基于房间空调器全年性能系数的室外机翅片设计

2016-03-08任滔吴国明丁国良郑永新高屹峰宋吉

任滔,吴国明,丁国良,郑永新,高屹峰,宋吉

(1-上海交通大学制冷与低温工程研究所,上海 200240;2-国际铜业协会(中国),上海 200020)

基于房间空调器全年性能系数的室外机翅片设计

任滔*1,吴国明1,丁国良1,郑永新2,高屹峰2,宋吉2

(1-上海交通大学制冷与低温工程研究所,上海 200240;2-国际铜业协会(中国),上海 200020)

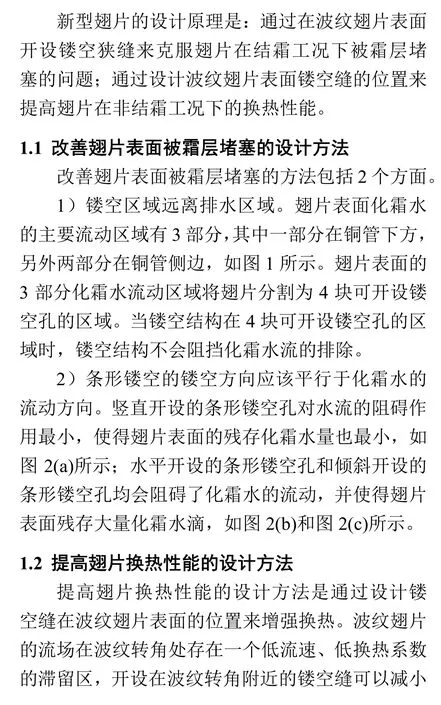

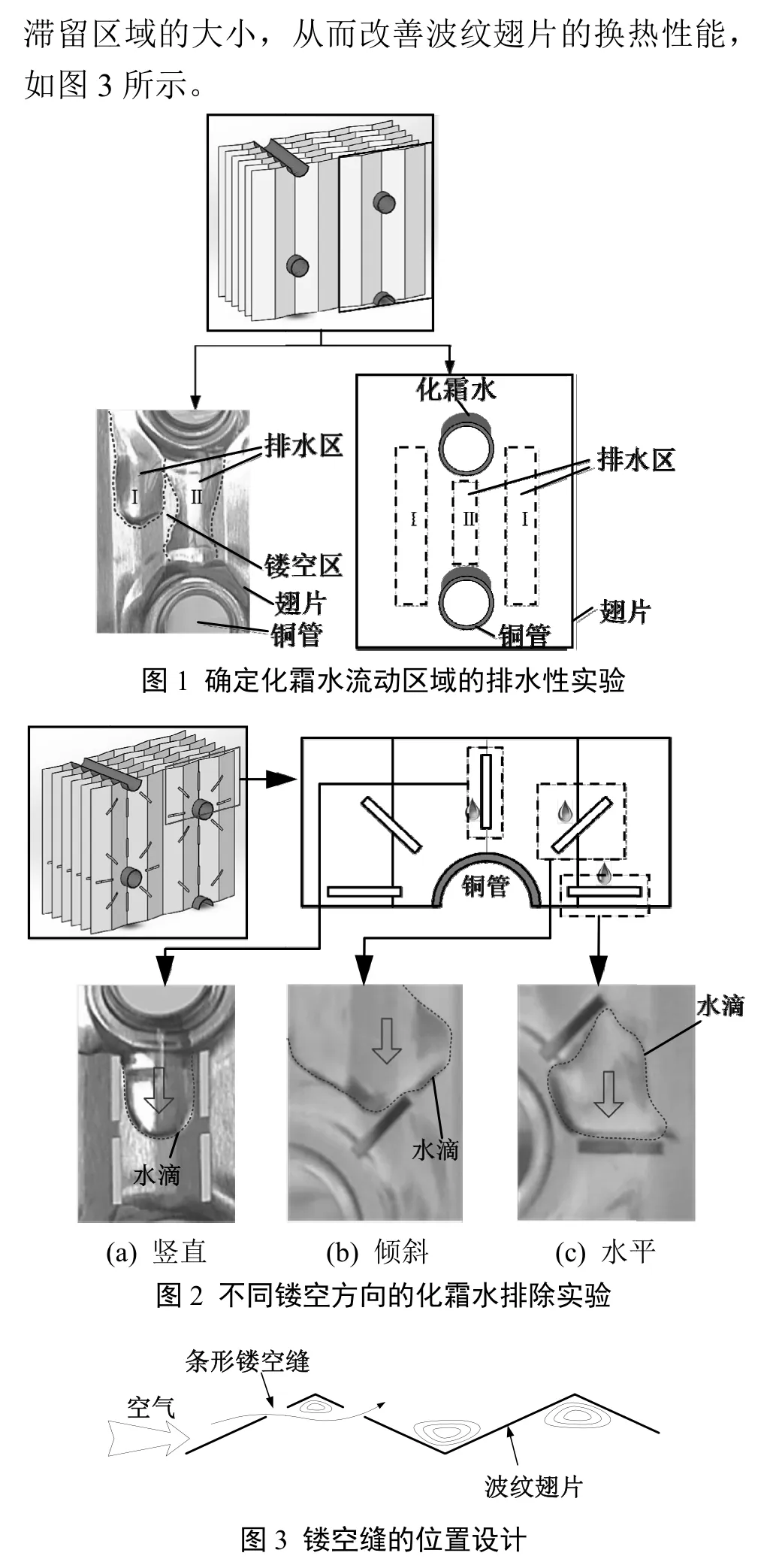

为了提高房间空调器的全年性能系数(APF),室外机翅片在结霜工况和非结霜工况下的性能均需要提高,传统的开缝翅片只适用于非结霜工况的传热强化。本文提出一种采用镂空的强化结构,能同时强化结霜工况下和非结霜工况下翅片的传热性能。本文通过单片翅片的排水性实验验证镂空区域和镂空方向,并通过CFD优化镂空位置和镂空长度、宽度和间距。排水实验表明,竖直方向镂空结构的排水性最好。本文将新型镂空翅片与热泵型空调室外机中使用最广泛的波纹翅片进行比较。在非结霜工况下,优化后的镂空翅片的换热量比波纹翅片高7.5%;在结霜工况下,优化后的镂空翅片的换热量比波纹翅片高3.4%。

空调室外机;镂空翅片;强化传热;结霜

0 引言

越来越多的国家将全年性能系数(APF)指标替代额定制冷能效比(EER)指标,作为空调器新的性能评价指标[1-2]。APF指标考核的全年运行工况分为非结霜工况和结霜工况两大类。提高空调器性能的方法主要有改善分配器性能[3-5]和优化换热器翅片结构两种[6-9]。由于分配器对每个APF测试工况具有相同的影响,无法使得空调器系统匹配达到APF最优,故本文主要通过优化换热器翅片结构改善空调器APF性能。

非结霜工况要求室外机翅片表面设计凸起或狭缝等局部复杂的结构,来提高翅片换热性能[10-11]。凸起和狭缝结构包括桥缝和百叶窗。狭缝结构能够切断翅片表面的空气边界层,使得边界层在狭缝后缘的翅片表面重新开始发展,从而减薄边界层。

1 新型翅片设计原理

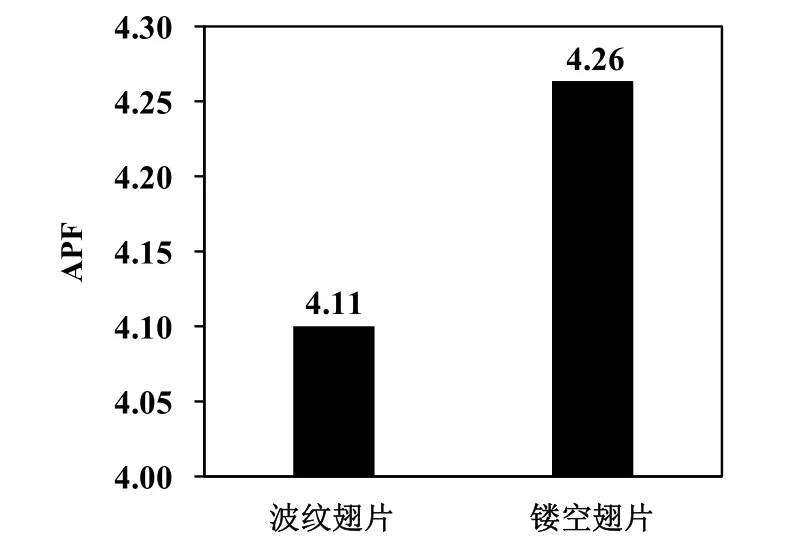

2 翅片性能模拟

2.4 APF性能比较

热泵型空调器的APF性能仿真采用了一种结合分布参数模型和分相参数模型的稳态系统仿真软件[16-17]。该软件不仅能够计算出换热器的换热量、能效等参数,而且能够计算换热器局部换热系数和压降。

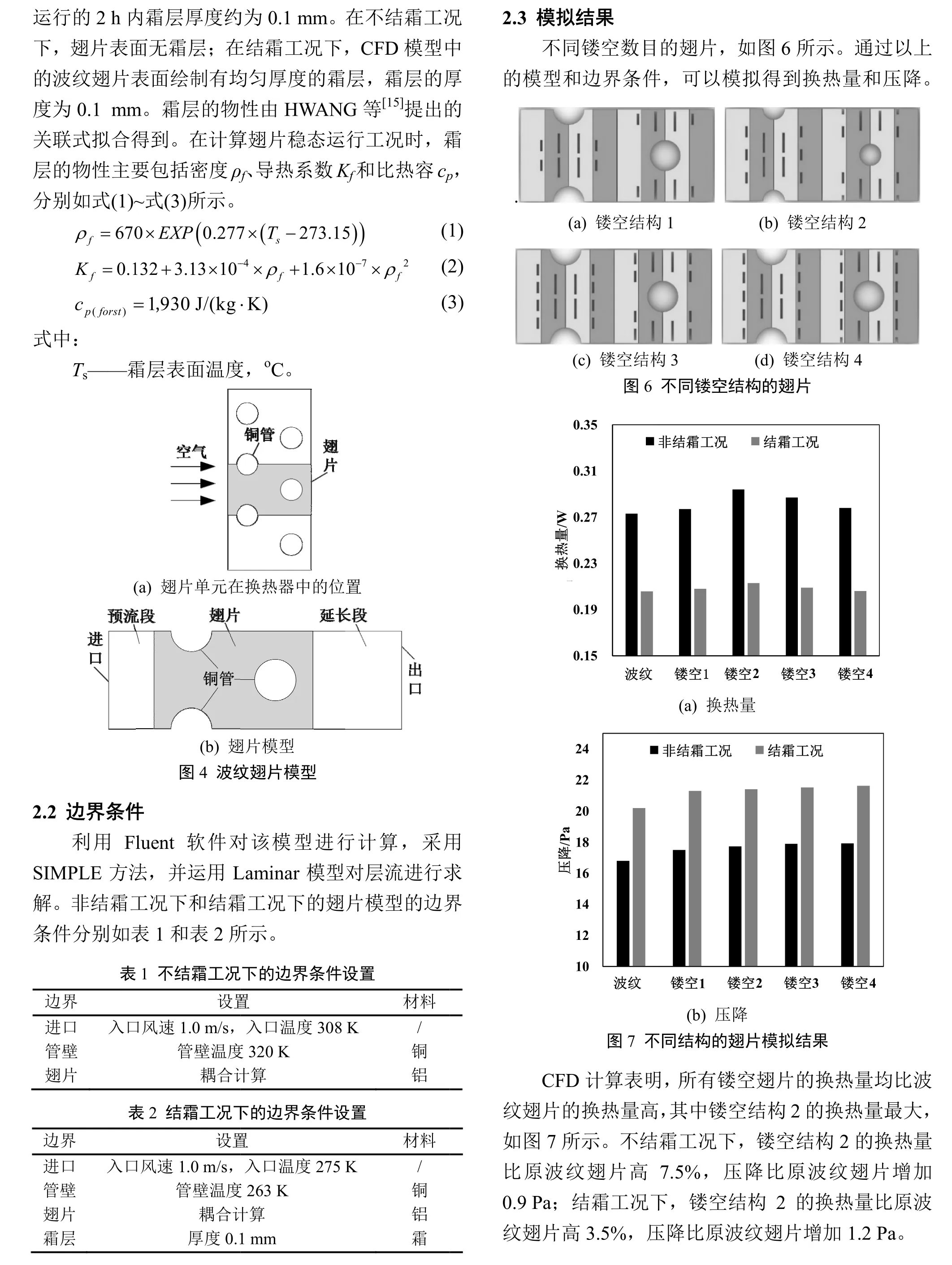

通过系统仿真软件可以计算得到3种不同室外机翅片的热泵型空调器的系统性能,包括波纹翅片、条缝翅片和新型镂空翅片,如图8所示。

仿真结果表明,使用新型镂空翅片的空调器APF比波纹翅片的空调器APF高4%,比条缝翅片的空调器APF高2.1%。仿真结果表明,新型镂空翅片是最佳的室外机翅片类型。

图8 不同热泵型空调器的APF性能

3 结论

1)在结霜工况和非结霜工况下,新型镂空翅片的换热系数均比波纹翅片高。

2)新型镂空翅片的换热量比波纹翅片在结霜和非结霜工况分别高7.5%和3.5%。

3)新型镂空翅片优于传统的波纹翅片,新型镂空翅片的空调器的全年性能系数(APF)比波纹翅片的空调器高4%。

[1] MADONNA F, BAZZOCCHI F. Annual performances of reversible air-to-water heat pumps in small residential buildings[J]. Energy and Buildings, 2013, 65: 299-309.

[2] KANG E C, RIEDERER P, YOO S Y, et al. New approach to evaluate the seasonal performance of building integrated geothermal heat pump system[J]. Renewable Energy, 2013, 54: 51-54.

[3] 翁建霆, 张利敏. 制冷用氟利昂液体分配器性能的实验研究[J]. 制冷技术, 1997, 17(2): 3-6.

[4] 黄晓清, 吴俊鸿, 杨杰, 等. 家用空调机组蒸发器优化设计[J]. 制冷技术, 2013, 33(2): 66-68.

[5] 高扬, 翁晓敏, 丁国良, 等. 全年能效消耗效率指标下的分配器分配特性分析及结构优化设计[J]. 制冷技术, 2015, 35(4): 22-27.

[6] 施骏业, 陈晓宁, 陆冰清, 等. 家用空调室外机波纹型翅片管换热器空气侧传热与压降性能研究[J]. 制冷技术, 2015, 35(6): 13-17.

[7] 王继稳. 翅片式换热器翅片传热与压降特性实验研究与分析[D]. 北京: 华北电力大学, 2011.

[8] 王厚华, 方赵嵩, 郑爽英. 圆孔翅片管式制冷换热器的节能性能试验[J]. 西南交通大学学报, 2009, 44(3): 455-460.

[9] 刘建, 魏文建, 丁国良, 等. 翅片管式换热器换热与压降特性的实验研究进展——实验研究[J]. 制冷学报, 2003, 24(3): 25-30.

[10] 田丽亭, 何雅玲, 楚攀, 等. 不同排列方式下三角翼波纹翅片管换热器的换热性能比较[J]. 动力工程, 2009, 29(1): 78-83.

[11] WEBB R L, KIM N H. Principle of enhanced heat transfer[M]. 2ndedition. Boca Raton, USA: Taylor Francis, 2005: 673-695.

[12] YE H Y, LEE K S. Performance prediction of a fin-and-tube heat exchanger considering air-flow reduction due to the frost accumulation[J]. International Journal of Heat and Mass Transfer, 2013, 67: 225-233.

[13] PARK J S, KIM D R, LEE K S. Frosting behaviors and thermal performance of louvered fins with unequal louver pitch[J]. International Journal of Heat and Mass Transfer, 2016, 95: 499-505.

[14] 黄东, 刘小玉, 王彦鲁. 翅片类型对热泵空调结霜特性的影响[J]. 制冷学报, 2012, 33(2): 12-17.

[15] LENIC K, TRP A, FRANKOVIC B. Transient two-dimensional model of frost formation on a fin-and-tube heat exchanger[J]. International Journal of Heat and Mass Transfer, 2009, 52(1): 22-32.

[16] HWANG J, CHO K. Numerical prediction of frost properties and performance of fin-tube heat exchanger with plain fin under frosting[J]. International Journal of Refrigeration, 2014, 46: 59-68.

[17] SUN H R, REN T, DING G L, et al. A general steady state mathematical model for multi-unit air conditioner system based on graph theory[C]. The 24th IIR International Congress of Refrigeration (ICR), Yokohama, Japan, 2015.

Fin Design for Outdoor Unit based on Annual Performance Factor of Room Air Conditioner

REN Tao*1, WU Guo-ming1, DING Guo-liang1, ZHENG Yong-xin2, GAO Yi-feng2, SONG Ji2

(1-Institute of Refrigeration and Cryogenics, Shanghai Jiao Tong University, Shanghai 200240, China; 2-International Copper Association Shanghai Office, Shanghai 200020, China)

To achieve high performance of annual performance factor (APF) of room air conditioner, it requires high heat transfer performance of outdoor unit fin under both frost and non-frost conditions, but traditional slit and louver fins only work well under non-frost conditions. A perforated fin to enhance heat transfer under both frost and non-frost working conditions was presented. In this paper, a drainage experiment for single piece of fin was carried out to figure out the best perforated zone and direction firstly; and then a CFD based optimization was processed to obtain perforated position, perforated length, width and pitch. The drainage experiment shows that the short vertical rectangle perforated multiple-hole has best performance. The designed fin was compared with the wavy fin, which is the most widely used in outdoor unit of heat pump air conditioner. The simulations result shows that the capacity of perforated fin is 7.5% higher than that of wavy fin under non-frosting condition and 3.4% higher than that of wavy fin under frosting condition.

Outdoor unit of air conditioner; Perforated fin; Enhanced heat transfer; Frost

10.3969/j.issn.2095-4468.2016.06.101

*任滔(1985-),男,博士后。研究方向:换热器仿真和设计。联系地址:上海市闵行区东川路800号机械与动力工程学院C楼263室。邮编:200240。联系电话:13764148238。E-mail:Tren@sjtu.edu.cn。