The Cause of Tanker Cleaning Accident

2016-05-03

Recently, the International Maritime Contractors Association(IMCA)issued a safety incident occurred during tanker cleaning operations.Experts said that due to complexity of tanker cleaning operation, it’s full of danger and more likely to cause marine pollution, combustion, explosion, or personal injury and death accidents in the process. In view of the high incidence of accident during the process, how to put those“tigers”in the“cage”has caught the industry’s focus of attention.

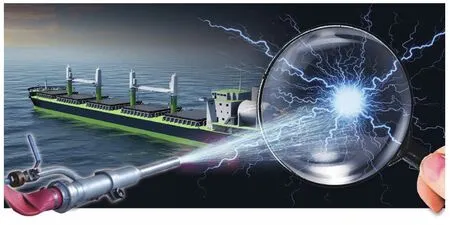

The journalist has launched a single-selection vote on“which is the highest risk source during the tanker cleaning operation?”on the Internet. Nearly 80% of the first mates of cruise ships or chemical carriers who have voted chose“static electricity”. Why static electricity has become the first killer in their eyes during tanker cleaning operation?

One first mate mentioned that for the time being, in order to prevent combustion or explosion, the common approach is to control the oxygen content in the tank. This method is simple, safe and reliable, and what you should only do is to fill the tank with so-called inert gas so as to keep oxygen content below the critical point, in this way, the gas content in the oil tanks can be contained within the range of safety under any operation state of oil tankers.

At the same time, the experts recommend that“Procedures and Arrangement Manual”rather than crew’s experience should be followed strictly during tanker cleaning.

In the interview, a first mate who has once worked in bulk chemical carriers told the journalist frankly that during the whole process of bulk chemical transportation, it could be said that the tank cleaning operation reflects the most the characteristics of the chemical transportation, and at the same time it is the most dangerous operation link with the maximum work intensity.

In addition, for the supplement and improvement of“Tanker Cleaning Guidance”or“Tanker Cleaning Manual,”the interviewees think that there is lots of technical information on tanker cleaning operations, e.g.a Japanese company had compiled a tanker cleaning guidance which introduces in detail the method of tanker cleaning operation using their products. He said honestly that although most of this information is commercial,it has to be admitted that their contents are finer than ordinary“Tanker Cleaning Guidance”or the Manual.It is worthy of the industry’s attention as to whether the improvement of“Tanker Cleaning Guidance”can make reference to other models.

On the problem of the necessity of crew getting into the tank after tanker cleaning operations, the experts said that for the normal process it should be first confirmed that the tank has been degassed, and then, the captain issue a permit before the crew go into the tank. The tank should be ventilated continuously and the crew must strictly comply with the relevant provisions of Entering Enclosed Space.