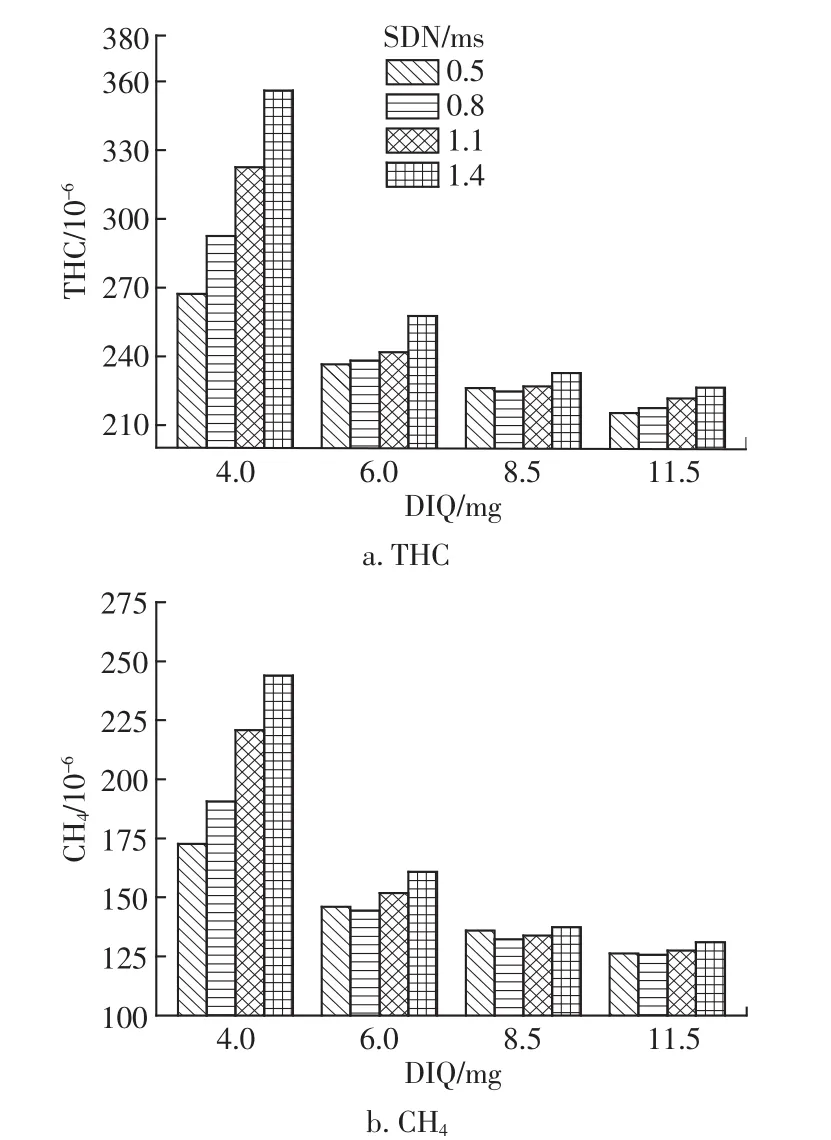

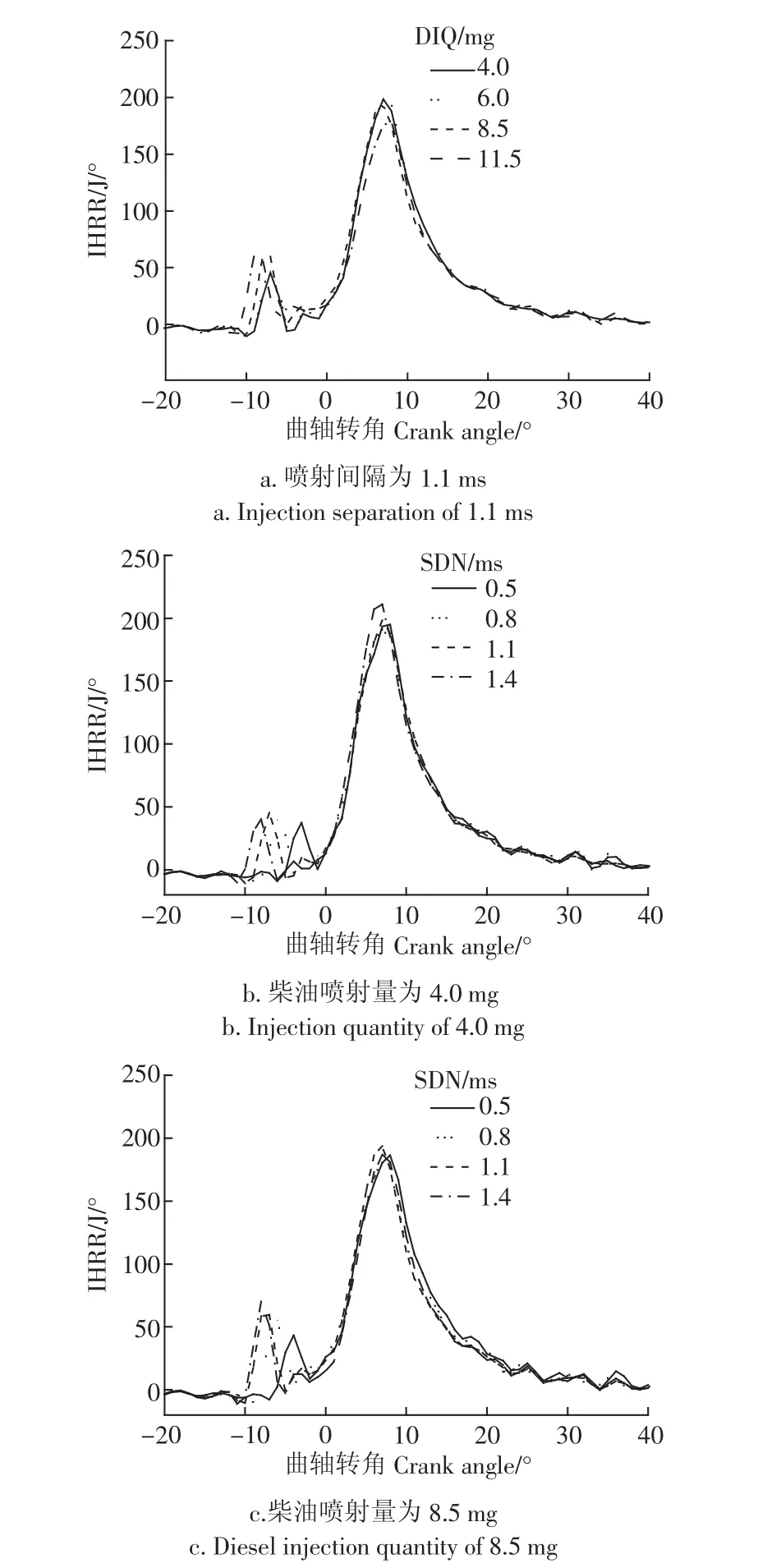

图2为引燃柴油喷射量及喷射间隔对总碳氢(total hydrocarbons,THC)及CH4排放的影响。如图所示,随着引燃柴油量的增加THC排放及CH4呈减小的趋势。因为随着柴油喷射量的增加,柴油引燃火焰的强度增加,如图3c所示,随着引燃柴油喷射量的增加,柴油燃烧阶段瞬时放热率的峰值增加,增加了对主燃料天然气的引燃能力,抑制了天然气向远端的扩散,且由于天然气所需喷射量降低,天然气喷射脉宽相应缩短,同样降低了天然气的扩散距离,减小了壁面淬熄发生的可能性,THC排放降低;另外如图中THC和CH4的排放数据所示,在试验工况下,CH4在THC中占的比例为60%左右,同样工况下柴油喷射量增加后,天然气的比例减少,THC排放相应降低。柴油喷射量为4.0 mg时,THC排放明显高于其他3种柴油喷射量时的THC排放。这是因为此时柴油喷射量最小,柴油引燃火焰的强度较弱,引燃能量不足,引燃稳定性较差,导致整个燃烧过程的稳定性降低,由于天然气燃烧不完善生成的HC显著增加。

图2 引燃柴油喷射量及喷射间隔对THC及CH4排放的影响Fig.2 Effects of diesel injection quantity and injection separation on THC and CH4emissions

由图2还可以看出,随着柴油和天然气喷射间隔的增加在柴油喷射量较少时THC及CH4呈升高趋势,柴油喷射量较多时排放量差别小,但仍为喷射间隔大时排放高。因为随着柴油/天然气喷射间隔角的增加,柴油火焰发展时间较充分,如图3所示,喷射间隔较大时,天然气喷射时刻柴油放热量较多,柴油火焰周围的氧气被消耗的比较多,此刻天然气喷入柴油燃烧后的废气区域,形成燃料的过浓区,喷入柴油已燃区的部分天然气因缺氧而未参与燃烧,主要以CH4的形式排出,造成HC排放升高。柴油喷射量为4.0和6.0 mg时,柴油喷射量较小,柴油燃烧持续期短,此时由喷射间隔过大导致的HC排放的增加较为明显。喷射量为8.5和11.5 mg时,柴油喷射量增加,柴油燃烧持续期相应延长,喷射间隔对HC排放的影响减小。

图3 引燃柴油量及喷射间隔对放热率的影响Fig.3 Effects of diesel injection quantity and injection separation on heat release rate

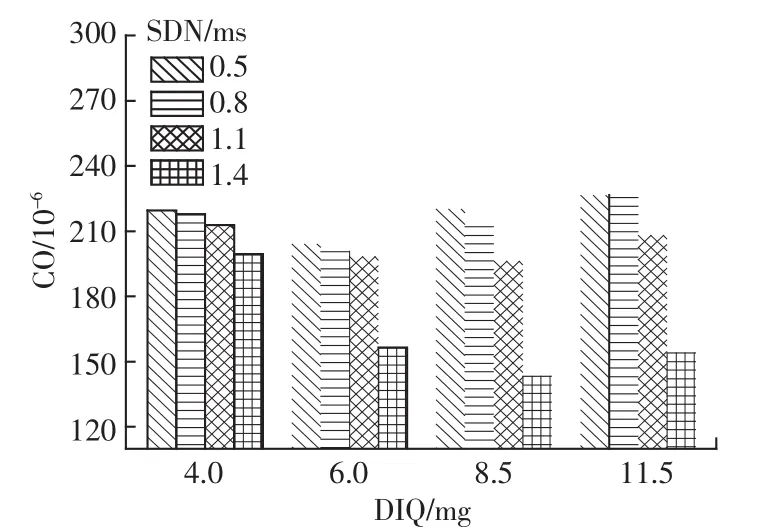

2.2 CO排放

图4为引燃柴油量及喷射间隔对CO排放的影响。如图所示,CO排放随柴油喷射量的变化规律为先降低后升高。分析原因为:直喷天然气发动机CO来源包括不完全燃烧的引燃柴油和不完全燃烧的主燃料天然气,引燃柴油量过小时(4.0 mg),引燃柴油喷射脉宽过短(0.25 ms),引燃能力弱,同时喷射脉宽过短容易因柴油轨压波动等原因导致的引燃柴油喷射量循环差异性较大,直接影响整个燃烧过程的稳定性,CO排放相对较高;引燃柴油量过大时(11.5 mg),一方面天然气喷入柴油已燃区导致燃烧不充分,另外,柴油火焰在引燃时刻燃烧过度,其引燃能力下降,导致CO排放值的增加。在喷射间隔为0.5和0.8 ms时,柴油和天然气之间的时间间隔相对较短,在柴油喷射量为6.0 mg时出现CO排放的最低值;在喷射间隔为1.1和1.4 ms时,2种燃料喷射之间的时间间隔增加,柴油喷射量为8.5 mg时可以实现引燃能量和引燃时刻的兼顾。

由图4可见,增加喷射柴油/天然气喷射间隔可以降低CO的排放值。当引燃柴油喷射量为6.0、8.5和11.5 mg时,柴油燃烧持续期较长,喷射间隔从1.1 ms增加到1.4 ms会大幅降低CO的生成,然而,引燃柴油量为4.0 mg时,引燃柴油喷射量较小,燃烧持续期较短,增加喷射间隔对CO排放减排的效果下降。这是因为:2种燃料喷射间隔较近时,在混合过程中较冷的天然气喷束会影响引燃柴油的雾化,产生局部燃料过浓的区域,并且在引燃柴油燃烧过程中,天然气的引燃会加剧2种燃料氧气的争夺,进而造成局部缺氧,促进了CO的生成,喷射间隔较高时在柴油的焰后区形成天然气的过浓区,但这部分燃料不燃烧主要以CH4形式排出,对CO排放的贡献较小,因此适当增加喷射间隔有利于减小两种燃料燃烧之间的干涉,降低CO的排放,实际标定中根据HC和CO排放综合考虑确定最优的喷射间隔角。

图4 引燃柴油量及喷射间隔对CO排放影响Fig.4 Effects of diesel injection quantity and injection separation on CO emissions

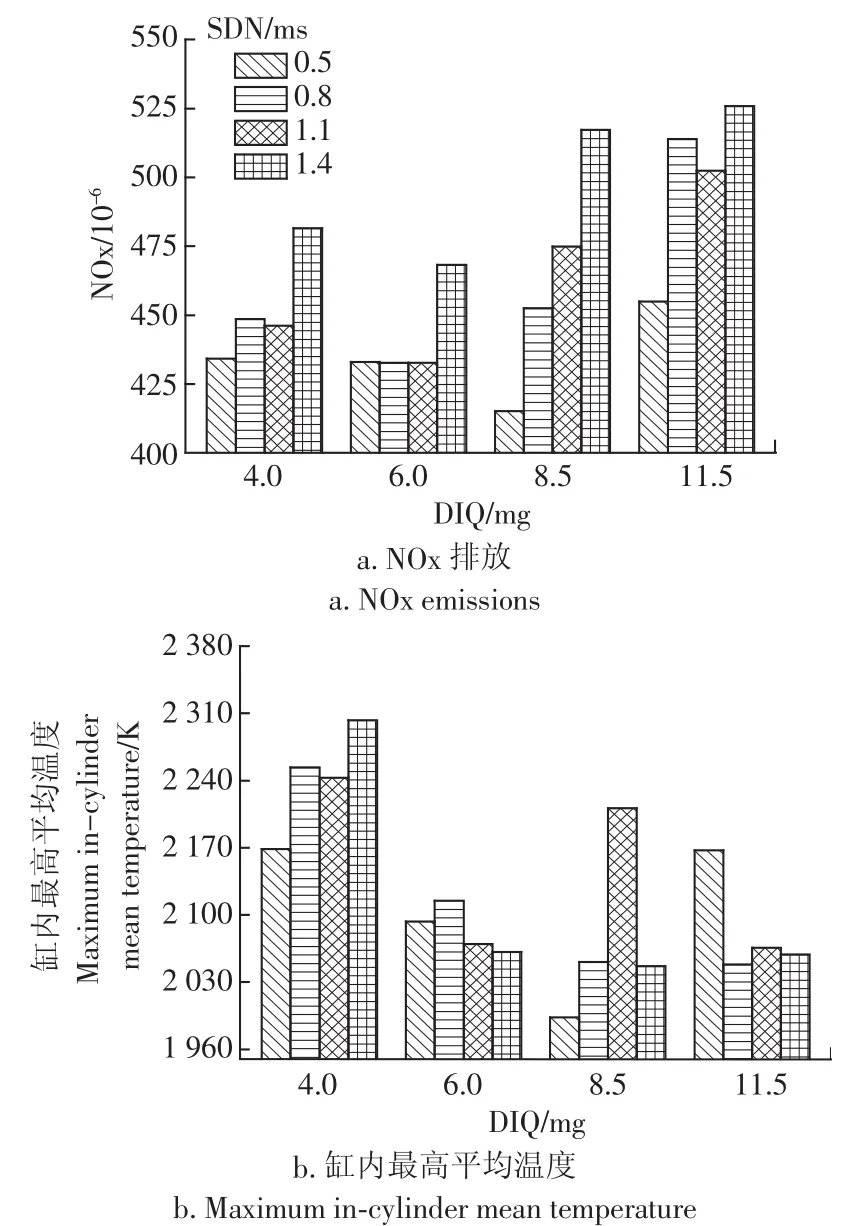

2.3 NOx排放

图5a为引燃柴油量及喷射间隔对NOx排放的影响。NOx排放主要受缸内工质温度和局部氧气含量的影响。从4种引燃柴油在不同喷射间隔下的NOx排放数值看,NOx排放随柴油喷射量的增加呈现先降低后升高的变化规律,柴油喷射量为11.5 mg时NOx排放最高,柴油喷射量为8.5 mg时次之,柴油喷射量为6.0 mg时NOx排放最低。因为液体燃料蒸发过程中更易出现混合不均匀的区域,使富氧区增加,且绝热火焰温度相对较高,因此柴油喷射量为11.5 mg时NOx排放最高。如图5b所示,当柴油量为4.0 mg时,缸内最高平均燃烧温度最高,促进了NOx的生成,使其排放高于柴油喷射量为6.0 mg的情况。

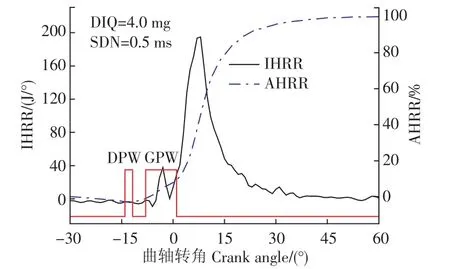

喷射间隔对NOx排放的影响规律为:在同一柴油喷射量下,NOx排放在喷射间隔为0.5 ms时较低,在喷射间隔为1.4 ms时达到峰值;当喷射间隔从0.8 ms增加到1.1 ms时,不同的引燃柴油量下NOx排放的变化规律不一致。这是因为当喷射间隔为0.5 ms时,从图6中2种燃料的喷射信号(DPW和GPW)和放热率的对比图可以得出,柴油的燃烧阶段和天然气的喷射阶段有一定的重合期,柴油蒸汽和天然气共同和空气形成混合气,燃烧过程中火焰区及火焰前锋面的高温区氧含量相对较低,从而抑制了NOx的生成;喷射间隔为1.4 ms时,天然气被引燃时柴油放热已基本结束,2种燃料之间争夺氧气的干涉作用降低,在引燃柴油燃烧期间及主喷天然气燃烧期间,高温区的氧含量相对充足,使NOx生成量较大;喷射间隔为0.8和1.1 ms时,由于燃烧温度和高温区氧化量的影响程度不同,在不同引燃柴油喷射量呈现不同的规律。

图5 引燃柴油量及喷射间隔对NOx排放及缸内最高平均温度的影响Fig.5 Effects of diesel injection quantity and injection separation on NOx emissions and maximum in-cylinder mean temperature

图6 喷射过程及燃烧过程对比Fig.6 Comparison between injection process and combustion process

3 结论

以一台六缸直喷天然气发动机为研究对象,研究了不同引燃柴油量及柴油/天然气喷射间隔下发动机的各项排放,结论如下:

1)在喷射间隔一定时,THC及CH4排放随引燃柴油喷射量的增加而降低;在引燃柴油喷射量为4.0 mg时,THC及CH4排放随喷射间隔的增加而增加;在引燃柴油喷射量在6.0~11.5 mg范围内时,THC及CH4排放在喷射间隔从0.5 ms变化到1.1 ms时,变化较小,喷射间隔增加到1.40 ms时,THC及CH4排放升高较明显。

2)喷射间隔在0.5~1.4 ms范围内时,CO排放随引燃柴油喷射量的变化规律为先降低后升高,排放的最低值出现在引燃柴油喷射量为6.0或8.5 mg时;在不同的柴油喷射量下增加喷射间隔均可以实现CO的减排。

3)在喷射间隔一定时,NOx排放随引燃柴油喷射量的增加呈现先降低后升高的变化规律;不同引燃柴油喷射量下,NOx排放随喷射间隔无一致的变化规律,在喷射间隔为0.50 ms时,NOx排放相对较小,在喷射间隔为1.40 ms时,NOx排放最高。

[1]Selim M Y E.Effect of exhaust gas recirculation on some combustion characteristics ofdualfuelengine.Energy Conversion and Management[J].2003,44:707-721.

[2]Abd-Alla G H,Soliman H A,Badr O A,et al.Effect of injection timing on the performance of a dual fuel engine[J].Energy Conversion and Management,2003,43(2):269-277.

[3]Zhou L,Liu Y F,Wu C B,et al.Effect of the diesel injection timing and the pilot quantity on the combustion characteristics and the fine-particle emissions in a micro-diesel pilot ignited natural-gas engine.Proceedings of the Institution of Mechanical Engineers[J].Part D:Journal of Automobile Engineering,2013, 227(8):1142-1152.

[4]Korakianitis T,Namasivayam A M,Crookeset R J.Natural-gas fueled spark ignition(SI)and compression-ignition (CI)engine performance and emissions [J].Progress in Energyand Combustion Science,2011,37:89-112.

[5]Peterson M B,Barter G E,West T H,et al.A parametric study of light-duty natural gas vehicle competitiveness in the United States through 2050[J].Applied Energy,2014,125:206-217.

[6]Christopher A L,Combustion of Natural Gas with Entrained Dieselina Heavy-duty Compression-ignition Engine[D].Vancouver: The University of British Columbia,2009.

[7]Douville B,Ouellette P,Touchette A,et al.Performance and emissions of a two-stroke engine fueled using high-pressure direct injection of natural gas[R].SAE Technical Paper 981160, 1998.

[8]Ouellette P.High Pressure Injection of Natural Gas for DieselEngineFueling[D].Vancouver:TheUniversityofBritishColumbia, 1992.

[9]Larson C R.Injection Study of a Diesel Engine Fueled with Pilot-ignited,Directly-injected Natural Gas[D].Vancouver:The University of British Columbia,2003.

[10]Munshi S R,McTaggart-Cowan G P,Huang J,et al.Development of a partially-premixed combustion strategy for a low emission, direct injection high efficiency natural gas engine[C].Proceedings of the AMSE 2011 Internal Combustion Engine Division Fall Technical Conference,Morgantown,West Virginia,USA,2011, ICEF2011-60181.

[11]Kalam M A,Masjuki H H.An experimental investigation of high performance natural gas engine with direct injection[J].Energy, 2011,36:3563-3571.

[12]McTaggart-Cowan G P,Mann K,Wu N,et al.An efficient directinjection of natural gas engine for heavy duty vehicles[R].SAE Technical Paper 2014-01-1332;2014.

[13]Lee W G,Montgomery D.Numerical investigation of the performance of a high pressure direct injection(HPDI)natural gas engine[R].Proceedingsofthe ASME 2014 internal combustion engine division fall technical conference,2014, Columbus,USA,ICEF2014-5681.

[14]McTaggart-Cowan G P,Bushe W K,Rogak S N,et al.Injection parameter effects on a direct injected,pilot ignited,heavy duty natural gas engine with EGR.SAE Technical Paper 2003-01-3089,2003.

[15]McTaggart-Cowan G P,Rogak S N,Munshi S R,et al.The influence of fuel composition on a heavy-duty,natural-gas direct-injection engine[J].Fuel,2010,89:752-59.

[16]Trusca B.High Pressure Direct Injection of Natural Gas and Hydrogen Fuel in a Diesel Engine[D].Vancouver:The University of British Columbia,2001.

[17]McTaggart-Cowan G P,Jones H L,Rogak S N,et al.The effects of high pressure injection on a compression ignition,direct injection of natural gas engine[R].ASME J Eng Gas Turbines Power,2007,129:579-88.

[18]McTaggart-Cowan G P,Bushe W K,Rogak S N,et al.PM and NOx reduction by injection parameter alterations in a direct injected,pilot ignited,heavy duty natural gas engine with EGR at various operating conditions[R].SAE 2005-01-1733,2005.

[19]Reifarth S,Angstrom H E.Transient EGR in a high-speed DI diesel engine for a set of different EGR-routings[R].SAE technical paper,2010-01-1271,2010.

[20]Ishiki K,Oshida S,Takiguchi M.A study of abnormal wear in power cylinder of diesel engine with EGR-wear mechanism of soot contaminated in lubricating oil[R].SAE technical paper, 2000-01-0925,2000.

[21]Gautam M,Chitoor K,Durbha M,et al.Effects of diesel soot contaminated oil on engine wear-investigation of Noval oil formulations[J].Tribology International,1999,32:687-699.

[22]Aldajah A,Ajayi O O,Fenske G R,et al.Effect of exhaust gas recirculation(EGR)contamination of diesel engine oil on wear [J].Wear,2007,263:93-98.

[23]George S,Balla S,Gautam M.Effect of diesel soot contaminated oil on engine wear[J].Wear,2007,262:1113-1122.

[24]Singh S K,Agarwal A K,Sharma M.Experimental investigations of heavy metal addition in lubricating oil and soot deposition in an EGR operated engine[J].Applied Thermal Engineering, 2006,26:259-266.

[25]Agarwala D,Singha S K,Agarwal A K.Effect of Exhaust Gas Recirculation(EGR)on performance,emissions,deposits and durability of a constant speed compression ignition engine[J]. Applied Energy,2011,88(8):2900-2907.

Effects of diesel injection quantity and injection interval on emission characteristics of directly injected natural gas engine

Li Menghan1,Zhang Qiang1,Li Guoxiang1※,Shao Sidong2

(1.School of Energy and Power Engineering,Shandong University,Jinan 250061,China;2.State Key Laboratory for Reliability of Internal Combustion Engines at Weichai Power,Weifang 261001,China)

Adjustment of injection strategy has been considered as an effective and reliable way for the emission control of directly injected natural gas engines.However,the system investigation on the effects of pilot diesel quantity and injection separation is scarce.In order to achieve better emission characteristics by optimizing the injection strategy of directly injected natural gas engine,experimental investigation was conducted on a 6-cylinder pilot-ignited natural gas engine to study the effects of diesel injection quantity(DIQ)and separation between diesel and natural gas injection(SDN).The test engine was modified from a diesel engine with bore diameter of 126 mm,stroke of 155 mm and compression ratio of 17.The design of cylinder head was redesigned to adapt to the installation of the dual fuel injector,which had two concentric needles and two electronically controlled solenoid valves.An integrated pressure regulating module was added to controlthe injection pressure of diesel and natural gas.The supply system of natural gas,including compressor and buffer tank,was also added to provide compressed pipeline natural gas.Besides,the control module of natural gas injection was integrated into the original electronic controlled unit to realize the accurate control of both diesel and natural gas injection.In the experiment process,the intake temperature was fixed at 22°CA and the intake air pressure was maintained at 101 kPa while the diesel rail pressure was adjusted to 18MPa.To prevent natural gas leaking into diesel,the rail pressure of natural gas was slightly lower than that of diesel(17.5 MPa).The tested operating condition was at engine speed of 1 275 r/min with brake specific effective pressure of 0.54Mpa,which was a typical operating point of European steady state cycle.To evaluate the effects of diesel injection quantity(DIQ)and separation between diesel and natural gas injection(SDN),the injection timing of natural gas was kept constant at 8°BTDC while diesel injection quantity was varied from 4.0 to 11.5 mg under four different injection separations(0.5 ms,0.8 ms,1.1 ms and 1.4 ms).The natural gas pulse width was adjusted in accordance with the diesel injection quantity to maintain the fixed engine brake specific power.The emissions were measured by a Horiba MEXA 7 200 exhaust gas analyzer.CO emissions were tested by nondispersive infrared technology. HC emissions were tested by flame ionization detector.NOx emissions were tested by chemiluminescent detector(CLD). The emissions of each operating point were collected after 5 minutes of steady operation and all the emissions were recorded three times to obtain the averaged values for further analysis.The experimental results showed that HC emissions decreased with the increase of diesel injection quantity at the same injection separation and increased with increasing injection separation at the diesel injection quantity of 4.0 mg;in the diesel injection quantity range of 6.0~11.5 mg.HC emissions changed slightly when the injection separation varied from 0.5 ms to 1.1ms,however,when injection separation extended to 1.4 ms,the rising trend of HC emissions became more obvious.CO emissions exhibited a first decrease then increase trend with the increase of diesel injection quantity,and the minimum value occurred at the diesel injection quantity of 6.0 mg or 8.5 mg;a decrease with the increase of injection separation at all diesel injection quantities can also be observed.NOx emissions firstly declined and then rise with the increasing diesel injection quantity;additionally,at the injection separation of 0.5 ms,NOx emissions were relatively lower while reached the peak value at the injection separation of 1.4 ms.It can be concluded that the increase of diesel injection quantity has beneficial effects on HC emissions and negative effects on NOx emissions while exerts little influence on CO emissions;the extension of injection separation results in higher HC and NOx emissions as well as reduced CO emissions.

engines;diesel engines;fuel injection;diesel injection quantity;injection separation;natural gas engine; emission characteristics

10.11975/j.issn.1002-6819.2016.06.013

TK421.5

A

1002-6819(2016)-06-0095-06

2015-10-20

2016-01-18

国家高技术船舶科研项目(2060303)

李孟涵(1990-),女,山东淄博人,博士研究生,主要从事天然气发动机燃烧及排放控制研究。济南 山东大学能源与动力工程学院内燃机研究所,250061。Email:sdulmh@163.com;

※通信作者:李国祥(1965-),男,山东蓬莱人,博士,教授,博士生导师,主要从事发动机燃烧及排放控制研究。济南 山东大学能源与动力工程学院内燃机研究所,250061。Email:liguox@sdu.edu.cn